Flange gaskets provide a reliable seal that stops leaks and protects pipe joints. Quality flanges, such as Sunhy’s stainless steel flanges, help the gasket perform at its best. These components address issues like leaks, pressure loss, corrosion, vibration, and noise. The table below shows how flange gaskets reduce common pipe problems:

| Pipe Problem | Gasket Role |

|---|---|

| Leaks | Fills surface gaps and blocks leakage paths |

| Pressure Loss | Maintains tight seal under pressure |

| Corrosion | Prevents fluid escape that may cause corrosion |

| Vibration | Absorbs movement and reduces fastener loosening |

| Noise | Dampens vibrations and noise transmission |

Proper gasket selection and installation extend system life and lower repair costs.

What is a flange gasket?

A flange gasket is a sealing component placed between two pipe flanges to prevent leaks and maintain system integrity.

This simple part plays a critical role in industrial piping systems. It fills the microscopic gaps between flange surfaces, creating a tight seal that keeps fluids and gases contained.

Key Functions of a Flange Gasket:

The table below highlights the main functions of a flange gasket in industrial piping:

| Function | Description |

|---|---|

| Prevent Leakage | Creates a reliable barrier to prevent leakage and environmental contamination. |

| Compensate Imperfections | Compensates for imperfections on flange surfaces, ensuring tighter sealing. |

| Temperature and Pressure Resistance | Provides resistance to fluctuations in temperature and pressure within piping systems. |

| Enhance Safety | Enhances safety by effectively containing hazardous or volatile fluids. |

Common Materials Used in Flange Gaskets:

Manufacturers select gasket materials based on the fluid type, temperature, and pressure.

- Compressed Non-Asbestos Fiber (CNAF): Offers good chemical resistance, used in water treatment and HVAC systems.

- PTFE (Polytetrafluoroethylene): Delivers high chemical resistance, ideal for chemical pipelines and pharmaceutical production.

- Rubber (EPDM, NBR, Neoprene): Provides versatility for movement; EPDM suits water, NBR suits oils, Neoprene suits weather resistance.

- Spiral Wound Gaskets: Combine metal and filler for strength and flexibility, used in oil and gas pipelines.

- Ring-Type Joint (RTJ) Gaskets: Made of solid metal for high-pressure applications, used in refineries and subsea pipelines.

- Metal Jacketed Gaskets: Feature a soft filler in a metal shell for strength, used in heat exchangers and reactors.

- Corrugated Metal Gaskets: Designed for better compression recovery, used in power plants and chemical reactors.

Industry regulations influence the selection and use of flange gaskets.

Engineers must choose gaskets that comply with emissions standards and industry requirements.

Recent technological advancements have improved flange gasket performance:

- CNC-controlled die cutting ensures exact fit in critical applications.

- Laser measurement enhances dimensional accuracy.

- Form-in-place (FIP) technology automates gasket creation for a seamless seal.

A flange gasket must match the flange surface finish for best results. A rougher finish can improve grip, while a smoother finish may require precise torque to avoid leaks. Modern gaskets use new materials and manufacturing methods to handle higher pressures and temperatures, making them safer and more reliable.

Flange Gasket Solutions

How Gaskets Seal

A flange gasket creates a seal by compressing and deforming to fill gaps between flange surfaces.

When the bolts on a flange joint are tightened, the gasket material compresses. This compression causes the gasket to change shape and fill tiny imperfections on the flange faces. The tight contact blocks fluid or gas from escaping. The effectiveness of this seal depends on the pressure applied and the properties of the gasket material. High-quality flanges, such as those with a phonographic finish from Sunhy, help the gasket grip better and maintain a strong seal.

Tip: Always match the gasket type and material to the flange and the application. This reduces the risk of leaks and improves system reliability.

Types of Flange Gaskets

Different flange gasket types offer unique strengths for various applications.

The table below compares common gasket types and their performance:

| Gasket Type | Strength | Temperature Resistance | Leak Prevention | Best Use Case |

|---|---|---|---|---|

| Spiral Wound | High | Up to 1,100°F | Excellent | High-pressure flanges, chemical lines |

| Sheet/Flat | Moderate | Up to 800°F | Good | Smooth-surface flanges |

| Ring Type Joint | High | Up to 1,200°F | Excellent | Oil and gas, high-pressure systems |

Spiral wound gaskets combine metal and filler for flexibility and strength. Sheet gaskets work well with smooth flanges. Ring type joint gaskets suit high-pressure and high-temperature environments.

Material Choices

Selecting the right gasket material is essential for long-lasting, reliable pipe joints.

The material must resist the fluid, temperature, and pressure in the system. For example, PTFE gaskets resist corrosion better than graphite gaskets, which can cause more corrosion on flange surfaces. This choice affects how long the joint lasts, especially in harsh or corrosive environments.

- The wrong material can break down, leading to leaks and environmental harm.

- PTFE works well with aggressive chemicals and reduces corrosion.

- Graphite handles high temperatures but may increase corrosion risk.

- Rubber gaskets (like EPDM or NBR) suit water or oil lines but may not last in extreme heat.

Note: Over 30% of flange leaks in chemical plants result from incorrect gasket selection. Always consult with the manufacturer, especially for non-metallic or lined flanges.

The flange surface finish also impacts gasket performance:

- A rougher finish increases friction, helping soft gaskets stay in place and resist blowout.

- A smooth finish may not provide enough grip, leading to gasket movement and leaks.

- Sunhy’s phonographic finish ensures the right texture for optimal gasket seating and sealing.

Summary Table: Gasket Material Impact

| Material | Corrosion Resistance | Temperature Range | Environmental Impact |

|---|---|---|---|

| PTFE | Excellent | -200 to 260°C | Low risk of leaks |

| Graphite | Good | -200 to 450°C | May increase flange corrosion |

| Rubber | Moderate | -40 to 120°C | Suitable for water/oil lines |

Choosing the correct flange gasket and matching it to the flange type and finish ensures a safe, leak-free, and long-lasting piping system.

Fixing Pipe Issues

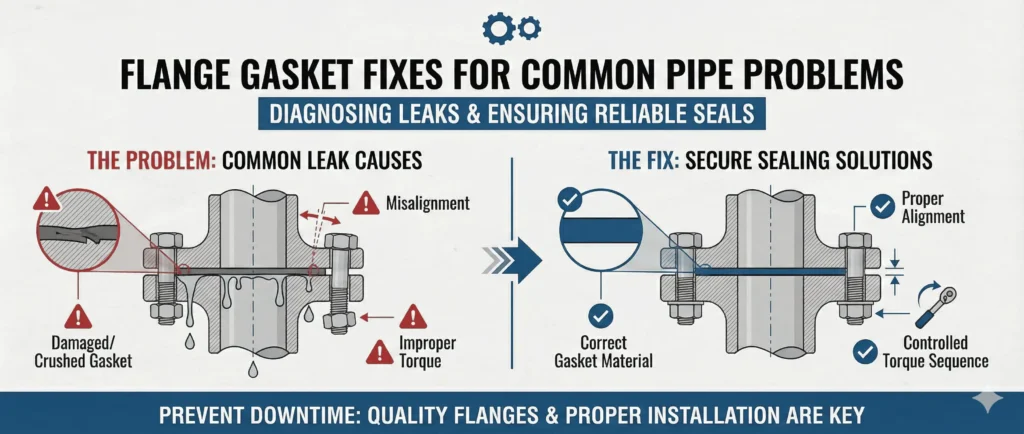

Identifying Problems

The most common pipe problems involve leaks, pressure loss, and gasket damage.

Technicians often spot these issues by looking for visible leaks, corrosion, or unusual noises. They also check for signs of improper gasket compression or chemical attack. Common causes include:

- Under compression, over compression, or uneven compression of the gasket

- Re-using old gaskets

- Chemical attack leading to cracking or softening

- Improper gasket size or material

- Excessive vibration or thermal shock

- Dirty or damaged flange faces

A table below shows how experts diagnose gasket-related issues:

| Diagnostic Method | Signs/Indicators |

|---|---|

| Visual Inspection | Little change in gasket thickness, faint flange marks, surface residue |

| Chemical Attack | Cracking, softening, discoloration |

| Hardening of Elastomers | Brittle or cracked gasket material |

| Installation Issues | Powder or pits on gasket surface |

| Uneven Compression | Stress cracks, uneven thickness |

| Over Compression | Crushed or damaged gasket |

| Re-use of Gaskets | Multiple compression lines |

Choosing a Flange Gasket

Selecting the right gasket ensures a safe and leak-free connection.

Engineers consider several criteria when choosing a gasket for high-pressure or critical applications:

| Criteria | Description |

|---|---|

| Pressure Rating | Maximum pressure the gasket can withstand |

| Temperature Resistance | Ability to handle system temperatures |

| Chemical Compatibility | Resistance to process fluids |

| Flange Type and Size | Proper fit to the flange for even sealing |

They always match the gasket material to the fluid and operating conditions. Proper sizing prevents leaks and ensures long-term reliability.

Installation Steps

Correct installation prevents leaks and extends gasket life.

The recommended steps include:

- Align the flanges using alignment tools.

- Insert the gasket evenly and center it between the flange faces.

- Lubricate bolt threads and nut-bearing surfaces.

- Hand-tighten bolts in a crisscross pattern.

- Use a torque wrench to tighten bolts gradually in increments.

- Inspect the connection and perform a pressure test.

Tip: Always inspect all components before installation and avoid over-tightening bolts.

Testing the Repair

Testing confirms the effectiveness of the repair and ensures safety.

Technicians use several methods:

| Testing Procedure | Description |

|---|---|

| Visual Inspection | Check for surface damage, deformation, and bolt condition |

| Dimensional Inspection | Verify fit and flange face condition |

| Pressure Testing | Use hydrostatic or pneumatic tests to check for leaks |

| Nondestructive Testing (NDT) | Detect internal flaws with ultrasonic or magnetic particle testing |

| Torque and Tightness Verification | Confirm bolts are tightened to specification |

| Material Testing | Analyze material composition and hardness |

These steps help maintain system integrity and prevent future failures.

Maintenance Tips

Spotting Gasket Failure

Early detection of gasket failure prevents leaks and costly repairs.

Technicians look for several signs that indicate a problem with the flange gasket:

- Visible leaks or drips around the flange joint

- Corrosion or discoloration on flange faces

- Loose or uneven bolts

- Unusual noises or vibrations from the pipe

- Cracks, swelling, or brittleness in the gasket material

Regular inspections help identify these issues before they lead to system downtime. Technicians also use ultrasonic or infrared testing to find hidden leaks.

Preventive Care

Consistent preventive care extends the life of flange gaskets and improves system reliability.

Leading manufacturers recommend the following steps:

| Preventive Measure | Benefit |

|---|---|

| Proper installation | Ensures tight seal and prevents early failure |

| Material selection | Matches gasket to temperature and pressure |

| Routine inspections | Detects wear, corrosion, or misalignment |

| Use of high-quality gaskets | Maintains sealing integrity |

| Flange protection | Prevents damage during storage |

| Environmental shielding | Reduces exposure to harsh conditions |

Technicians should use calibrated torque wrenches and follow a crisscross pattern when tightening bolts. Training staff on installation and maintenance procedures reduces the risk of errors.

When to Replace

Replace the gasket when signs of wear, damage, or loss of sealing integrity appear.

Common reasons for replacement include:

- Gasket shows cracks, swelling, or brittleness.

- Flange faces display corrosion or irregularities.

- Bolts lose tension or show fatigue.

- System experiences persistent leaks despite retightening.

- Maintenance records indicate repeated issues at the same joint.

Keeping detailed logs of inspections and replacements helps schedule maintenance and avoid unexpected failures.

Regular inspection and maintenance of flange gaskets support safety, cost control, and longer service life. Sunhy’s commitment to quality ensures that their stainless steel flanges and recommended maintenance practices deliver reliable performance in demanding environments.

Flange gaskets paired with quality flanges solve common pipe problems.

They prevent leaks, reduce downtime, and support safe operations. Case studies show that choosing the right gasket and installing it correctly avoids costly delays.

Proactive maintenance and correct gasket selection ensure long-term reliability.

Teams who inspect and maintain their systems save money and meet safety standards.

Expert advice helps with challenging applications.

Industry experts recommend clean flange surfaces, proper material selection, and careful installation for the best results. Sunhy’s team can guide users through these steps.

FAQ

What causes flange gasket leaks?

Improper installation, incorrect gasket selection, or damaged flange surfaces cause leaks.

Technicians often find leaks when bolts are unevenly tightened or when the gasket material does not match the fluid or pressure in the system.

How often should flange gaskets be inspected?

Inspect flange gaskets every six months or during routine maintenance.

Regular checks help spot early signs of wear, corrosion, or leaks. Teams can prevent major failures by following a consistent inspection schedule.

Which gasket material works best for chemical pipelines?

PTFE gaskets offer excellent chemical resistance for most chemical pipelines.

Engineers choose PTFE because it resists aggressive fluids and maintains a strong seal. The table below shows common materials and their best uses:

| Material | Best Use Case |

|---|---|

| PTFE | Chemical pipelines |

| Rubber | Water, oil lines |

| Graphite | High-temperature |

Can technicians reuse flange gaskets?

Technicians should not reuse flange gaskets.

Reusing gaskets increases the risk of leaks and system failure. New gaskets ensure a proper seal and maintain safety standards.

What signs show a gasket needs replacement?

Visible cracks, swelling, leaks, or loss of bolt tension show a gasket needs replacement.

Technicians also look for corrosion on flange faces and repeated leaks at the same joint.