Butt Weld Fittings (ASME B16.9) | Elbows, Tees, Reducers

Source factory-made butt weld pipe fittings for high-integrity piping systems. Our range covers the most common B16.9 fitting types for process piping, oil & gas, chemical, power, marine, and water treatment projects.

Home / Industrial Pipe Fittings / Butt-Weld Fittings

Types of Butt Weld Fittings We Supply

Butt Weld (ASME B16.9)

Forged Fittings

Low Pressure (Threaded/Class 150)

Advanced Materials

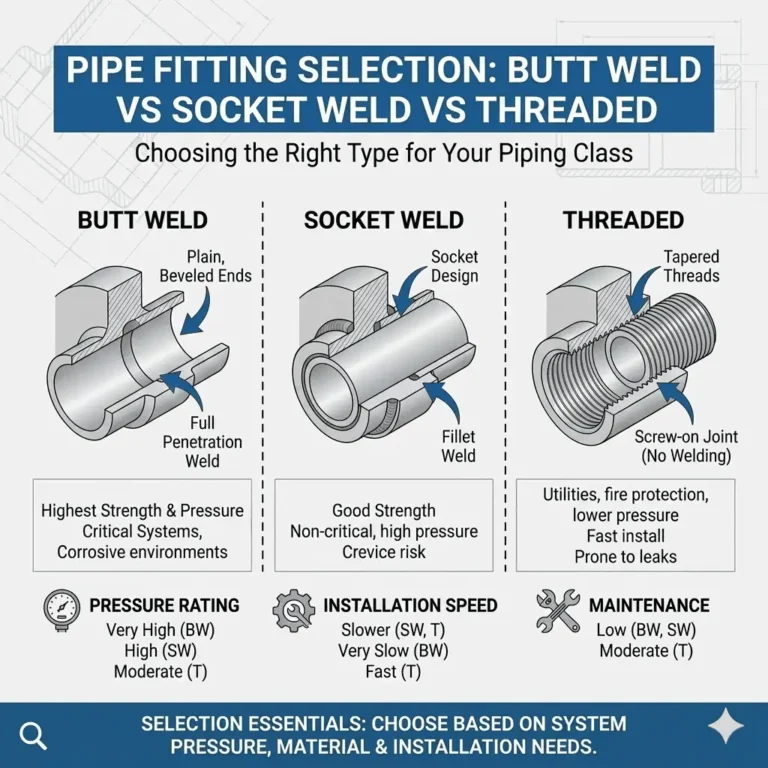

Butt Weld vs Socket Weld vs Threaded: Which One to Use?

- Butt weld fittings (B16.9): Best for high pressure/temperature and critical services—smooth bore, strong joint, good for NDT.

- Socket weld fittings (B16.11): Common for small-bore high-pressure piping where fabrication space is limited.

- Threaded fittings: Used for low-pressure utility lines or where welding is not practical (verify code limits).

What is Butt Weld Fitting?

A butt weld fitting is a factory-made pipe fitting with bevelled ends, prepared to ASME B16.25, that is welded to the pipe by a butt weld. It forms a permanent, full-penetration joint with strength similar to the pipe, making it ideal for high-pressure and high-temperature piping systems.

| Item | What to Specify |

|---|---|

| Dimensional Standard | ASME B16.9 (factory-made wrought butt-welding fittings) |

| Light-Wall Stainless Option | MSS SP-43 (typically for Sch 5S / 10S systems) |

| Butt-Weld End Prep | ASME B16.25 bevel ends (when required by project) |

| Material Specs (Common) | Carbon steel: ASTM A234 (e.g., WPB) Stainless steel: ASTM A403 (e.g., WP304/304L, WP316/316L) Duplex/Super Duplex: ASTM A815 (project-dependent) |

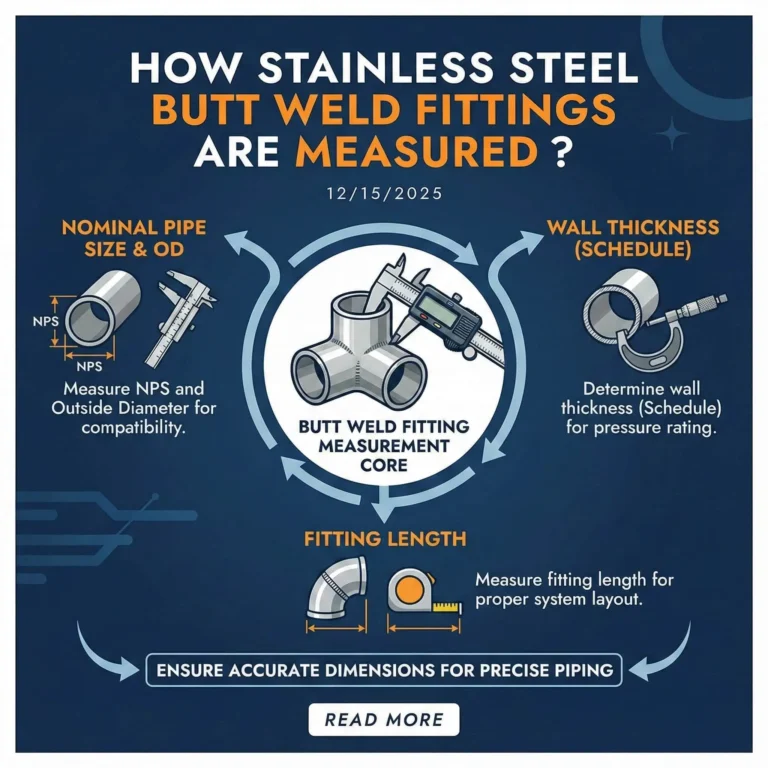

| Size Range | NPS 1/2″ and up (confirm final range by standard + project spec) |

| Wall Thickness | Sch 10 / 40 / 80, XS, XXS, and other producible thicknesses per your pipe schedule |

| Deliverables | MTR (EN 10204 3.1 if required), packing list, heat number traceability |

Data is for reference only. Always follow the project datasheet, piping class, and code requirements.

Dimensional Reference Example: 90° Long Radius Elbow (Center-to-End “A”)

For LR elbows, a common rule is a 1.5D radius design. Below is a quick reference for several NPS sizes. If you need the full chart for your size range, tell us your NPS list and schedule.

*”Data is for reference only. Always consult the specific project engineering requirements.”

| NPS | OD at Bevel (mm) | Center-to-End A (mm) |

|---|---|---|

| 1/2 | 21.3 | 38.1 |

| 1 | 33.4 | 38.1 |

| 2 | 60.3 | 76.2 |

| 4 | 114.3 | 152.4 |

| 6 | 168.3 | 228.6 |

| 8 | 219.1 | 304.8 |

| 10 | 273.1 | 381.0 |

| 12 | 323.9 | 457.2 |

Manufacturing & Quality Control

- Forming & fit-up: control ovality, squareness, and end prep for reliable welding.

- Weld integrity (for welded fittings): inspection plans available per project requirement.

- Material verification: PMI available for alloy identification (especially stainless/duplex/nickel alloys).

- Dimensional inspection: check key “A/C/H” dimensions, OD at bevel, and end condition.

- Traceability: heat number marking and MTR package for QA/QC review.

What We Need for a Fast Quote (RFQ Checklist)

- Fitting type(s): elbow / tee / reducer / cap / stub end / cross

- Size: NPS (and outlet size for reducing tees / reducers)

- Wall thickness: Sch / XS / XXS (match your pipe schedule)

- Standard: ASME B16.9 or MSS SP-43 (if light-wall stainless)

- Material grade: A234 WPB, A403 WP316L/WP304L, duplex, nickel alloy, etc.

- Quantity + delivery location

- Documentation/testing requirements: MTR, PMI, NDT, special marking, etc.

RELATED INDUSTRIES & APPLICATIONS

FAQ

Are “butt weld fittings” and “butt weld pipe fittings” the same?

Yes, “Butt Weld Fittings” and “Butt Weld Pipe Fittings” refer to the exact same product category. The terms are interchangeable in industrial engineering and procurement. “Pipe Fittings” is the formal terminology used in technical standards like ASME B16.9 and material specifications (e.g., ASTM A234), while “Butt Weld Fittings” is the common shorthand widely used in field installation and commercial trade. Both refer to components (elbows, tees, reducers) designed to be welded on-site to connect pipes.

Technical Context: The term “Butt Weld” (BW) is the critical descriptor here. It indicates that the fitting has a beveled end (typically 37.5° as per ANSI/ASME B16.25) to match the pipe’s bevel. This design allows for a full penetration weld, providing a continuous metal structure.

Stress Distribution: Unlike threaded or socket-weld fittings, butt weld connections distribute internal pressure and structural stress uniformly into the pipe, avoiding stress concentration points.

NDT Capability: The butt weld design allows for Radiographic Testing (RT) or Ultrasonic Testing (UT), making these fittings the mandatory choice for critical, high-pressure, or lethal service applications where joint integrity must be verified.

What’s the difference between ASME B16.9 and MSS SP-43?

The primary difference lies in their pressure rating scope and wall thickness coverage. ASME B16.9 is the comprehensive standard for factory-made wrought butt-welding fittings across all wall thicknesses (from Sch 5 to XXS) and materials, suitable for high-pressure and high-temperature industrial applications. In contrast, MSS SP-43 is specifically designed for low-pressure, corrosion-resistant applications (typically Stainless Steel and Nickel Alloys) and strictly covers lightweight wall thicknesses (Schedule 5S and 10S).

| Feature | ASME B16.9 | MSS SP-43 |

| Application | High Pressure / High Temperature | Low Pressure / Corrosion Resistant |

| Wall Thickness | All Schedules (Sch 10, 40, 80, XXS, etc.) | Light Wall Only (Sch 5S, 10S) |

| Materials | Carbon, Alloy, & Stainless Steel | Stainless Steel & Nickel Alloys |

| Manufacturing | Wrought (Seamless or Welded) | Wrought or Fabricated |

Engineering Note on Stub Ends: Pay close attention when specifying Lap Joint Stub Ends. While ASME B16.9 and MSS SP-43 dimensions are often compatible, MSS SP-43 defines specific “Type A” and “Type B” stub ends which have different face diameters. Selecting the wrong type may result in incompatibility with standard backing flanges.

Do you offer seamless butt weld fittings?

Yes, we supply a full range of Seamless Butt Weld Fittings, primarily recommended for high-pressure, high-temperature, or critical safety applications. Seamless fittings are manufactured directly from seamless pipe or tube sections using mandrel forming methods, meaning they contain no metallurgical weld seams. This eliminates the risk of preferential corrosion or seam failure under extreme stress.

Seamless vs. Welded Selection:

Seamless: Essential for services requiring uniform grain structure and maximum reliability (e.g., Hydrogen service, High-Pressure Steam).

Welded (Seam): For larger diameters (typically >24″) or cost-sensitive projects, we offer Welded Fittings. To ensure E-E-A-T compliance and safety, our welded fittings can be supplied with 100% Radiographic Testing (RT) to achieve a Joint Efficiency factor of 1.0, making them structurally equivalent to seamless for calculation purposes .

Can I mix stainless fittings with carbon steel pipe?

Directly connecting Stainless Steel fittings to Carbon Steel pipe is generally NOT recommended without isolation due to the risk of Galvanic Corrosion. In the presence of an electrolyte (such as moisture or water), the Carbon Steel (anode) will corrode rapidly because of the significant electrochemical potential difference between it and the Stainless Steel (cathode). Additionally, the Thermal Expansion Coefficient of austenitic stainless steel is roughly 50% higher than carbon steel, which can cause dangerous thermal stress and weld fatigue during temperature cycling.

Recommended Solutions: If dissimilar connection is unavoidable, use one of the following engineering controls:

Dielectric Unions or Flange Kits: To electrically isolate the two metals and break the galvanic circuit.

Transition Pups: A factory-welded spool piece with an internal alloy barrier.

Lined Systems: Using internal cladding to prevent the fluid from bridging the two metals .

How do I choose concentric vs eccentric reducers?

The choice between Concentric and Eccentric reducers depends entirely on the pipeline’s orientation and the need to prevent air pockets.

Concentric Reducers: Have a common centerline. Use these for vertical pipe runs to maintain flow symmetry and structural alignment.

Eccentric Reducers: Have one flat side. These are critical for horizontal pipe runs to manage fluid and gas behavior.

Critical Application Rules:

Pump Suction (The “Flat on Top” Rule): On horizontal pump suction lines, you MUST use an Eccentric Reducer installed “Flat-Side-Top” (FOT). This prevents air bubbles from accumulating in the top of the reducer (which happens with concentric reducers), thereby eliminating the risk of air entering the pump and causing cavitation.

Pipe Racks: For general process lines on supports, use an Eccentric Reducer installed “Flat-Side-Bottom” (FOB). This keeps the bottom of the pipe elevation constant, allowing it to rest perfectly on the pipe rack without requiring custom support shoes.