Selecting the right flange & fittings supplier isn’t just a purchase; it’s a strategic decision that shapes the success of your entire project. In my experience, a single delayed shipment or a batch of non-compliant materials can shut down a multi-million dollar installation. Before you verify quality, reliability, and expertise, sending that Request for Quote (RFQ) is a gamble. Asking targeted, tough questions helps you avoid costly mistakes and ensures your supplier meets strict standards. Use these 10 questions as your ultimate vetting checklist to protect your project’s integrity.

1. What experience and capabilities does your flange & fittings supplier have?

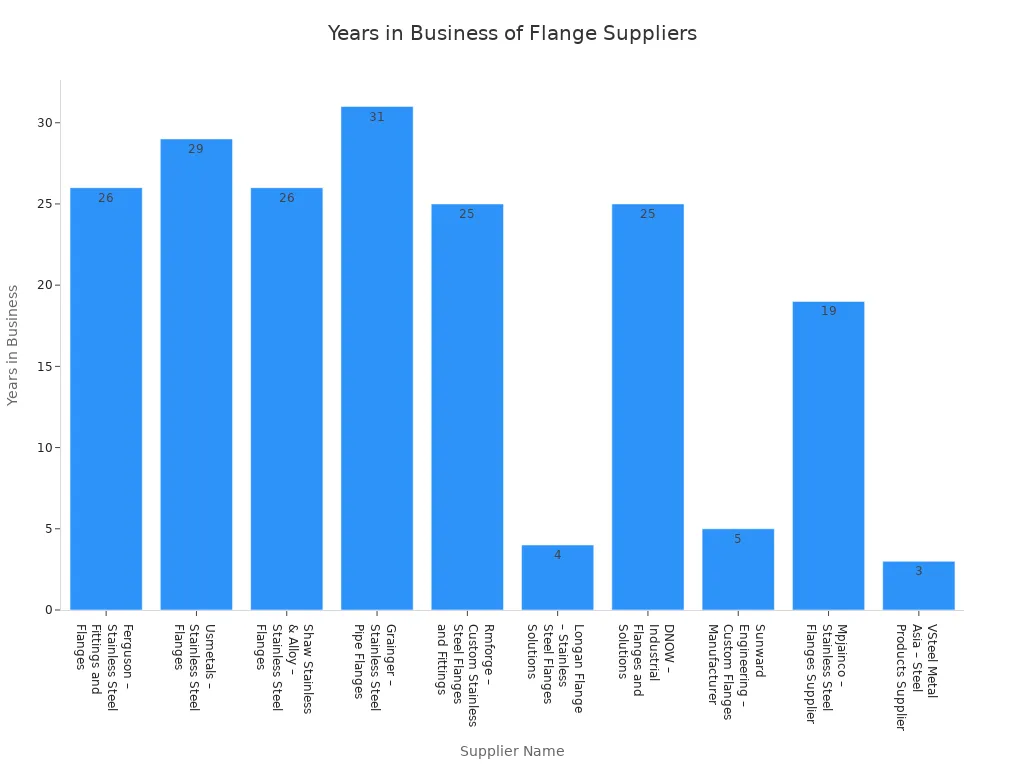

Years in Business

Experience is the best filter for reliability. Choose a supplier who has weathered market cycles.

You want a supplier who has demonstrated reliability and expertise over many years, not a trading company that popped up yesterday. Suppliers with deep experience understand the nuances of manufacturing flanges for complex piping systems. They have refined their forging processes and can handle demanding technical specifications. The table below shows the market tenure of various suppliers in the industry:

| Supplier Name | Years in Business |

|---|---|

| Jinan Enying Machinery Manufacturing Co., Ltd. | 6 |

| Shandong Zouping Jianhua Industry Co., Ltd. | 16 |

| Shanxi Xinshunda Flange Manufacturing Co., Ltd. | 3 |

| US Huitong Pipeline Equipment CoLtd | 2 |

| Tianjin Youfa International Trade Co., Ltd. | 13 |

| Hebei Lanwei Imp.& Exp. Co., Ltd. | 16 |

| Ding Xiang Huang Xing Machinery Fabrication Co., Ltd. | 3 |

| Shangdian Flange Pipe Fittings Co., Ltd. | 1 |

| Wenzhou Welsure Steel Co., Ltd. | 9 |

| Metal Industrial (shanghai) Co., Ltd. | 9 |

I recommend looking for a flange & fittings supplier with at least a decade of experience. SUNHY, for example, brings over 30 years of manufacturing expertise, which significantly exceeds the industry average and ensures stable production capability.

Certifications & Standards

Insist on accredited certifications. They are the baseline for safety.

Certifications aren’t just paperwork; they prove a supplier meets strict industry standards for flanges and fittings. These standards ensure safety, performance, and compatibility with your global projects. The most respected suppliers hold several key certifications:

| Certification/Standard | Description |

|---|---|

| ASME B16.5 | The bible for pipe flanges, specifying dimensions, tolerances, and pressure ratings (Class 150-2500). |

| AWWA C207 | Specific to the waterworks industry, covering flanged fittings for steel pipes. |

| MSS SP-44 | Standard for steel pipeline flanges, essential for large diameter high-pressure lines. |

| NACE Certification | Mandatory for sour gas service (H2S environments) to verify material hardness and corrosion resistance. |

| Fire-Safe Certification | Essential for valves and flanges in flammable environments to mitigate explosion risks. |

Beyond the basics, you should verify these specific credentials:

- ISO 9001:2015 (Quality Management System)

- API 6A (Wellhead Equipment Standard)

- PED 2014/68/EU (European Pressure Equipment Directive)

- NACE MR0175/ISO 15156 (Anti-sulfide stress cracking)

- NORSOK M-650 (Norwegian petroleum standard for special alloys)

- ATEX (Explosion-proof certification for hazardous zones)

A supplier holding these certifications isn’t just selling metal; they are selling compliance and safety.

In-House vs. Outsourced Production

Always select a supplier with comprehensive in-house manufacturing.

In-house production (Forging, Heat Treatment, Machining) gives you control. Suppliers who outsource are merely middlemen, adding risk and margin. Suppliers with their own advanced equipment can produce flanges with tighter tolerances and react faster to changes.

Key advantages of direct manufacturers include:

- Precision: Advanced CNC machining achieves precise dimensions consistently.

- Scale: Large facility size supports efficient production runs.

- Speed: Automated CNC cells can produce 20 to 50 flanges per day with in-process inspection.

- Consistency: Direct control over Quality Control (QC) improves performance reliability.

For instance, SUNHY operates a 20,000 square meter facility with over 200 CNC machines. This setup allows for the production of both standard and custom flanges with guaranteed lead times.

Expert Tip: Ask if they do their own heat treatment. This critical step determines the mechanical strength of the flange and is often outsourced by smaller shops to cut costs.

2. How do you assure product quality from raw material to final inspection?

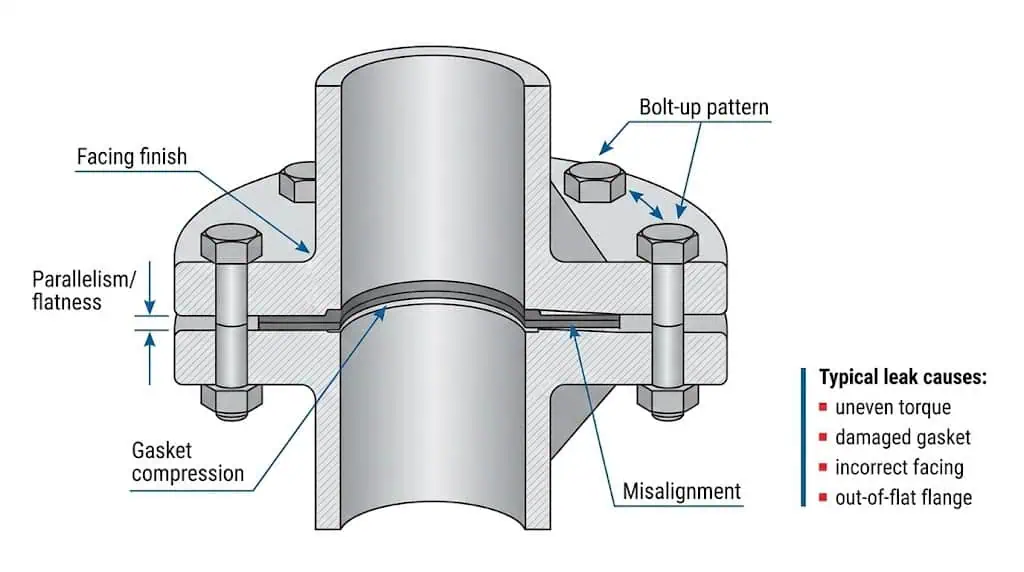

Quality Control Processes

You need a supplier who implements rigorous quality control at every stage, not just at the end.

Quality starts with strict procedures. I look for suppliers who combine traditional craftsmanship with modern digital tracking. Real-time analytics in top facilities protect the structural integrity of every flange.

- SOPs: Standard Operating Procedures ensure consistency.

- Verification: Products must meet dimensional accuracy before moving to the next station.

- Prevention: Early defect detection (e.g., during forging) minimizes scrap.

- Efficiency: Reduced waste translates to better pricing for you.

- Safety: Strict compliance prevents catastrophic failures onsite.

| Core Elements of Quality Control | Description |

|---|---|

| Material Verification (PMI) | Spectral analysis to confirm chemical composition before production begins. |

| Dimensional Inspection | CMM and caliper checks for tolerance accuracy. |

| Non-Destructive Testing (NDT) | Ultrasonic (UT) or Magnetic Particle (MPI) testing to confirm internal integrity. |

| Pressure Testing | Hydrostatic and pneumatic tests validate pressure containment capability. |

| Traceability | Full batch tracking ensures every flange can be linked to its raw material. |

Material Traceability

Demand full traceability from the steel mill to your warehouse.

Traceability is your insurance policy. If a failure occurs, you must be able to identify the specific batch. Reliable suppliers provide:

| Traceability Marker | Why It Matters |

|---|---|

| Manufacturer’s Mark | Identifies the factory liable for the product. |

| Material Designation | Specifies grade (e.g., F316L) to prevent mixing alloys. |

| Heat Number | The DNA code linking to the original mill melt analysis. |

| Unique Serial Number | Tracks individual flanges for critical/high-pressure applications. |

You should expect EN 10204 3.1 MTCs with every shipment. If they can’t provide this, do not buy.

Third-Party Audits

Do they welcome independent eyes?

Third-party audits (TPI) add an unbiased layer of protection. Experienced engineers from agencies like SGS, BV, or TUV inspect the entire process.

| Service Type | Description |

|---|---|

| Supplier Technical Evaluation | Audits factory capacity and quality management systems. |

| Design Review | Ensures custom designs meet ASME calculations. |

| Raw Material Control | Verifies incoming billets against standards. |

| Welding Inspection | Checks weld quality for fabricated fittings. |

| Nondestructive Testing (NDT) | Independent verification of internal flaws. |

| Dimensional Inspection | Final check of critical dimensions before packing. |

| Coating/Painting Inspection | Measures dry film thickness (DFT) for corrosion protection. |

| Packaging Inspection | Ensures seaworthy packing to prevent transit damage. |

Tip: Always ask to see previous audit reports from other clients (redacted if necessary). It proves they are accustomed to scrutiny.

3. Can you supply the stainless steel grades and materials my project requires?

Yes, a top-tier supplier must offer a full range of stainless steel and exotic alloys.

Material availability is often the biggest bottleneck. You need to confirm that your supplier stocks or can quickly source the right billets for your seamless and welded pipe fittings. This choice directly affects the lifespan and safety of your system.

Material Grades (304/316L & Exotic Alloys)

You should expect access to all standard and high-performance grades.

While 304 and 316L are standard, critical projects often require materials that can withstand extreme heat or acid. A capable supplier keeps stock of:

| Material Type | Description |

|---|---|

| Stainless Steel Flanges | 304/L, 316/L, 321, 347. Used for general corrosion resistance. |

| Duplex & Super Duplex | 2205 (S31803), 2507 (S32750). Used for high strength and chloride resistance. |

| Exotic Alloy Flanges | Inconel 625, Hastelloy C276, Monel 400. Used for extreme environments. |

- Inconel (High Heat)

- Hastelloy (Acid Resistance)

- Haynes (Aerospace grade)

Tip: Ask your supplier for their “Stock List” of raw billets. This reveals their true readiness for urgent orders.

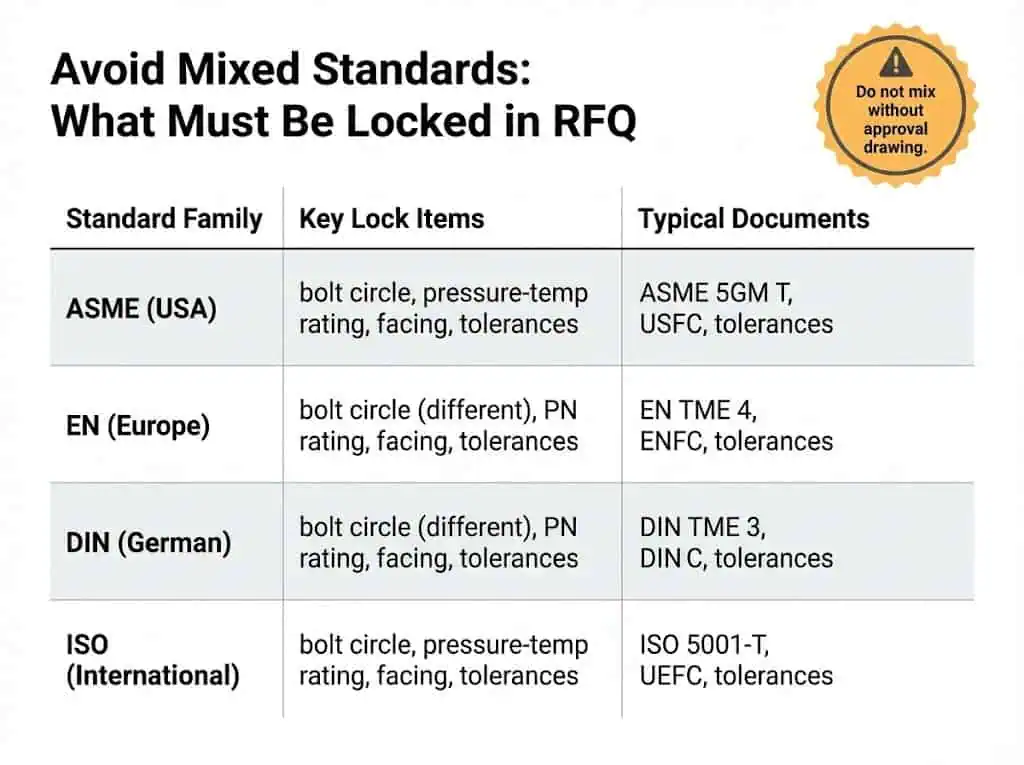

Compliance with ASTM, DIN, ISO

Compliance is not optional.

Your supplier must be able to manufacture to global standards without error. A flange made to ASTM specifications may not fit a DIN system.

| Testing Method | Purpose |

|---|---|

| Chemical Analysis | Ensures alloy composition matches the standard (e.g., Carbon % in 316L). |

| Mechanical Testing | Tensile, Yield, and Impact testing (Charpy V-Notch). |

| Hardness Testing | Verifies NACE compliance (Max 22 HRC for sour service). |

| Intergranular Corrosion | ASTM A262 Practice E for stainless steels. |

Suppliers should provide MTRs verifying compliance with ASTM A182 (Forged) or A403 (Wrought) standards.

Note: Always verify the standard version (e.g., ASME B16.5 2020 vs 2017) to ensure compatibility.

4. How accurate and transparent is your quotation?

Quote Accuracy

You deserve precise, line-item quotations.

Vague quotes hide incompetence or extra costs. Reliable suppliers break down pricing so you can analyze value. I look for:

- Unit price per item (validity period clearly stated).

- Separate machining and material costs (if custom).

- Inspection fees listed separately (TPI).

- Packing charges (Pallet vs. Wooden Case).

| Quotation Element | Description |

|---|---|

| Unit Price | Price per flange/fitting (FOB/EXW/CIF). |

| Raw Material Surcharge | If applicable for exotic alloys. |

| Machining Cost | Labor and CNC processing fees. |

| Inspection Cost | NDT, PMI, and TPI fees. |

| Shipping & Packaging | Seaworthy export packing charges. |

| Taxes & Duties | Clear indication of HS Codes for duty calculation. |

Tip: Request a breakdown of weight per line item. This helps you calculate freight costs accurately.

What’s Included/Excluded

Transparency prevents “surprise” invoices.

You should know exactly what the Incoterms cover. Are you paying for unloading? Is insurance included?

- Included: Standard markings, basic protection caps, MTCs, packing list.

- Excluded: Special color coding, TPI witness fees, legalized documents (embassy attestation), expedited air freight.

Comparing quotes line-by-line ensures you are evaluating the true cost-effectiveness of each supplier.

5. What are your lead times and how do you handle urgent or custom orders?

Standard vs. Custom Orders

Expect rapid turnaround for stock, but realistic timelines for custom work.

Lead times vary wildly based on stock levels. A manufacturer with billet stock is weeks faster than one who has to order steel. Here is a realistic benchmark:

| Order Type | Typical Lead Time |

|---|---|

| Standard Flanges (Stock) | 7 to 14 days |

| Custom Forged Flanges | 21 to 30 days |

| Order Type | Lead Time |

|---|---|

| Standard Adapter Flanges | 2 to 4 weeks |

| Custom Designed Adapters | 4 to 8 weeks |

Suppliers like SUNHY can often expedite these times because they control the entire forging process in-house.

Handling Delays & Urgent Needs

How resilient is their supply chain?

Delays happen. The difference is how they are managed. Reliable suppliers use:

- ISO 9001 Production Planning to foresee bottlenecks.

- Buffer stock of common billets (A105, 304, 316) to start machining immediately.

- Multiple logistics partners to find alternative shipping routes.

- “Green Channel” production lines reserved for urgent breakdown orders.

Tip: Ask: “What is your protocol for a plant-down emergency order?” The answer should be specific, not vague.

6. What warranties and after-sales support do you provide?

Product Warranties

You need a written warranty, not a verbal promise.

A warranty proves confidence. I recommend insisting on:

- Coverage Period: 12 months from installation or 18 months from delivery.

- Scope: Defects in material, workmanship, and dimensional errors.

- Claim Process: A clear path to resolution (RMA procedure).

- Remedies: Replacement (including air freight) or refund.

| Warranty Feature | What to Check For |

|---|---|

| Coverage Period | Is it standard (12 months) or extended? |

| Scope | Does it cover consequential damages (rare) or just replacement? |

| Claim Process | Is there a dedicated quality team to handle this? |

Tip: Keep your installation logs. Warranties often require proof of proper installation.

Emergency Support

Will they answer the phone when it matters?

After-sales support is critical during commissioning. If a flange doesn’t seal, you need instant technical advice.

- 24/7 Technical support line.

- Fast-track replacement manufacturing.

- On-site troubleshooting (for major contracts).

7. How easy is it to communicate with your team during a project?

Project Updates

Silence creates anxiety. Expect proactive updates.

I value suppliers who use proactive communication. You should receive a Weekly Status Report (WSR) containing:

- Production milestones (Forging complete, Machining started).

- QC status (NDT scheduled/passed).

- Shipping booking confirmation.

Tip: Ask for a sample WSR during the RFQ phase to see how they report progress.

Response Time

Speed wins.

In global procurement, waiting 24 hours for a reply adds days to a project. Leading suppliers respond instantly.

| Supplier | Response Time Standard |

|---|---|

| High Pressure Flange Specialists (e.g. SUNHY) | < 2 Hours |

| General Traders | 12 – 24 Hours |

8. What technical documentation and engineering support can you offer?

Drawings & Custom Design Support

Never manufacture custom parts without an approved drawing.

Suppliers should use design tools like AutoCAD to generate approval drawings. This ensures the flange dimensions match your mating equipment.

- Design: Supplier creates CAD drawing based on your specs.

- Review: You approve dimensions and tolerances.

- Production: Machining follows the approved print exactly.

| Type of Support | Description |

|---|---|

| Custom Flanges | Requires full CAD drawings for approval. |

| Calculation | ASME VIII calculations for non-standard pressure ratings. |

Mill Test Certificates, EN 10204 3.1, PMI / NDT Reports

Documentation is part of the product.

A Mill Test Certificate (MTC) according to EN 10204 3.1 is mandatory. It confirms:

| Inspection Method | Description |

|---|---|

| Chemical Analysis | % of C, Mn, Si, P, S, Cr, Ni, Mo. |

| Mechanical Test | Tensile, Yield, Elongation, Hardness. |

| Heat Treatment | Solution annealing temp and cooling method. |

| NDT | Ultrasonic or Radiographic test results. |

Compliance with Project Specifications & Data Books

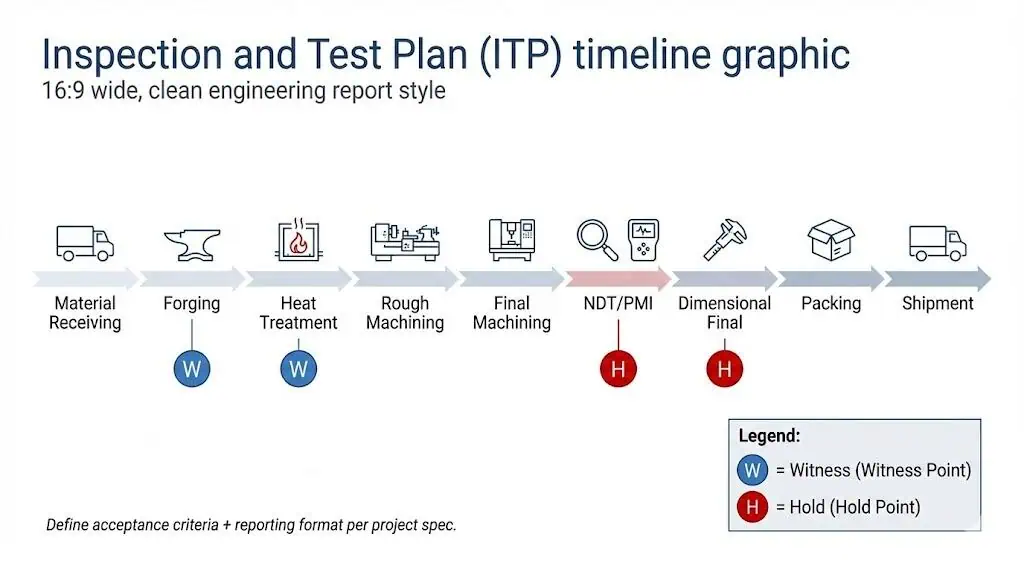

Major projects require comprehensive Data Books (MRB).

Ensure your supplier can compile a full Manufacturer Record Book, including:

- Quality Plan (ITP)

- Welding Procedure Specifications (WPS/PQR)

- NACE Certificates

- Raw Material MTCs

- Calibration Certificates of gauge tools

Callout: An incomplete Data Book can prevent you from handing over the project to the end client.

9. What is your track record with similar projects?

References & Case Studies

Past performance is the best predictor of future success.

Don’t just take their word for it. Look for specific case studies where they solved problems similar to yours:

- Flanged Root Valves: Helped a global manufacturer reduce leak paths by consolidating connections.

- Tire Press Hoses: Optimized fittings to improve lifespan under cyclic pressure.

- FRP CONE for Hatch Sealing: Custom engineered solution for chemical loading.

- Pet Food Maker: Achieved a 90% reduction in downtime using hygienic connectors.

- Hydrogen Pipe Connection: Provided specialized sealing solutions for high-permeability gas.

Tip: Ask for a reference list of clients in your specific region or industry.

Performance History

Consistency matters.

Reputable suppliers track their own KPIs. Ask for data on their:

| Indicator | Target |

|---|---|

| On-Time Delivery Rate | > 95% |

| Product Rejection Rate | < 0.5% |

Suppliers listed on Approved Vendor Lists (AVL) of major companies (Shell, Aramco, Exxon) have already passed rigorous audits, making them safer bets.

10. Is the supplier financially stable enough for long-term cooperation?

A bankrupt supplier voids your warranty and halts your supply chain.

In today’s volatile market, financial stability is a key quality indicator. You need a partner who can afford to buy raw materials and withstand shipping delays.

Indicators of a safe partner:

| Indicator | Description |

|---|---|

| Absence of Bankruptcy | No history of financial distress in the last 10 years. |

| Asset Ownership | Owns factory land and machinery (vs. renting). |

| Credit Risk Profile | Stable credit rating with insurers like Sinosure. |

Long-Term Contract Capability

Can they support a framework agreement?

Suppliers like NFF or SUNHY, with decades of operations, have the capital to agree to fixed-price annual contracts, protecting you from market volatility.

| Supplier | Experience | Capability |

|---|---|---|

| NFF | 30+ years | High pressure fittings contract management. |

| SUNHY | 30+ years | Global flange supply framework agreements. |

Conclusion: The Power of Due Diligence

By asking these 10 questions, you move from “hoping for the best” to “ensuring the best.” This checklist is your tool to expose weaknesses and validate strengths. Whether it’s inspecting their Quality Control or confirming their financial health, every question reduces your risk and secures your project’s success.

FAQ

What documents should you request with your flange and fittings order?

Always request Mill Test Certificates (MTCs), Packing Lists, and Commercial Invoices.

For critical items, also ask for Heat Treatment Charts and NDT Reports.

How do you verify the authenticity of stainless steel grades?

Require a Positive Material Identification (PMI) report.

This non-destructive test confirms the alloy composition instantly. You can also hire a 3rd party to perform this verification before shipment.

What is the typical warranty period for flanges and fittings?

Industry standard is 12 months from installation or 18 months from shipment.

Be cautious of suppliers offering less. Extended warranties can often be negotiated for large projects.

How can you track your order status?

Expect a Weekly Status Report (WSR).

Professional suppliers will email you a progress report showing raw material status, machining percentage, and estimated completion date.

Which industries use high-quality flanges and fittings?

| Industry | Critical Need |

|---|---|

| Oil & Gas | Pressure containment & safety. |

| Chemical | Corrosion resistance (Exotic alloys). |

| Pharmaceutical | Hygienic surfaces & traceability. |

| Power Gen | High temperature endurance. |