You need the right npt pipe fittings to keep your project safe and reliable. Choose based on (1) the thread standard you actually have on the port, (2) the fitting construction/standard, (3) material compatibility with the media and environment, and (4) pressure/temperature at operating and upset conditions. Stainless steel NPT fittings are commonly used across industrial piping, marine systems, and chemical service when corrosion resistance is required. If you purchase stainless fittings, confirm the thread form (NPT vs NPTF vs BSP), verify the fitting standard (e.g., forged threaded fittings commonly reference ASME B16.11), and select a sealant proven for your media.

- Industrial piping

- Food and beverage processing (utility and support lines; product-contact lines usually avoid NPT crevices)

- Marine and coastal systems

- Pharmaceutical manufacturing (utility lines; hygienic product-contact lines usually follow ASME BPE clamp/weld standards)

Understanding NPT Pipe Fittings

What Are NPT Fittings

NPT fittings use a tapered thread design to help form a pressure-tight joint in piping systems.

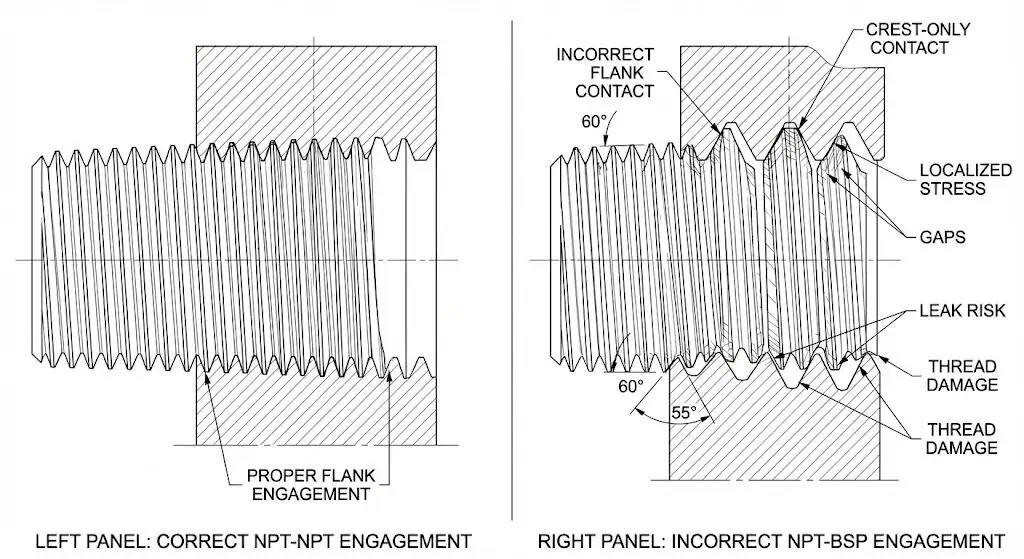

The commonly referenced standard is ASME B1.20.1 for general-purpose inch taper pipe threads. The thread form is 60° and the taper is 1 in 16 on diameter (often described as 0.75 in per foot). When you tighten an NPT male into an NPT female, flank contact increases with engagement and the sealant fills spiral leak paths. For applications where “dryseal” is needed, NPTF (Dryseal) threads (commonly referenced by ASME B1.20.3) are designed to reduce reliance on sealant by crest/root interference—still, good practice is to follow the component manufacturer’s assembly guidance.

Practical shop check: if your system is imported, do not assume “pipe thread = NPT.” Verify with a pitch gauge and a thread gage or a reliable thread identification guide before you commit to torque.

NPT Standard Pipe Fitting Features

NPT standard pipe fitting features help you achieve a tight, leak-resistant connection when the threads are correct and the joint is assembled properly.

The seal mechanism is not a gasket. It is controlled metal-to-metal thread flank engagement plus sealant filling helical leak paths. Key features include:

- Tapered threads that increase flank contact as you tighten.

- 60-degree thread angle and taper governed by the national pipe thread standard (commonly referenced by ASME B1.20.1).

- Mechanical holding strength primarily from thread flank engagement; sealing improved by sealant (PTFE tape or anaerobic/paste sealant selected for media).

- Clear limitation: damaged threads (nicks, cross-threading, galling) turn into leak paths quickly—especially in stainless-on-stainless joints.

- Engineer’s assembly rule: if the joint binds early, stop and inspect; forcing a mismatched or galled thread often cracks the female port or destroys the first threads.

Field example (installation failure): In a coastal compressor skid, a 316 SS male NPT was driven into a stainless female port without lubricant/sealant rated for the media. The nut “felt tight” early due to galling. Result: torn thread crests, persistent leak at 150–180 psi cycling. Fix: replace both parts, confirm NPT with gage, apply sealant compatible with the media, tighten to engagement guidance, and re-test under cycling.

Leak-Proof Connection Benefits

A leak-proof connection protects your system and keeps operations safe, but “leak-proof” has conditions.

NPT can perform reliably in many services when you control the basics: correct thread standard, good thread condition, correct sealant, and correct engagement. Benefits include:

- Tapered threads reduce air or fluid escape when properly engaged and sealed.

- Low part count and broad availability in North American supply chains.

- Works well for utility and support lines where frequent disassembly is not required.

- Good vibration performance when engagement is correct and sealant selection matches temperature and media.

Where NPT often gets into trouble: frequent disassembly, high vibration with poor engagement, dirty threads (tape fragments), oxygen/clean service without approved materials, or when mixed with BSP threads by mistake.

Project Requirements for Choosing the Right NPT Pipe Fittings

Application and Environment

You must match your npt pipe fittings to your project’s specific application and environment.

Start with the media (air, water, steam, hydrocarbons, solvents), then define temperature range (normal + upset), pressure range (static + surge), vibration/cycling, and corrosion drivers (chlorides, cleaning chemicals, salt spray). Then choose fitting material and construction standard accordingly.

- Common applications for npt standard pipe fitting include:

- Pressure systems

- Cooling systems

- Gas supply lines

- Hydraulic systems (low-pressure and auxiliary circuits; many hydraulic circuits prefer ORB/JIC/flare)

- Pressure washers

- Home plumbing

- Industrial air compressors

- Breweries and distilleries (utility lines; product-contact typically uses sanitary clamp/weld)

- Automotive fuel systems (application-specific; verify thread and sealing method)

- Agricultural irrigation

- Key factors to assess before choosing the right npt pipe fittings:

- Material compatibility with media and cleaners

- Pressure-temperature rating of the fitting and the mating port

- Corrosion drivers (chlorides, washdown chemicals, salt spray)

- Mechanical factors (vibration, thermal cycling, bending load on the port)

- Size/configuration and access for correct assembly

- Quality controls: thread gaging, material certs (MTR/CMTR), traceability if required

Tip: In coastal or washdown areas, 316/316L is usually chosen over 304 to reduce chloride pitting risk. If you have repeated salt exposure, also control crevices and avoid stagnant pockets around the joint.

Field example (environment mismatch): A small seawater wash line used 304 NPT fittings because “stainless is stainless.” Pitting initiated at the thread roots (crevice + chlorides). Fix: upgrade to 316/316L, improve drainage, and reduce stagnant exposure around the joint.

Safety and Compliance

You need to ensure your fittings meet all safety and compliance standards for your industry.

For industrial piping, compliance usually means (1) correct thread standard, (2) correct fitting construction standard and pressure class, (3) correct material standard, and (4) documentation consistent with your QA requirements. For hygienic industries, it also means selecting connection types that can be cleaned and inspected.

- Industries with strict requirements include:

- Food and beverage

- Pharmaceutical and biopharmaceutical

- Chemical processing

| Standard / Certification | What it controls (why it matters) |

|---|---|

| ASME B1.20.1 | NPT thread form, taper, and dimensional requirements; reduces mismatch and leak risk. |

| ASME B16.11 | Forged threaded/socket-weld fitting dimensions, classes, and material requirements; ties into pressure-temperature design by piping codes. |

| ASME B31 (e.g., B31.3 / B31.1) | System-level piping design rules (allowables, testing, materials, pressure-temperature limits). |

| ASTM material specs (e.g., A182/A276 for stainless) | Material chemistry/mechanical properties; critical for corrosion, toughness, and traceability. |

| ASME BPE | Hygienic design expectations for bioprocessing; product-contact lines often avoid NPT crevices and favor clamp/weld designs. |

| ISO 9001 (supplier QMS) | Process control consistency; does not replace technical standards, but supports repeatability. |

Note: In regulated sanitary/product-contact service, NPT is often avoided because thread crevices can trap residues. Many facilities keep NPT on utility lines and use clamp or weld connections for product-contact piping.

Material Selection for NPT Fittings

Stainless Steel vs. Other Materials

You should choose stainless steel for npt pipe fittings when you need durability and corrosion resistance, and when the media is compatible.

Stainless steel is common for chemical, marine, and washdown environments. Brass and plastics can be appropriate in clean, low-stress services, but they have different failure modes (dezincification for some brasses, cracking/creep for plastics, temperature limits).

- Stainless steel npt fittings are often selected for corrosive service, washdown, and outdoor exposure.

- Brass fittings can be effective for water/air and mild service, but selection must consider corrosion mechanisms and environment.

- Plastic fittings can be useful in low-pressure, compatible-chemical service, but pressure/temperature derating is usually the first constraint.

Tip: Material “compatibility” is two checks: (1) media vs material (corrosion/attack), and (2) material pair vs material pair (galling/galvanic risk). Stainless-on-stainless threads may require controlled assembly practice to reduce galling risk.

Table: Relative chloride pitting resistance indicator (PREN) for common stainless options

Typical engineering range; actual performance depends on temperature, chloride concentration, crevices, oxygen, and surface condition. PREN ranks alloys; it does not guarantee suitability.

| Environment driver | 304 / 304L (Typical PREN) | 316 / 316L (Typical PREN) |

|---|---|---|

| General indoor industrial | 18.0 – 20.0 | 22.6 – 27.9 |

| Washdown / intermittent chlorides | Often marginal (depends on crevices) | Typically preferred vs 304 (Mo improves pitting resistance) |

| Coastal / salt spray exposure | Higher pitting risk in crevices | Lower pitting risk vs 304; still manage crevices and stagnant exposure |

Durability and Corrosion Resistance

Stainless steel npt fittings offer high durability and corrosion resistance, especially with grades 316 and 316L where molybdenum improves pitting resistance in chloride environments.

Selection should be driven by the actual corrosive drivers and cleaning chemicals, not just “stainless.” If you are seeing repeated pitting at thread roots, treat it as a crevice + chloride problem and address both alloy and geometry (drainage/cleaning).

- 316/316L is commonly selected over 304/304L for chloride exposure because molybdenum improves resistance to pitting and crevice corrosion.

- Surface condition matters: rough threads, damage, or debris increase crevice severity and create leak paths.

- If stainless threads gall during assembly, you can lose both sealing and holding strength; use proper sealant/assembly guidance and replace damaged parts.

Note: “Corrosion resistance” is not one number. Define your chloride exposure, temperature, and cleaning chemistry before you lock in 304 vs 316/316L.

Summary:

Choose stainless steel npt fittings for corrosive environments and long-term service, but confirm media compatibility and manage crevices. When in doubt, define the environment (chlorides, cleaners, temperature) and document the basis for material selection.

Sizing and Thread Type in NPT Pipe Fittings

NPT Sizing Guide

You must select the correct size to ensure system compatibility and prevent leaks.

NPT “size” is nominal; it is not the measured outside diameter of the male thread. In field work, the reliable method is: identify the nominal size using a thread gage/pitch gage and a reference chart, then confirm with the component datasheet.

| Size | Description | Common Applications |

|---|---|---|

| 1/8 NPT Fitting | Small ports and fittings for low flow (gauges, instrumentation taps, small regulators). | Instrumentation and small pneumatic/hydraulic auxiliary lines |

| 1/2 NPT Fitting | General-purpose connection for higher flow utility piping. | Industrial air/water utility lines, manifolds, general process support |

| 3/4 NPT Fitting | Higher flow utility connections where port size and wrench access allow correct assembly. | Compressed air headers, wash lines, general utility distribution |

You should always match the fitting size to your pipe diameter and system needs. If you are unsure, stop and gage the threads—misidentified size is a common reason fittings “never seal.”

Matching Threads for Leak-Proof Connection

You need to match thread types to avoid leaks and mechanical failures.

NPT uses a 60° thread form and taper. BSP threads often use a 55° form and can be parallel or tapered depending on subtype. The joint may feel tight early when mixed, but flank contact is wrong and sealing is unreliable.

Field example (mismatch failure): An imported pump had a BSP female port. A technician installed an NPT male because “it threaded in.” It leaked under vibration and required port replacement after thread damage. Prevention: verify thread family with a gage and use certified adapters designed for the specific thread standards.

You should always check the thread standard before installation. Use only compatible thread standards, and when you must adapt, use a rated adapter with correct thread forms on each side.

Summary:

Choose the correct size and match thread types for every npt thread fitting. Confirm thread standard with a gage and follow the adapter manufacturer’s rating guidance when bridging standards.

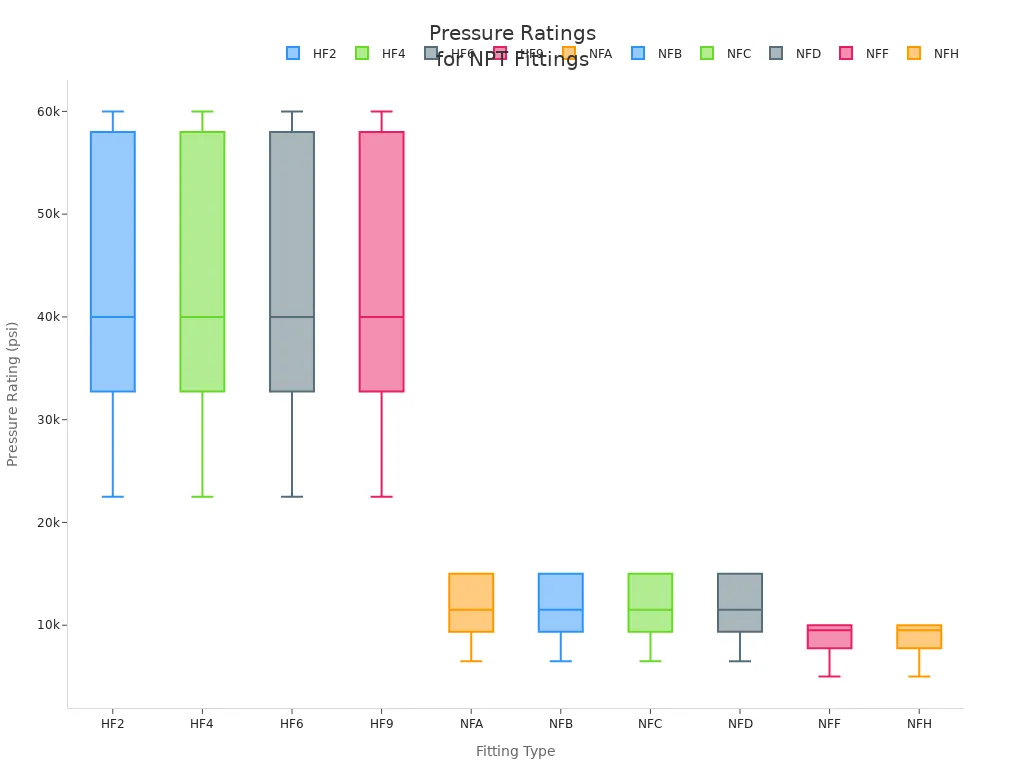

Pressure and Temperature Ratings

High-Pressure Applications

You need to choose fittings with pressure-temperature ratings that match your system’s demands.

For threaded forged fittings, many industrial specifications reference ASME B16.11 class designations. The actual allowable pressure depends on material, temperature, and the governing piping code. Treat any single “psi number” as meaningless unless it is tied to a specific product datasheet and temperature.

| Fitting Standard / Type | How it is commonly rated | Engineer’s selection note |

|---|---|---|

| ASME B16.11 threaded forged fittings | Class 2000 / 3000 / 6000 (designation) | Confirm material (e.g., ASTM A182) and use piping code pressure-temperature allowables. |

| Threaded fittings (product datasheet) | Manufacturer pressure-temperature curve | Use for specialty/high-pressure designs; verify test basis and temperature. |

| System ports/manifolds | Component rating (often lower than fitting) | The port material and wall thickness can be the limiting factor. Do not “upgrade” fitting class without checking the port. |

- Always check the manufacturer’s specifications for each fitting and the mating port.

- For cycling service (compressors, pumps), design for surge/vibration and verify joint support to reduce bending load at the port.

- If you see repeat leaks, inspect thread damage and sealant compatibility before you “tighten more.”

Tip: Select fittings with an engineering margin above maximum operating pressure, but do not exceed the rated capability of the weakest component (often the port or manifold).

Temperature Considerations

You must consider temperature ratings to avoid leaks and material failure.

Stainless steel itself can tolerate a wide range, but the joint is usually limited by sealant, gaskets, and the piping code’s allowable stresses at temperature. PTFE thread seal tape is commonly used and many manufacturer datasheets list broad service temperature ranges, but always confirm the specific tape/compound you are using and ensure it is compatible with the media (e.g., oils, solvents, oxygen service requirements).

- Stainless steel fittings resist heat/cold better than many plastics, but sealants may be the limiting factor.

- High temperatures can accelerate sealant breakdown and leakage if the wrong compound is used.

- Thermal cycling can “work” the joint; ensure correct engagement and provide support to reduce bending and vibration at the threaded port.

Note: If alignment is critical, never “back off” a tapered thread joint to point it in a direction. Backing off disrupts sealant continuity and commonly creates leaks. Use the correct orientation fittings/adapters instead.

Summary:

Choose npt pipe fittings with pressure-temperature ratings that meet the system’s true operating envelope, and confirm sealant selection for temperature and media. Treat the mating port as part of the rating chain.

Comparing NPT Fittings with Other Connection Types

NPT vs. Tri-Clamp

NPT standard pipe fitting creates a strong mechanical threaded joint, while Tri-Clamp fittings are designed for rapid disassembly and hygienic cleanability.

You should choose NPT fittings when you need a compact, pressure-rated connection for utility and support lines and you do not require frequent cleaning access. The tapered threads can seal reliably when the thread standard matches and the joint is assembled correctly.

Tri-Clamp fittings use a clamp and gasket and are commonly used in hygienic systems where disassembly, inspection, and cleaning are routine. Many bioprocessing applications align with ASME BPE expectations for defined purity and cleanability.

| Feature | NPT Standard Pipe Fitting | Tri-Clamp Fitting |

|---|---|---|

| Seal Type | Tapered thread + sealant | Gasket + clamp |

| Leak Protection | High when correctly assembled | High when gasket and clamp are correct |

| Assembly/Disassembly | Requires tools; thread condition matters | Fast; designed for frequent access |

| Cleaning / inspectability | Limited; thread crevices | High; designed for hygienic access |

| Best Use | Permanent utility/support installations | Hygienic/product-contact systems |

Tip: Keep NPT on utility and instrument support where it belongs. For product-contact and frequent cleaning, clamp or weld connections are typically easier to validate and maintain.

When to Use NPT Standard Pipe Fitting

You should use NPT standard pipe fitting in systems that demand a secure, pressure-resistant connection and do not require hygienic disassembly.

NPT standard pipe fitting is common in:

- Oil and gas: utility lines, sampling, instrument taps (application-specific).

- Manufacturing: pneumatic devices, utility distribution.

- Automotive: auxiliary fluid connections where NPT is specified.

- Plumbing and HVAC: many legacy and utility applications.

- Marine: service lines where corrosion resistance is required.

- Agriculture: irrigation and equipment service lines.

NPT joints can tolerate vibration when engagement is correct and the assembly is not used as a structural support. Provide pipe supports to reduce bending loads on the threaded port.

Note: Always check pressure-temperature rating for both the fitting and the mating component. The thread is not the rating.

Hybrid Systems and Adapters

You can connect NPT standard pipe fitting to Tri-Clamp systems using specialized adapters, but treat the adapter as a rated component.

Hybrid systems are common when upgrading a process line while keeping legacy utility piping. When you adapt, specify the thread standard on one side and the hygienic standard on the other side, then confirm the pressure-temperature limits and gasket compatibility.

- Tri-Clamp to NPT adapters connect a clamp ferrule on one side and an NPT thread on the other.

- Adapters help retrofit legacy equipment or create hygienic access points without replacing entire lines.

- Always verify the adapter’s rating basis and gasket/material compatibility.

| Adapter Type | Use Case |

|---|---|

| Tri-Clamp to Male NPT | Connect Tri-Clamp systems to an NPT female port |

| Tri-Clamp to Female NPT | Connect Tri-Clamp systems to an NPT male pipe/fitting |

Tip: Use rated adapters and keep the “hygienic side” hygienic. Avoid placing NPT threads where product residue can accumulate.

Summary:

You should choose NPT standard pipe fitting for permanent, pressure-rated utility connections and Tri-Clamp fittings for hygienic, easy-to-clean systems. Hybrid adapters can work, but only when ratings and materials are verified.

Installation and Maintenance Tips for NPT Pipe Fittings

Proper Installation for Leak-Proof Connection

You need to follow standard installation practices to achieve a leak-proof connection with npt pipe fittings.

Here is a step-by-step guide for installing npt fittings:

- Inspect and Clean Threads: Confirm both male and female threads are clean and undamaged. Remove tape fragments, burrs, and dirt. If the first threads are deformed, replace the part—sealant does not fix damaged geometry.

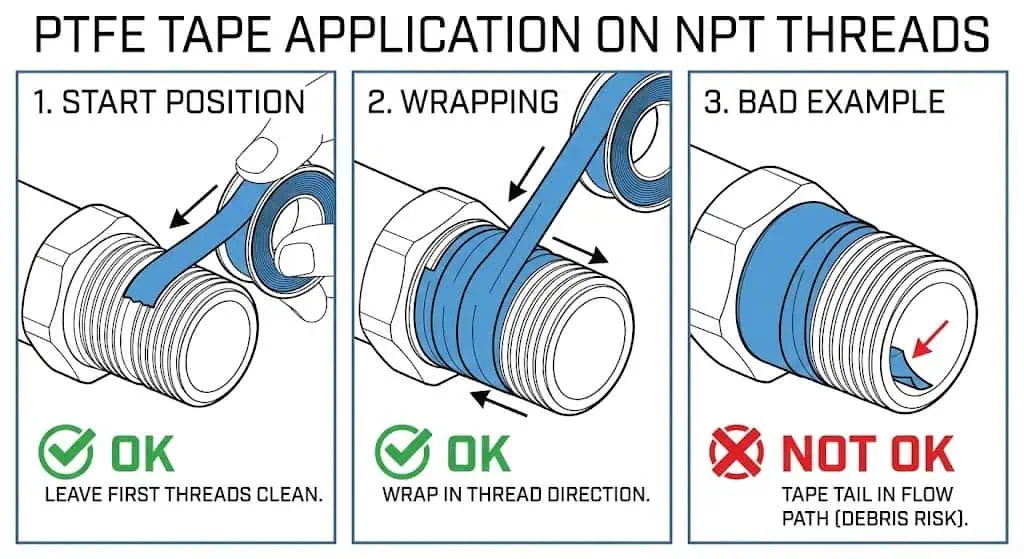

- Apply Thread Sealants: Choose a sealant proven for your media and temperature. Apply PTFE tape or a compatible paste/anaerobic sealant to fill spiral leak paths. Keep sealant out of the system: avoid loose tape tails and leave the first thread clean if your procedure requires it.

- Hand-Tighten First: Start by hand to avoid cross-threading. If it does not run smoothly, stop and verify thread standard and condition.

- Wrench-Tighten: Tighten according to fitting guidance. Over-tightening can crack female ports or gall stainless threads; under-tightening can leak.

- Test for Leaks: After installation, test at operating pressure with an appropriate method (soap solution for air, pressure hold for liquids, or higher-sensitivity methods where required).

Tip: Never back off an installed fitting to correct alignment. This disrupts the sealant film and commonly creates leaks.

Field example (sealant contamination): In an instrumentation panel, excess PTFE tape tore off and lodged in a regulator seat. Symptoms looked like a “leaking fitting,” but the real problem was debris in the control element. Prevention: controlled tape application, cut ends clean, and verify no tape enters the flow path.

Common installation errors include improper tightening, misalignment, mixing thread standards, and using worn threads. Diagnose the thread condition before you diagnose “pressure problems.”

Maintenance and Inspection

You must inspect and maintain npt pipe fittings regularly to prevent leaks and system failures.

- Set inspection frequency based on risk and failure development time. A common maintenance approach is to inspect at intervals shorter than the time a defect typically takes to develop into failure (site-specific).

- During inspection, look for seepage, corrosion at thread roots, vibration loosening, and support issues that load the port.

- Clean exposed threads and replace damaged fittings immediately. Re-torque without understanding the cause often worsens galling and port damage.

| Maintenance Task | Frequency | Purpose |

|---|---|---|

| Visual Inspection | Risk-based / site-specific | Detect leaks, corrosion, loosening, support issues |

| Leak Test (appropriate method) | After installation and after intervention | Confirm leak-tight performance |

| Thread/port condition check | When leaks recur | Identify galling, cracking, thread damage, mismatch |

| Fitting Replacement | When worn/damaged | Avoid system failure and port damage escalation |

Note: Regular inspection works best when you also check pipe supports. Many “fitting leaks” are actually bending load and vibration at the threaded port.

Quick Checklist for Choosing the Right NPT Pipe Fittings

You need a checklist that reflects how NPT joints fail in the field: wrong thread standard, damaged threads, wrong sealant, wrong rating chain, or wrong environment.

1. Confirm Your Application and Environment

- Direct Answer: Match fittings to your media, temperature range, pressure range (including surge), and environment (chlorides, washdown, chemicals).

- Decide whether the line is utility/support or hygienic/product-contact.

- Evaluate vibration and bending load at the port; plan supports accordingly.

2. Select the Right Material

- Direct Answer: Choose material based on corrosion drivers and media compatibility, not habit.

- For chlorides/washdown: 316/316L is commonly preferred over 304/304L.

- For repeated galling in stainless threads: tighten only after confirming thread condition and sealant/assembly practice; replace damaged parts.

3. Verify Pressure and Temperature Ratings

- Direct Answer: Confirm rating for the fitting and the mating port/manifold at temperature.

- Use product datasheets and the governing piping code basis; do not rely on generic “psi tables.”

4. Match Thread Type and Size

- Direct Answer: Verify NPT vs BSP vs NPTF using gages; avoid mixing standards.

- Use certified adapters when bridging standards, and confirm adapter ratings.

5. Inspect for Quality and Documentation

- Direct Answer: For critical service, require thread gaging, material certs (MTR/CMTR), and traceability as needed.

- Confirm the fitting standard reference (commonly ASME B16.11 for forged threaded fittings) and the thread standard reference (commonly ASME B1.20.1 for NPT).

Tip: If a joint leaks, do not jump straight to “tighten more.” First verify: correct thread standard, intact threads, correct sealant for media/temperature, and no bending load at the port.

You need to match fitting type, material, size, and ratings to your project for reliable results. Stainless steel NPT pipe fittings can deliver consistent performance in demanding environments when the thread standard is correct and the assembly is controlled. If your service is hygienic/product-contact, evaluate clamp/weld standards for cleanability and validation.

| Selection Outcome | Controlled / documented selection | Uncontrolled selection |

|---|---|---|

| Leak recurrence risk | Lower (thread standard + sealant + rating chain verified) | Higher (mismatch, damaged threads, wrong sealant) |

| Maintenance pattern | Predictable; root causes corrected | Repeated rework; port damage escalation |

| Life-cycle cost | Lower when fit-for-service | Higher due to downtime and rework |

FAQ

What is the main advantage of using stainless steel NPT fittings?

Stainless steel NPT fittings offer durability and corrosion resistance when matched to the environment.

You get improved performance in washdown and chloride-exposed areas when you select the right grade (often 316/316L for chlorides) and control thread condition and sealant choice.

- Better corrosion resistance than many carbon steels

- Good mechanical strength for industrial service

- Common availability in multiple configurations

How do you choose the correct NPT fitting size?

Always identify the thread standard and nominal size with gages rather than guessing by outside diameter.

NPT sizes are nominal. Use a pitch gauge/thread gage and a reference chart, then confirm with the component datasheet.

| Pipe Size | Common Use |

|---|---|

| 1/8″ | Instrumentation |

| 1/2″ | Industrial systems |

| 3/4″ | Large flow utility lines |

Can you mix NPT threads with other thread types?

Do not mix thread standards (e.g., NPT with BSP) in a direct joint.

Mismatched thread forms often feel tight but do not have correct flank engagement, and they frequently leak or damage the port. Use certified adapters with the correct thread standards on each side.

Use certified adapters if you need to connect different thread types.

What sealant should you use for NPT fittings?

Use a sealant compatible with your media and temperature—PTFE tape and paste/anaerobic sealants are common, but selection is service-specific.

Apply sealant to clean threads, keep debris out of the system, and avoid backing off after tightening.

- PTFE tape: common for many utilities when applied cleanly

- Pipe dope / anaerobic sealant: often used where vibration or temperature cycling is higher (confirm media compatibility)

How often should you inspect NPT pipe fittings?

Inspect on a risk-based interval tied to your service severity and leak consequence.

For high-vibration or corrosive environments, shorten intervals and include support checks (bending load at the port is a frequent root cause). Always leak-test after installation and after any intervention.

Early inspection helps you catch leaks before they cause damage.

Why do stainless NPT threads sometimes gall during assembly?

Galling is adhesive wear that can occur in stainless-on-stainless threads under high contact stress, especially with dirty or dry threads.

Prevention includes verifying thread condition, using the correct sealant/assembly method, and avoiding forced make-up when the joint binds early. Replace damaged parts; do not “power through” galling.

When should you avoid NPT in process systems?

Avoid NPT on product-contact piping where cleanability and crevice control are critical.

Threads create crevices that can trap residues. In hygienic systems, clamp or weld connections aligned with hygienic standards are commonly used, keeping NPT on utility/support lines where appropriate.