ASME B16.5 Flanges - Dimensions, Bolt Torque & Manufacturing Standard (Class 150 - 2500)

Manufacturer & Supplier of ANSI/ASME B16.5 Pipe Flanges in Stainless and Alloy Steel.

Home / Stainless Steel Flange / Standards / ASME-B16-5

Types of ASME B16.5 Flanges We Supply

By Design Type

By Standard & Class

Advanced Materials

Difference Between ANSI and ASME Flanges

This is one of the most common questions in the piping industry.

The Short Answer: Technically and physically, there is no difference. An “ANSI flange” and an “ASME flange” refer to the same component.

The Detailed Explanation: The distinction is purely historical.

“ANSI Flange”: This is an older, obsolete term. Before 1996, the standard was accredited by ANSI (American National Standards Institute) and often referred to as ANSI B16.5.

“ASME Flange”: This is the correct, modern term. Since 1996, the standard has been published and maintained solely by ASME (American Society of Mechanical Engineers) as ASME B16.5.

Professional Advice: When writing purchase orders or engineering specifications today, always use the designation ASME B16.5 to ensure clarity and adherence to current standards.

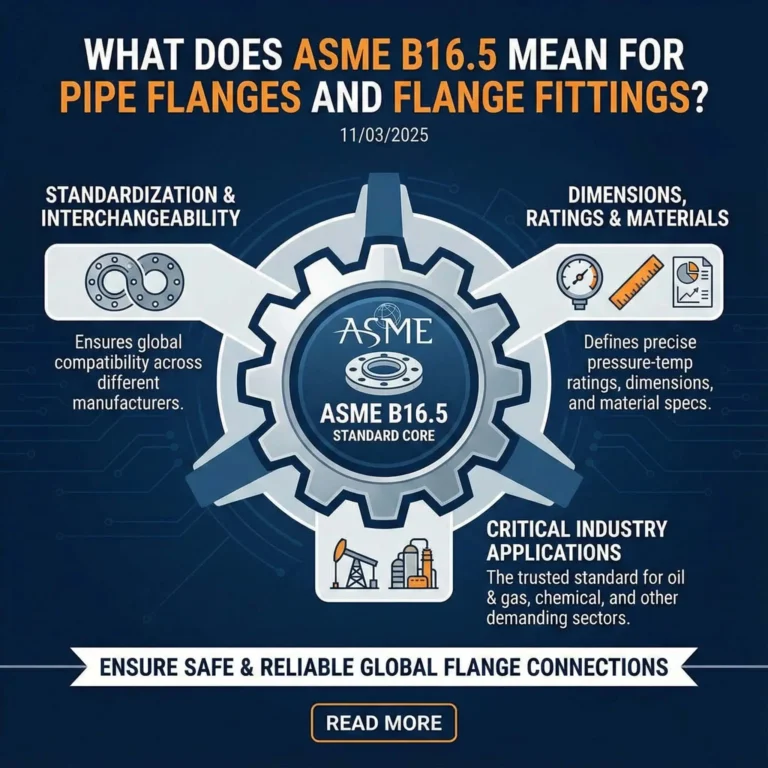

What is ASME B16.5 Flange?

ASME B16.5 is the authoritative industrial standard for Pipe Flanges and Flanged Fittings. It covers nominal pipe sizes from NPS 1/2 through NPS 24 and pressure ratings from Class 150 to Class 2500. The standard specifies detailed requirements for dimensions, pressure-temperature ratings, materials, tolerances, marking, and testing, ensuring the interchangeability and sealing integrity of piping, valves, and fittings.

ASME B16.5 Flange Dimensions (Class 150 to 2500)

Note: All dimensions below are in Inches, per the ASME B16.5 standard specifications.

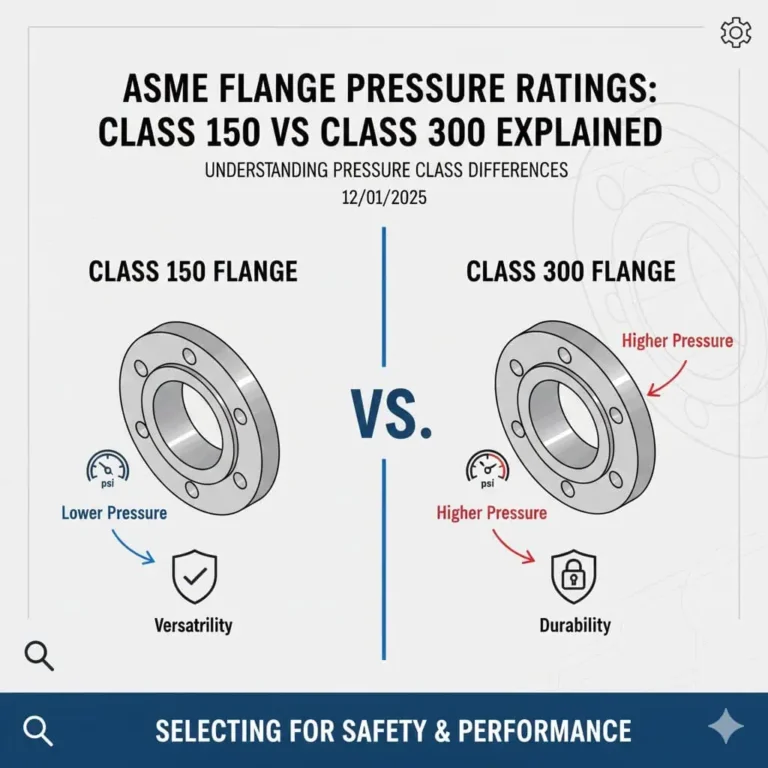

The ASME B16.5 standard categorizes flanges into seven pressure classes. As the Class number increases, the flange becomes thicker, heavier, and more robust to withstand higher pressures.

Class 150: Standard low-pressure applications.

Class 300 & 400: Medium pressure applications.

Class 600 & 900: High pressure, often used in oil & gas pipelines.

Class 1500 & 2500: Extreme pressure applications.

*”Data is for reference only. Always consult the specific project engineering requirements.”

| Nominal Pipe Size (NPS) | Outside Diameter (O) | Flange Thickness (tf) | Bolt Circle Diameter (W) | Number of Bolts | Diameter of Bolts | Diameter of Holes |

| 1/2 | 3.50 | 0.44 | 2.38 | 4 | 0.50 | 0.62 |

| 3/4 | 3.88 | 0.50 | 2.75 | 4 | 0.50 | 0.62 |

| 1 | 4.25 | 0.56 | 3.12 | 4 | 0.50 | 0.62 |

| 1-1/4 | 4.62 | 0.62 | 3.50 | 4 | 0.50 | 0.62 |

| 1-1/2 | 5.00 | 0.69 | 3.88 | 4 | 0.50 | 0.62 |

| 2 | 6.00 | 0.75 | 4.75 | 4 | 0.62 | 0.75 |

| 2-1/2 | 7.00 | 0.88 | 5.50 | 4 | 0.62 | 0.75 |

| 3 | 7.50 | 0.94 | 6.00 | 4 | 0.62 | 0.75 |

| 3-1/2 | 8.50 | 0.94 | 7.00 | 8 | 0.62 | 0.75 |

| 4 | 9.00 | 0.94 | 7.50 | 8 | 0.62 | 0.75 |

| 5 | 10.00 | 0.94 | 8.50 | 8 | 0.75 | 0.88 |

| 6 | 11.00 | 1.00 | 9.50 | 8 | 0.75 | 0.88 |

| 8 | 13.50 | 1.12 | 11.75 | 8 | 0.75 | 0.88 |

| 10 | 16.00 | 1.19 | 14.25 | 12 | 0.88 | 1.00 |

| 12 | 19.00 | 1.25 | 17.00 | 12 | 0.88 | 1.00 |

| 14 | 21.00 | 1.38 | 18.75 | 12 | 1.00 | 1.12 |

| 16 | 23.50 | 1.44 | 21.25 | 16 | 1.00 | 1.12 |

| 18 | 25.00 | 1.56 | 22.75 | 16 | 1.12 | 1.25 |

| 20 | 27.50 | 1.69 | 25.00 | 20 | 1.12 | 1.25 |

| 24 | 32.00 | 1.88 | 29.50 | 20 | 1.25 | 1.38 |

| Nominal Pipe Size (NPS) | Outside Diameter (O) | Flange Thickness (tf) | Bolt Circle Diameter (W) | Number of Bolts | Diameter of Bolts | Diameter of Holes |

| 1/2 | 3.75 | 0.56 | 2.62 | 4 | 0.50 | 0.62 |

| 3/4 | 4.62 | 0.62 | 3.25 | 4 | 0.62 | 0.75 |

| 1 | 4.88 | 0.69 | 3.50 | 4 | 0.62 | 0.75 |

| 1-1/4 | 5.25 | 0.75 | 3.88 | 4 | 0.62 | 0.75 |

| 1-1/2 | 6.12 | 0.81 | 4.50 | 4 | 0.75 | 0.88 |

| 2 | 6.50 | 0.88 | 5.00 | 8 | 0.62 | 0.75 |

| 2-1/2 | 7.50 | 1.00 | 5.88 | 8 | 0.75 | 0.88 |

| 3 | 8.25 | 1.12 | 6.62 | 8 | 0.75 | 0.88 |

| 3-1/2 | 9.00 | 1.19 | 7.25 | 8 | 0.75 | 0.88 |

| 4 | 10.00 | 1.25 | 7.88 | 8 | 0.75 | 0.88 |

| 5 | 11.00 | 1.38 | 9.25 | 8 | 0.75 | 0.88 |

| 6 | 12.50 | 1.44 | 10.62 | 12 | 0.75 | 0.88 |

| 8 | 15.00 | 1.62 | 13.00 | 12 | 0.88 | 1.00 |

| 10 | 17.50 | 1.88 | 15.25 | 16 | 1.00 | 1.12 |

| 12 | 20.50 | 2.00 | 17.75 | 16 | 1.12 | 1.25 |

| 14 | 23.00 | 2.12 | 20.25 | 20 | 1.12 | 1.25 |

| 16 | 25.50 | 2.25 | 22.50 | 20 | 1.25 | 1.38 |

| 18 | 28.00 | 2.38 | 24.75 | 24 | 1.25 | 1.38 |

| 20 | 30.50 | 2.50 | 27.00 | 24 | 1.25 | 1.38 |

| 24 | 36.00 | 2.75 | 32.00 | 24 | 1.50 | 1.62 |

| Nominal Pipe Size (NPS) | Outside Diameter (O) | Flange Thickness (tf) | Bolt Circle Diameter (W) | Number of Bolts | Diameter of Bolts | Diameter of Holes |

| 1/2 | 3.75 | 0.56 | 2.62 | 4 | 0.50 | 0.62 |

| 3/4 | 4.62 | 0.62 | 3.25 | 4 | 0.62 | 0.75 |

| 1 | 4.88 | 0.69 | 3.50 | 4 | 0.62 | 0.75 |

| 1-1/4 | 5.25 | 0.81 | 3.88 | 4 | 0.62 | 0.75 |

| 1-1/2 | 6.12 | 0.88 | 4.50 | 4 | 0.75 | 0.88 |

| 2 | 6.50 | 1.00 | 5.00 | 8 | 0.62 | 0.75 |

| 2-1/2 | 7.50 | 1.12 | 5.88 | 8 | 0.75 | 0.88 |

| 3 | 8.25 | 1.25 | 6.62 | 8 | 0.75 | 0.88 |

| 3-1/2 | 9.00 | 1.38 | 7.25 | 8 | 0.88 | 1.00 |

| 4 | 10.00 | 1.38 | 7.88 | 8 | 0.88 | 1.00 |

| 5 | 11.00 | 1.50 | 9.25 | 8 | 0.88 | 1.00 |

| 6 | 12.50 | 1.62 | 10.62 | 12 | 0.88 | 1.00 |

| 8 | 15.00 | 1.88 | 13.00 | 12 | 1.00 | 1.12 |

| 10 | 17.50 | 2.12 | 15.25 | 16 | 1.12 | 1.25 |

| 12 | 20.50 | 2.25 | 17.75 | 16 | 1.25 | 1.38 |

| 14 | 23.00 | 2.38 | 20.25 | 20 | 1.25 | 1.38 |

| 16 | 25.50 | 2.50 | 22.50 | 20 | 1.38 | 1.50 |

| 18 | 28.00 | 2.62 | 24.75 | 24 | 1.38 | 1.50 |

| 20 | 30.50 | 2.75 | 27.00 | 24 | 1.50 | 1.62 |

| 24 | 36.00 | 3.00 | 32.00 | 24 | 1.75 | 1.88 |

| Nominal Pipe Size (NPS) | Outside Diameter (O) | Flange Thickness (tf) | Bolt Circle Diameter (W) | Number of Bolts | Diameter of Bolts | Diameter of Holes |

| 1/2 | 3.75 | 0.56 | 2.62 | 4 | 0.50 | 0.62 |

| 3/4 | 4.62 | 0.62 | 3.25 | 4 | 0.62 | 0.75 |

| 1 | 4.88 | 0.69 | 3.50 | 4 | 0.62 | 0.75 |

| 1-1/4 | 5.25 | 0.81 | 3.88 | 4 | 0.62 | 0.75 |

| 1-1/2 | 6.12 | 0.88 | 4.50 | 4 | 0.75 | 0.88 |

| 2 | 6.50 | 1.00 | 5.00 | 8 | 0.62 | 0.75 |

| 2-1/2 | 7.50 | 1.12 | 5.88 | 8 | 0.75 | 0.88 |

| 3 | 8.25 | 1.25 | 6.62 | 8 | 0.75 | 0.88 |

| 3-1/2 | 9.00 | 1.38 | 7.25 | 8 | 0.88 | 1.00 |

| 4 | 10.75 | 1.50 | 8.50 | 8 | 0.88 | 1.00 |

| 5 | 13.00 | 1.75 | 10.50 | 8 | 1.00 | 1.12 |

| 6 | 14.00 | 1.88 | 11.50 | 12 | 1.00 | 1.12 |

| 8 | 16.50 | 2.19 | 13.75 | 12 | 1.12 | 1.25 |

| 10 | 20.00 | 2.50 | 17.00 | 16 | 1.25 | 1.38 |

| 12 | 22.00 | 2.62 | 19.25 | 20 | 1.25 | 1.38 |

| 14 | 23.75 | 2.75 | 20.75 | 20 | 1.38 | 1.50 |

| 16 | 27.00 | 3.00 | 23.75 | 20 | 1.50 | 1.62 |

| 18 | 29.25 | 3.25 | 25.75 | 20 | 1.62 | 1.75 |

| 20 | 32.00 | 3.50 | 28.50 | 24 | 1.62 | 1.75 |

| 24 | 37.00 | 4.00 | 33.00 | 24 | 1.88 | 2.00 |

| Nominal Pipe Size (NPS) | Outside Diameter (O) | Flange Thickness (tf) | Bolt Circle Diameter (W) | Number of Bolts | Diameter of Bolts | Diameter of Holes |

| 1/2 | 4.75 | 0.88 | 3.25 | 4 | 0.75 | 0.88 |

| 3/4 | 5.12 | 1.00 | 3.50 | 4 | 0.75 | 0.88 |

| 1 | 5.88 | 1.12 | 4.00 | 4 | 0.88 | 1.00 |

| 1-1/4 | 6.25 | 1.12 | 4.38 | 4 | 0.88 | 1.00 |

| 1-1/2 | 7.00 | 1.25 | 4.88 | 4 | 1.00 | 1.12 |

| 2 | 8.50 | 1.50 | 6.50 | 8 | 0.88 | 1.00 |

| 2-1/2 | 9.62 | 1.62 | 7.50 | 8 | 1.00 | 1.12 |

| 3 | 9.50 | 1.50 | 7.50 | 8 | 0.88 | 1.00 |

| 4 | 11.50 | 1.75 | 9.25 | 8 | 1.12 | 1.25 |

| 5 | 13.75 | 2.00 | 11.00 | 8 | 1.25 | 1.38 |

| 6 | 15.00 | 2.19 | 12.50 | 12 | 1.12 | 1.25 |

| 8 | 18.50 | 2.50 | 15.50 | 12 | 1.38 | 1.50 |

| 10 | 21.50 | 2.75 | 18.50 | 16 | 1.38 | 1.50 |

| 12 | 24.00 | 3.12 | 21.00 | 20 | 1.38 | 1.50 |

| 14 | 25.25 | 3.38 | 22.00 | 20 | 1.50 | 1.62 |

| 16 | 27.75 | 3.50 | 24.25 | 20 | 1.62 | 1.75 |

| 18 | 31.00 | 4.00 | 27.00 | 20 | 1.88 | 2.00 |

| 20 | 33.75 | 4.25 | 29.50 | 20 | 2.00 | 2.12 |

| 24 | 41.00 | 5.50 | 35.50 | 20 | 2.50 | 2.62 |

| Nominal Pipe Size (NPS) | Outside Diameter (O) | Flange Thickness (tf) | Bolt Circle Diameter (W) | Number of Bolts | Diameter of Bolts | Diameter of Holes |

| 1/2 | 4.75 | 0.88 | 3.25 | 4 | 0.75 | 0.88 |

| 3/4 | 5.12 | 1.00 | 3.50 | 4 | 0.75 | 0.88 |

| 1 | 5.88 | 1.12 | 4.00 | 4 | 0.88 | 1.00 |

| 1-1/4 | 6.25 | 1.12 | 4.38 | 4 | 0.88 | 1.00 |

| 1-1/2 | 7.00 | 1.25 | 4.88 | 4 | 1.00 | 1.12 |

| 2 | 8.50 | 1.50 | 6.50 | 8 | 0.88 | 1.00 |

| 2-1/2 | 9.62 | 1.62 | 7.50 | 8 | 1.00 | 1.12 |

| 3 | 10.50 | 1.88 | 8.00 | 8 | 1.12 | 1.25 |

| 4 | 12.25 | 2.12 | 9.50 | 8 | 1.25 | 1.38 |

| 5 | 14.75 | 2.88 | 11.50 | 8 | 1.50 | 1.62 |

| 6 | 15.50 | 3.25 | 12.50 | 12 | 1.38 | 1.50 |

| 8 | 19.00 | 3.62 | 15.50 | 12 | 1.62 | 1.75 |

| 10 | 23.00 | 4.25 | 19.00 | 12 | 1.88 | 2.00 |

| 12 | 26.50 | 4.88 | 22.50 | 16 | 2.00 | 2.12 |

| 14 | 29.50 | 5.25 | 25.00 | 16 | 2.25 | 2.38 |

| 16 | 32.50 | 5.75 | 27.75 | 16 | 2.50 | 2.62 |

| 18 | 36.00 | 6.38 | 30.50 | 16 | 2.75 | 2.88 |

| 20 | 38.75 | 7.00 | 32.75 | 16 | 3.00 | 3.12 |

| 24 | 46.00 | 8.00 | 39.00 | 16 | 3.50 | 3.62 |

| Nominal Pipe Size (NPS) | Outside Diameter (O) | Flange Thickness (tf) | Bolt Circle Diameter (W) | Number of Bolts | Diameter of Bolts | Diameter of Holes |

| 1/2 | 5.25 | 1.19 | 3.50 | 4 | 0.75 | 0.88 |

| 3/4 | 5.50 | 1.25 | 3.75 | 4 | 0.75 | 0.88 |

| 1 | 6.25 | 1.38 | 4.25 | 4 | 0.88 | 1.00 |

| 1-1/4 | 7.25 | 1.50 | 5.12 | 4 | 1.00 | 1.12 |

| 1-1/2 | 8.00 | 1.75 | 5.75 | 4 | 1.12 | 1.25 |

| 2 | 9.25 | 2.00 | 6.75 | 8 | 1.00 | 1.12 |

| 2-1/2 | 10.50 | 2.25 | 7.75 | 8 | 1.12 | 1.25 |

| 3 | 12.00 | 2.62 | 9.00 | 8 | 1.25 | 1.38 |

| 4 | 14.00 | 3.00 | 10.75 | 8 | 1.50 | 1.62 |

| 5 | 16.50 | 3.62 | 12.75 | 8 | 1.75 | 1.88 |

| 6 | 19.00 | 4.25 | 14.50 | 8 | 2.00 | 2.12 |

| 8 | 21.75 | 5.00 | 17.25 | 12 | 2.00 | 2.12 |

| 10 | 26.50 | 6.50 | 21.25 | 12 | 2.50 | 2.62 |

| 12 | 30.00 | 7.25 | 24.38 | 12 | 2.75 | 2.88 |

| Temperature (°F) | Class 150 (psig) | Class 300 (psig) | Class 400 (psig) | Class 600 (psig) | Class 900 (psig) | Class 1500 (psig) | Class 2500 (psig) |

| -20 to 100 | 285 | 740 | 985 | 1480 | 2220 | 3705 | 6170 |

| 200 | 260 | 680 | 905 | 1360 | 2035 | 3395 | 5655 |

| 300 | 230 | 655 | 870 | 1310 | 1965 | 3270 | 5450 |

| 400 | 200 | 635 | 845 | 1265 | 1900 | 3170 | 5280 |

| 500 | 170 | 605 | 805 | 1205 | 1810 | 3015 | 5025 |

| 600 | 140 | 570 | 755 | 1135 | 1705 | 2840 | 4730 |

| 650 | 125 | 550 | 730 | 1095 | 1640 | 2730 | 4555 |

| 700 | 110 | 530 | 710 | 1065 | 1600 | 2665 | 4440 |

| 750 | 95 | 505 | 675 | 1010 | 1510 | 2520 | 4200 |

| 800 | 80 | 410 | 550 | 825 | 1235 | 2060 | 3430 |

| 850 | 65 | 320 | 425 | 640 | 955 | 1595 | 2655 |

| 900 | 50 | 230 | 305 | 460 | 690 | 1150 | 1915 |

| 950 | 35 | 135 | 185 | 275 | 415 | 695 | 1155 |

| 1000 | 20 | 85 | 115 | 170 | 255 | 430 | 715 |

| Temperature (°F) | Class 150 (psig) | Class 300 (psig) | Class 400 (psig) | Class 600 (psig) | Class 900 (psig) | Class 1500 (psig) | Class 2500 (psig) |

| -20 to 100 | 275 | 720 | 960 | 1440 | 2160 | 3600 | 6000 |

| 200 | 230 | 600 | 800 | 1200 | 1800 | 3000 | 5000 |

| 300 | 205 | 540 | 720 | 1080 | 1620 | 2700 | 4500 |

| 400 | 190 | 495 | 660 | 995 | 1490 | 2485 | 4140 |

| 500 | 170 | 465 | 620 | 930 | 1395 | 2330 | 3880 |

| 600 | 140 | 435 | 580 | 875 | 1310 | 2185 | 3640 |

| 650 | 125 | 430 | 575 | 860 | 1290 | 2150 | 3585 |

| 700 | 110 | 425 | 565 | 850 | 1275 | 2125 | 3540 |

| 750 | 95 | 415 | 555 | 830 | 1245 | 2075 | 3460 |

| 800 | 80 | 405 | 540 | 805 | 1210 | 2015 | 3360 |

| 850 | 65 | 395 | 530 | 790 | 1190 | 1980 | 3300 |

| 900 | 50 | 390 | 520 | 780 | 1165 | 1945 | 3240 |

| 950 | 35 | 380 | 510 | 765 | 1145 | 1910 | 3180 |

| 1000 | 20 | 320 | 430 | 640 | 965 | 1605 | 2675 |

| Temperature (°F) | Class 150 (psig) | Class 300 (psig) | Class 400 (psig) | Class 600 (psig) | Class 900 (psig) | Class 1500 (psig) | Class 2500 (psig) |

| -20 to 100 | 275 | 720 | 960 | 1440 | 2160 | 3600 | 6000 |

| 200 | 235 | 620 | 825 | 1240 | 1860 | 3095 | 5160 |

| 300 | 215 | 560 | 745 | 1120 | 1680 | 2795 | 4660 |

| 400 | 195 | 515 | 685 | 1025 | 1540 | 2570 | 4280 |

| 500 | 170 | 480 | 635 | 955 | 1435 | 2390 | 3980 |

| 600 | 140 | 450 | 600 | 900 | 1355 | 2255 | 3760 |

| 650 | 125 | 440 | 590 | 885 | 1325 | 2210 | 3680 |

| 700 | 110 | 435 | 580 | 870 | 1305 | 2170 | 3620 |

| 750 | 95 | 425 | 570 | 855 | 1280 | 2135 | 3560 |

| 800 | 80 | 420 | 565 | 845 | 1265 | 2110 | 3520 |

| 850 | 65 | 420 | 555 | 835 | 1255 | 2090 | 3480 |

| 900 | 50 | 415 | 555 | 830 | 1245 | 2075 | 3460 |

| 950 | 35 | 385 | 515 | 775 | 1160 | 1930 | 3220 |

| 1000 | 20 | 365 | 485 | 725 | 1090 | 1820 | 3030 |

| Temperature (°F) | Class 150 (psig) | Class 300 (psig) | Class 400 (psig) | Class 600 (psig) | Class 900 (psig) | Class 1500 (psig) | Class 2500 (psig) |

| -20 to 100 | 230 | 600 | 800 | 1200 | 1800 | 3000 | 5000 |

| 200 | 195 | 510 | 680 | 1020 | 1530 | 2550 | 4250 |

| 300 | 175 | 455 | 605 | 910 | 1365 | 2275 | 3790 |

| 400 | 160 | 420 | 560 | 840 | 1260 | 2100 | 3500 |

| 500 | 145 | 395 | 525 | 785 | 1180 | 1965 | 3275 |

| 600 | 140 | 385 | 515 | 770 | 1155 | 1925 | 3210 |

| 650 | 125 | 375 | 500 | 750 | 1125 | 1875 | 3125 |

| 700 | 110 | 370 | 495 | 740 | 1110 | 1850 | 3085 |

| 750 | 95 | 365 | 490 | 735 | 1100 | 1835 | 3060 |

| 800 | 80 | 360 | 480 | 720 | 1080 | 1800 | 3000 |

Pressure-Temperature Ratings (Material Groups)

The maximum allowable working pressure of a flange depends on both the operating temperature and the material group. As temperature increases, the pressure rating decreases.

Material Groups Overview:

Group 1.1 (Carbon Steel): Common materials like A105, A216 WCB.

Group 2.1 (Stainless Steel 304): Standard austenitic stainless steel.

Group 2.2 (Stainless Steel 316): Molybdenum-bearing stainless steel for better corrosion resistance.

Group 2.3 (Low Carbon Stainless Steel 304L/316L): Used to prevent intergranular corrosion, but with lower strength at high temperatures.

*”Data is for reference only. Always consult the specific project engineering requirements.”

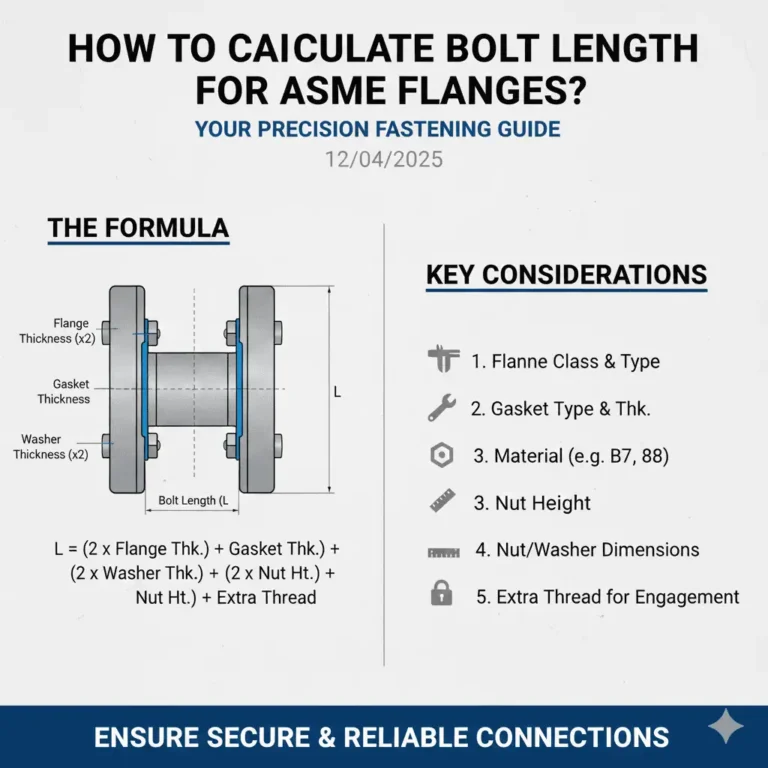

Bolt Torque Chart for ASME B16.5 Flanges

Torque values are based on ASTM A193 B7 Bolts with lubricated usage.

Download: ASME flange bolt torque chart PDF

*”Data is for reference only. Always consult the specific project engineering requirements.”

| Flange Size (NPS) | Bolt Size (Inch) | Bolts Qty | Target Torque (ft-lbs) | Target Torque (Nm) |

| 1/2″ | 1/2″ | 4 | 30 | 41 |

| 3/4″ | 1/2″ | 4 | 30 | 41 |

| 1″ | 1/2″ | 4 | 40 | 54 |

| 1-1/2″ | 1/2″ | 4 | 50 | 68 |

| 2″ | 5/8″ | 4 | 80 | 108 |

| 3″ | 5/8″ | 4 | 110 | 149 |

| 4″ | 5/8″ | 8 | 100 | 136 |

| 6″ | 3/4″ | 8 | 170 | 230 |

| 8″ | 3/4″ | 8 | 240 | 325 |

FAQ

How do I find the correct bolt torque for ASME B16.5 flanges?

The ASME B16.5 standard does not contain mandatory bolt torque tables. While the standard specifies flange dimensions and pressure ratings, the required tightening torque depends on the gasket type, bolt material (e.g., ASTM A193 B7), and the lubricant’s friction factor (Nut Factor, K).

For accurate torque specifications, engineers typically reference ASME PCC-1 (Guidelines for Pressure Boundary Bolted Flange Joint Assembly). Below are reference torque values for Class 150 flanges using a friction factor of K=0.17:

| Flange Size (NPS) | Bolt Diameter | Bolt Count | Target Torque (ft-lbs) | Target Torque (N-m) |

| 1/2″ | 1/2″ | 4 | 30 – 45 | 40 – 60 |

| 2″ | 5/8″ | 4 | 60 – 90 | 80 – 120 |

| 4″ | 5/8″ | 8 | 60 – 90 | 80 – 120 |

| 6″ | 3/4″ | 8 | 100 – 130 | 135 – 175 |

What is the difference between ASME B16.5 and B16.47?

The primary difference between ASME B16.5 and ASME B16.47 is the applicable size range (NPS).

ASME B16.5: Covers standard pipe flanges from NPS 1/2 to NPS 24. This is the most widely used standard for process piping.

ASME B16.47: Covers large-diameter steel flanges from NPS 26 to NPS 60.

Additionally, ASME B16.47 divides flanges into Series A (formerly MSS SP-44; heavier and stronger) and Series B (formerly API 605; lighter and more compact). ASME B16.5 does not have this series distinction.

Does ASME B16.5 cover metric dimensions?

Yes, ASME B16.5 is a dual “Metric/Inch” standard. Since the 2003 edition, the standard has provided dimensions in both millimeters (SI units) and inches (U.S. Customary units).

However, a critical engineering nuance exists regarding interchangeability:

Flange Dimensions: The metric dimensions are generally “soft conversions” of the inch dimensions.

Bolting Hardware: Despite the metric data in the standard, bolt holes and fasteners typically retain inch-series threads (UNC) to ensure compatibility with existing equipment globally. Specifying true metric bolting (e.g., M16) for ASME flanges is non-standard and may require special ordering.

What do the Classes (150, 300, 600) mean in ASME B16.5?

A Pressure Class is a dimensionless designator that identifies the pressure-temperature rating of a flange; it does not directly correspond to a maximum pressure in psi.

The Maximum Allowable Working Pressure (MAWP) for any given Class decreases as the operating temperature increases. The table below illustrates this inverse relationship for Carbon Steel (Group 1.1) flanges:

| Temperature | Class 150 Max Pressure | Class 300 Max Pressure |

| Ambient (100°F) | 285 psi | 740 psi |

| 400°F | 200 psi | 635 psi |

| 600°F | 140 psi | 570 psi |

Are ASME B16.5 flange dimensions in mm or inches?

ASME B16.5 dimensions are specified in both millimeters and inches. Users may utilize either system, provided they apply it consistently.

However, the standard was originally designed using the U.S. Customary (Inch) system. Consequently, when measuring an ASME flange with a metric tool, you will often find non-integer values (e.g., a bolt circle of 120.65 mm rather than 120 mm). If your measurements yield exact integers in millimeters, the flange likely conforms to a DIN or ISO standard, not ASME B16.5.

Stainless Steel Flanges

Stainless Steel Flanges