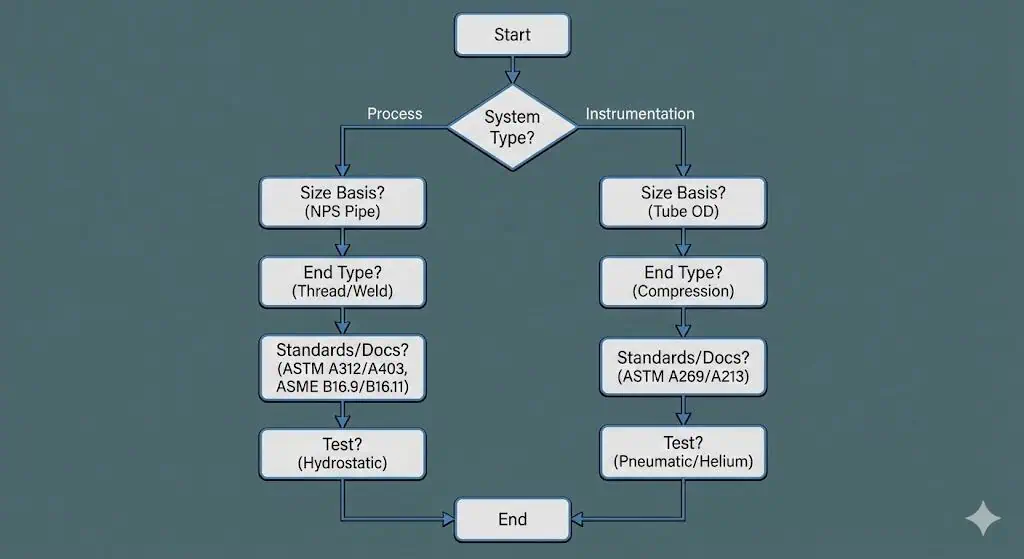

The main difference between stainless steel pipe fittings and stainless steel tube fittings is the sizing system they are built around—and that directly changes where they belong in real piping work. In the field, the most common failure mode is not “bad stainless,” it’s a mismatch: ordering a tube fitting by OD when the line is actually NPS pipe (or the other way around). That mistake shows up as leaks, forced rework, or unsafe joints under pressure.

- Correct fitting choice affects pressure capability, leak risk, inspection acceptance, and maintenance time (especially in ASME-coded systems).

- Pipe fittings are typically selected for process piping and utility lines where NPS/Schedule and code-based pressure-temperature design governs.

- Tube fittings are typically selected for instrumentation, laboratory, medical, pneumatic/hydraulic controls, and sanitary systems where OD tolerance and repeatable sealing matter.

- If you want a practical shortcut: decide the system first (process piping vs instrumentation/sanitary tubing), then lock sizing and connection method before purchasing.

Stainless steel accessories: distinguish between “nominal-size pipe systems” and “true-OD tube systems”

| Feature | Stainless Steel Pipe Fittings | Stainless Steel Tube Fittings |

| Analogy | 🏭 Process Pipe Run (plant / utility main line) | 🧪 Instrument / Sanitary Tube Run (precision OD tubing) |

| Primary Function | Transport & containment: water, steam, oil, gas, chemicals under code-driven design | Control & cleanliness: accurate flow control, sampling, hygienic transfer, compact routing |

| Dimension Focus | Focus on NPS + Schedule (standardized OD + wall by schedule; “nominal” naming) | Focus on True OD + Wall Thickness (measured OD with tighter tolerance) |

| Key Metric | Nominal Pipe Size (NPS) and Schedule (e.g., 1″ Sch40) | Exact Outside Diameter (OD) and Wall Thickness (e.g., 6 mm × 1 mm, or 1/4″ × 0.035″) |

| Connection Method | Threaded / Socket-weld / Butt-weld / Flanged (often permanent joints; inspection sensitive) | Compression / Flare / Face-seal / Hygienic clamp (serviceable joints; repeatable assembly) |

| Tolerance / Precision | General precision for transfer lines; schedule governs wall; OD standardized by pipe tables (ASME B36.10/19) | Higher OD control (instrument/sanitary standards like ASTM A269); sealing depends on tube roundness & finish |

| Common Applications | Process piping, building services, firewater, steam, chemical transfer, equipment connections | Instrumentation impulse lines, analyzer panels, lab/medical, food/pharma, pneumatics/hydraulics |

Key Differences Overview

Purpose and Application

The difference between pipe fittings and tube fittings is not just “shape,” but the design basis: code-governed piping vs OD-controlled tubing systems.

If your system is a process line (steam, water, oil, gas, chemicals), you typically design around NPS/Schedule and the applicable piping code. In practice, that means the fitting family you see most often aligns with common ASME dimensional standards (for example, factory-made buttwelding fittings are commonly referenced under ASME B16.9; forged threaded/socket-weld fittings under ASME B16.11). This matters because inspectors and maintenance teams will verify dimensional compatibility, weld prep, and marking—not marketing claims.

If your system is instrumentation or sanitary tubing, the system “language” changes: you select tubing by true OD and wall thickness, and you select fittings that can seal reliably on that OD with repeatable assembly torque and surface condition. That’s why tube fittings dominate in analyzer houses, sampling systems, laboratories, medical equipment, and hygienic process skids.

Field example #1 (mismatch that causes rework): A maintenance team orders “1/2 inch” compression tube fittings for what they believe is a “1/2 inch line.” On arrival, they discover the line is actually 1/2″ NPS pipe (OD about 0.84″), not 1/2″ OD tube. The compression nut physically won’t fit. The fix is not forcing it—it’s converting with a proper pipe-to-tube adapter or re-specifying the correct NPS-threaded fitting set for that line.

You will find these fittings across industries. Common use patterns look like this:

- Oil & gas and chemical plants rely heavily on pipe fittings for higher pressure and code inspection regimes.

- Pharmaceutical/food plants often use sanitary tubing assemblies where cleanability and surface finish are critical.

- Water treatment and coastal utilities demand higher corrosion resistance (chlorides), often pushing material selection beyond basic 304.

When you choose, treat it as an engineering decision: define pressure/temperature, media (chlorides, acids, solvents), cleanliness requirement, and whether the joint must be serviceable or permanent.

Shape and Design

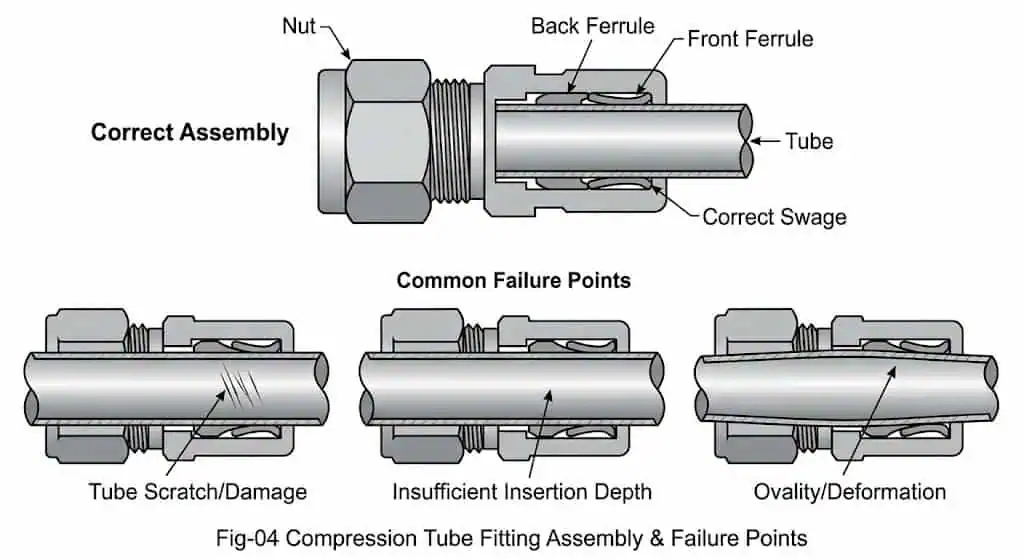

Pipe fittings and tube fittings differ in wall section, end preparation, and sealing mechanism—and that changes failure modes.

Pipe fittings usually present as thicker-section components with end types that tolerate welding and higher mechanical loading. Common connections include threaded (often NPT), socket weld, butt weld, and flanged joints. The sealing is handled by thread interference + sealant, or by weld integrity, or by gasketed flange compression.

Tube fittings are built around controlled tube OD. The joint quality depends heavily on tube cut squareness, roundness, surface condition, and correct assembly. In the field, leaks on tube fittings are most often traced to tube ovality, scratches, poor deburring, or incorrect make-up turns—not “bad stainless.” (See our Standard Operating Procedure for Tube Fittings for detailed installation steps).

Field example #2 (typical tube fitting leak root cause): A technician cuts tubing with a worn wheel cutter, leaving a raised burr and a slightly out-of-round end. The fitting assembles, but a small seep appears during pneumatic test. Re-cutting square, deburring, and ensuring correct insertion depth typically resolves it without replacing the entire fitting.

Quick comparison:

| Feature | Pipe Fittings | Tube Fittings |

|---|---|---|

| Wall Thickness | Typically thicker section | Often thinner section, OD controlled |

| End Preparation | Threads / weld bevels / socket ends / flange faces | Compression/flare/face seal geometries |

| Sealing Principle | Thread interference, weld integrity, or gasket compression | Ferrule bite/seal, flare seat, face seal, or clamp gasket |

| Best Fit | High-pressure process/utility piping | Instrumentation, sanitary, precision routing |

Match the fitting design to how the system will be installed, inspected, and maintained. A “strong” fitting chosen on the wrong sizing basis is still the wrong fitting.

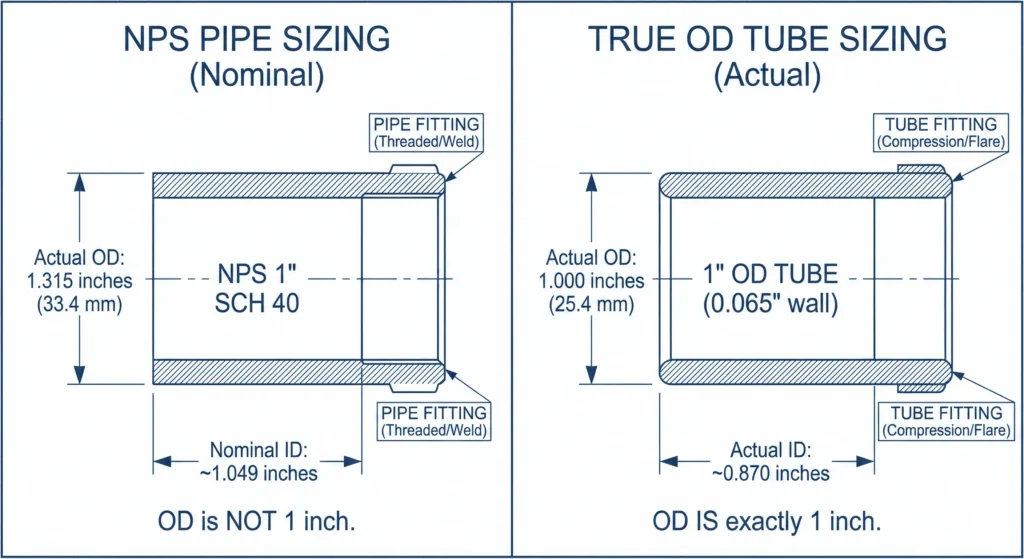

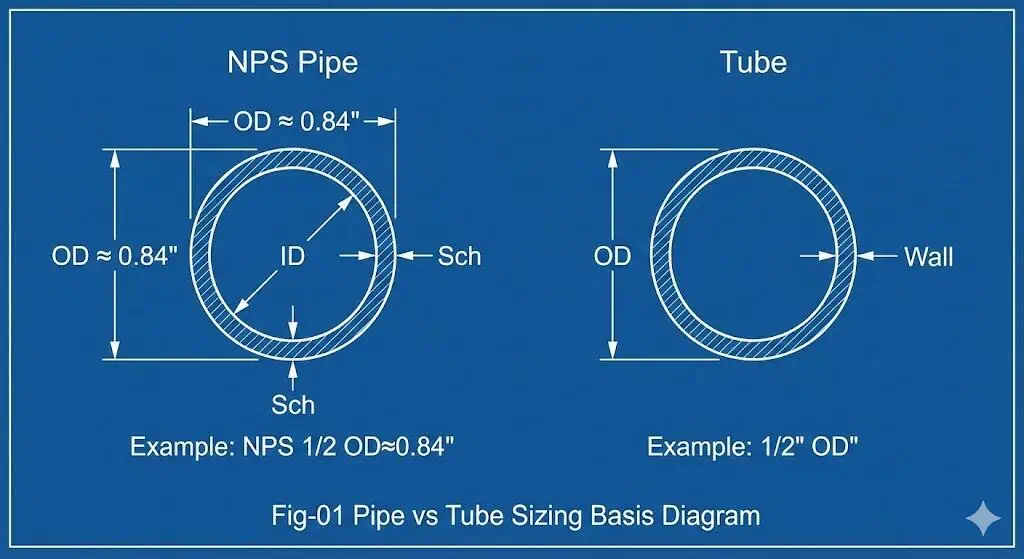

Pipe vs Tube Sizing: Why NPS is not OD

Pipe Sizing (Stainless Pipe)

Stainless pipe fittings are sized by NPS and Schedule—so the name does not equal the measured OD or ID. This is the point that causes the most purchasing mistakes.

For stainless and process piping, the pipe OD is standardized by NPS tables (commonly referenced by ASME pipe dimensional standards). For example, NPS 4 has an OD of 4.5 inches (114.3 mm), not 4.0 inches. Wall thickness then changes by schedule (Sch 10/40/80/etc), which impacts pressure capability and welding procedure selection.

Practical check (shop-floor method): If the line is called “4-inch pipe,” use calipers on the OD. If it reads about 4.5″, you are in NPS pipe territory and must order by NPS/Schedule—not by “4-inch OD tube.”

- Confirm whether the system is NPS pipe or true-OD tube before ordering anything.

- Confirm end type: NPT vs BSP, socket weld vs butt weld, flange type if applicable.

- Confirm schedule or wall requirement based on pressure/temperature design.

- Verify applicable standards for the fitting family (example references commonly used in industry: ASME B16.9 / ASME B16.11).

Helpful internal references (if you are comparing connection styles in practice): see the Sunhy guide on BSP vs NPT threads and the overview of stainless threaded couplings.

Tube Sizing (Stainless Steel Tube Fittings)

Tube fittings are sized by true OD and wall thickness, because sealing depends on the tube OD being correct and consistent.

For tubing, OD is the “primary dimension” and wall thickness is specified directly (inch/mm) or sometimes expressed using gauge systems such as BWG in certain markets. The engineering takeaway is simple: if the fitting says 1/4″ OD, the tube must actually be 1/4″ OD, not “roughly close.”

| Measurement Type | Description |

|---|---|

| Outside Diameter (OD) | The true outside diameter used to select the fitting (critical for sealing). |

| Inside Diameter (ID) | Calculated from OD minus 2×wall; affects flow but not fitting selection in most tube systems. |

| Wall Thickness (WT) | Drives pressure capability, stiffness, and vibration resistance. |

| Common Tubing Specs | General service tubing often references ASTM A269; sanitary tubing often references ASTM A270. |

Field example #3 (why OD control matters): In an analyzer cabinet, a slightly undersized tube OD (out of tolerance) can assemble “tight” but still fail a helium leak test. That’s why tubing spec + mill certification + OD tolerance matters more in instrumentation than in utility pipe runs.

Why Sizing Matters

Accurate sizing prevents leaks, forced rework, and unsafe joints under pressure. Mixing pipe and tube sizing is a frequent cause of commissioning delays.

- Pipe fittings use NPS + schedule; the “named size” is nominal.

- Tube fittings use true OD + wall; the named size is literal.

- A 4″ pipe is not 4″ OD, but a 4″ OD tube is actually 4″ OD.

- For threaded systems, specifying thread standard (NPT/BSP) is non-negotiable for leak control.

Tip: Before ordering, write the size in a “two-part format.” Example: “NPS 1/2 Sch40, NPT” (pipe) or “1/2″ OD × 0.065″ wall” (tube). If you cannot write it that way, the spec is not complete.

Shapes and Sizes

Pipe Fitting Shapes

Stainless steel pipe fittings come in a wide range of shapes. In practice, each shape exists to solve a routing or equipment-connection problem while staying within code and maintenance constraints.

- Elbow fittings: change direction (90°, 45°, 180°). For process piping, elbow radius and wall schedule matter for pressure drop and erosion control.

- Tee fittings: branch connections; branch reinforcement may become a design consideration in higher stress lines.

- Reducer fittings: transition between sizes; specify concentric vs eccentric based on drainage/venting needs.

- Coupling fittings: straight connection; threaded couplings require thread standard control (NPT/BSP) and sealing practice.

- Union fittings: serviceability where disassembly is required without cutting.

- Flange fittings: equipment connections where gasketed joints are required; face type (RF/FF/RTJ) and bolt grade control leakage risk.

- Caps and plugs: blind termination; be explicit whether the end is threaded, socket, or weld-cap.

If you are buying by catalog name alone, you will miss critical details. A reducer is not “a reducer” until you specify ends + schedule + standard + material grade. See Sunhy’s internal examples like stainless reducers and how fitting style changes with thread choice (BSP vs NPT).

Tube Fitting Shapes

Tube fittings also come in familiar shapes, but the engineering focus is sealing reliability on OD-controlled tubing and repeatable assembly.

- Elbows and tees: compact routing in panels and skids; vibration support and tube clamp spacing become important.

- Couplings and unions: allow disassembly for maintenance; confirm whether ferrules are reusable per the fitting design.

- Adapters: common when connecting tubing to NPT ports on instruments or valves; specify the port thread standard explicitly.

- Caps and plugs: used during flushing/commissioning; ensure compatibility with cleaning media and pressure test requirements.

Field example #4 (adapter selection error): A tube-to-male-thread adapter is selected as “1/4″” without confirming the instrument port is NPT vs BSP. Assembly “feels tight” but leaks at test pressure. The correct fix is a thread-standard match—not extra tape. Use thread gauges or confirm with the instrument datasheet.

Size Variations

Size control affects compatibility, pressure capability, and inspection acceptance. Pay attention to:

| Dimension Type | Importance in System Design |

|---|---|

| Outside Diameter (OD) | Critical for tube sealing; standardized for pipe by NPS tables. |

| Inside Diameter (ID) | Affects velocity, pressure drop, and cleaning/flush effectiveness. |

| Wall Thickness | Directly impacts pressure capability and weld procedure selection. |

Accurate measurement requires proper tools: calipers for OD, wall gauges for thickness, and thread gauges for port verification. “Ruler estimates” are a repeat offender in wrong orders.

NPS (Nominal Pipe Size) exists to standardize piping OD series while schedule varies wall thickness. Tube systems typically standardize OD and vary wall thickness directly.

Manufacturing Processes

Pipe Fitting Production

Stainless steel pipe fittings are typically produced by forging/forming plus machining, followed by heat treatment and surface conditioning. Real performance is driven by grain flow (for forged parts), wall thickness consistency, and quality control (NDE, dimensional checks, marking/traceability).

| Step | Description |

|---|---|

| 1 | Raw Material: select billet/forging stock or pipe sections per spec and heat lot. |

| 2 | Heating: bring material to forging/forming temperature under controlled conditions. |

| 3 | Forming/Forging: hot forging, upsetting, or forming to create elbows/tees/reducers/caps. |

| 4 | Trimming & Pre-machining: remove flash; establish reference surfaces. |

| 5 | Heat Treatment: solution anneal as required to restore corrosion resistance after forming. |

| 6 | Pickling/Passivation: remove scale and improve surface condition for corrosion resistance. |

| 7 | Machining: CNC machining of ends, bevels, threads, and sealing surfaces. |

| 8 | End Prep: bevel angle, land, root face per welding method; thread gaging if threaded. |

| 9 | NDE/Inspection: dimensional checks; visual; and NDE where specified (PT/UT/RT as applicable). |

| 10 | Marking: grade, heat number, size, schedule, standard (traceability for QA). |

| 11 | Cleaning/Packaging: protect end surfaces and threads; cap ends to prevent contamination. |

| 12 | Final Release: QC review, MTC/COC documentation, shipment release. |

For projects with inspection requirements, you should request documentation like heat number traceability and material test reports, especially for safety-critical services.

Tube Fitting Production

Tube fittings are generally more machining- and tolerance-driven than pipe fittings, because sealing relies on controlled geometry at the ferrule/seat interface. That typically means tighter dimensional inspection and surface condition control.

- Tube fittings often require stricter tolerance checks on bores, cone angles, ferrule geometry, and thread finish.

- Surface finish control is more important when fittings are used in sanitary/high-purity service.

- Production cost is usually higher due to machining time and inspection intensity.

| Aspect | Tube Fittings | Pipe Fittings |

|---|---|---|

| Tolerance Focus | High (sealing geometry and repeatability) | Moderate (fit-up and end prep, schedule, weldability) |

| Surface Finish Sensitivity | Higher (especially hygienic/high purity) | Depends on service; often less critical than weld/end requirements |

| Serviceability | Often designed for disassembly and maintenance | Often permanent joints (welded) or gasketed maintenance (flanges) |

| Measurement Basis | True OD and wall | NPS and schedule |

These differences are why tube systems can pass very strict leak tests when built correctly, but can also become leak-prone when tubing prep is poor.

Seamless vs. Welded

You choose between seamless and welded components based on pressure, fatigue/vibration, corrosion risk at seams, and inspection requirements.

In general terms, “seamless” removes one potential discontinuity, which can be beneficial in higher cyclic services or where corrosion at seam regions is a concern. “Welded” often offers broader availability and cost advantages, but you should evaluate weld quality, NDE requirements, and service medium.

| Feature | Seamless (general guidance) | Welded (general guidance) |

|---|---|---|

| Corrosion Concern | Lower seam-related concern | Must control weld quality and surface condition |

| Cost | Often higher | Often lower |

| Availability | Can be more limited in some sizes | Often wider range |

| Best Fit | Higher criticality or fatigue/vibration-sensitive service | General service where spec allows |

Tip: For critical systems, define acceptance requirements first (NDE, documentation, PMI, hydrotest/leak test). “Seamless” alone is not a guarantee if the installation practice is poor.

Material Uses & Suitability

Pipe Fitting Materials

Select pipe fitting materials based on corrosion risk, temperature, and fabrication method—not just grade popularity. For many general environments, 304/304L works. For chloride-bearing environments or more aggressive media, 316/316L is commonly selected, and duplex grades may be considered when chloride stress corrosion cracking or pitting risk becomes a design driver.

| Grade | Properties (practical) | Common Fit |

|---|---|---|

| 304 | General corrosion resistance, good formability | Utilities, general process in mild media |

| 304L | Lower carbon helps reduce weld sensitization risk | Welded assemblies where corrosion performance after welding matters |

| 316 / 316L | Better resistance in chloride-bearing service vs 304 series (condition-dependent) | Coastal plants, brackish water, chemical environments |

When you specify fittings for process piping, it is also common to reference product specifications by family: for example, stainless buttwelding fittings under ASTM A403, stainless pipe under ASTM A312, depending on scope and project requirements.

Where flanged connections are part of the piping system, you can cross-check flange selection basics using Sunhy’s internal guide on ANSI flange types (useful for understanding face types and typical service expectations).

Tube Fitting Materials

Tube fitting materials must match both corrosion environment and sealing expectations. In high-corrosion environments, higher alloy stainless and nickel alloys may be considered, but the correct choice depends on the exact media, temperature, and cleaning chemicals.

| Stainless Steel Grade / Alloy | Typical Rationale |

|---|---|

| Duplex 2507 | Often considered where high chloride resistance is required (service-dependent) |

| Alloy 825 | Considered in certain corrosive media where SCC/pitting concerns exist (spec-driven) |

| Alloy 625 | Considered for severe corrosion conditions; selection must be media-verified |

For sanitary or high purity applications, material selection goes together with surface finish, cleaning, and documentation. Many hygienic systems focus on surface finish targets and cleanability requirements rather than “grade only.”

Environmental Suitability

Stainless steel performs well in long-life infrastructure when properly specified and installed. It is recyclable and can reduce replacement frequency—however, corrosion failures still happen if chloride exposure, crevice conditions, or wrong installation practice is ignored.

- Durability helps reduce lifecycle maintenance when the correct grade and finish are selected.

- Recyclability supports sustainability goals.

- Installation practice (crevice control, proper passivation, correct gasket selection) often decides real service life.

Note: In chloride-bearing environments, crevices (under ferrules, gaskets, deposits) can become the real corrosion trigger. Good design + good assembly practice is usually more important than “upgrading grade” blindly.

Stainless Tubing & Pipe Applications

Industrial Uses

Stainless pipe fittings dominate industrial systems where pressure, code compliance, and robust connections drive the design.

- Chemical processing: corrosion resistance + temperature capability matter.

- Oil and gas: pressure containment and inspection practices matter.

- Water treatment: chloride exposure often drives grade selection and crevice control.

- Power generation: steam and condensate systems require robust joints and predictable maintenance.

In these systems, fitting selection is typically integrated with welding procedures, NDE requirements, and documentation (MTC/traceability).

Precision & Laboratory Uses

Tube fittings are commonly used where cleanliness, compact routing, and repeatable leak-tight joints are required.

- Analyzer houses, sampling panels, and lab automation systems.

- Medical/lab: needles, capillaries, dispensing and sampling lines (spec-driven).

- High-purity or hygienic skids where cleanability and surface finish are part of acceptance criteria.

In these settings, tubing prep and assembly discipline (cut, deburr, insert depth, make-up turns, and reassembly rules) often decides pass/fail more than the material grade label.

Choosing the Right Fitting

Selecting the correct fitting means verifying service conditions, interface standards, and test requirements before purchasing. The table below summarizes the most important engineering checks:

| Criteria | Description |

|---|---|

| Leak-tightness | Define test method: hydrotest, pneumatic, soap test, or helium leak test for critical service. |

| Temperature rating | Confirm pressure-temperature design basis and gasket/seat compatibility. |

| Pressure ratings | Use code/design basis—do not rely on “catalog feel.” |

| Material compatibility | Confirm media, chlorides, cleaning chemicals, and galvanic considerations. |

| Compliance with standards | Confirm dimensional/spec requirements (thread standard, fitting family standard, material spec). |

Tip: If your system interfaces between pipe equipment ports (NPT/BSP) and tubing runs, plan adapters deliberately. Most field leaks come from “assumed thread type” rather than defective parts.

Stainless Steel Tube Fittings Selection Tips

Key Factors to Consider

Tube fittings succeed when the system is specified as a complete set: tubing spec + fitting spec + assembly method. Use this engineering checklist:

- Assess operating conditions:

Define maximum pressure, temperature, vibration, duty cycle, and media. If the system is subject to vibration, add tube clamps and consider thicker wall tubing. - Choose fitting type based on service:

Compression for general instrumentation; welded/face-seal for higher purity or when reassembly behavior must be controlled; hygienic clamp for sanitary transfer where cleanability is required. - Lock the tubing specification:

OD, wall, material grade, and tubing standard. Make sure the tube is compatible with the fitting design (hardness/finish/roundness considerations). - Define installation and test method:

Set assembly rules (make-up turns, whether ferrules are reusable) and define leak test acceptance criteria.

Tip: A “good” tube fitting on poor tube prep is still a leak risk. Standardize how tubing is cut, deburred, and cleaned—then your pass rate improves immediately.

Common Mistakes to Avoid

Most tube fitting issues trace back to prep and interface control. These are common mistakes and field-proven fixes:

| Common Mistakes | Solutions |

|---|---|

| Not cleaning tube ends / leaving cutting oil or debris | Clean and dry tubing; avoid embedding particles into sealing surfaces. |

| Poor tube cut (angled) / burrs not removed | Cut square, deburr ID/OD, ensure full insertion depth before tightening. |

| Using the wrong thread standard on adapters (NPT vs BSP) | Verify with gauges or datasheets; do not “force-fit” threads. |

| Over-tightening / under-tightening compression nuts | Follow the manufacturer’s make-up guidance (turns past finger-tight), then verify with leak testing. |

| Distortion during welding near fittings | Control heat input, use proper fixturing, and consider 304L/316L where welding sensitization is a concern. |

You should treat tube fitting work like precision assembly. Good tools and consistent method usually matter more than “brand swapping.”

Note: If you see repeat leaks on the same line, stop replacing parts blindly. Inspect tube ovality, scratches, insertion depth witness marks, and thread compatibility first—then decide whether parts truly need replacement.

How to Buy the Right Stainless Steel Fitting?

Step 1: Confirm the System’s Primary Function

Start by defining whether you are building process piping or an OD-controlled tubing system.

You must know if the system is pressure/code-driven, sanitary/cleanability-driven, or maintenance-driven (frequent disassembly). This single decision typically determines pipe fittings vs tube fittings.

Step 2: Demand Clear and Unambiguous Dimensions

Write the size specification in a form that cannot be misunderstood.

Use drawings where possible and include end types. Examples:

- Pipe example: “NPS 1/2, Sch 40, NPT female” (or socket-weld / butt-weld as required)

- Tube example: “1/2″ OD × 0.065″ wall, compression union”

For threaded interfaces, reference the thread standard (for example, NPT commonly references ASME B1.20.1 in industry documentation). When buyers skip this line item, installers end up “making it fit,” and that’s where leaks begin.

Step 3: Verify the Connection Method and Pressure Rating

Verify connection type and rating against your design basis—not a generic catalog statement.

Use this process:

- Read the manufacturer datasheet for pressure-temperature limits and assembly rules.

- Confirm material spec and fitting family spec (material and dimensional standards).

- Define how you will test and accept the joint (hydro, pneumatic, helium as required).

Tip: Proper verification prevents leaks and avoids rework at commissioning, when schedule pressure is highest.

Step 4: Confirm Material Grade and Certification

Request the material grade and documentation appropriate to your project risk.

This table shows why these checks matter:

| Aspect | Explanation |

|---|---|

| Quality Assurance | Material documentation confirms composition/mechanical properties match the specified standard. |

| Regulatory Compliance | Many industries require certifiable material and traceability for safety and audits. |

| Traceability | Traceability supports failure investigation and prevents mixed-material installation in critical service. |

Step 5: Contact Sunhy experts for purchase and consultation

If your project includes mixed interfaces (pipe ports + tubing runs) or corrosion-critical media, it is worth having the specification reviewed before bulk purchasing.

Provide your line list (pressure/temperature/media), connection map (NPT/BSP, weld types), and any required documentation (MTC/PMI/NDE). This is usually faster and cheaper than troubleshooting leaks after installation.

Choosing the right stainless steel fitting helps your system run safely, efficiently, and with fewer service calls.

| Benefit | How Stainless Steel Fittings Help |

|---|---|

| Corrosion Resistance | Reduces leakage and replacement frequency when grade/finish matches the environment |

| Temperature Stability | Supports a wider range of operating conditions when specified correctly |

- Stainless steel fittings can reduce maintenance when the correct grade and joint type are selected.

- Durability can offset higher upfront cost, especially in corrosive service.

- Documentation and traceability reduce project risk in safety-critical systems.

- For complex or custom needs, get the interface and standards checked before ordering.

FAQ

Can I thread a pipe fitting directly into a tube fitting?

Only if you use a specific “Pipe-to-Tube Adapter.” You cannot mix the connections directly. Pipe fittings typically use tapered threads (NPT/BSP) to seal, while tube fittings use ferrules to grip the tube OD. To connect them, you must use an adapter that has a thread on one side (to match the pipe) and a compression tube stub or port on the other side. Never force a threaded pipe into a compression nut.

Can I use tube fittings in high-pressure industrial systems?

Sometimes—but only if the fitting type, tubing wall, vibration control, and test method are specified for that pressure regime. Many industrial plants use tube fittings successfully in instrumentation and impulse lines, while main process lines remain pipe fittings due to code practice and robustness. If the service is high vibration, high temperature, or safety-critical, welded or flanged pipe connections are often preferred.

Rule of thumb: Use tube fittings where OD-controlled tubing and serviceable joints are needed (instrumentation/sampling). Use pipe fittings where code piping and robust permanent joints dominate.

What certifications or standards should I look for when buying stainless steel fittings?

Look for standards in three layers: material spec, dimensional/fitting family spec, and connection spec. Examples commonly referenced in industry include material specifications like ASTM A312 (pipe), ASTM A269/ASTM A270 (tubing), ASTM A403 (buttwelding fittings), and connection standards like NPT thread references under ASME B1.20.1—when applicable to your system.

- They help ensure dimensional compatibility and predictable performance.

- They support inspection acceptance and documentation requirements.

- They reduce the risk of mixed, incompatible parts on-site.

How can I tell if my “1/2 inch line” is pipe or tube before ordering fittings?

Measure the OD with calipers and confirm thread/end type. If the OD is about 0.84″, it is typically 1/2″ NPS pipe OD. If the OD is exactly 0.50″, it is 1/2″ OD tubing. Then confirm whether the connection is threaded (NPT/BSP) or welded/compression.

Why do tube fittings leak after reassembly?

Most reassembly leaks come from altered tube surface condition or incorrect make-up procedure. Scratches, tube ovality, insufficient insertion depth, or mixing ferrules can cause small leaks. Standardize your cut/deburr process and follow the fitting’s specified make-up turns.