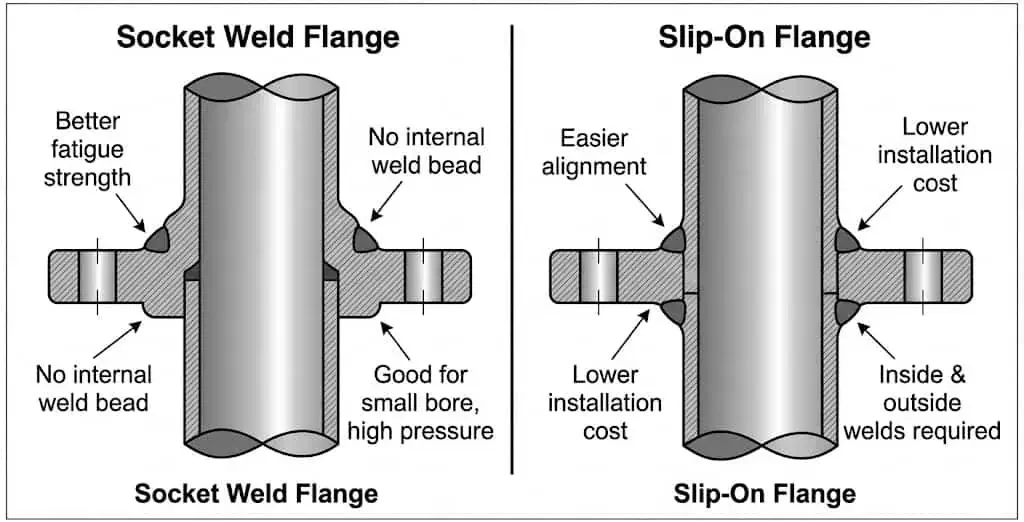

The main difference between socket weld flanges and slip on flanges lies in how the pipe is seated and welded—this directly affects fatigue behavior, leak risk at the weld/root, and how sensitive the joint is to fit-up errors.

You select the flange type based on pressure class, pipe size (especially small-bore vs. larger diameters), vibration/cyclic loading, corrosion risk, and how much rework your site can tolerate during construction and maintenance. If your project is built to ASME standards, both types are commonly specified under ASME B16.5 flange dimensions and drilling patterns, then further restricted by the piping class and fabrication rules. For the standard scope summary (sizes, ratings, flange types), see ASME B16.5 overview.

From a procurement standpoint, it helps to treat this as an engineering decision, not a “cheapest flange” decision. Sunhy supplies both socket weld flanges and slip on flanges in stainless grades with controlled machining, traceability, and consistent fit-up—so the selection can match actual service conditions instead of availability.

Here is a quick, engineering-oriented comparison (typical behavior; final allowance depends on code + piping class + vibration/load review):

| Flange Type | Usage Characteristics | Applications |

|---|---|---|

| Slip-on flanges | Fast fit-up; double fillet weld; cost-effective when external loads are stable | Water/utility services, HVAC, general plant piping where vibration and cyclic bending are controlled |

| Socket weld flanges | Socketed pipe seat; typically used on small-bore; higher sensitivity to workmanship at the socket region | Small diameter, higher-pressure services; instrument/hydraulic tie-ins; compact joints where alignment is tight |

You can make the best choice by understanding how socket weld flange vs slip on flange fits your specific service envelope: pressure/temperature, vibration, media corrosiveness, and whether the line is expected to be opened or modified later.

Socket weld flange overview

Socket welded flange design

Socket welded flanges are designed so the pipe OD nests into a counterbore (“socket”), then the joint is made with an external fillet weld.

The socket geometry helps locate the pipe during fit-up, which is one reason these flanges are common in small-bore work. In stainless systems, the critical engineering detail is not the socket itself—it is the combination of (a) fit-up discipline, (b) weld profile/quality, and (c) how the joint behaves under vibration and thermal cycling. For dimensional compatibility, verify your project spec against ASME B16.5 and confirm the stainless material standard and heat treatment requirements (typical forged stainless flange material specs are defined by project requirements and purchase documents).

Procurement note (common mismatch in the field): ensure the PO clearly states NPS, class, facing (RF/FF/RTJ where applicable), bore, and the “socket weld” end type. Socket depth and bore finish matter for repeatable fit-up. If you are ordering for a skid or repeat build, it is worth standardizing the datasheet format—see how to order socket weld flanges for a practical ordering checklist.

| Feature | Description |

|---|---|

| Type | Socket Weld Flange |

| Design Similarity | Similar outside profile to a slip on flange, but with a socket/counterbore |

| Bored and Counter Bore | Pipe seats into the socket for location; fillet weld is applied externally |

| Bore Diameter | Selected to match the intended pipe schedule/OD seating; verify against the piping class |

| Application | Best known for small diameter, higher-pressure services where compact joints are needed |

How socket weld flanges work

Socket welded flanges create a pressure boundary by seating the pipe in the socket and applying a controlled fillet weld at the hub.

You insert the pipe into the flange’s counter bore, then weld around the outside. In practice, many specifications require a small “stand-off” (gap) between the pipe end and the bottom of the socket to reduce weld shrinkage stress and improve consistency; the exact gap is spec-driven and should follow the qualified WPS and project standard.

Engineer’s installation checklist (socket weld):

- Confirm engagement: pipe fully seats, then pull back to the required stand-off per spec/WPS (do not “bottom out” and weld blind).

- Control alignment: tack in at least 3–4 points, re-check squareness and flange face parallelism to the mating flange.

- Protect the bore: prevent excessive weld penetration or spatter that can disturb flow or create crevice traps.

- Verify facing condition: gasket surface finish and facing type must match the gasket selection and bolt load method.

| Pressure Class | Flange OD | Hub Bore ID | Flange Thickness |

|---|---|---|---|

| 150 | 3.5″ – 20.5″ | 0.5″ – 14″ | 0.56″ – 1.75″ |

| 300 | 3.88″ – 23.5″ | 0.5″ – 14″ | 0.62″ – 2.12″ |

| 600 | 4.25″ – 25.5″ | 0.5″ – 14″ | 0.75″ – 2.5″ |

| 900 | 5″ – 27.5″ | 0.5″ – 14″ | 0.88″ – 3″ |

| 1500 | 5.75″ – 30″ | 0.5″ – 14″ | 1.12″ – 3.62″ |

| 2500 | 6.75″ – 32.5″ | 0.5″ – 14″ | 1.38″ – 4.25″ |

Engineering note: the dimensional ranges above are illustrative across multiple NPS sizes/classes. For exact flange OD, bore, and thickness, use the governing standard tables and the project piping class.

Common uses and limitations

Socket welded flanges are commonly used where small-bore piping needs a compact joint and higher pressure capability—provided workmanship and vibration control are strong.

Typical placements include instrument/hydraulic tie-ins, compact skid piping, and small lines where weld access is limited. They are not a “free upgrade” everywhere: socket geometry can create crevice conditions in corrosive services, and small-bore lines near vibrating equipment often fail from fatigue if supports/guides are not designed correctly.

- Common use case: small-bore, higher-pressure lines where joint compactness and repeatable fit-up matter.

- Where engineers get cautious: strong vibration, thermal cycling, and corrosive wet services where crevice attack is likely.

- What decides success: WPS compliance, weld profile quality, support spacing, and correct gasket/bolting control.

However, you should consider a few limitations when selecting a socket welded flange vs slip on flange. Fatigue cracking may occur under fluctuating pressure/temperature combined with vibration. Material defects, misalignment, and poor facing/gasket pairing can also trigger leakage. Always confirm chemical compatibility between gasket and medium, and confirm the joint is not carrying unintended bending moments.

| Limitation Type | Description |

|---|---|

| Fatigue Cracking | Small-bore vibration + cyclic pressure/temperature can crack at the weld toe if supports are poor. |

| Material Defects | Porosity, lack of fusion, or poor heat input control can reduce fatigue life. |

| Misalignment | Flange face non-parallelism and pipe “spring” can unload the gasket and raise bolt stress. |

| Gasket/Face Mismatch | Wrong facing (RF/FF) or gasket type can lead to blowout/leakage under transients. |

| Crevice/Corrosion Risk | Socket region and poor drainage can concentrate chlorides or deposits in wet services. |

Field examples (problem → cause → prevention):

| Example | What happened | Likely cause | Fix / prevention |

|---|---|---|---|

| Hydraulic small-bore line weeping at a socket weld flange after a few months | Intermittent seepage, then a crack indication at the weld toe | Vibration + insufficient line support; weld profile stress concentration | Add/relocate supports, reduce cantilever mass, verify WPS and weld size/profile; confirm flange alignment before final bolt-up |

| Stainless utility chemical wash line showing localized corrosion near socket | External staining, later internal pitting evidence during turnaround | Wet service + deposits/crevice conditions + chloride concentration | Review service chemistry, improve drainage/cleaning, consider alternative joint types or corrosion controls per piping class |

You can rely on Sunhy’s stainless steel flanges for consistent machining and documentation, but joint performance in service is ultimately built by fit-up control, weld quality, and pipe support design.

Slip on flange overview

Slip on flange design

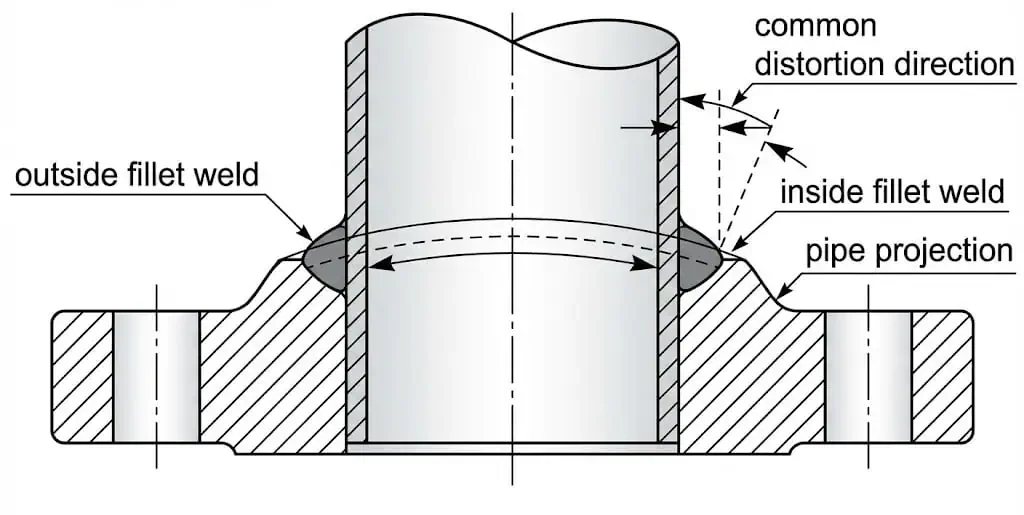

A slip on flange is a ring that slides over the pipe OD and is secured by fillet welds—simple geometry, but the joint is workmanship-sensitive.

You slide the pipe into the flange bore, set the pipe projection per WPS (to avoid creating a large crevice/undercut at the bore transition), then weld. Slip-on flanges are widely used because they are fast to fit and economical, especially in utility services where external loads are stable. If your system is built to ASME standards, confirm the drilling pattern and dimensions against ASME B16.5 scope and your project piping class.

Tip: Slip on flanges look forgiving during fit-up, but most leak problems trace back to weld profile/fit-up, flange face condition, bolt load control, or pipe supports—not the gasket alone.

How slip on flanges work

You install a slip on flange by sliding it onto the pipe and applying two fillet welds (inside + outside) per WPS.

This double fillet weld approach provides strength and helps seal, but it also introduces stress concentration at weld toes and demands consistent workmanship. In stainless service, the inside fillet region can be a crevice/corrosion initiation site if the service is wet and chloride-bearing and the surface condition is poor.

Engineer’s installation checklist (slip-on):

- Set the correct pipe projection: follow WPS so the inside fillet is sound without creating excessive crevice at the bore transition.

- Control distortion: weld sequence and heat input can pull the flange face out of square—check face parallelism before bolting.

- Verify weld size: under-sized fillet welds reduce fatigue margin; over-welding can distort the face and raise leak risk.

- Protect the gasket face: no arc strikes, no grinding marks across the sealing surface.

Common uses and limitations

Slip on flanges are common in moderate pressure/temperature services where speed and cost matter and vibration is controlled.

They are widely used in water/utility systems, HVAC, and general plant piping. The engineering limitation is not the “rating” printed on the flange—it is how the fillet-welded joint behaves in your real load case (vibration, thermal expansion, bending from unsupported valves/spools).

| Advantage | Description |

|---|---|

| Ease of installation | Fast fit-up; less bevel preparation than butt-weld joints |

| Cost efficiency | Lower unit cost; installed cost depends on rework and weld quality control |

| Versatility of materials | Available in multiple stainless grades and materials per the piping specification |

| Broad applicability | Works well where external loads are stable and inspection access is available |

| Flange Class | Maximum Pressure (bar) | Maximum Pressure (psi) | Temperature (°C) |

|---|---|---|---|

| Class 150 | 19.6 | 285 | 100 |

| Class 600 | 99.3 | 1440 | 100 |

Engineering note: “maximum pressure” is material- and temperature-dependent and is defined by the governing pressure-temperature tables. Always use the standard tables and the project piping class for the controlling values.

Note: Slip on flanges can be reliable when fit-up, weld profile, gasket selection, and bolt-up method are controlled. They become problem joints when installed near vibration, on poorly supported spans, or when the flange face is distorted during welding.

Socket weld flange vs Slip on flange: comparison

Installation process

Socket weld flanges demand tighter fit-up discipline at the socket region; slip on flanges generally install faster but require consistent control of two fillet welds.

Neither joint type “wins” if the flange face is pulled out of parallel or if the pipe is forced into alignment during bolt-up. Treat flange alignment and support conditions as part of installation—not as an afterthought.

- Socket weld flange: insert the pipe, set the required stand-off per WPS/spec, tack, verify squareness, then apply the external fillet weld with controlled heat input.

- Slip on flange: slide flange into position, set pipe projection per WPS, tack evenly, then weld inside + outside in a sequence that limits face distortion.

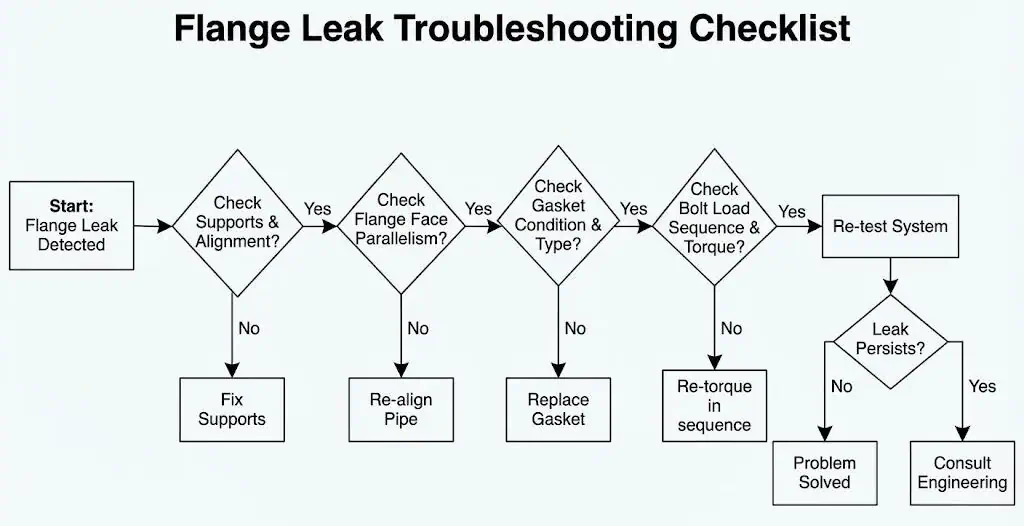

Tip: When a small-bore flange leaks after commissioning, check (1) flange face parallelism, (2) line supports/vibration, and (3) bolt load uniformity before blaming the gasket.

Strength and performance

Socket weld and slip on flanges can both be designed to code, but they respond differently to vibration and bending loads.

Socket weld flanges are commonly used in small-bore higher-pressure work because the pipe seating aids location and the joint is compact. Slip-on flanges are widely used in utility services because fit-up is quick and costs are lower. In fatigue-driven systems, weld profile quality, support spacing, and cyclic load magnitude dominate “strength” more than the flange label.

| Flange Type | Strength | Performance | Applications |

|---|---|---|---|

| Socket Weld Flange | Compact joint; performance is highly sensitive to fit-up and weld quality at the socket region | Good for small-bore if vibration and corrosion risks are managed | Small-bore higher-pressure systems, hydraulic/instrument tie-ins |

| Slip On Flange | Economical; relies on two consistent fillet welds | Good for stable-load services; more caution near vibration/cyclic bending | Utility and general piping where inspection access is available |

- If your line is near rotating equipment, evaluate vibration and cyclic bending first—poor supports will cause leaks regardless of flange type.

- If your service is wet and chloride-bearing, review crevice/corrosion risk at the weld region and verify surface condition/passivation expectations for stainless.

Pressure rating

Pressure capability is governed by the flange rating and pressure-temperature tables, then constrained by service rules in the piping class.

Both socket weld and slip on flanges are supplied in ASME pressure classes; however, many owner specifications restrict slip-ons and socket welds in severe cyclic, high vibration, or highly hazardous services. In the field, many “pressure leaks” are actually load/unloading leaks caused by flange face rotation from bending moments or thermal movement.

- High pressure + small-bore: socket weld is commonly specified when geometry and access favor compact joints.

- Stable-load utilities: slip-on is commonly specified where cost and speed matter and vibration is controlled.

- Severe cyclic/vibration: many piping classes move to higher-integrity designs (for example, weld neck flanges) rather than trying to “make slip-on work” in the wrong location.

If your system operates under high pressure and sees vibration or thermal cycling, treat supports, alignment, and weld acceptance as part of the pressure integrity decision.

Cost factors

Slip on flanges are usually lower unit cost and faster in production work; socket weld flanges can reduce rework risk in tight small-bore installations when fit-up is standardized.

- Slip on flange: fewer geometry constraints, fast fit-up, commonly lower purchase cost for many sizes/classes.

- Socket weld flange: often used where compactness and repeatable small-bore installation matter; installed cost depends on workmanship and inspection expectations.

- Hidden costs: rework from face distortion, leaks during hydrotest, and downtime to correct misalignment often exceed the flange price difference.

For budget-sensitive projects, a slip on flange can be the right choice—if the load case is stable and your welding QC is consistent.

Maintenance needs

Maintenance success is dominated by gasket/face pairing and bolt load control—not by flange type alone.

For bolted joint assembly discipline, many sites reference industry guidance such as ASME PCC-1 bolted flange joint assembly guidance (often adopted in owner specifications).

| Flange Type | Maintenance Requirements | Typical Applications |

|---|---|---|

| Socket Weld Flange | Pay attention to socket region cleanliness/corrosion risk; verify alignment and support conditions to limit cyclic load at the weld | Hydraulic/instrument small-bore lines, compact skid piping |

| Slip On Flange | Verify inside/outside fillet weld integrity; check face distortion before bolting; easier visual access to weld areas | Cooling water lines, utilities, accessible general piping |

- Bolting discipline matters: controlled tightening sequence, correct lubricant practice, and uniform bolt load are common leak reducers.

- Support check is mandatory: if the joint is carrying bending, you will chase gasket leaks even with perfect flanges.

Sunhy’s stainless steel flanges meet strict quality and testing expectations for both types. For best reliability, pair good components with controlled bolt-up and verified supports.

Pros and cons of each flange

Socket welded flange advantages

You gain several practical benefits when you select a socket welded flange in the right service:

- Compact joint for small-bore: useful where space is limited and alignment access is tight.

- Repeatable fit-up location: socket geometry helps locate pipe during installation (still requires stand-off per spec).

- Leak prevention potential: good performance when weld quality, supports, and corrosion risks are controlled.

- Good for standardized skid builds: when WPS and fit-up gauges are consistent, installation variability can drop.

- Long-term value: lower rework and fewer hydrotest leaks can outweigh higher component cost in some projects.

Tip: A socket welded flange is a strong candidate for high-pressure, small diameter piping only when vibration is managed and corrosion risks at the socket region are understood.

Socket welded flange disadvantages

You may encounter challenges with socket welded flanges if the service environment or installation control is weak:

| Feature | Socket Welded Flange | Slip On Flange |

|---|---|---|

| Installation Complexity | Requires tighter control of seating/stand-off and weld profile | Simpler positioning, but still workmanship-sensitive |

| Labor and Time | Small-bore fit-up discipline and inspection expectations can increase time | Often faster in repetitive utility work |

| Size Limitations | Commonly used for small-bore; not a universal solution for large diameters | Used across a wide size range depending on the standard/spec |

| Application Suitability | Best when vibration/corrosion risks are managed | Best in stable-load utility and general services |

- You can spend more effort during installation to control stand-off, alignment, and weld profile.

- Crevice/corrosion risk must be evaluated for wet services and aggressive media.

Slip on flange advantages

You benefit from several advantages when you use a slip on flange in the right service:

- Fast fit-up and economical installation in repetitive utility work.

- Flexible positioning during assembly; widely available across classes and sizes.

- Works well where inspection access is available and external loads are stable.

- Lower initial cost can be meaningful in large-quantity packages.

Note: Slip on flanges are a solid choice for moderate pressure systems where speed and cost matter and cyclic/vibration loads are controlled.

Slip on flange disadvantages

Slip on flanges can become problem joints in demanding load cases:

| Drawback | Explanation |

|---|---|

| Lower rigidity under bending | Fillet-welded joint can be more sensitive to bending/vibration and weld-toe stress concentration. |

| Service restrictions in many piping classes | Owner specs often restrict slip-ons in severe cyclic or high vibration areas even if rated. |

| Leak risk from distortion | Weld sequence/heat input can pull the flange face, reducing gasket compression uniformity. |

| Potential long-term cost | Hydrotest leaks and rework (face correction, gasket replacement) can dominate lifecycle cost if QC is weak. |

You should avoid placing a slip on flange near strong vibration sources or on unsupported spans where bending moments will rotate the flange face and unload the gasket.

Application suitability for flange types

High-pressure and small diameter pipes

Socket weld flanges are a common selection for high-pressure, small diameter piping when compact joints and repeatable fit-up are required.

Weld neck flanges also perform well in high pressure service due to their butt-welded, tapered-hub geometry, and they are widely selected for critical duty where vibration and cyclic loads are high. The table below is a simple selection cue (final decision = piping class + load review + weld/NDE plan):

| Flange Type | Description | High Pressure | Small Diameter |

|---|---|---|---|

| Weld Neck Flange | Tapered hub, butt weld for better stress transition | Yes | Often used, but not limited to small-bore |

| Socket Weld Flange | Socket fit, external fillet weld; compact small-bore joint | Yes (when allowed by spec) | Yes |

Sunhy’s product portfolio includes socket weld flanges and weld neck flanges, so you can match joint design to the service rather than forcing a single flange type across the plant.

Industry recommendations

Select flange types based on operational risk, not only pressure class.

In petrochemical, marine, and pressure vessel adjacent piping, you should include vibration/cyclic behavior, corrosion risk, inspection access, and maintenance philosophy. A practical selection routine looks like this:

- Confirm design pressure/temperature and the governing standard (for ASME flange patterns and ratings, review ASME B16.5 scope and your piping class).

- Evaluate vibration/cyclic loading and external bending at the flange location (supports, guides, and thermal growth control).

- Define inspection expectations (VT/PT/RT as required by spec) and confirm weld access.

- Lock gasket type and facing compatibility early (RF/FF and gasket style must match bolt load method).

Tip: If the line is cyclic or vibration-prone, do not “upgrade” by guessing—confirm the piping class and the joint’s stress/load condition, then select the flange style that the spec actually allows.

Comparison with weld neck flange

Weld neck flanges are often selected for critical duty because the butt weld and hub geometry reduce stress concentration and improve load transfer.

Socket weld flanges are frequently selected for high-pressure small-bore work when compactness matters and the spec allows it. Slip on flanges are frequently selected for stable-load utility services where speed and cost matter. The correct choice is driven by load case + service risk + inspection plan.

- Weld neck flanges: Common for severe service and higher external loads (critical lines, strong cyclic/vibration).

- Socket weld flanges: Common for small-bore higher-pressure service when fit-up and vibration control are strong.

- Slip on flanges: Common for general/utility services where loads are stable and accessibility is good.

If you need a broader flange taxonomy for your internal standards library, see different types of flanges for piping.

How to choose the right flange

Selection criteria

Prioritize pressure-temperature requirements, external loads, corrosion risk, and installation control when choosing between socket weld and slip on flanges.

These criteria prevent most “mystery leaks” seen during hydrotest and early operation:

- Pressure/temperature basis: confirm the controlling pressure-temperature table and the flange standard scope (ASME B16.5 overview) plus the project piping class restrictions.

- External loads and vibration: if the flange is near rotating equipment or on an unsupported span, assume cyclic load risk until proven otherwise by supports and stress review.

- Corrosion and crevice risk: wet chloride services require extra discipline around weld regions and crevice traps; confirm cleaning, drainage, and material strategy.

- Facing and gasket strategy: RF/FF selection, gasket type, and bolt load method must match—this is where many procurement packages fail.

- Repeatability of installation: if your site struggles with consistent weld profile and alignment, select the joint style that minimizes field “hero work.”

Quick decision table (typical engineering tendency; final decision = spec + load case):

| Condition at the joint | More typical choice | Why |

|---|---|---|

| Small-bore, higher-pressure, tight access | Socket weld flange | Compact joint; repeatable fit-up when WPS/stand-off is controlled |

| Utility service, stable supports, large quantity | Slip on flange | Fast fabrication and economical installation |

| Strong vibration/cyclic bending or critical duty | Weld neck flange (often) | Better stress transition and load transfer; commonly favored in strict piping classes |

Tip: If you are unsure, decide the support/vibration strategy first—many flange problems are structural-load problems in disguise.

Mistakes to avoid

Most field failures come from predictable mistakes—avoid these and your leak rate drops fast.

- Using flange “rating” as the only decision input: a rated flange can still be a poor choice in severe cyclic/vibration locations.

- Wrong gasket/facing pairing: mismatched RF/FF or wrong gasket style leads to blowout or weeping during thermal transients.

- Skipping controlled bolt-up: uneven bolt load is a top leak driver; follow a controlled sequence and verify final torque/tension.

- Forcing alignment at bolt-up: if you pull piping into place with bolts, you preload the joint and lose gasket compression uniformity.

Field examples (problem → cause → prevention):

| Example | What happened | Likely cause | Fix / prevention |

|---|---|---|---|

| Slip-on flange leaks during hydrotest on a utility header | Weeping at one quadrant after tightening | Face distortion from weld sequence; uneven bolt load | Check face flatness/parallelism, re-face if required, reassemble with controlled bolt-up sequence and lubrication practice |

| Socket weld flange leak appears after warm-up | Leak starts after thermal cycle | Pipe bottomed in socket or misalignment; thermal movement unloading gasket | Verify stand-off practice per WPS, check supports/guides for thermal movement, confirm flange face condition |

Note: Always verify that your flange, gasket, and bolt-up method match the operational demands and the project specification.

Practical tips

Use this short checklist to keep selection, procurement, and installation aligned.

- Confirm application and environment (media, chlorides, wet/dry cycles, external corrosion exposure).

- Confirm flange type + size + class + facing (RF/FF) + bore requirements in the datasheet.

- Confirm governing standard and compliance documents (MTC/traceability, dimensional inspection, PMI where required).

- Specify bolt-up method and acceptance criteria (sequence, torque/tension approach, re-torque policy as allowed).

- Standardize ordering language—use socket weld ordering guidance where applicable.

🛠️ Pro Tip: If you want fewer leaks, treat flange joints as a system: supports + alignment + facing condition + gasket match + controlled bolt load.

Socket weld flanges and slip on flanges serve different needs in piping systems. You can see the main differences below:

| Feature | Slip-On Flanges | Socket Weld Flanges |

|---|---|---|

| Installation Method | Fast fit-up; two fillet welds | Pipe seats into socket; external fillet weld with stand-off practice per spec |

| Pressure Handling | Used where spec allows; best in stable-load services | Common in small-bore higher-pressure service when allowed by piping class |

| Strength & Resistance | Good for stable-load utilities; more caution near vibration/cyclic bending | Good for compact small-bore joints; sensitive to vibration/corrosion if unmanaged |

You should use slip on flanges for accessible utility and general piping where loads are stable and installation speed matters. Choose socket weld flanges for small-bore higher-pressure lines where compactness and repeatable fit-up are required. For severe cyclic/vibration or critical duty, confirm whether the piping class favors alternatives such as weld neck flanges.

FAQ

What is the main difference between socket weld and slip on flanges?

Socket weld flanges seat the pipe into a socket and use an external fillet weld; slip on flanges slide over the pipe and typically require inside + outside fillet welds.

Socket weld flanges are commonly selected for compact small-bore work where fit-up must be repeatable. Slip on flanges are commonly selected for utility and general services where speed and cost are priorities and vibration is controlled.

Can you use slip on flanges for high-pressure applications?

Slip on flanges can be supplied in ASME pressure classes, but many piping classes restrict where they can be used.

In high-pressure service with vibration, thermal cycling, or critical duty, many owner specifications prefer higher-integrity joints (often weld neck) and stricter inspection. Always follow the piping class, code requirements, and weld/NDE plan for the specific line.

How do you select the right flange size?

Match NPS and class to the piping specification, then confirm bore, facing, and drilling pattern against the governing standard.

In practice: (1) confirm pipe NPS and schedule, (2) confirm pressure class and facing (RF/FF), (3) confirm bolt circle and drilling pattern (often ASME B16.5 in ASME systems), and (4) verify the gasket type and seating width are compatible with the selected facing.

What industries commonly use socket weld and slip on flanges?

Oil and gas, petrochemical, utilities/water systems, power, and HVAC all use these flange types—but in different locations and service envelopes.

Socket weld flanges are common in compact small-bore higher-pressure tie-ins (instrument/hydraulic/skid work). Slip on flanges are common in utility and general piping where loads are stable and installation speed matters.

What are the most common causes of flange leakage after commissioning?

Most leaks come from flange face distortion, misalignment/pipe spring, wrong gasket/facing pairing, or uneven bolt load.

Before replacing the gasket, check face parallelism, verify supports and thermal movement control, and reassemble using a controlled bolt-up sequence. Many sites reference bolted joint guidance such as ASME PCC-1 practices.

When should you avoid a socket weld flange?

Avoid socket weld flanges in services where crevice corrosion is likely or where small-bore vibration cannot be controlled.

If the service is wet and aggressive (for example, chloride-bearing and prone to deposits) or if the line is close to strong vibration sources, evaluate whether a different joint style is more reliable under the piping class rules.