Choosing the right hydraulic adapters ensures your system operates safely, complies with SAE/ISO standards, and remains leak-free under pressure spikes. To get it right, you must match the adapter to your system’s maximum working pressure (including transient shock), fluid compatibility, and vibration environment. A mismatch in thread pitch or seat angle—such as confusing a JIC 37° with an SAE 45°—will inevitably lead to thread stripping or high-pressure blowout.

Use this engineering selection checklist (STAMPED method):

- Size & Thread: Identify the standard (NPTF, BSPP, JIC 37°, ORFS, Metric DIN). Measure OD/ID and pitch.

- Temperature: Verify O-ring material (Buna-N vs. Viton) against operating extremes.

- Application: Is there high vibration? (Prefer ORFS). Is there limited wrench access? (Prefer JIC/NPT).

- Media (Fluid): Ensure wetted parts (Body: 316SS/Carbon Steel; Seal: NBR/FKM) resist the fluid.

- Pressure: Confirm the dynamic pressure rating meets the system’s relief valve setting + shock loads.

- Ends (Connection Style): Determine if a swivel nut is needed for orientation.

Field Note: 80% of hydraulic leaks are not due to “bad parts” but “wrong application.” Using NPT threads in a high-vibration mobile hydraulic application often leads to spiral leakage. Upgrading to O-Ring Face Seal (ORFS) adapters in these conditions significantly reduces maintenance costs.

| Specification Input | Engineering Reason |

|---|---|

| Thread Standard (e.g., 1/2″ NPT vs G 1/2″ BSPP) | Prevents cross-threading and thread galling (common in stainless steel). |

| Sealing Mechanism (Metal-to-Metal vs. Elastomeric) | Elastomeric seals (ORFS, O-ring Boss) handle vibration better than tapered threads (NPT). |

| Working Pressure (Dynamic) | Safety factor (typically 4:1) protects against hydraulic hammer/spikes. |

| Fluid Type (e.g., Phosphate Ester, Glycol) | Dictates seal material (e.g., EPDM is required for phosphate esters; Buna-N will fail). |

| Environment (Salt Spray, Acid) | Determines body material (316L Stainless vs. Zinc-Nickel Plated Steel). |

System Compatibility and Selection Criteria

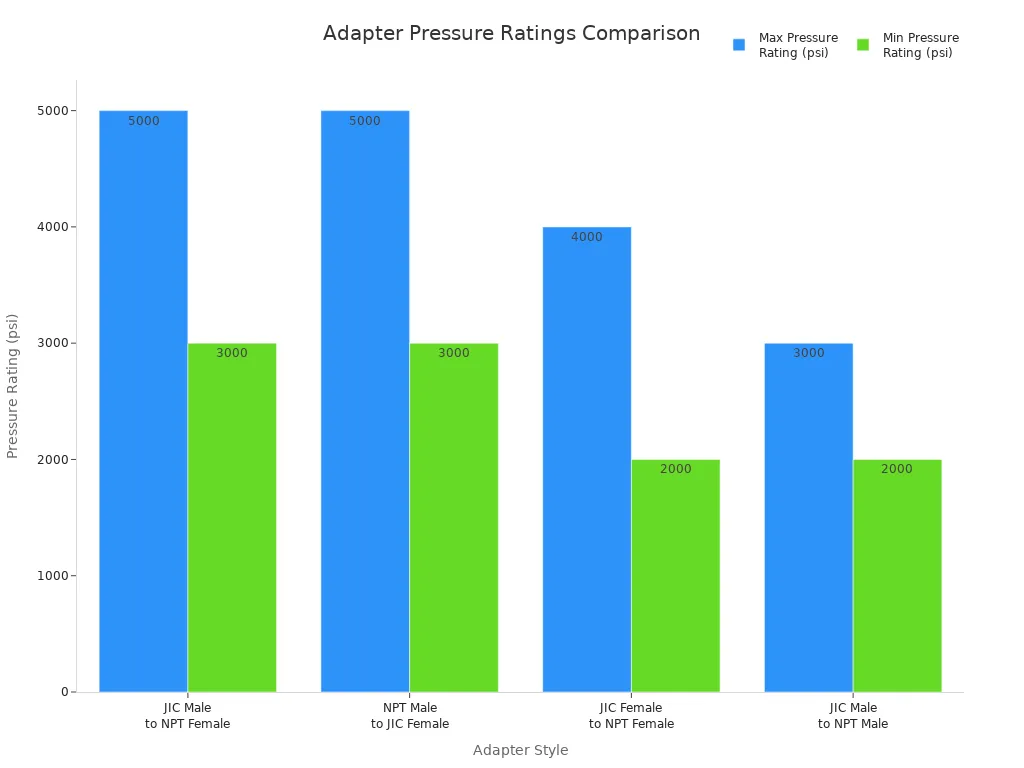

Pressure Ratings and Fluid Hammer

You must match hydraulic adapters to your system’s peak transient pressure, not just the static pump rating.

Hydraulic systems often experience “water hammer” or pressure spikes that can exceed the working pressure by 200–300% when valves close suddenly. If an adapter is rated only for static pressure, these spikes will eventually extrude the O-ring or deform the flare seat.

Material Hardness Rule: The adapter material must be compatible with the port. Screwing a stainless steel adapter into an aluminum manifold requires anti-seize (where permitted) and careful torque control to prevent thread galling.

Tip: Always check the Safety Factor. Standard hydraulic adapters typically carry a 4:1 design factor (Burst Pressure : Working Pressure) per SAE J514 standards.

| Factor | Failure Mode if Ignored |

|---|---|

| Pressure Spikes | O-ring extrusion (nibbling); Flare seat collapse. |

| Temperature Extremes | Compression set (seal flattens out and leaks when cooled). |

| Fluid Incompatibility | Swelling (O-ring grows >10%) or Shrinkage (loss of seal compression). |

Temperature and Seal Material

You need to select hydraulic adapters with seals that maintain elasticity across the full temperature range (-40°C to +200°C typical).

Temperature affects both the metal body (pressure derating at high heat) and, more critically, the elastomer seal. A standard NBR (Buna-N) O-ring may harden and crack if used in a high-temperature engine compartment (>120°C).

| Seal Material | Temp Range (Typical) | Application Note |

|---|---|---|

| NBR (Buna-N) | -40°C to +100°C | Standard for petroleum-based hydraulic oils. |

| FKM (Viton) | -26°C to +200°C | Best for high heat and chemical resistance. |

| EPDM | -55°C to +150°C | Required for Phosphate Esters (Skydrol); Incompatible with Oil. |

For corrosive environments (offshore, marine, washdown), 316 Stainless Steel adapters are the industry standard (ASTM A182 / A479), offering superior resistance compared to zinc-plated carbon steel.

Chemical Compatibility Standards

You must ensure chemical compatibility between the hydraulic fluid and the elastomer seal to prevent “Seal Swell” failure.

Reference established standards when selecting materials:

| Standard / Reference | Scope / Utility |

|---|---|

| ASTM D471 | Standard Test Method for Rubber Property—Effect of Liquids. |

| ISO 3601 | Global standard for O-ring dimensions and quality acceptance criteria. |

| SAE J1453 (ORFS) | Specifications for O-Ring Face Seal connectors (Zero-Leak performance). |

| ISO 8434-3 | Metric counterpart to SAE J1453 for ORFS connections. |

Warning: Never use Teflon tape (PTFE tape) on ORFS or JIC Flare fittings. The tape is only for tapered threads (NPT/BSPT). Using tape on a face seal or flare interferes with the seating and causes leaks.

Types of Hydraulic Adapters and Fittings

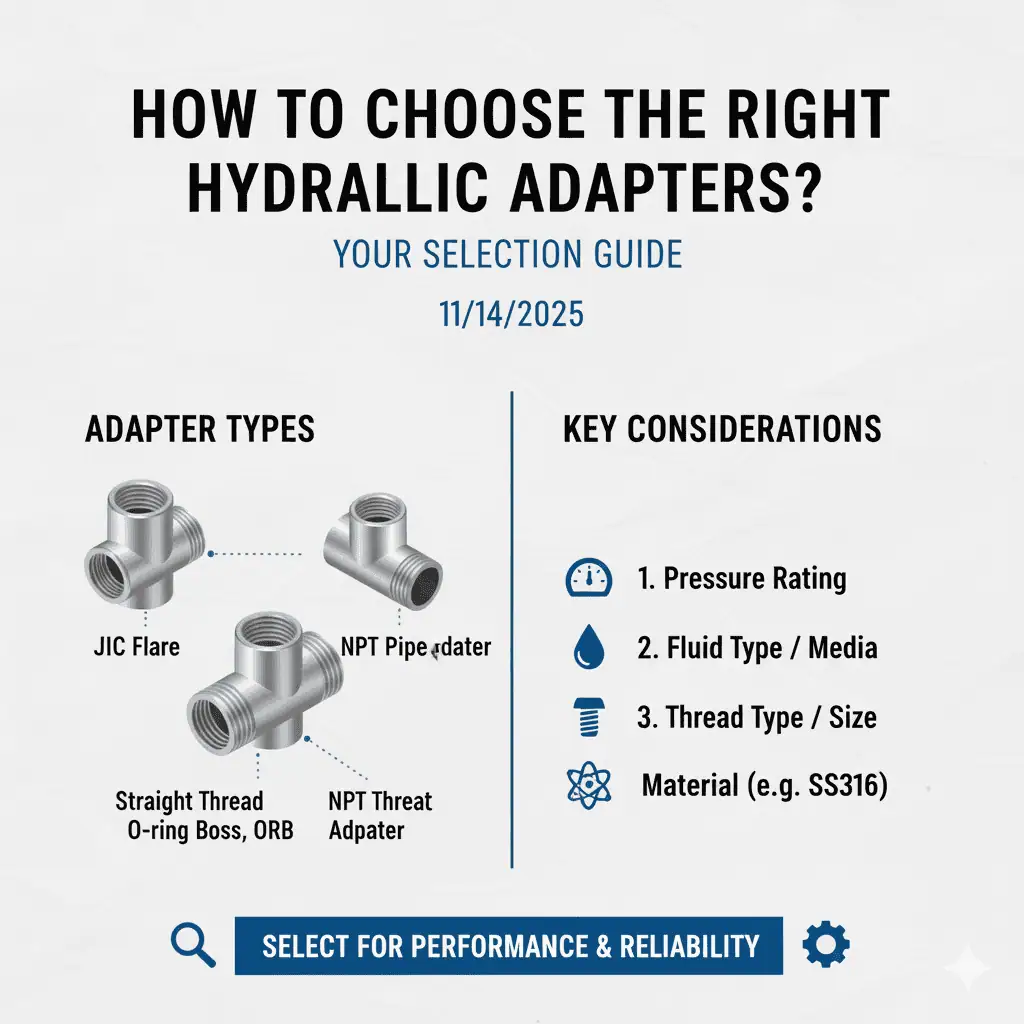

Common Hydraulic Adapter Types

You need to choose the adapter style that matches your port availability and maintenance philosophy.

Sunhy manufactures adapters compliant with SAE and ISO standards. Here is the functional breakdown:

| Adapter Style | Sealing Mechanism | Best Use Case | Vibration Resistance |

|---|---|---|---|

| JIC 37° Flare (SAE J514) | Metal-to-Metal (Cone Seat) | General hydraulic repairs; widely available. | Moderate |

| ORFS (O-Ring Face Seal) | Elastomer-to-Metal (Flat Face) | High-pressure, high-vibration mobile equipment. | Excellent |

| NPT / NPTF | Thread Interference | Legacy equipment; low-pressure plumbing. | Poor (Loosens easily) |

| BSP (BSPP/BSPT) | Bonded Washer or Thread | European/Asian machinery connections. | Good (with Bonded Seal) |

If you are retrofitting a system, see our guide on Identifying and Fixing Hydraulic Adapters for step-by-step thread identification.

Hydraulic Fittings and Hose Connections

The “Jump Size” Rule: When connecting hoses, avoid reducing the hose ID smaller than the adapter bore, as this creates flow restriction (heat) and cavitation. Conversely, utilizing a “Jump Size” adapter (e.g., 1/2″ Port to 3/4″ Hose) allows for lower fluid velocity.

- Straight Adapters: Minimal flow restriction.

- Elbows (45°/90°): Introduce pressure drop (Delta P). Use swept elbows where possible instead of sharp-block elbows to reduce heat generation.

- Bulkhead Fittings: Essential for passing lines through machine frames while protecting the hose from abrasion.

Material Options and Durability

Stainless Steel (316/316L) is the engineer’s choice for longevity in corrosive zones, but Carbon Steel remains the cost-effective standard for dry, indoor hydraulics.

| Material | ASTM Standard | Suitable Applications |

|---|---|---|

| Carbon Steel (Zinc-Nickel Plated) | ASTM A108 / SAE J514 | Agriculture, Construction Equipment (Standard duty). |

| Stainless Steel (316/316L) | ASTM A182 / A479 | Offshore, Chemical Processing, Food & Beverage (Washdown). |

| Brass | ASTM B16 | Low pressure (<500 psi), Pneumatics, Cooling lines. |

Installation Tip: When using Stainless Steel adapters, you must prevent thread galling. Use a nickel-based anti-seize or a dry-film lubricant on the threads (not the seat) during assembly.

Thread Identification and Connection Standards

Measuring and Identifying Threads

You cannot identify threads by eye. A 1/2″ BSPP and 1/2″ NPT look nearly identical but will leak or strip if forced.

Use the “I.D. Kit” approach:

- Step 1 (Caliper): Measure the Thread OD. (e.g., 1/2″ NPT is approx 21mm OD; 1/2″ BSPP is approx 21mm OD).

- Step 2 (Pitch Gauge): This is the tie-breaker. NPT is 14 TPI; BSPP is 14 TPI (wait, checking angle?).

- Step 3 (Angle/Seat): NPT is a 60° thread angle; BSPP is 55°. JIC is a 37° flare seat; SAE Automotive is 45°.

The “It Fits” Trap: A BSPP male fitting will screw loosely into an NPT female port. It will feel loose, and under pressure, it will blow out. Always verify the pitch.

For a deep dive on NPT specifically, see NPT Fittings: The Complete Guide.

Regional and Global Standards

Global OEMs use mixed standards. A single excavator may have JIC hoses (USA), BSPP pumps (Europe), and Metric DIN cylinders (Germany).

| Standard | Seat Type | Description |

|---|---|---|

| SAE J514 (JIC) | 37° Flare | The North American standard. Reliable, but prone to overtightening cracks. |

| ISO 8434-1 (DIN) | 24° Cone (Bite) | The European standard. “Bite type” compression fittings. Very high pressure. |

| BS 5200 (BSP) | 60° Cone | The UK/Commonwealth standard. Uses Whitworth threads. |

| SAE J1453 (ORFS) | Flat Face O-Ring | The Modern Global standard. Best for zero-leak requirements. |

Ensuring Leak-Proof Connections

Leak-free performance relies on the “Sealing Interface,” not the wrench force.

| Sealing Interface | Installation Rule | Do Not Do |

|---|---|---|

| O-Ring Face Seal (ORFS) | Torque to Spec. The metal faces touch, and the O-ring is compressed into the groove. | Do not use thread sealant. Do not over-torque (faces prevent crush). |

| JIC 37° Flare | Tighten until seats contact + “Flats Method” (e.g., 1/4 to 1/2 turn). | Do not over-torque. It cracks the female flare swivel. |

| Tapered Thread (NPT) | Use PTFE tape or paste. Tighten 2-3 turns past finger tight. | Do not back off (loosen) to align an elbow; the seal is broken. |

Engineering Fact: 90% of JIC flare leaks are caused by over-tightening, which ovalizes the female cone. If a JIC leaks, check for a cracked seat before tightening more.

Application-Specific Needs and Maintenance

Vibration and Corrosion Resistance

For high-vibration equipment (e.g., rock breakers, forestry heads), Tapered Threads (NPT) are forbidden by many engineering specs because they loosen.

Solution: Use ORFS adapters or DIN Metric fittings with elastomeric seals. The elasticity absorbs micro-movements that would otherwise loosen the nut.

Installation and Troubleshooting Tips

The #1 Rule of Assembly: Use a Backup Wrench.

When tightening a hydraulic hose onto an adapter, you must hold the adapter body stationary with a second wrench. Failure to do this transfers torque into the adapter-to-manifold connection, loosening it behind the scenes.

Leak Tracing Protocol:

- Don’t touch under pressure: Hydraulic injection injuries are fatal. Use cardboard to find the jet.

- Identify the path: Fluid follows gravity. The drip is rarely the leak source; look higher.

- Inspect the O-ring: Is it square (compression set)? Is it nibbled (extrusion)?

Custom Solutions for Unique Systems

Sometimes, standard off-the-shelf adapters add too many leak points (e.g., stacking a bushing + elbow + expander).

For OEM applications, Sunhy can engineer a single-piece “Jump Size” custom adapter (e.g., M22x1.5 Male to 3/4″ JIC Male 90° Elbow). This eliminates two potential leak paths and reduces assembly time.

When selecting hydraulic couplers, apply the same rigor: verify flow rate (Cv) to prevent overheating.

FAQ

What is the difference between JIC and NPT adapters?

JIC (Joint Industry Council) uses a 37° flare and parallel threads to seal metal-to-metal, making it reusable. NPT (National Pipe Taper) uses tapered threads that deform to seal, making them less suitable for high-pressure disassembly/reassembly.

Why do my hydraulic adapters leak after a few days?

Delayed leaks are often caused by vibration loosening NPT fittings, or by O-ring “compression set” where the rubber loses its bounce due to heat. Alternatively, omitting the backup wrench during installation left the adapter loose from the start.

Can I use stainless steel adapters with carbon steel ports?

Yes, but beware of Galvanic Corrosion in saltwater environments (zinc anode effect). Also, stainless steel is harder than carbon steel; over-tightening can damage the carbon steel port threads permanently. Use anti-seize.

How tight should I tighten hydraulic fittings?

Stop guessing. For JIC, use the “Flats From Resistance” (FFR) method (typically 1.5 to 2 flats past finger tight). For ORFS, use a torque wrench to SAE specifications. “Tight until it stops” is the leading cause of cracked flares.

What is the best adapter for high vibration?

ORFS (O-Ring Face Seal) or DIN 24° with O-ring. These designs decouple the sealing function from the thread holding function, preventing the seal from breaking when the nut vibrates.