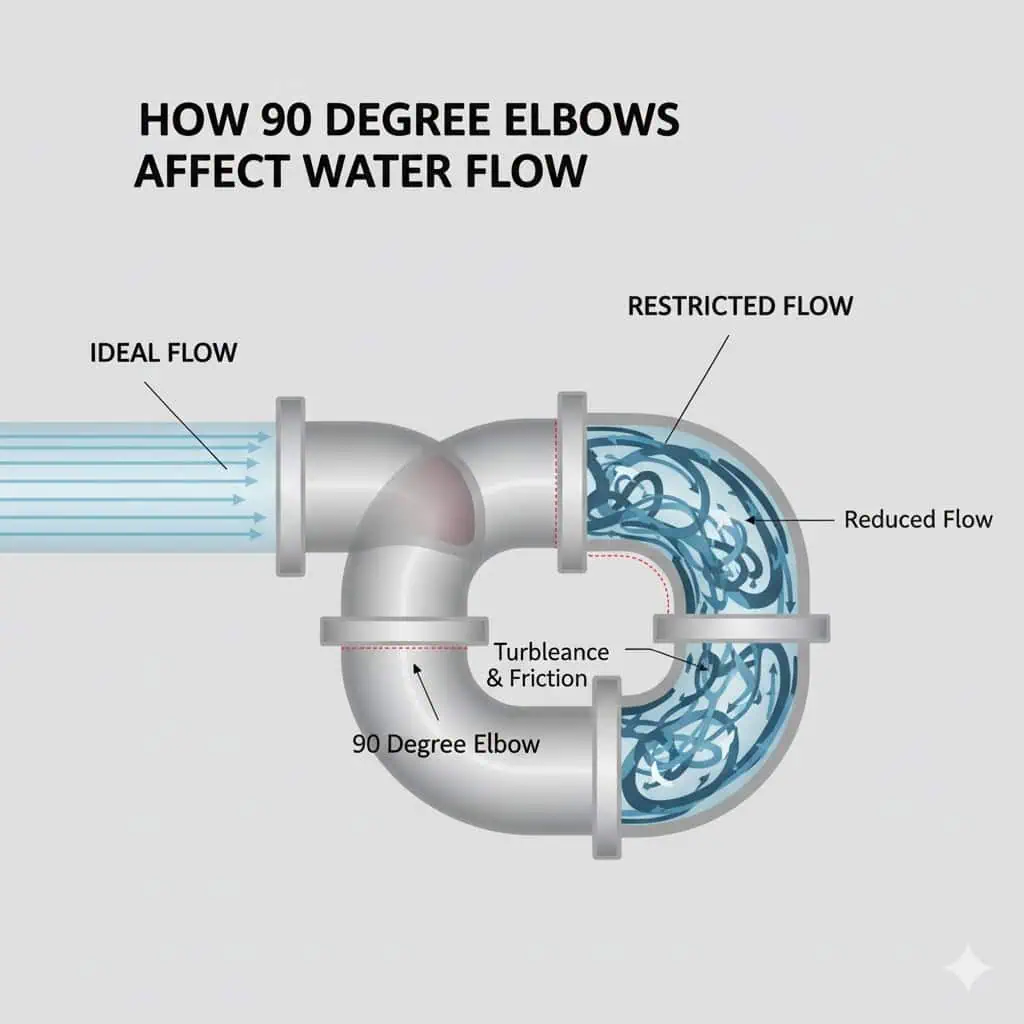

90 degree elbows increase resistance and reduce water flow in your plumbing system. When water hits these sharp bends, the abrupt change in direction causes friction and turbulence. In engineering, this is treated as a minor loss and is commonly calculated using a loss coefficient (K):

ΔP = K · ρ · v² / 2 (pressure loss), or as head loss hL = K · v² / (2g). You can verify typical elbow K-values in published tables (for example, regular 90° elbows are usually higher than long-radius elbows). See reference tables here: Engineering ToolBox – Minor loss coefficients (K) for fittings.

For both homeowners and professionals, understanding how fittings affect water flow helps you choose the right components and maintain optimal performance.

Impact of 90 Degree Elbows on Water Flow

Increased Resistance and Friction

90 degree elbows create significant resistance and friction, making it harder for water to move through your pipes.

Imagine water racing down a straight pipe. It moves smoothly, like a car on a highway. When the water hits a 90 degree elbow, it must make a sharp turn, similar to a car suddenly swerving. This abrupt change slows the water and increases losses inside the fitting.

You can see the difference in resistance by comparing common 90° elbow designs. Typical K values (minor loss coefficient) for elbows are shown below (values vary by geometry, connection type, and radius):

| Type | Typical K (Minor Loss Coefficient) |

|---|---|

| 90° elbow, threaded regular | ≈ 1.5 |

| 90° elbow, flanged long radius | ≈ 0.2 |

Data reference: Engineering ToolBox. (Use this as a design starting point; always confirm with your project spec.)

In practice, suppliers and hydraulic references also show that elbow losses vary noticeably by connection style and radius. A useful quick-check is to compare “regular” vs “long radius” and “threaded” vs “flanged/welded.” (One example of published variation notes is collected here: Pumps.org – fitting loss variation table.)

Here is a clean summary you can use (keeps your original table position but removes the duplicate rows):

| Type of Elbow | Variation / Notes (Typical) |

|---|---|

| 90 Deg. Elbow (Regular, Screwed) | Higher loss due to tighter internal turn and threaded geometry |

| 90 Deg. Elbow (Long Radius, Screwed) | Lower loss than regular; smoother radius reduces separation |

| 90 Deg. Elbow (Regular, Flanged/Welded) | Often lower than screwed; depends on radius and bore alignment |

| 90 Deg. Elbow (Long Radius, Flanged/Welded) | Typically lowest among common 90° elbows |

| 90 Deg. Elbow (Mitered) | Can be high loss unless multi-segmented; confirm per spec |

Reference for variation concept: Pumps.org.

Tip: The more 90 degree elbows you use, the greater the resistance and the lower the efficiency of your water system.

Turbulence and Pressure Drop

90 degree elbows cause turbulence and pressure drops, which reduce the efficiency of your water system.

When water moves through a sharp bend, it swirls and tumbles, creating turbulence. This turbulence disrupts the smooth flow and leads to energy loss. As a result, you will notice a drop in water pressure after the elbow.

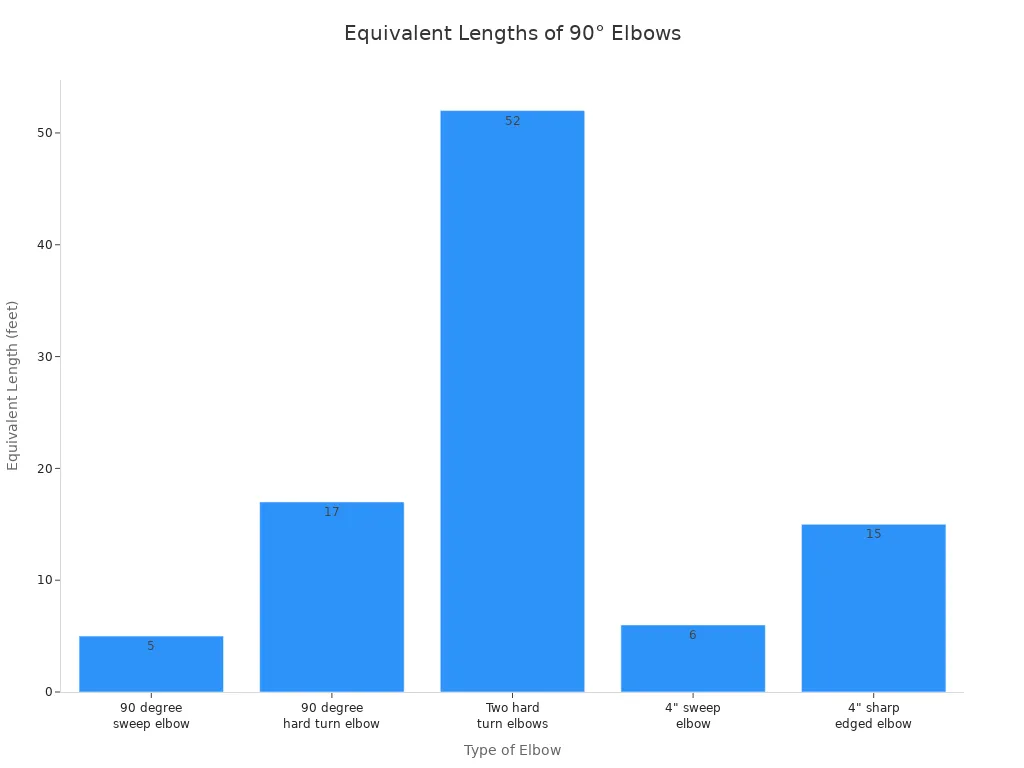

The pressure drop caused by elbows can also be expressed using the equivalent length method (convert a fitting into “feet of straight pipe” that causes the same loss). Many published tables provide equivalent lengths by pipe size and fitting type, for example: Engineering ToolBox – Equivalent length (PVC/CPVC fittings).

The table below keeps your original “feet” style. Treat the values as typical rule-of-thumb examples (actual values depend on pipe size, radius, and flow regime):

| Type of Elbow | Equivalent Length (feet) |

|---|---|

| 90 degree sweep (long radius) elbow | ~ 1–6 (depends on pipe size) |

| 90 degree hard turn (tight radius) elbow | ~ 3–17 (depends on pipe size) |

| Two hard turn elbows | ~ 2× single elbow (can compound) |

| 4″ sweep elbow (example) | ~ 6 |

| 4″ sharp-edged elbow (example) | ~ 15 |

Equivalent length tables vary by material and standard—use a table matching your pipe material and size. Example reference: Engineering ToolBox.

Turbulence and friction from 90 degree elbows lead to significant pressure losses. This means your water system must work harder to deliver the same amount of water, which can lower overall flow efficiency.

Note: Even a single 90 degree elbow can have the same effect as adding several feet of straight pipe, making careful planning essential for efficient plumbing.

How Much Pressure Do They Cause?

A single 90 degree elbow can cause a significant pressure drop in your water system, often equal to adding many feet of straight pipe.

When you install a 90 degree elbow, you force water to change direction sharply. This sudden turn increases resistance and creates turbulence, which leads to pressure losses. The amount of pressure drop depends on the elbow design (radius, connection type) and how many you use in your system.

You can estimate the pressure drop by looking at the equivalent length method. This method compares the resistance of an elbow to a certain length of straight pipe. The table below shows typical values for different types of 90 degree elbows:

| Fitting Type | (L/D)eq (Equivalent Length/Diameter) |

|---|---|

| 90° Elbow Curved, Threaded (Std. R) | ≈ 30 |

| 90° Elbow Curved, Threaded (Long R) | ≈ 16 |

| 90° Elbow Curved, Flanged/Welded (Std. R) | ≈ 20 |

| 90° Elbow Curved, Flanged/Welded (Long R) | ≈ 17 (R/D=2), 14 (R/D=4), 12 (R/D=6) |

| 90° Elbow Mitered (1 weld, 90°) | ≈ 60 |

| 90° Elbow Mitered (2 welds, 45°) | ≈ 15 |

| 90° Elbow Mitered (3 welds, 30°) | ≈ 8 |

Equivalent length ratio reference examples: Katmar Software – equivalent length and related K/geometry ranges: Bentley HAMMER – typical fitting K values.

The number of 90-degree bends you use directly increases the total pressure drop. For example, each standard 90-degree elbow can add a large L/D ratio, which can have a big impact on your plumbing system.

Practical example (easy to verify): If water velocity is 2 m/s and an elbow has K = 1.5, then ΔP ≈ 1.5 × 1000 × (2²)/2 = 3000 Pa ≈ 0.44 psi for that single elbow. Ten elbows can turn into ~4.4 psi of additional loss at the same velocity (actual results vary by pipe size and flow rate). K ranges for elbows are published in multiple references, such as: Engineering ToolBox.

If you add more elbows, the pressure drop multiplies. You should always consider the total number of elbows when designing your system. Using long radius elbows or reducing the number of sharp bends can help minimize pressure losses and keep your water flow strong. If you need industrial-grade elbows and consistent geometry, you can source elbows under ASME B16.9 / B16.11 categories here: Butt Weld Fittings (ASME B16.9) and Socket Weld Fittings (ASME B16.11).

Why 90 Degree Elbows Affect Water Flow

90 degree elbows affect water flow by forcing water to change direction abruptly, which increases turbulence, energy loss, and pressure drop.

Abrupt Direction Change

When you install a 90 degree elbow in your piping system, you create a sharp turn for the water. This sudden change in direction disrupts the smooth movement of water and causes several issues:

- Pipe elbows cause flow separation, which breaks up the steady stream of water.

- Secondary flow patterns develop, increasing turbulence and energy loss.

- Eddies form inside the elbow, further reducing efficiency.

- Sharp bends lead to measurable head loss (minor loss) and pressure drops.

- Increased energy losses mean your pump must work harder, raising operating costs.

- Overall system efficiency drops due to these factors.

For example, if you picture water moving through a straight pipe, it flows smoothly like cars on a highway. When the water hits a 90 degree elbow, it must swerve sharply, much like a car making a sudden turn. This action slows the water and creates swirling currents that waste energy.

Flow Distortion and Swirl

The science behind flow distortion and swirl in 90 degree elbows is well documented. Both experimental and CFD studies show secondary flow structures (often described as Dean-type vortices in curved ducts) that increase mixing and losses. A practical way to connect the “science” to daily design is to use K or equivalent-length tables, then validate the final system using field measurements or commissioning data.

- CFD and lab measurements consistently show that elbows create secondary flows and increased turbulence compared with straight pipe.

- These secondary flows can increase local wall shear and contribute to wear in abrasive or high-velocity services.

- The magnitude depends strongly on radius (long radius generally lowers loss) and on upstream flow conditioning.

- Published K ranges and equivalent-length methods allow engineers to quantify the impact early in design.

- For extreme conditions, software tools and validated databases (e.g., hydraulic modeling software docs) provide typical coefficient ranges.

- After installation, good practice is to verify pressure at key points to confirm design assumptions.

In large-scale plumbing systems, these effects become even more important. Sudden turns from 90 degree elbows increase turbulence, which leads to extra pressure loss. This pressure loss can add up quickly, especially if your system has many elbows. Even small losses at each bend can combine to create a big drop in water pressure throughout your system.

In real-world terms, if you have a long pipe with several 90 degree elbows, you may notice weaker water flow at the end of the line. This happens because each elbow adds resistance and reduces the energy available to push water forward.

When Should You Use 90-Degree Elbows?

You should use 90-degree elbows when you need to change the direction of water flow sharply in limited spaces or when the piping layout demands a compact turn.

You often face situations where space is tight or the design requires a precise change in direction. In these cases, a 90-degree elbow provides a practical solution. You see these fittings in residential plumbing, industrial systems, and commercial buildings. They help you route pipes around obstacles, fit piping into corners, and connect equipment efficiently.

Consider these common scenarios:

- Space Constraints: You need to fit pipes in small rooms, behind walls, or under floors. A 90-degree elbow allows you to make a sharp turn without extending the pipe run.

- Equipment Connections: You must connect pumps, tanks, or valves that sit at right angles to the main line. The elbow creates a direct path between components.

- System Layout: You design a piping system with multiple branches or levels. Elbows help you organize the layout and maintain a neat appearance.

Tip: Use 90-degree elbows when you cannot use gradual bends due to space or design limitations. Always consider the impact on flow and pressure.

Here is a table to help you decide when a 90-degree elbow is appropriate:

| Situation | Use 90-Degree Elbow? | Reason |

|---|---|---|

| Tight corners | ✅ | Fits in limited space |

| Connecting equipment | ✅ | Aligns with inlet/outlet orientation |

| Long straight runs | ❌ | Prefer gradual bends for better flow |

| High-flow systems | ❌ | Minimize elbows to reduce pressure loss |

| Complex layouts | ✅ | Organizes piping efficiently |

You should always weigh the benefits against the potential for increased resistance and pressure drop. If you must use a 90-degree elbow, select consistent-geometry fittings and plan your system to minimize negative effects. For industrial piping, you can browse elbow-related fitting categories here: Butt Weld Elbows (LR/SR) and for threaded low-pressure elbows you can start from: Threaded Fittings (includes threaded elbows list).

Flow Reduction Quantified

Friction Loss Equivalents

A single 90-degree elbow can add the same friction loss as several feet of straight pipe, significantly reducing water flow.

When you install a 90-degree elbow, you increase the resistance in your piping system. You can measure this resistance by comparing it to the length of straight pipe that would cause the same friction loss. For many water systems, published equivalent-length tables show that a standard 90° elbow often equals a few feet of straight pipe (depending on size), while long-sweep/long-radius designs are lower. See an example table by pipe size here: Engineering ToolBox – Equivalent length of fittings.

Here is a quick reference table (directionally correct and consistent with common published tables; confirm exact values for your pipe size/material):

| Fitting Type | Equivalent Straight Pipe Length (feet) |

|---|---|

| Standard 90° elbow | ~ 2–6 (depends strongly on pipe size) |

| Long radius / long sweep 90° elbow | ~ 1–4 (typically lower than standard 90°) |

| Sharp / tight turn elbow | Can be much higher; verify per geometry |

Example published equivalent lengths by pipe size: Engineering ToolBox.

You should always account for these equivalents when planning your system. If you use multiple elbows, the total friction loss can add up quickly.

Typical Pressure Drop Values

Each 90-degree elbow causes a noticeable pressure drop, which can lower the efficiency of your water system.

Pressure drop refers to the reduction in water pressure as it moves through a fitting. A robust way to estimate the drop is to use K (minor loss coefficient) and your actual flow velocity. Typical K ranges for elbow designs are published in multiple sources, such as: Engineering ToolBox – K values and hydraulic modeling documentation: Bentley HAMMER – typical K coefficients.

Consider these typical ranges (illustrative):

- Standard 90-degree elbow (threaded regular): K ≈ 1.5 (higher loss)

- Long radius 90-degree elbow: K often ≈ 0.2–0.7 (lower loss)

- Mitered/tight bends: may exceed standard elbows depending on segmentation and radius

If you notice weak water flow at the end of your line, check how many elbows you have installed. Each fitting adds resistance and lowers pressure.

Key Takeaway:

You should minimize the number of 90-degree elbows in your system. Choose gradual bends or long radius elbows when possible to keep friction loss and pressure drop low. This approach helps you maintain strong, efficient water flow throughout your piping network.

Solutions to Minimize Negative Effects

You can reduce the negative effects of 90-degree elbows by choosing better designs, optimizing pipe layout, and using advanced fittings.

Sharp bends in your piping system often lead to increased resistance and pressure loss. You have several practical strategies to minimize these issues and maintain efficient water flow.

Key Strategies for Reducing Impact

- Select elbows with improved internal design. Some elbows feature guide vanes that direct water more smoothly around the bend. (In airflow/duct design, vane bends also show lower loss coefficients—same concept applies to guiding flow.) Reference example: Engineering ToolBox – bend with vanes vs sharp bend.

- Use flow-conditioning where needed. In systems with high velocity/solids, upstream conditioning can reduce localized impact and wear at bends.

- Prefer long-radius elbows when space allows. Long radius bends typically reduce separation and lower K compared with tight bends. (See K table: Engineering ToolBox.)

- Choose reducing elbows carefully for diameter transitions. Use smooth transitions and confirm flow direction/installation to prevent swirl and noise.

- Limit the number of sharp bends in your system. Fewer elbows mean less resistance and better overall performance.

Tip: When you plan your piping layout, try to use gradual bends instead of sharp turns. This simple change can make a big difference in water pressure and system efficiency.

Comparison Table: Elbow Solutions

| Solution Type | Benefit | Application |

|---|---|---|

| Guide vane elbows | Reduces turbulence, erosion | Industrial, commercial |

| Flow conditioning upstream | Stabilizes approach flow | High-velocity or sensitive systems |

| Long radius elbows | Lowers K / equivalent length | Most water systems |

| Smoother transitions | Reduces separation at diameter change | Mixed-diameter networks |

| Fewer sharp bends | Lowers resistance | All systems |

You can combine these strategies to achieve the best results. Advanced fittings and thoughtful design choices help you maintain strong water flow and extend the lifespan of your piping system.

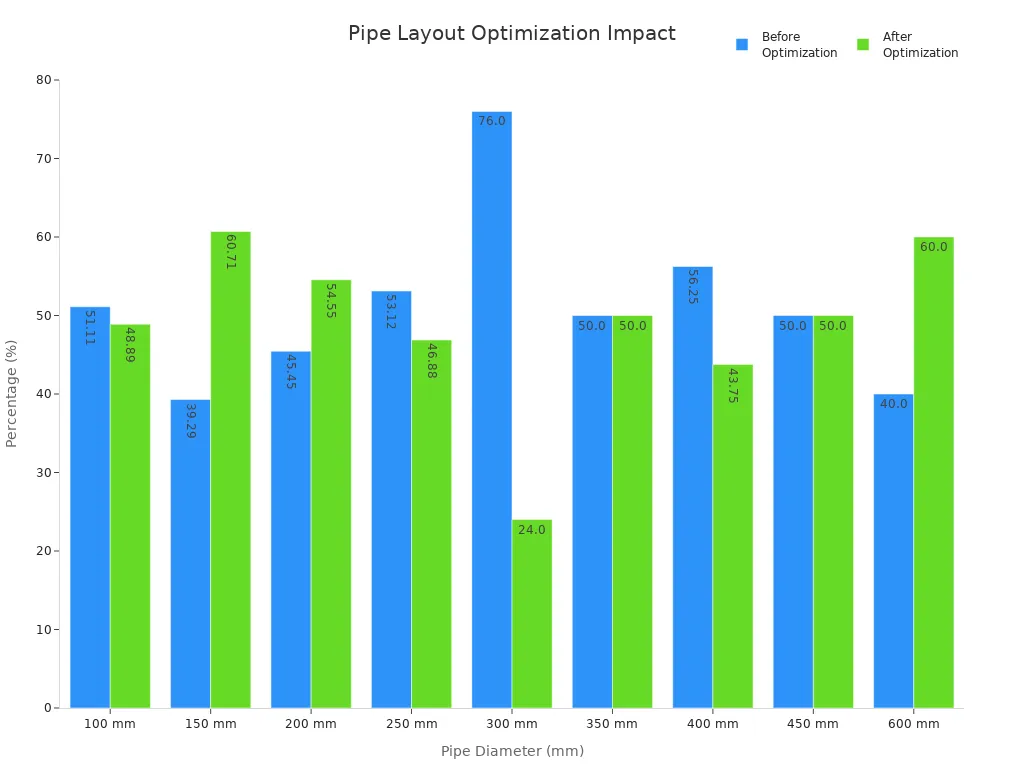

Optimize Pipe Layout

You can improve system reliability and reduce maintenance by optimizing your pipe layout to minimize sharp turns and unnecessary elbows.

A well-designed layout lowers hydraulic losses and helps your system meet local pressure standards. When you plan your piping, keep bends to a minimum and use the shortest, most direct routes possible. This approach reduces the risk of leaks and pipe bursts, especially in large networks.

The optimization of pipe layout not only reduces costs and hydraulic losses but also significantly enhances the reliability of the water distribution system. By ensuring that the majority of pressure values meet local standards, the risk of pipe bursts and leaks is minimized, leading to improved long-term performance.

Choose Quality Fittings

You can prevent leaks and maintain strong water pressure by selecting high-quality, precision-manufactured fittings.

Quality fittings, such as those crafted with advanced tooling and strict tolerances, help you achieve reliable, leak-free connections. When you choose products like Sunhy stainless steel fittings, you benefit from robust materials and consistent geometry. These fittings follow common industrial standards and can be specified for demanding applications: Sunhy Industrial Pipe Fittings.

| Feature | Description |

|---|---|

| Precision Manufacturing | Crafted using advanced tooling techniques, ensuring tighter tolerances. |

| Reduced Risk of Callbacks | Enjoy fewer service calls due to leaks or faulty fittings. |

| Improved Water Flow | Designed to minimize restrictions, providing more stable flow. |

| Easier Code Compliance | Meets common industry standards for easier inspections. |

Tip: Always select fittings that match your system’s requirements. High-quality products help you avoid costly repairs and ensure long-term performance.

90 degree elbows increase resistance, create turbulence, and reduce water flow in your system. You need to understand these effects to design efficient piping. Instead of vague “research says,” the most actionable industry approach is to quantify elbows using K or equivalent length and sum losses across the system (ΔP total = ΔP major + ΔP minor). Reference example K tables: Engineering ToolBox.

| Key Findings | Description |

|---|---|

| Quantification Method | Elbow losses are commonly modeled with K (minor loss coefficient) or equivalent length. |

| Radius Matters | Long-radius elbows usually reduce loss compared with tight/regular elbows. |

| System Impact | Multiple elbows can create meaningful cumulative pressure drop in long runs. |

Quality fittings help you maintain strong, leak-free connections. Their durability and corrosion resistance support stable performance—especially when elbows, valves, and flanged joints must work together in one system.

FAQ

How do 90-degree elbows affect water pressure?

90-degree elbows reduce water pressure.

You force water to change direction sharply, which increases minor loss (K) and causes a pressure drop. If several elbows are installed in series, cumulative losses can noticeably reduce pressure at the outlet.

Can you minimize flow loss from elbows?

You can minimize flow loss by using long radius elbows and optimizing pipe layout.

Choose gradual bends, reduce the number of sharp turns, and select quality fittings.

- Use long radius elbows

- Limit sharp bends

- Install precision-manufactured fittings

Are stainless steel flanges compatible with 90-degree elbows?

Stainless steel flanges work well with 90-degree elbows.

You can connect elbows securely using flanges, especially in high-pressure or industrial systems. Quality flanges and proper bolting/gaskets help ensure leak-free performance: Sunhy Stainless Steel Flanges.

When should you avoid using 90-degree elbows?

Avoid 90-degree elbows in high-flow or long-distance systems.

You should use gradual bends or fewer elbows to maintain strong water flow and reduce pressure loss.

| Situation | Recommendation |

|---|---|

| High-flow systems | Use gradual bends / long radius elbows |

| Long pipe runs | Minimize elbows and optimize layout |