The main practical difference between BPE and 3A sanitary fittings is that BPE fittings have stricter surface finish and traceability standards, while both provide sanitary solutions for industrial needs. You often see these fittings in industries where hygiene is critical. In real plants, the decision is usually driven by (1) how you clean (CIP/SIP), (2) whether you must document traceability for audits, and (3) whether equipment must meet a 3-A sanitary design / verification pathway.

- Pharmaceutical manufacturing often specifies ASME-BPE when surface condition and documentation are part of qualification/validation.

- Food and beverage processing, like dairy and breweries, depends on sanitary fittings to meet hygienic design expectations; 3-A standards and the Symbol/TPV ecosystem are commonly referenced in equipment specifications (see About 3-A and TPV Manual).

When you compare BPE vs 3A, you find both use stainless steel and offer reliable end styles. The table below highlights their similarities and differences. For authoritative context on BPE scope (materials, design, fabrication, inspection/testing, certification), refer to ASME’s overview: ASME BPE.

| Feature | BPE Fittings | 3A Fittings |

|---|---|---|

| Sanitary | Yes | Yes |

| Common Materials | 316L Stainless Steel | 304 and 316 Stainless Steel |

| Surface Finish | Multiple options, often electropolish | Commonly referenced sanitary criterion is ≤32 µin Ra (0.8 µm) and defect-free product-contact surfaces (see 3-A hygienic design guidance PDF) |

| Traceability | Always includes certificates | Often depends on PO/spec; require MTR/heat cert explicitly if needed |

Choosing the right sanitary fittings matters. From a procurement and QA standpoint, the “right” part is the one that meets your written acceptance basis: the correct standard, finish, dimensions, and the documentation pack you will actually review at receiving (MTR/heat, surface finish certificate where required, and 3-A TPV/Symbol evidence when specified).

BPE vs 3A: Overview

What is BPE?

BPE stands for Bioprocess Equipment Standard, which sets strict requirements for fittings used in industries where cleanliness and purity matter most. You find bpe fittings in pharmaceutical, biotech, and personal care production. The American Society of Mechanical Engineers publishes ASME-BPE (overview: ASME). This standard focuses on tight tolerances, smooth surfaces, and full traceability. You often see bpe fittings in places where you need to prevent contamination and ensure product safety.

- Common uses for bpe fittings include:

- Pharmaceuticals

- Biotech

- Food & Beverage

- Beer, Wine & Spirits

- Dairy

- Personal Care

- Sanitary processes

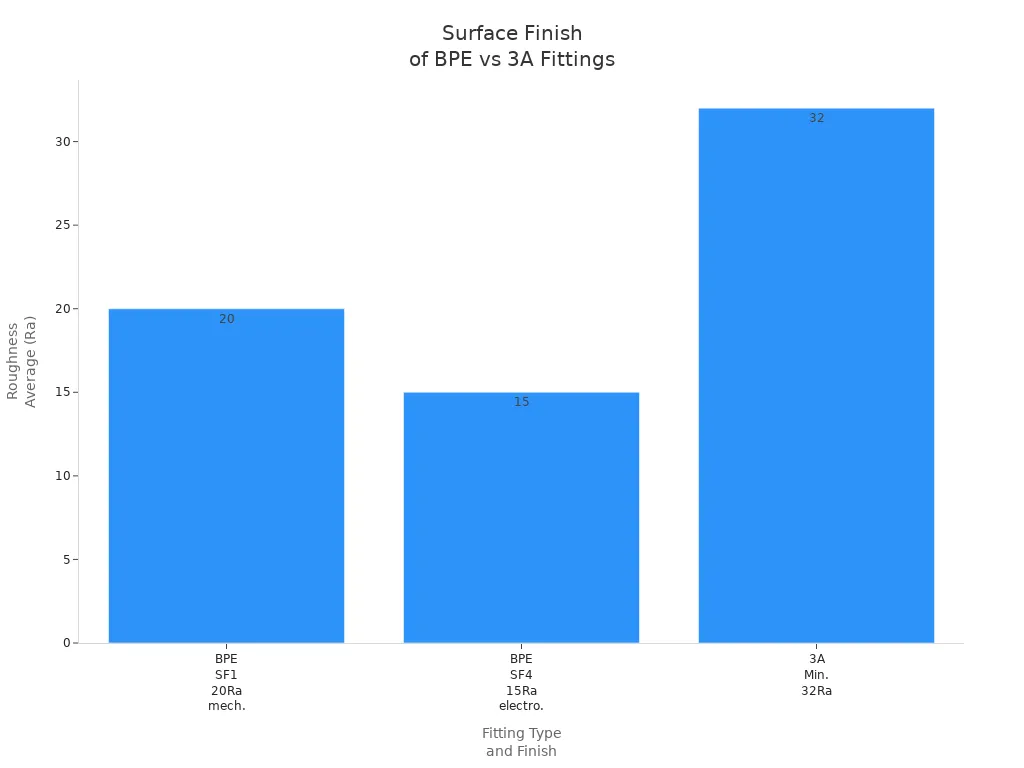

Bpe vs 3a often comes down to the level of control you need over surface finish and documentation. In many BPE projects, SF1 (20 µin Ra mechanical polish) and SF4 (15 µin Ra electropolish) are common callouts; see a practical SF1/SF4 explanation here: SF1 vs SF4 (PDF). You can see this in the table below.

| Feature | BPE Standards | 3A Standards |

|---|---|---|

| Tolerances | Tighter tolerances | Standard tolerances |

| Surface Finish | 20Ra (mechanical), 15Ra (electropolish) | Commonly referenced criterion is ≤32 µin Ra and defect-free product-contact surfaces (see 3-A hygienic design guidance PDF) |

| Material Specifications | Stricter than 3A | Less strict than BPE |

Engineering example (cleanability failure): A line passed hydrotest but repeatedly failed post-CIP swab results at one elbow. Root cause was an internal weld profile + rough ID transition that held residue. Fix was replacing the spool with a controlled finish (BPE-specified) part and adding borescope acceptance for internal weld condition at receiving/turnover.

What is 3A?

3A refers to a set of standards for fittings used mainly in food, dairy, and beverage processing. You use 3a fittings when you need reliable, sanitary connections but do not require the highest level of surface finish or traceability. 3-A is a not-for-profit standards organization; its membership includes industry groups and representatives of USDA and FDA (see About 3-A). If your specification requires 3-A Symbol authorization, Third Party Verification (TPV) is part of the pathway; see TPV programs and the TPV manual.

| Organization Type | Description |

|---|---|

| 3-A SSI standards body | Publishes hygienic design criteria and accepted practices (catalog: 3-A Standards). |

| Processors / manufacturers | Food, beverage, dairy equipment users reference 3-A criteria for cleanability and inspection access. |

| Third Party Verification | TPV supports program integrity where 3-A Symbol authorization is required (see TPV Manual). |

When you compare bpe vs 3a, you see that both types of fittings support sanitary processes. However, bpe fittings usually offer more control over purity and documentation. In mixed plants, a common approach is zoning: 3-A hygienic components where cleanability/inspection drives, and BPE-specified components where validation + documentation control drives.

Sanitary Fittings: Similarities

Hygienic Design

Both BPE and 3A sanitary fittings use hygienic design principles to protect product safety. You need these principles in industries like dairy, food, and pharmaceuticals. The main goal is to prevent contamination and make cleaning easy. Here are the shared design features:

- Smooth, non-porous product-contact surfaces reduce places where residue and microbes can persist.

- You can clean all product contact surfaces mechanically.

- Manual inspection is possible, so you can check for cleanliness.

- The design allows for easy disassembly and reassembly.

These features help you meet strict hygiene standards in every process. You can trust both bpe and 3a fittings to keep your products safe.

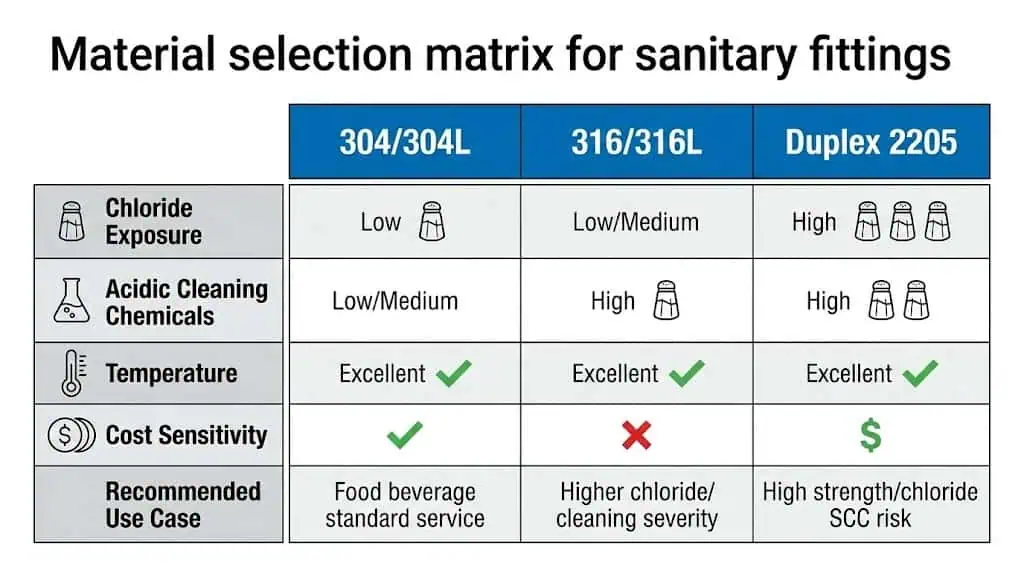

Material Choices

BPE and 3A sanitary fittings both use high-quality stainless steel for strength and cleanliness. You often see 316L stainless steel in both types. This material resists corrosion and stands up to harsh cleaning chemicals. In general metallurgy terms, Type 316 contains 2–3% molybdenum and is commonly more resistant to chloride-related corrosion than Type 304 (see Nickel Institute guideline PDF).

| Material Type | Common Use in BPE | Common Use in 3A |

|---|---|---|

| 316L | Yes | Yes |

| 304 | Rare | Yes |

You should always check which material fits your process best. Both standards help you avoid rust and keep your sanitary systems reliable.

End Styles

You will find similar end styles on both BPE and 3A sanitary fittings, making installation flexible. The most common end styles include:

- Clamp ends for quick assembly and cleaning.

- Weld ends for permanent, leak-free connections.

- Threaded ends for easy replacement in some systems.

These options let you match fittings to your existing equipment. You can use the same end styles in dairy, food, and pharmaceutical plants, which makes upgrades and repairs simple. For installation/maintenance references, keep a plant-side checklist in your SOPs (you can also place a supporting internal guide link here if your site has one, e.g., a “tri-clamp installation guide”).

Tip: Choosing the right end style helps you save time during maintenance and ensures a secure fit. In hygienic service, “easy to inspect” often beats “fast to install.”

BPE vs 3A: Key Differences

Surface Finish and Purity

BPE fittings have stricter surface finish requirements than 3A fittings. You will notice this difference when you look at the numbers. BPE fittings must meet a lower roughness average (Ra), which means the inside surface is smoother. This smoothness helps reduce residue retention and improves cleanability. If you need a practical SF1/SF4 finish reference (20 µin vs 15 µin), see this PDF. For how grit correlates to estimated Ra, see MicroGroup’s conversion table (PDF).

| Fitting Type | Interior Surface Finish | Roughness Average (Ra) |

|---|---|---|

| BPE | SF1 (20Ra mechanical) | 20Ra |

| BPE | SF4 (15Ra electropolish) | 15Ra |

| 3A | Minimum requirement | 32Ra |

You should choose a smoother surface if you work in pharmaceuticals or high-purity environments. Here is why smoother surfaces matter:

- Smoother surfaces reduce the risk of microbial contamination and residue retention.

- They minimize places where corrosive agents can collect.

- Lower Ra values improve how liquids and gases flow.

- Smooth surfaces are easier to clean, which saves time and reduces cleaning variability.

- Meeting these standards helps you keep your products safe.

If you need a quick guide, use this list:

- 32 Ra: Good for many sanitary uses, cleanable when geometry is hygienic.

- 20 Ra: Better for higher cleanliness expectations and reduced hold-up risk.

- 15 Ra: Often selected for stricter high-purity expectations (electropolish commonly specified).

You will find that bpe fittings offer the highest level of purity. This makes them the top choice for pharmaceutical and biotech plants. 3a fittings work well in food and dairy applications, but they do not reach the same level of smoothness as bpe.

Traceability and Certification

BPE fittings require tighter traceability and certification expectations than 3A fittings when you are operating in regulated or validated environments. You need to know where your fittings come from, especially in audited systems. ASME describes BPE as covering materials, design, fabrication, inspections, testing and certification (ASME BPE overview). In practice, many BPE purchase specs require MTR/heat traceability, and sometimes finish certificates.

| Requirement Type | BPE Standards (ASME-BPE) | 3A Standards |

|---|---|---|

| Tolerances | Stricter | Less strict |

| Surface Finish | Cleaner | Standard |

| Material Traceability | Tighter | Looser unless specified |

You will see that bpe fittings often come with certificates when your PO/spec requires them. These documents typically show the material grade, batch/heat, and the manufacturing controls needed for your acceptance basis. 3a fittings may not always include this level of detail unless you require it. If you work in pharmaceuticals or biotech, define traceability and documentation requirements in writing to avoid receiving “sanitary-looking” parts that do not meet QA expectations.

Supplier note (engineering perspective): if a supplier claims compliance, the practical proof is a consistent document pack and receiving inspection outcomes. If your project requires ISO management system certificates, list them as supporting evidence—but do not treat ISO certificates as a substitute for material/finish traceability on product-contact parts.

Application Suitability

BPE fittings suit high-purity and regulated industries, while 3A fittings work best for food and beverage processing. You should match the fitting to your industry’s needs.

- Use bpe fittings in pharmaceutical, biotech, and personal care production. These industries need the highest purity, strict tolerances, and documentation control.

- Choose 3a fittings for food, beverage, and dairy applications. These fittings meet sanitary design expectations; if 3-A Symbol authorization is required, confirm the TPV pathway (see TPV manual).

BPE fittings have stricter tolerances and smoother surfaces. This gives you greater dimensional consistency and better performance in high-purity systems. 3a fittings provide reliable sanitary connections for less demanding environments.

Note: If you need help choosing the right fittings, base the decision on your written acceptance basis (finish, dimensions, material, and documentation). That reduces rework and mismatch when you mix components across suppliers.

Sanitary Fittings: Material Options

Stainless Steel Grades

The best sanitary fittings use high-grade stainless steel for strength and hygiene. You will find that Sunhy manufactures fittings from ASTM A403 WP316L/304L and Duplex Tube. These materials set the standard for durability in industrial applications. For duplex fabrication and corrosion performance guidance, see IMOA’s duplex guideline PDF.

- 316L stainless steel resists corrosion and heat. You often see it in bpe and 3A fittings for pharmaceutical and food processing.

- 304 stainless steel offers good corrosion resistance and a clean appearance. You may find it in 3A fittings, but it is less common in bpe systems because it does not provide the same level of chloride corrosion resistance as 316 (see Nickel Institute PDF).

- Duplex stainless steels, such as UNS S31803 and UNS S32205, deliver even higher strength and corrosion resistance. You can use these for fittings in harsh or demanding environments (see IMOA PDF).

| Material Type | Used in BPE | Used in 3A | Key Benefits |

|---|---|---|---|

| 316L Stainless | Yes | Yes | Superior corrosion resistance |

| 304 Stainless | Rare | Yes | Good for less demanding processes |

| Duplex Stainless | Yes | Yes | High strength, excellent durability |

Tip: Choose 316L or Duplex Tube for critical bpe applications where purity and longevity matter most, and verify corrosion compatibility with your actual CIP chemistry.

Corrosion Resistance

Superior corrosion resistance ensures your fittings last longer and maintain sanitary conditions. You want materials that stand up to cleaning chemicals, high temperatures, and constant use.

- 304 and 316L stainless steels resist heat, wear, and corrosion. They keep your fittings clean and safe for sanitary use. For a practical 304 vs 316 corrosion comparison (including chloride environments), see Nickel Institute PDF.

- Duplex stainless steels provide strong chloride pitting/crevice corrosion resistance and higher strength; fabrication guidance is available from IMOA (see IMOA duplex guideline PDF).

Bpe fittings often require the highest corrosion resistance, especially in pharmaceutical or biotech plants. 3A fittings work well in food and beverage settings, but you should avoid 304 stainless steel for processes with strong chlorides or aggressive cleaning regimes unless your corrosion review supports it.

Direct answer: For the best performance and safety, select fittings made from 316L or Duplex stainless steel, especially for bpe systems.

Choosing Between BPE and 3A

Industry Needs

Direct answer: You should choose bpe fittings for industries that demand the highest purity and traceability, while 3a fittings work best for food and beverage processing.

Your industry shapes your choice. If you work in pharmaceuticals or biotechnology, you need bpe fittings because they offer strict quality assurance, smooth surfaces, and full traceability. These features help you prevent contamination and meet high-purity standards. In food and beverage processing, 3a fittings provide reliable hygiene and meet industry expectations for safe production. For BPE scope, refer to ASME BPE. For 3-A background and standards catalog, refer to About 3-A and 3-A Standards.

Here is a quick comparison of industry needs:

| Feature | BPE Standards | 3-A Standards |

|---|---|---|

| Quality Assurance | Strict protocols, traceability, and high-purity manufacturing | High standards for hygienic processing and packaging |

| Surface Finish | 20Ra or 15Ra (electropolished) for enhanced smoothness | Commonly referenced sanitary criterion is ≤32 µin Ra and defect-free product-contact surfaces (see 3-A guidance PDF) |

| Regulatory Requirements | ASME-BPE standards for material, dimensions, and packaging | 3-A programs may require independent Third Party Verification for Symbol authorization (see TPV manual) |

| Application | Bioprocessing, pharmaceuticals, contamination-free transfer | Food & Beverage hygienic processing |

You should match your fittings to your process. For sensitive goods like medicines, bpe fittings give you the control you need. For dairy or beverage plants, 3a fittings keep your products safe and clean.

Compliance Factors

Direct answer: You must select fittings that comply with the standards and regulations of your industry.

Regulatory compliance protects your process and your customers. Bpe fittings follow ASME BPE standards, which cover material composition, surface finish, and documentation (see ASME BPE overview). 3a fittings must meet 3-A Sanitary Standards criteria for hygiene in food and beverage production; if Symbol authorization is required, TPV is part of the process (see TPV manual).

Here is a table of key compliance factors:

| Compliance Factor | Relevant Standards |

|---|---|

| 3-A Sanitary Standards | 3-A Sanitary Standards, Inc. (catalog) |

| Good Manufacturing Practices | Site SOPs + GMP expectations (industry dependent) |

| TPV / 3-A Symbol authorization (when required) | TPV manual |

| ASME BPE Standards | ASME BPE |

You should always check which standards apply to your facility. If you need to prove traceability or meet strict audits, bpe fittings help you stay compliant. For food and beverage, 3a fittings meet the requirements for safe and hygienic production, especially when the equipment is designed and verified per applicable 3-A program requirements.

Tip: On the PO, state what you will actually inspect at receiving: (1) standard, (2) finish/Ra, (3) material grade, (4) documentation pack. This avoids “almost right” sanitary parts that fail audits.

Cost Considerations

Direct answer: Bpe fittings usually cost more than 3a fittings, but they offer higher purity and better documentation.

You need to balance your budget with your process needs. Bpe fittings require advanced manufacturing, smoother finishes, and full traceability, which increases their price. These fittings are essential for pharmaceuticals and other sensitive industries. 3a fittings cost less and provide reliable performance for food and beverage applications.

When you plan your project, consider these points:

- Bpe fittings are essential for regulated/high-purity zones where traceability and defined finishes matter.

- High-quality materials and documentation increase the cost but reduce batch risk and rework.

- 3a fittings offer a cost-effective solution for less demanding processes.

- Investing in controlled specifications improves efficiency and reduces long-term risks.

Note: In hygienic systems, lifecycle cost is usually dominated by downtime, cleaning failures, and rework—not the fitting unit price.

BPE fittings offer stricter surface finishes and traceability, while 3A fittings provide reliable hygiene for food and beverage use. Both types use stainless steel and support sanitary design. Your choice depends on your industry, compliance needs, and performance goals. Use the table below to guide your decision:

| Key Factor | Description |

|---|---|

| Material Choice | Stainless steel ensures durability and compatibility. Use 316L/duplex when corrosion risk justifies it (see Nickel Institute PDF). |

| Industry Standards | Reference ASME-BPE or applicable 3-A standards; confirm TPV/Symbol requirements when specified (see TPV manual). |

| Compatibility | Match fittings to your system and process fluids; verify dimensions and gasket geometry. |

| Performance Needs | Consider operating conditions, cleanability, and inspection/maintenance reality. |

| Regulatory Compliance | Meet hygiene and safety standards for your industry, including documentation pack when audits require it. |

For expert advice, consult with your process/QA requirements first, then select fittings that meet the written acceptance basis (finish, material, dimensions, documents).

FAQ

What is the main difference between BPE and 3A sanitary fittings?

BPE fittings have stricter surface finish and traceability standards.

You use BPE for high-purity industries like pharmaceuticals. 3A fittings work well for food and beverage processing, especially when equipment is designed to meet applicable 3-A criteria and verification expectations.

Can you use 3A fittings in pharmaceutical applications?

No, you should use BPE fittings for pharmaceuticals in validated/high-purity product-contact systems.

- BPE fittings meet higher purity and documentation standards.

- 3A fittings do not automatically provide the same level of traceability unless your PO/spec requires it.

Which stainless steel grade is best for sanitary fittings?

316L stainless steel is the best choice in many hygienic systems when corrosion risk is higher. For 304 vs 316 corrosion guidance (including chloride environments), see Nickel Institute PDF.

| Grade | Corrosion Resistance | Common Use |

|---|---|---|

| 316L | Excellent | BPE, 3A |

| 304 | Good | 3A |

Do BPE and 3A fittings have the same end styles?

Yes, both offer similar end styles.

- Clamp ends

- Weld ends

- Threaded ends

You can match fittings to your system easily.

How do you choose between BPE and 3A fittings?

Match the fitting to your industry and compliance needs.

Use BPE for pharmaceuticals and biotech. Choose 3A for food and beverage. Always check your regulatory requirements and specify the document pack you need.