Proactive prevention is the most reliable way to stop HISC in subsea flanges—because once cracks initiate, growth can be rapid and hard to arrest. In practice, prevention comes down to three controllable levers:

(1) selecting duplex/super duplex materials and product forms with verified microstructure quality,

(2) preventing excessive hydrogen generation from cathodic protection (CP), and

(3) keeping local stress/strain below conservative thresholds at known hot-spots (hub transitions, bores, weld toes, and threaded/fastener roots). Industry guidance for duplex stainless subsea components exposed to CP is formalized in DNV-RP-F112, while CP design and operating philosophy are covered by DNV-RP-B401.

DNV-RP-F112 (official overview) and DNV-RP-B401 (official overview) are good starting points for engineering teams aligning design, fabrication, and operations. For connector integrity, sealing qualification testing and failure-mode awareness remain essential, especially where leaks translate directly into safety and downtime exposure. Example of connector sealing performance testing in subsea context.

HISC Risks in Subsea Flanges

What Is HISC?

Hydrogen Induced Stress Cracking (HISC) is a brittle cracking mechanism driven by atomic hydrogen uptake combined with tensile stress/strain. In subsea service, hydrogen is commonly generated on metal surfaces receiving cathodic protection. If hydrogen is absorbed into susceptible microstructures and the component sees high local stress (or local plastic strain), cracks can initiate and propagate with limited warning. Unlike “general corrosion” problems, HISC is often a geometry-and-stress-concentration problem: a part can look intact externally while a crack grows from a stressed surface zone inward.

Engineering reality check: HISC is not prevented by “good corrosion resistance” alone. Duplex and super duplex stainless steels can resist seawater corrosion well and still crack if (a) CP drives hydrogen evolution and (b) local stress/strain exceeds conservative limits. This is why stress-based design guidance exists for duplex subsea components under CP.

Why Subsea Flanges Are Vulnerable

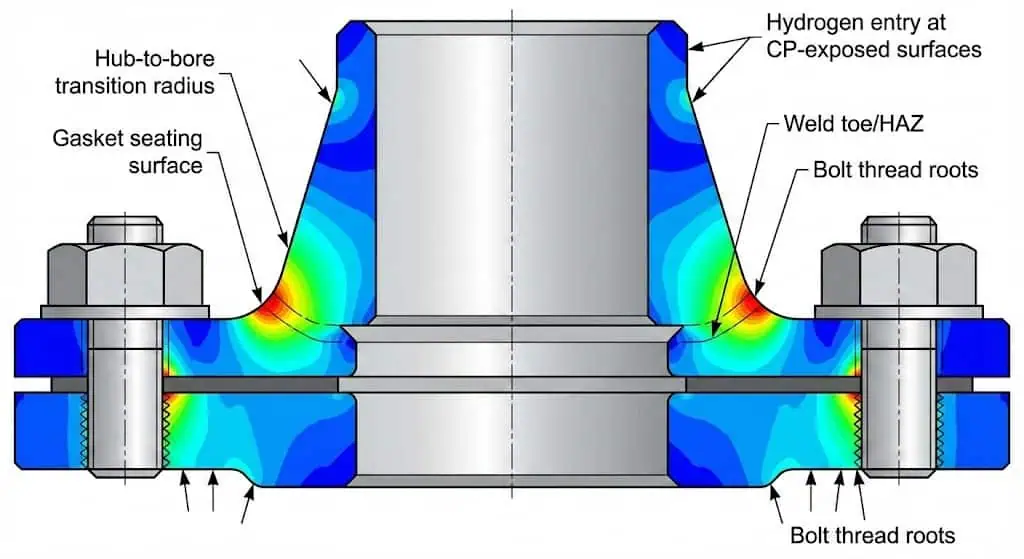

Subsea flanges are vulnerable because they combine CP exposure, complex geometry, and high constraint stresses—often concentrated at the hub/bore transition and weld toes. Several factors increase the probability of HISC initiation:

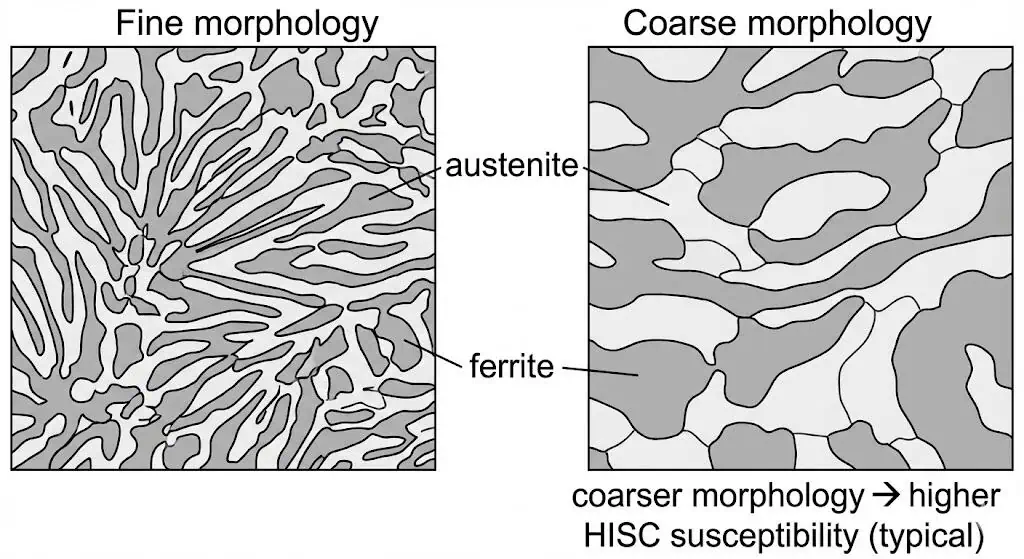

- Duplex and super duplex product forms used in subsea equipment have experienced HISC failures in service; susceptibility correlates strongly with microstructure, particularly austenite spacing and “coarse vs. fine” morphology in highly stressed zones. TWI published paper (HISC in subsea duplex components).

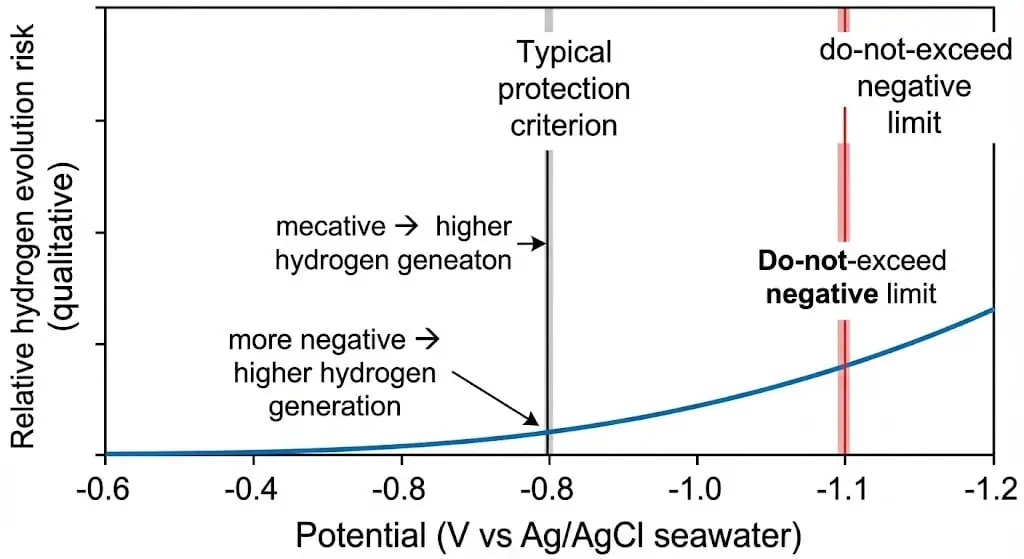

- Cathodic protection can create atomic hydrogen at the metal surface; more negative potentials generally increase hydrogen evolution and raise embrittlement risk for susceptible steels. DNV-RP-B401 (CP design).

- Fasteners and high-strength steel components tied into CP circuits can be vulnerable; hardness/strength limits and material selection matter for subsea bolting and threaded features. ABS Guidance Notes (CP of Offshore Structures, hydrogen considerations).

- Exposed or damaged coatings increase hydrogen access and may create local current density “hot spots” that accelerate hydrogen uptake.

- High tensile stress (bolt preload, bending, thermal gradients, installation misalignment) increases crack initiation probability, especially where geometry creates stress concentration (SCF).

Subsea flanges often operate in extreme conditions: high hydrostatic pressure, cyclic loading, and limited inspectability. When coatings are compromised, CP reactions generate hydrogen that can be absorbed at stressed surfaces. In practice, the highest risk locations are where hydrogen generation and peak tensile stress overlap—for example at hub transitions, bores, weld toes/HAZs, and threaded roots on fasteners.

Engineering example (failure pattern seen in practice): A forged hub or high-pressure weld neck flange can develop an initiating crack at a high-SCF corner or surface imperfection. If initiation occurs under CP exposure, crack growth can be fast enough that “next planned inspection” is not a safe strategy—design must avoid initiation in the first place. Review and data discussion on HISC failures and thresholds (shot peening/forging route effects).

The table below highlights material and stress drivers engineers typically screen when assessing HISC risk. Values and thresholds are project-specific; treat them as a screening framework, not a universal pass/fail rule.

| Property | Effect on HISC Susceptibility |

|---|---|

| Microstructure (coarse vs. fine) | Coarse morphology and unfavorable phase distribution increase susceptibility; fine microstructures generally perform better under CP exposure. Evidence and discussion (TWI). |

| Austenite spacing measurement | HISC susceptibility correlates with austenite spacing, but measurement reproducibility and “what is fine enough” must be agreed and controlled in procurement/QA. Practical limitations noted in published work (TWI). |

| Product form (forging vs. wrought pipe) | Forgings can be more prone than wrought product forms; process route and heat treatment quality materially affect performance. General guidance (ABS). |

| Local tensile stress / plastic strain | High local stress/strain accelerates initiation and growth; the practical target is to keep peak stress below conservative limits using geometry control, fit-up control, and stress-based design methods. |

| CP potential and current density | More negative potentials generally increase hydrogen evolution; operating windows and monitoring are critical, especially for mixed-material subsea assemblies. Potential limits and hydrogen notes (ABS). |

| Weld/HAZ quality (duplex) | Welding can increase susceptibility in weld/HAZ if ferrite balance and heat input are not controlled; procedure qualification and microstructure checks are not optional in critical subsea hardware. Duplex welding susceptibility note (ABS). |

Prevention Importance

Preventing HISC in subsea flanges protects safety, reliability, and project delivery. What makes HISC high-consequence is the combination of (1) brittle behavior, (2) limited visibility subsea, and (3) the fact that “repair” usually means retrieval and replacement. Prevention planning is therefore not a single action; it is a controlled chain across procurement, design verification, fabrication qualification, and CP operations.

Tip: Treat HISC as a controlled risk chain—if you cannot demonstrate control of microstructure, CP window, and local stress/strain, you do not have a defensible prevention strategy.

Prevention Strategies for Subsea Flanges

Material Selection

Material selection is the most effective lever for preventing HISC in subsea flanges—because it sets the baseline resistance before design and operations add risk. For duplex/super duplex stainless steels, “grade name” alone is not enough. Engineers should specify and verify: product form, heat treatment route, microstructure acceptance (including phase balance where applicable), and traceable certification. Where components are exposed to CP subsea, teams commonly align selection and acceptance criteria with DNV-RP-F112 principles (stress-based design + material quality control). DNV-RP-F112 (official overview).

Practical procurement control (what prevents “paper compliance”): Require traceability to heat/lot, verify solution anneal records where applicable, and ensure testing reflects the actual highly stressed region (not only “easy-to-sample” locations). For critical subsea projects, audit readiness depends on documentation completeness and consistency across MTCs, WPS/PQRs, heat treatment records, and inspection reports.

The DNV-RP-F112 standard guides engineers in designing duplex stainless components installed subsea and exposed to cathodic protection. It emphasizes that allowable limits must consider loads, stress factors, geometry hot-spots, and environmental conditions. The table below summarizes how engineers typically apply it on real projects:

| Aspect | Description |

|---|---|

| What it applies to | Duplex stainless components installed subsea and exposed to CP; used to avoid HISC initiation by keeping stress/strain within conservative limits. |

| What engineers actually check | Membrane and membrane+bending stress at hot-spots (hub transitions, bores, weld toes), plus material quality indicators that correlate with HISC performance. |

| Material quality reality | Microstructure matters; procurement must define what is acceptable and how it is measured, otherwise “pass/fail” can be inconsistent across labs. |

| Design requirement implication | Geometry control (radii, transitions, surface finish) and validated load paths are as important as nominal pressure class. |

Note: Audit-ready documentation should allow an independent reviewer to trace material, heat treatment, welding qualification, and inspection results back to each flange/connector. This is a practical requirement on subsea projects, not a marketing preference.

Design for HISC Resistance

Designing flanges to minimize stress concentration—and to avoid local plastic strain in CP-exposed zones—directly reduces HISC initiation risk. In high-pressure flanges, the “average stress” is rarely the problem; the problem is peak tensile stress at geometric transitions and surface discontinuities. Engineers should combine conservative stress-based guidance (for duplex subsea components under CP) with geometry discipline: generous radii, smooth transitions, controlled surface finish, and verified fit-up/alignment.

Key design actions include:

- Use rounded transitions at the hub and bore; avoid sharp corners, undercuts, and abrupt thickness changes that elevate SCF.

- Control stress at weld toes and adjacent HAZ through profile, weld procedure qualification, and realistic bending loads (including installation misalignment cases).

- Specify microstructure acceptance criteria and sampling plans that cover the highest-stress region (not just sacrificial test coupons).

- Apply stress-based design principles aligned to duplex subsea CP exposure guidance, and document assumptions, boundary conditions, and hot-spot extraction logic. Published stress/threshold discussion (TWI).

Engineering case (design hot-spot control): A subsea forging showed repeated crack initiation at a transition corner after CP exposure. Root cause was a combination of (a) high SCF at a tight radius and (b) bolt preload plus bending from installation misalignment. Corrective actions were geometry revision (larger radius + improved surface finish) and qualification by stress-based assessment at the revised hot-spot. The key lesson was that “pressure rating” did not predict hot-spot stress—geometry did.

Tip: If your design review does not include a hot-spot map (where hydrogen + tensile stress overlap), you are guessing. A single “nominal stress” check is not a HISC prevention check.

Cathodic Protection Control

Controlling cathodic protection reduces excessive hydrogen generation and lowers HISC risk in susceptible subsea flange materials. The practical goal is to achieve corrosion control for the overall structure without driving local potentials into an “overprotected” regime where hydrogen evolution accelerates. This requires (1) a defined potential window, (2) measurement points/coupons, and (3) operations discipline—especially on mixed-material assemblies where carbon steel protection requirements can unintentionally overprotect adjacent duplex components.

| Evidence Description | Impact on HISC |

|---|---|

| Typical protection criterion for steels in seawater is around −0.80 V (Ag/AgCl/seawater) or more negative; more negative limits apply for anaerobic conditions. ABS CP guidance. | Defines the baseline window engineers target for corrosion control. |

| Polarized potentials should not be driven excessively negative (e.g., not more negative than about −1.10 V vs Ag/AgCl for many materials) due to increased hydrogen embrittlement risk. ABS CP guidance. | Overprotection increases hydrogen evolution and raises HISC/HE probability at stressed hot-spots. |

Practical steps:

- Define a measurable potential window using a consistent reference electrode (Ag/AgCl/seawater is common offshore) and document any temperature/salinity corrections. Reference electrode and criteria notes (ABS).

- Place test points/coupons where duplex components sit near carbon steel structures; this is where “unintended overprotection” is most likely.

- Monitor CP data trends, not one-off readings; investigate sudden shifts (coating damage, electrical continuity changes, anode depletion, ICCP setting drift).

Engineering case (operations-driven overprotection): A project increased CP output after coating damage on a nearby carbon steel structure. Duplex-adjacent hardware later showed cracking at a stressed transition. Post-event review found potentials had drifted into an overly negative range at the duplex location. The corrective control was not “more inspection”—it was restoring coating integrity and rebalancing CP output to maintain a controlled window at the duplex hot-spot.

Alert: If you cannot measure potential at the duplex hot-spot, you cannot claim you controlled hydrogen generation there.

Coatings and Surface Treatments

Coatings and surface treatments reduce hydrogen ingress risk and can improve resistance by changing the near-surface stress state and hydrogen uptake behavior. In published testing on super duplex materials, controlled shot peening that induces compressive residual stress has been reported to improve the threshold stress to initiate HISC by about 10–15% (typical reported range; performance depends on process control and microstructure). Shot peening/HISC threshold discussion (Rolled Alloys paper).

Other effective treatments and controls engineers use:

- Surface compressive stress methods (shot peening, laser peening) to reduce effective tensile stress at the crack initiation layer. Published data example.

- Coating systems qualified for CP compatibility to reduce local current density spikes and limit hydrogen access; ensure coating selection considers CP-induced disbonding risk. CP and coating interaction notes (ABS).

- Controlled forging/heat treatment routes aimed at improved toughness and higher HISC threshold stress ratios (reported in literature; must be validated per project acceptance and QA). Process route discussion and threshold ratio data.

Engineering case (surface + stress synergy): A high-preload subsea flange joint showed recurring non-conformances at near-surface indications after CP exposure. Corrective action combined (1) improved surface finish specification at a hot-spot transition and (2) compressive surface treatment qualification. The lesson is that “surface condition” is not cosmetic in HISC control—it is part of the stress/hydrogen boundary layer.

Callout: Coatings help only when they stay intact and are compatible with CP. A failed coating can increase local hydrogen uptake risk by creating current density hot-spots at defects.

Welding and Fabrication

Welding and fabrication quality directly affect HISC susceptibility in subsea flanges because the weld/HAZ often becomes both a stress concentrator and a microstructure-sensitive zone. For duplex materials, the objective is controlled heat input and phase balance so the weld metal and HAZ do not become locally brittle or overly ferritic. Guidance documents note that welding may increase HISC susceptibility in duplex weld/HAZ and that ferrite content control is a practical lever. Duplex welding susceptibility and ferrite notes (ABS).

Recommended actions:

- Qualify WPS/PQR for the exact joint configuration and thickness range; do not “port” procedures from less constrained geometries.

- Control heat input and interpass temperature to avoid detrimental phase formation; verify ferrite balance per agreed acceptance method.

- Inspect welds and adjacent HAZ with methods appropriate for defect type (surface-breaking: PT; volumetric: UT/PAUT). Keep acceptance linked to criticality and hot-spot location.

- Manage residual stress: fit-up, alignment, and controlled welding sequence often matter more than “post-event polishing.”

Engineering case (fabrication-driven risk): A subsea connector weld passed volumetric inspection but later cracked near the toe under CP exposure. Root cause was a combination of misalignment-induced bending (raising local tensile stress) and an unfavorable weld toe profile. Corrective action focused on fit-up tolerances, toe geometry control, and hot-spot stress evaluation—not simply increasing inspection frequency.

Tip: If the weld/HAZ sits inside a CP-exposed hot-spot, treat procedure qualification and toe profile control as part of the HISC prevention plan, not as “standard QA.”

Inspection and Monitoring

Inspection and monitoring should be designed to detect early signs and confirm that the prevention controls remain intact—coatings, CP window, and mechanical integrity. Because subsea access is limited, engineers typically combine: (1) front-loaded prevention controls (design/material/qualification), (2) condition monitoring (CP potentials, electrical continuity, anode depletion), and (3) targeted NDT when retrieval or access is feasible.

Inspection checklist (field-practical):

- Coating condition checks (visual where accessible; ROV survey plans where applicable) and defect repair criteria.

- NDT selection aligned to expected cracking location: PT for surface-breaking indications; UT/PAUT for volumetric crack sizing where possible.

- Review CP system data: potentials at defined test points, current outputs, and anomalies tied to coating events or electrical continuity changes.

- Confirm traceability and records consistency: MTCs, WPS/PQR, heat treatment logs, inspection reports, and as-built deviations.

Note: Monitoring is only meaningful when it is tied to an action threshold (e.g., CP potential drift beyond a defined window triggers investigation and correction).

Implementation Checklist

Step-by-Step Actions

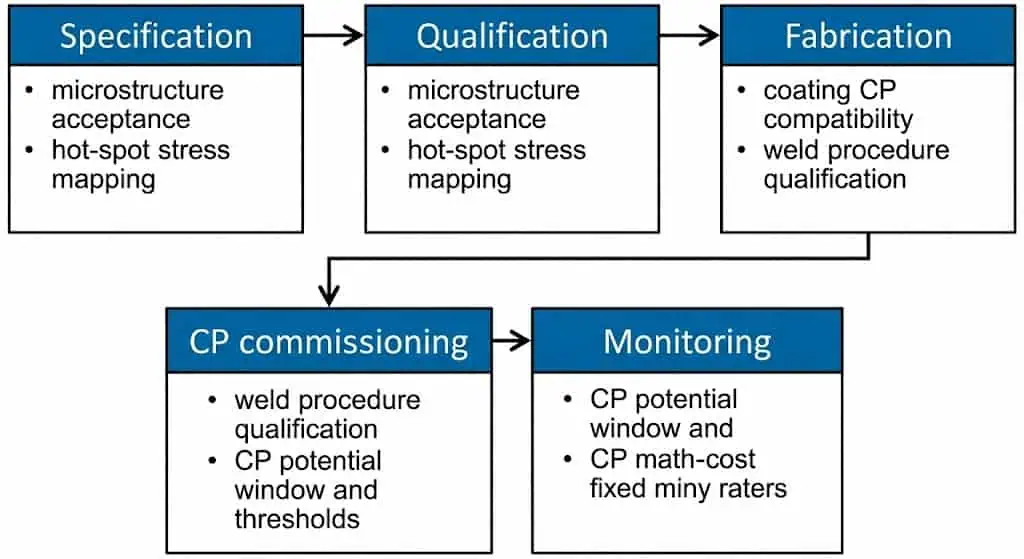

Teams reduce HISC risk in subsea flanges by controlling the full chain: specification → qualification → fabrication → CP operation → monitoring. The following steps are written as an execution checklist rather than general advice.

- Define service conditions and constraints: seawater temperature range, CP philosophy (galvanic vs ICCP), design life, and inspectability limitations.

- Review project requirements and select materials with documented traceability and validated microstructure quality for CP exposure.

- Align duplex subsea design approach with stress-based guidance appropriate for CP exposure; document hot-spots and extraction method. DNV-RP-F112 (overview).

- Map stress risers: hub/bore transitions, gasket seating transitions, weld toes/HAZ, threads/fastener roots; specify geometry controls (radii, finish) in drawings and inspection plans.

- Set a measurable CP potential window and test point plan; define thresholds that trigger investigation (overly negative drift, sudden shifts after coating events). ABS CP guidance.

- Specify coatings and surface treatments for CP compatibility; for high-stress hot-spots, consider surface compressive treatment qualification if supported by project testing. Published data example.

- Qualify welding/fabrication procedures for the exact joint and thickness; include microstructure/ferrite checks for duplex weld/HAZ where critical. ABS duplex notes.

- Execute NDT and dimensional verification at the highest-stress regions (not only “easy access” zones); record as-built deviations that affect stress.

- Commission CP with verification measurements; confirm the duplex hot-spot does not see unintended overprotection due to proximity to carbon steel structures.

- Schedule monitoring and inspection based on risk: CP trends, coating condition, and criticality of the flange/connector location.

Quick HISC risk screen (project tool): Use the table below to prevent common “gaps” between disciplines (design vs CP vs QA). It is not a substitute for stress-based design; it is a practical completeness check.

| Control Item | Pass Criteria (Project-defined) | Evidence to File |

|---|---|---|

| Microstructure quality | Acceptance method + sampling plan agreed; results traceable to part/heat/zone | MTC + microstructure report + sampling sketch |

| Hot-spot stress mapping | Hot-spots identified; stress extraction method documented; design limits applied | Calculation note + FEA report (if used) + assumptions |

| CP potential window | Window defined at duplex hot-spot; thresholds set for action | Commissioning CP log + trend plan + electrode method |

| Coating compatibility | Coating system qualified for CP; defect repair criteria defined | Coating spec + inspection reports + repair log |

| Welding/fabrication control | WPS/PQR qualified; duplex weld/HAZ controls executed | Weld maps + ferrite/microstructure checks + NDT |

Tip: The fastest way to lose control is to treat CP, welding, and flange stress as separate workstreams. HISC lives in the overlap.

Project Documentation

Comprehensive documentation supports HISC prevention and project defensibility. On subsea projects, documentation is not “paperwork”; it is how you prove that the part you installed is the part you designed and qualified.

| Documentation Type | Purpose | Example |

|---|---|---|

| Material Certificates | Verify chemical/mechanical properties and traceability | EN 10204 3.1 MTC + heat/lot trace |

| Design Records | Demonstrate stress-based compliance and hot-spot logic | Stress note + FEA report + assumptions register |

| Welding Logs | Track procedures and qualifications | WPS/PQR, weld maps, welder qualifications |

| Coating & Surface Treatment Reports | Confirm CP compatibility and surface integrity controls | Coating ITP, repair logs, peening qualification (if used) |

| CP Commissioning & Monitoring | Prove controlled CP window and response to drift | Potential logs, current output records, test point layout |

| Inspection Checklists | Ensure repeatable monitoring tied to action thresholds | NDT results, dimensional checks, as-built deviation record |

Note: Audit-ready documentation is how you prevent “unknown unknowns” during retrieval, failure analysis, or regulatory review.

Common Pitfalls to Avoid

Material Selection Errors

Most material selection errors are not “wrong grade”—they are gaps in verification. Common failure-enabling mistakes include accepting duplex/super duplex components without controlling microstructure quality in the highest-stress zone, relying on generic certificates without traceability to the actual part/zone, and ignoring product form differences (forging vs wrought).

- To avoid these errors, teams should:

- Define a microstructure acceptance method and sampling plan that targets the hot-spot region, not only coupon locations.

- Require heat/lot traceability, heat treatment records where applicable, and consistent cross-referencing across MTC, part markings, and inspection reports.

- Confirm material is compatible with CP exposure and subsea constraints; duplex steels are susceptible to HISC under CP even when corrosion resistance is excellent. ABS duplex susceptibility note.

- Document deviations and disposition: “use-as-is” decisions must include stress and CP implications, not only dimensional tolerance checks.

Engineering takeaway: If your acceptance criteria do not control microstructure and hot-spot verification, you will not discover the gap until service—when fixes are most expensive.

Cathodic Overprotection

Overprotection is a system behavior, not a local “mistake.” It often happens when CP is tuned to protect carbon steel structure areas and inadvertently drives nearby duplex/fastener locations into a more negative potential range. This increases hydrogen evolution and raises the likelihood of hydrogen-related cracking at stressed hot-spots. ABS CP guidance on criteria and negative limits.

| Best Practice | Explanation |

|---|---|

| Reference electrode consistency | Use a consistent reference electrode basis (commonly Ag/AgCl/seawater offshore) and document corrections for salinity/temperature where applicable. |

| Test point placement at duplex hot-spots | Measure where risk lives—near duplex flanges/fasteners close to carbon steel CP demand. |

| Action thresholds | Define what potential drift triggers investigation and correction; do not rely on “annual review” alone. |

| Coating repair discipline | Coating damage can increase current demand and cause local potential changes; repair criteria should be part of integrity management. |

| Mixed-material awareness | Duplex components can become collateral exposure under CP designed for carbon steel; design and monitoring must account for this. |

| Documentation | Keep CP commissioning and trend logs; without data, post-event analysis becomes speculation. |

Teams should treat CP settings as a controlled operating envelope, not a “set and forget” configuration.

Inadequate Inspection

Inadequate inspection is usually a planning error: inspecting what is easy, not what is critical. For HISC control, the priority is verifying prevention controls (microstructure, stress hot-spots, CP window, coating integrity) and using targeted NDT where it can actually reduce uncertainty at the hot-spot.

| Aspect | Description |

|---|---|

| Hot-spot targeting | Inspection plans should align to known hot-spots (hub transitions, weld toes, bores, threads), not only accessible surfaces. |

| Method selection | PT for surface-breaking cracks; UT/PAUT for sizing where geometry allows; link acceptance to criticality and location. |

| Trend-based monitoring | Use CP potential trends and coating condition changes as leading indicators that trigger focused inspection. |

| Feedback loop | Integrate findings into design/QA updates; recurring indications usually point to a control gap, not “bad luck.” |

Comprehensive inspection is not “more checks.” It is checks that reduce uncertainty at the hot-spot and confirm your prevention controls are still working.

Neglecting Post-Weld Treatment

For subsea hardware, the core mistake is not “skipping a generic post-weld step”—it is failing to manage weld-driven stress and microstructure in CP-exposed zones. In duplex systems, the relevant controls are procedure qualification, heat input, phase balance, weld toe profile, fit-up/alignment, and hot-spot stress management. Where other alloys or steels are used (fasteners, attachments), hardness/strength compatibility with CP becomes a separate control item. ABS notes on hydrogen considerations for fasteners and steels under CP.

- Verify welding qualification matches actual restraint and thickness (avoid non-representative qualifications).

- Control weld toe geometry and alignment to prevent bending-driven hot-spot stress.

- Record and disposition as-built deviations that change stress paths in service.

Teams that treat welding as a “compliance checkbox” often miss the real driver: weld profile + alignment + CP exposure + stress hot-spot overlap.

Teams prevent HISC in subsea flanges by applying a controlled, auditable approach across materials, stress-based design, CP operation, and integrity management. On well-run projects, the benefits are measurable: fewer unplanned retrievals, lower downtime exposure, and improved integrity confidence on long-life subsea assets. Example discussion on subsea inspection and CP context (FORCE Technology).

- Reduced crack initiation risk through hot-spot stress control

- Lower hydrogen exposure risk through controlled CP window

- Better integrity decision-making through traceable documentation

- More predictable lifecycle cost and fewer emergency interventions

Ongoing vigilance and regular reviews help maintain safety and reliability. Adopting best practices ensures strong performance for subsea flanges in demanding environments.

FAQ

What is the most effective way to prevent HISC in subsea flanges?

Start with material and microstructure control, then keep hydrogen generation and hot-spot stress/strain within a controlled window.

In subsea service under CP, “grade name” alone is not enough. Prevention is strongest when you can demonstrate:

- Traceable material certificates + verified microstructure quality in the hot-spot region

- Stress hot-spot identification (hub transitions, bores, weld toes) with conservative stress-based checks

- CP potential monitoring at the duplex location to avoid unintended overprotection

How often should teams inspect subsea flanges for HISC?

Inspection frequency should be risk-based, not calendar-based.

As a practical baseline, teams commonly combine CP trend monitoring with targeted inspection opportunities (retrieval events, planned interventions, or accessible topside tie-ins). Increase frequency when any of the following occur:

- CP potential drift beyond the defined window at the duplex location

- Coating damage events or electrical continuity changes

- Installation misalignment, abnormal loading, or evidence of bending-driven stress at the joint

Which standards guide HISC prevention in flange design?

DNV-RP-F112 is a key reference for duplex stainless subsea components exposed to cathodic protection.

For flange ratings and dimensional conventions, many projects also reference ASME B16.5 (where applicable) while subsea CP design is typically aligned to CP guidance such as DNV-RP-B401 and offshore CP criteria documents.

| Standard | Focus Area |

|---|---|

| DNV-RP-F112 | Stress-based design approach for duplex subsea components under CP (HISC avoidance) |

| DNV-RP-B401 | Cathodic protection design philosophy and parameters |

| ABS CP Guidance Notes | Operational CP criteria, reference electrodes, negative limits and hydrogen considerations |

| ASME B16.5 | Pipe flange pressure-temperature ratings, dimensions and marking (where relevant) |

Why is cathodic protection control important for HISC prevention?

Because CP can generate the hydrogen that drives HISC.

When potentials become overly negative at susceptible steels, hydrogen evolution increases. Practical controls include:

- Monitor potentials at the duplex hot-spot using a consistent reference electrode basis

- Adjust CP output and repair coatings to reduce current demand and avoid overprotection

- Use action thresholds: “drift triggers correction,” not “drift triggers more inspection later”

What documentation supports HISC prevention in projects?

Audit-ready documentation proves control across material, design, fabrication, and CP operations.

Teams should maintain:

- Material certificates (traceable to heat/lot and part marking)

- Design stress notes / hot-spot mapping records

- Welding logs (WPS/PQR, weld maps, qualifications)

- Coating/surface treatment reports and repair logs

- CP commissioning logs and monitoring trends

What are practical early warning signs that HISC risk is increasing?

Most early warnings are control deviations, not visible cracks.

Watch for:

- CP potential trending more negative than the defined window at the duplex location

- Coating damage, disbonding, or repeated repair events near the flange/connector

- Unexplained changes in electrical continuity or CP current demand

- As-built misalignment or unexpected bending loads identified during commissioning