ANSI flanges (officially governed by ASME B16.5/B16.47) connect pipes, valves, and equipment using a strict grid of dimensions and pressure ratings. These standards prevent mismatched connections that lead to catastrophic leaks. You see their critical role in every high-integrity industry, from 2,500 PSI offshore oil rigs to hygienic food processing lines.

🛡️ Supply Chain Reliability

Sunhy supplies stainless steel flanges built for precision and corrosion resistance. Standardized ANSI flange dimensions offer you:

- Interchangeability: An NPS 4 Class 150 flange from Sunhy will bolt perfectly to an existing pump from 1980.

- Leak-Free Assurance: Precise tolerances on the sealing face (Roughness Ra 3.2-6.3µm) ensure gaskets bite and seal.

- Safety Compliance: Proven pressure retention capabilities under cyclic loading and thermal shock.

You can trust these flanges to fit and perform as needed, provided you verify the material grade against your process temperature.

ANSI Flanges Overview

What Are ANSI Flanges

“ANSI flange” is the industry term for flanges manufacturing to ASME B16.5 (up to 24″) and ASME B16.47 (26″ and above).

While ANSI accredits the standard, ASME defines the engineering rules. These flanges are designed with a specific “safety factor” to withstand pressures well above their rated class during hydro-testing.

Here is a table distinguishing ANSI/ASME flanges from other systems:

| Characteristic | ANSI/ASME Flanges Description |

|---|---|

| Standard Scope | ASME B16.5 (NPS ½ – 24) & ASME B16.47 (NPS 26 – 60). |

| Pressure Classes | Class 150, 300, 400, 600, 900, 1500, 2500. (Note: Not “PN” ratings). |

| Sealing Face | Raised Face (RF), Flat Face (FF), and Ring Type Joint (RTJ) for high pressure. |

| Material Groups | Strict P-T ratings for Material Group 1.1 (Carbon), 2.2 (Stainless), etc. |

| Bolt Pattern | Unique Bolt Circle Diameter (BCD) that does not mate with DIN/EN flanges. |

Role in Piping Systems

ANSI flanges allow for the “Undo Button” in piping: safe disassembly.

Unlike welded joints, flanges allow you to remove valves for service or clean out clogged lines. However, they introduce a potential leak path, so correct assembly (torque sequence) is critical.

- Inspection Access: Essential for inspecting corrosion or erosion in pipe spools.

- Equipment Isolation: Inserting a “Blind Flange” or spectacle blind allows for safe maintenance downstream.

- Modular Upgrades: Swap out a pump or valve without cutting and re-welding pipe.

Importance of Standardization

Standardization prevents catastrophic mismatches.

A Class 300 flange is physically thicker and has a larger bolt circle than a Class 150 flange. This design prevents a technician from accidentally bolting a low-pressure component into a high-pressure line.

Common materials for ansi flanges include:

- ASTM A105 (Carbon Steel): Standard for high-temp piping.

- ASTM A182 F304/F316 (Stainless): For corrosive chemical service.

- ASTM A350 LF2 (Low Temp Carbon): Essential for cryogenic or cold-climate service (<-20°F).

💡 Field Tip: Never mix materials blindly. Bolting Stainless Steel flanges with Carbon Steel bolts can lead to galvanic corrosion and bolt failure.

Types of Flanges

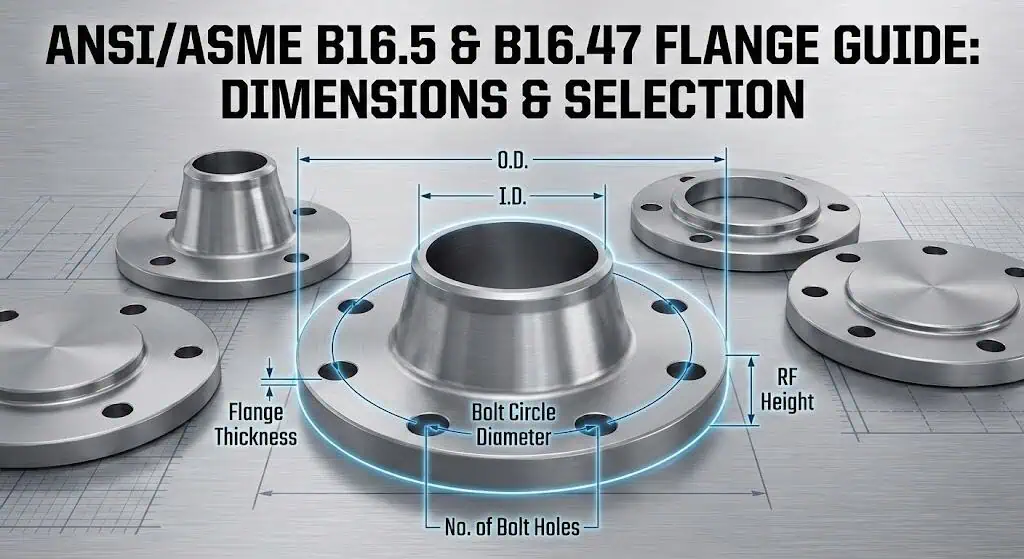

Weld Neck Flanges (WN)

The standard for fatigue resistance and critical service.

Weld Necks feature a tapered hub that transfers stress from the flange to the pipe wall. You MUST specify the Bore Schedule (e.g., Sch 40 or Sch 80) to match the pipe ID. A mismatch creates a turbulence step that accelerates erosion.

Slip-On Flanges (SO)

The economic choice for low-pressure utility lines.

The pipe slides into the flange and is welded both inside and outside.

Engineering Limitation: Their fatigue life is only ~30% of a Weld Neck. Avoid using Slip-Ons in systems with high vibration (like compressor discharge) or severe thermal cycling.

Blind Flanges (BL)

Blind flanges are pressure-retaining plates used to terminate lines.

Because they bear the full system pressure on a flat face, they are subjected to the highest bending stress. Never drill a center hole (e.g., for a gauge) without engineering recalculation, as it weakens the plate significantly.

Socket Weld Flanges (SW)

For small-bore (NPS 2 and under) high-pressure lines.

The pipe inserts into a socket.

🔧 Installation Rule: You must leave a 1/16″ (1.5mm) expansion gap between the pipe end and the socket bottom. Without this gap, thermal expansion will crack the weld.

Threaded Flanges (THD)

Connects via NPT threads; no welding required.

Ideal for explosive environments where welding is prohibited (e.g., gas stations). However, they are prone to leakage in cyclic service as the threads can loosen. Often “seal welded” in critical applications.

Lap Joint Flanges (LJF)

A two-piece system: A Stub End (wetted) and a Backing Flange (loose).

The backing flange rotates freely, making bolt alignment effortless. This is a cost-saver for stainless piping: use a stainless stub end with a cheaper carbon steel backing flange.

Tip: Use Lap Joint flanges in systems that require frequent dismantling for cleaning, like food processing (CIP systems).

Flange Applications and Market Dynamics

| Flange Type | Engineering Strength | Typical Application |

|---|---|---|

| Weld Neck | High Fatigue Resistance | Main Steam Lines, High Pressure Gas |

| Slip-On | Ease of Alignment | Cooling Water, Low Pressure Utility |

| Socket Weld | Leak-Proof Small Bore | Instrumentation Air, Hydraulic Lines |

| Threaded | No Hot Work Required | Fire Protection, Galvanized Piping |

| Blind | Line Termination | Future Expansion Headers, Manways |

| Lap Joint | Rotatable Bolt Holes | SS Piping, Frequent Maintenance Lines |

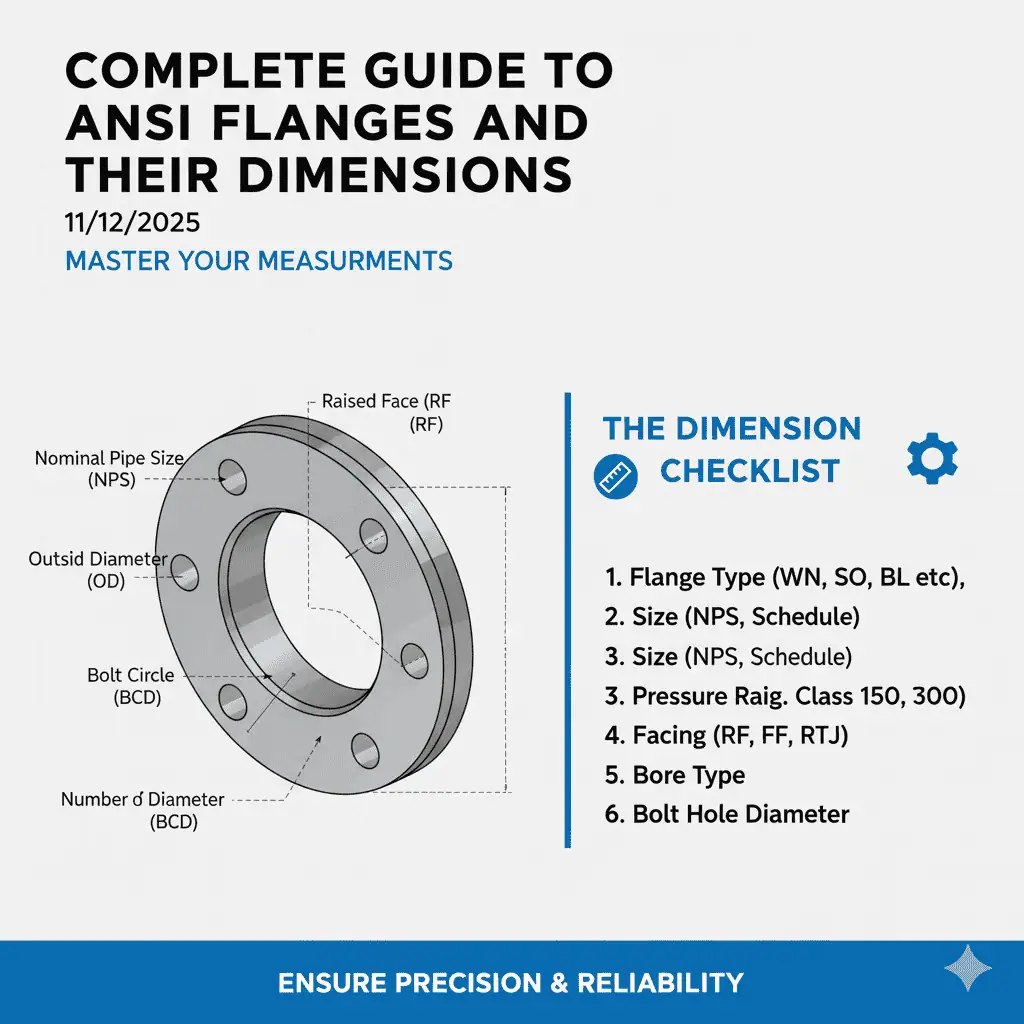

Differences in Flange Dimensions

Dimensions are dictated by Pressure Class, not just pipe size.

An NPS 4 Class 150 flange has an OD of 9.00 inches. An NPS 4 Class 600 flange has an OD of 10.75 inches. They are not interchangeable.

| Parameter | Class 150 (Standard) | Class 300 (Heavy Duty) |

|---|---|---|

| Bolt Circle (NPS 4) | 7.50 inches | 7.88 inches |

| Number of Bolts (NPS 4) | 8 bolts | 8 bolts (Larger diameter) |

| Wall Thickness | Standard | Increased for pressure |

| Compatibility | Mates with Class 150 Only | Mates with Class 300 Only |

You should always verify the Bolt Circle Diameter (BCD) before attempting installation.

ANSI Flange Dimensions Verification

Don’t assume “It fits.” Verify these three dimensions to prevent returns. Sunhy uses automated CMM inspection to guarantee these critical tolerances.

Nominal Pipe Size (NPS) vs O.D.

NPS is a designator, not a direct measurement.

For NPS 14 and larger, NPS equals the Outside Diameter (O.D.). But for NPS 12 and smaller, it does not. For example, an NPS 2 flange fits a pipe with an O.D. of 2.375 inches. The ASME B16.5 standard defines these conversions.

| NPS | Actual Pipe O.D. (inches) |

|---|---|

| NPS 1/2 | 0.840 |

| NPS 2 | 2.375 |

| NPS 12 | 12.750 |

| NPS 14+ | Matches NPS (e.g., NPS 14 = 14.000) |

Tip: Measure the mating pipe OD to confirm the required Flange NPS.

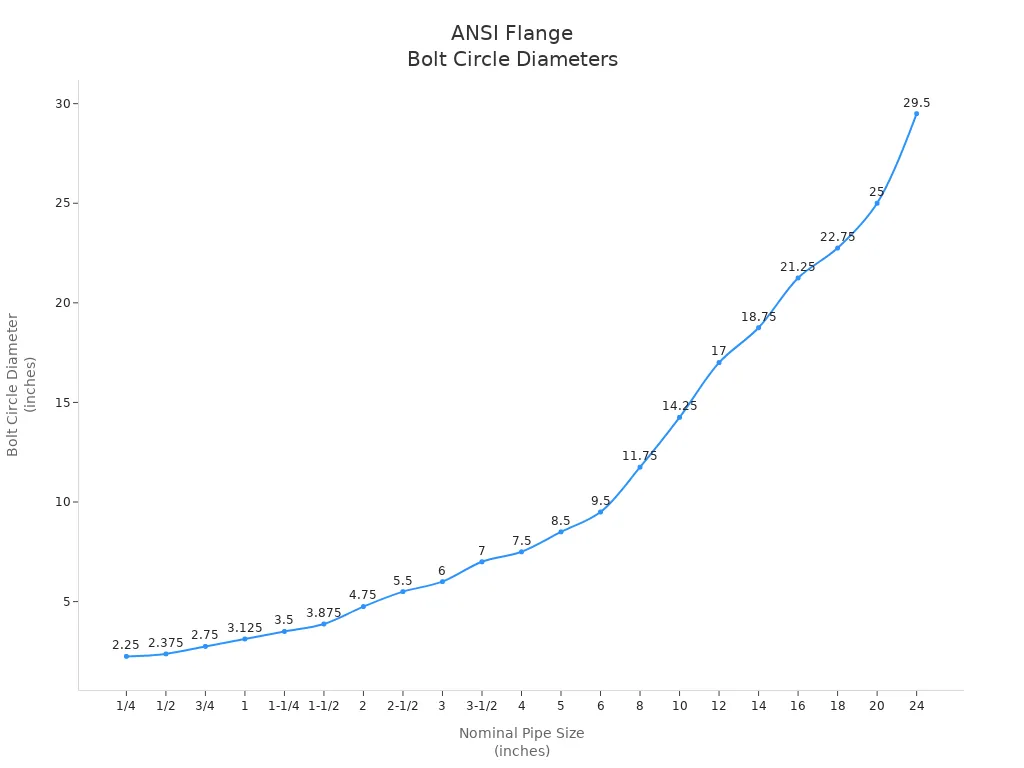

Bolt Circle Diameter (BCD)

The #1 compatibility check.

The bolt circle is the diameter of the circle passing through the center of the bolt holes. If the BCD is off by even 1/8 inch, the bolts will bind. This is the fastest way to distinguish between a Class 150 flange (BCD 7.50″ for NPS 4) and a PN16 flange (BCD 180mm / 7.08″ for DN100). They do not mate.

Inside Diameter (I.D.) & Bore

Matching the Bore Schedule is critical for Weld Necks.

If you order an NPS 4 Class 150 WN flange without specifying the schedule, you might get “Standard” bore. If your pipe is “Schedule 80” (thicker wall), the flange bore will be too large, creating a step that causes turbulence and erosion.

- Weld Neck: Bore must match Pipe ID exactly.

- Slip-On: Bore is slightly larger than Pipe OD to slide over.

- Threaded: Bore matches NPT thread taper.

Bolt Hole Pattern Reference

Standardized patterns prevent rotation errors.

Bolt holes are always drilled in multiples of 4 (4, 8, 12, 16…) and straddle the centerline.

| NPS (Class 150) | Flange OD (in) | No. of Bolts | Bolt Dia. (in) | Bolt Circle (in) |

|---|---|---|---|---|

| 1/2 | 3.50 | 4 | 1/2 | 2.38 |

| 1 | 4.25 | 4 | 1/2 | 3.12 |

| 2 | 6.00 | 4 | 5/8 | 4.75 |

| 4 | 9.00 | 8 | 5/8 | 7.50 |

| 6 | 11.00 | 8 | 3/4 | 9.50 |

| 8 | 13.50 | 8 | 3/4 | 11.75 |

| 12 | 19.00 | 12 | 7/8 | 17.00 |

⚠️ Warning: Verify hole count. NPS 3 Class 150 has 4 holes, but NPS 3 Class 300 has 8 holes.

Flange Face Types & Finish

The face finish must match the gasket.

| Flange Face | Features & Rules |

|---|---|

| Raised Face (RF) | Concentrates bolt load. Use with Spiral Wound gaskets. Standard finish is Serrated (125-250 Ra). |

| Flat Face (FF) | Full face contact. Mandatory for Cast Iron/Plastic/Glass equipment to prevent cracking. |

| Ring Type Joint (RTJ) | Uses a metal ring gasket. Essential for high pressure (Class 900+) to withstand extreme stress. |

💡 Field Tip: Never machine a Raised Face off to make it Flat unless you verify the flange thickness still meets code.

Sunhy’s Precision and Quality Control

Sunhy ensures every flange meets strict dimensional standards. You benefit from:

- High-precision CNC machining to ensure Ra surface finish requirements.

- PMI (Positive Material Identification) to verify alloy composition.

- Compliance with global standards: ASME, ASTM, DIN, EN1092-1, ISO 9001, and PED.

You can trust Sunhy flanges for reliable performance and perfect fit in any piping system.

Flange Dimension Standards

ANSI/ASME B16.5 (NPS ½ to 24)

B16.5 is the “Bible” for standard piping flanges.

It covers pressure-temperature ratings, materials, dimensions, tolerances, marking, testing, and methods of designating openings. If you are working on general process piping, this is your governing document.

ANSI/ASME B16.47 (NPS 26 to 60)

The “Large Diameter” Standard.

Once you exceed 24 inches, you enter B16.47 territory. You MUST choose between two series:

- Series A (MSS SP-44): Heavy duty, larger bolts, thicker ring.

- Series B (API 605): Compact, smaller bolts, thinner ring.

Critical Warning: Series A and Series B have different bolt patterns. They cannot be bolted together.

| Feature | ASME B16.5 (<NPS 26) | ASME B16.47 Series A (≥NPS 26) | ASME B16.47 Series B (≥NPS 26) |

|---|---|---|---|

| Bolt Circle | Standard | Large | Compact |

| Bolt Size | Standard | Large Diameter | Smaller Diameter |

| Compatibility | Universal | Incompatible with B | Incompatible with A |

Note: Always verify the “Series” on existing large-diameter equipment before ordering replacements.

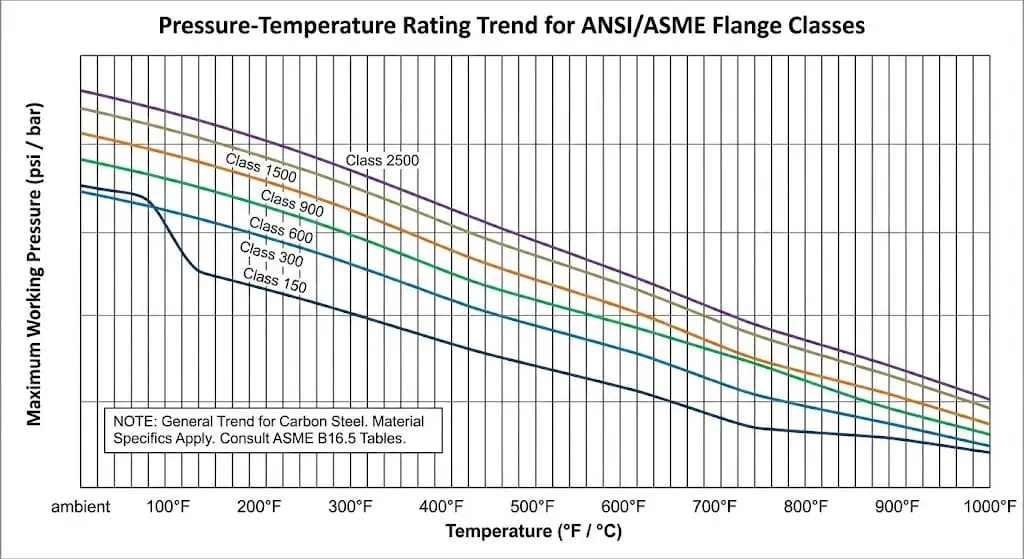

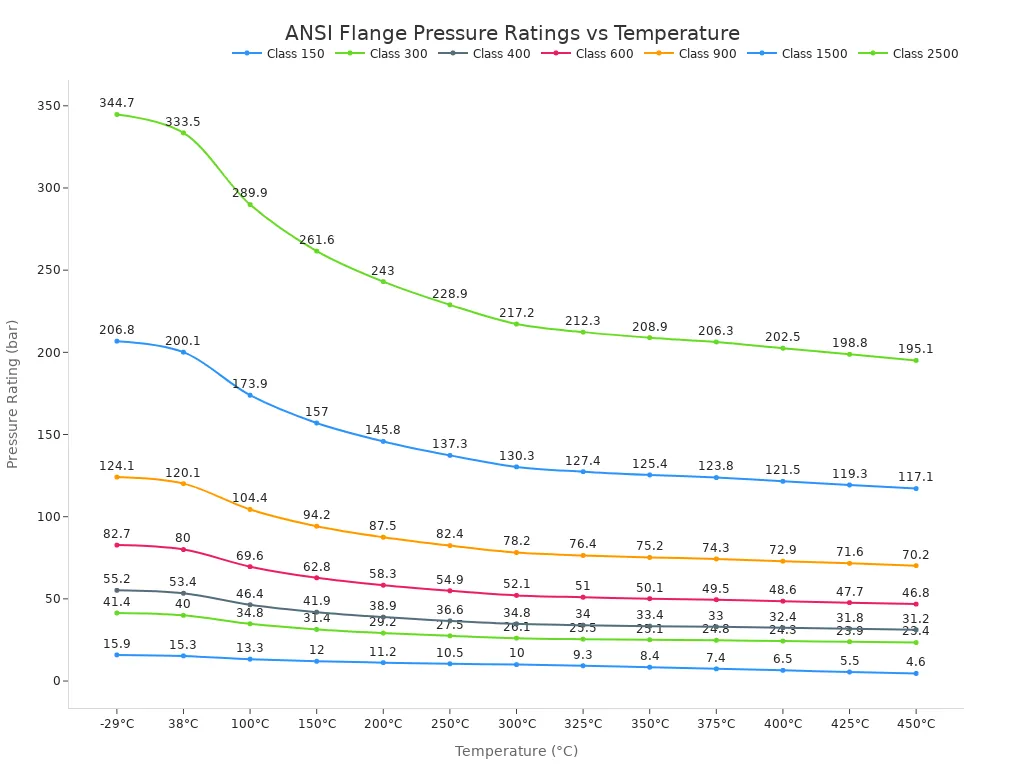

Pressure Classes vs Temperature (Derating)

“Class 150” does NOT mean 150 PSI limit.

A Class 150 flange can handle ~285 PSI at ambient temperature (100°F). However, as temperature rises, the steel weakens, and the rating drops. This is called “Derating”.

| Material Group 1.1 (Carbon Steel) | Class 150 Rating | Class 300 Rating |

|---|---|---|

| 100°F (38°C) | 285 PSI | 740 PSI |

| 400°F (204°C) | 200 PSI | 635 PSI |

| 700°F (371°C) | 110 PSI | 535 PSI |

Tip: Stainless Steel (Group 2.2) loses pressure capability faster than Carbon Steel at intermediate temperatures. Always consult ASME B16.5 Table 2.

How to Order Correctly

Avoid mistakes by specifying all 7 parameters.

Follow this order:

- Size: NPS 4

- Type: Weld Neck

- Class: Class 150

- Face: Raised Face (RF)

- Bore: Schedule 40

- Material: ASTM A105N

- Standard: ASME B16.5

Standardized ordering codes help you get the exact part you need. You can trust ansi flanges to fit, provided the data is correct.

Remember: “Standard” bore is NOT a valid engineering spec. Always state the Schedule.

Flange Connections in Industry

Applications in Oil, Gas, and Chemical

You find ansi flanges handling the world’s most dangerous fluids.

In these industries, leak-free performance is a safety necessity, not just a preference.

- Upstream (Drilling): High pressure RTJ flanges (Class 1500/2500) handle wellhead pressure.

- Midstream (Pipeline): Large diameter B16.47 Series B flanges transport oil/gas across countries.

- Downstream (Refining): Weld Neck flanges handle thermal cycling in cracking units.

Note: The oil and gas sector demands traceability (MTRs) for every flange to prove material grade.

Use in Food Processing and Waterworks

Hygiene and corrosion resistance are key here.

These industries require materials that resist cleaning chemicals (CIP) and rust.

- Food/Pharma: Use Stainless Steel (304/316L) flanges. Often Flat Face to mate with lined equipment.

- Waterworks: Often use Class 150 or AWWA C207 flanges. Flat Face flanges are common to connect to Cast Iron Gate Valves.

| Industry | Material Focus | Key Challenge |

|---|---|---|

| Food Processing | 316L Stainless | Cleanability & Corrosion |

| Waterworks | Carbon Steel / Galvanized | Large Diameter & Cost |

Power Plants and Mechanical Systems

Steam requires handling extreme thermal expansion.

Power plants rely on Chrome-Moly (A182 F11/F22) flanges to withstand high-pressure steam without creeping (stretching) over time.

- Boiler Feed: Heavy wall Weld Necks.

- Cooling Water: Large diameter Slip-Ons or Rubber Lined piping.

Tip: In steam systems, always retorque flanges after the first thermal cycle (Hot Torquing) to prevent leaks.

Selecting ANSI Flanges: The Engineer’s Checklist

Assessing Application Needs

Matching the flange to the “Weakest Link”.

Your flange selection is often dictated by the equipment you are connecting to. If you are connecting to a Pump with a Class 150 Flat Face nozzle, your mating flange MUST be Class 150 Flat Face.

| Factor | Decision Rule |

|---|---|

| Equipment Material | If Cast Iron -> Use Flat Face. If Steel -> Use Raised Face. |

| Vibration? | If High Vibration -> Use Weld Neck. Avoid Slip-On. |

| Erosion Risk? | Match Bore Schedule exactly to avoid turbulence. |

| Space Constraint? | Use Slip-On (shorter hub) if space is tight and pressure allows. |

Tip: Sunhy offers custom machining to modify flange faces for specific equipment needs.

Pressure and Temperature Considerations

Don’t guess. Check the P-T Chart.

A common mistake is assuming a flange is safe because the system pressure is under 150 PSI. You must also check the surge pressure (water hammer) and maximum design temperature.

- Identify Max Design Pressure AND Temperature.

- Check the Material Group P-T Rating in ASME B16.5.

- Safety Rule: Never operate a flange at 100% of its rating. Leave a safety margin (typically 10-15%).

Note: Flanges are often the limiting factor in piping system pressure ratings, not the pipe itself.

Material Selection

Corrosion allowance and cost balance.

Material choice affects longevity. Stainless steel costs more upfront but saves money on replacement labor in corrosive environments.

| Material | ASTM Standard | Best Use Case |

|---|---|---|

| Carbon Steel | A105 / A105N | General Oil, Gas, Water, Steam. |

| Low Temp Carbon | A350 LF2 | Cold environments (Canada/Russia) below -20°F. |

| Stainless 304/316 | A182 F304/F316 | Chemicals, Food, Corrosive Water. |

| Duplex Steel | A182 F51/F53 | Offshore, Desalination (High Chloride resistance). |

Sunhy specializes in stainless steel flanges, providing superior corrosion resistance and precision for critical industries.

Step-by-Step Selection Guide

Follow this sequence to ensure zero errors on your Purchase Order.

- Verify Standard: Is it ASME B16.5, B16.47 Series A, or DIN?

- Check Mating Component: Is it RF or FF? What is the Bolt Circle?

- Determine Bore: Check the pipe wall thickness (Schedule).

- Select Material: Ensure material grade handles the min/max temp.

- Seek expert advice. Contact Sunhy’s technical team for guidance on custom or complex projects.

Sunhy supports industries such as oil and gas, power generation, food processing, and waterworks with standard and custom flanges. You can rely on Sunhy for high-performance solutions and expert support.

Choosing the correct flange dimensions and pressure class is essential for safety and efficiency.

You protect your system from leaks, failures, and downtime by making informed choices. Sunhy’s precision manufacturing and quality control ensure every flange meets strict standards for reliability.

Precise ANSI flange dimensions keep your piping systems safe and efficient.

You gain long-term reliability when you choose high-quality, standardized flanges.

- Eliminate field modifications and installation delays.

- Ensure stable operation in critical industries

- Rely on verifiable material certifications (MTRs)

| Standard | What It Covers |

|---|---|

| ANSI Flange (Trade Name) | Refers to ASME B16.5 compliant products |

| ASME B16.5 | Dimensions and P-T Ratings for NPS ½ to 24 |

| ASME B16.47 | Dimensions for Large Diameter NPS 26 to 60 |

| ASME PCC-1 | Guidelines for Bolting Assembly and Torque |

You should always consult these standards, use dimension tables, and seek expert advice for complex projects. For technical support or custom flange solutions, contact Sunhy.

FAQ

What is the significance of the Outside Diameter (O.D.) in ANSI flanges?

O.D. is the quickest check for pressure class.

A Class 300 flange has a larger O.D. than a Class 150 flange of the same pipe size. Checking O.D. helps you instantly verify if you have the correct pressure rating part in hand.

Which dimensions should you check when selecting an ANSI flange?

You must check NPS, O.D., I.D. (Bore), Bolt Circle (BCD), and Face Type.

The Bolt Circle Diameter is the most critical for fit-up. If the bolts don’t line up, nothing else matters.

| Dimension | Why It Matters |

|---|---|

| NPS | Matches pipe size |

| O.D. | Indicates Pressure Class |

| I.D. (Bore) | Matches Pipe Schedule (Erosion prevention) |

| Bolt Circle | Ensures bolting compatibility |

| Thickness | Mechanical strength |

| Face Type | Gasket Sealing Compatibility |

How do bolt holes affect flange performance?

Bolt hole spacing ensures uniform gasket compression.

ASME B16.5 specifies exact hole patterns to prevent the flange from bowing between bolts, which would cause leaks. Always tighten bolts in a star pattern.

Do ANSI flanges have different pressure ratings?

Yes, Classes 150 to 2500.

Remember that these are “Classes,” not PSI limits. The actual PSI limit changes with temperature and material.

Why should you choose stainless steel flanges for your system?

To prevent downstream contamination and failure.

Carbon steel rusts. In food or water systems, this rust contaminates the product. In chemical systems, corrosion thins the flange until it bursts. Stainless steel solves both.