The main difference between UNC vs UNF threads isn’t just pitch—it’s application. UNC is the global standard for heavy-duty flange bolting, while UNF is the preferred standard for precision hydraulic ports and instrumentation.

Choosing the correct thread type is critical for ensuring safety. A mismatch doesn’t just mean “it won’t fit”—it can lead to stripped threads on expensive valve blocks or catastrophic pressure blowouts. Sunhy’s engineering team breaks down the coarse vs fine pitch debate to help you select the right components:

| Thread Type | Engineering Strength | Primary Sunhy Application |

|---|---|---|

| UNC (Coarse) | High stripping resistance in soft metals; fast assembly | Flange Bolt Kits (Studs & Hex Bolts), Structural Mounting |

| UNF (Fine) | Higher tensile strength; superior vibration resistance | Hydraulic Adapters (SAE ORB), Instrumentation Fittings |

Sunhy supplies both: high-grade stainless steel fittings (UNF) for fluid control and certified bolting kits (UNC) for flange assembly.

UNC vs UNF Fittings Overview

What Are UNC Threads? (The Industrial Workhorse)

UNC (Unified National Coarse) uses a deep, broad thread pitch designed for speed and durability.

You will find that UNC is the default standard for mass-produced fasteners, such as the bolts used to secure ANSI B16.5 flanges. This thread type is part of the Unified Thread Standard (ASME B1.1).

Why Engineers Specify UNC for Flanges:

- Assembly Speed: Fewer threads per inch (TPI) mean faster rundown times during installation.

- Cross-Thread Resistance: The deep thread profile makes it harder to cross-thread, which is vital when handling heavy steel pipes in dirty field conditions.

- Coating Clearance: The coarser pitch allows room for heavy protective coatings (like hot-dip galvanizing) without jamming the nut.

💡 Procurement Tip: When ordering flanges from Sunhy, ask for the matching Bolt Kit. For most ANSI flanges (Class 150-2500), this will be ASTM A193 B7 Stud Bolts with UNC threads.

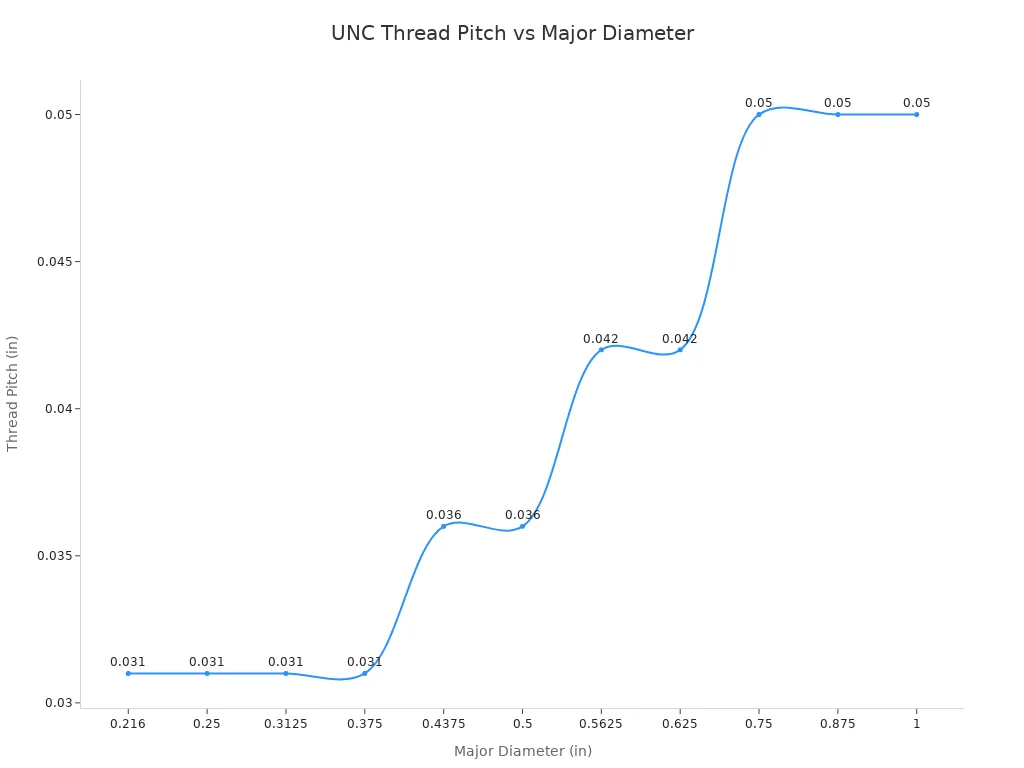

You can see the typical thread dimensions for UNC fittings in the table below:

| Nominal Diameter | Major Diameter (in) | TPI (UNC) | Pitch (in) |

|---|---|---|---|

| 1⁄4″ | 0.25 | 20 | 0.050 |

| 5⁄16″ | 0.3125 | 18 | 0.056 |

| 3⁄8″ | 0.375 | 16 | 0.063 |

| 7⁄16″ | 0.4375 | 14 | 0.071 |

| 1⁄2″ | 0.5 | 13 | 0.077 |

| 5⁄8″ | 0.625 | 11 | 0.091 |

| 3⁄4″ | 0.75 | 10 | 0.100 |

| 1″ | 1 | 8 | 0.125 |

What Are UNF Fittings? (The Hydraulic Standard)

UNF (Unified National Fine) uses a tightly spaced thread pitch for high-pressure sealing and precision adjustment.

In the fluid power world, UNF is synonymous with the SAE J1926 (O-Ring Boss) port standard. Unlike UNC, which is designed to hold things together, UNF in fittings is often designed to facilitate a seal.

Why Hydraulic Systems Use UNF:

- Vibration Resistance: The shallow helix angle (less tilt) prevents the fitting from backing out under pump vibration.

- Increased Tensile Strength: Because the threads are shallower, the bolt/fitting has a larger “root diameter” (more solid metal core), making it stronger in tension.

- Fine Adjustment: Essential for orienting elbow fittings or setting specific torque on O-rings without crushing them.

| Characteristic | Description |

|---|---|

| Thread Pitch | Significantly finer (more threads per inch) than UNC. Example: 1/2″ UNF has 20 threads, UNC has 13. |

| Sealing Method | UNF fittings typically seal via an O-ring, metal-to-metal face, or bonded washer—not by the threads themselves. |

| Standard | SAE J514 (JIC 37°) and SAE J1926 (ORB) utilize UNF threads. |

UNC vs UNF: Key Differences: Deep Dive

Thread Pitch and Profile

The “Finger Test”: UNC feels bumpy; UNF feels smooth.

You will notice the difference immediately. UNC threads have fewer threads per inch, meaning the “valleys” between threads are deeper and wider. UNF threads are crowded closely together. This physical difference dictates their function:

- UNC (Coarse): Deep threads bite better into soft materials like aluminum castings or cast iron flanges without stripping.

- UNF (Fine): Shallow threads require a tapped hole in harder materials (like steel) or a nut, but they offer more contact surface area for load distribution.

| Thread Type | 1/2″ Diameter Example | Key Advantage |

|---|---|---|

| UNC | 13 Threads Per Inch | Fast assembly, durable in dirty environments |

| UNF | 20 Threads Per Inch | Precise torque control, vibration locking |

Application and Strength

UNC is for “Building”; UNF is for “Flowing” and “Precision”.

You will find UNC vs UNF fittings in distinct zones of a plant:

- Choose UNC (Bolts) For:

- Securing ANSI/ASME Flanges (The industry standard bolt).

- General structural steel assembly.

- Situations where rapid disassembly for maintenance is needed.

- Choose UNF (Fittings) For:

- Hydraulic circuits (SAE Ports).

- Instrumentation lines requiring fine calibration.

- High-vibration machinery (pumps, engines, turbines).

- Aerospace and automotive precision assemblies.

⚠️ Warning: Never use a UNC bolt in a hydraulic port designated for UNF. It will cross-thread immediately and destroy the port, leading to costly equipment housing replacement.

Identification and Interchangeability

They are 100% Non-Interchangeable.

A 1/2″-13 UNC bolt cannot screw into a 1/2″-20 UNF nut. They will jam after less than one turn.

Important engineering note for Fluid Systems: UNC/UNF are “Straight Threads.” They do not seal by tightening the threads alone (unlike NPT tapered threads).

• If you use a UNF fitting (SAE ORB), it needs an O-Ring.

• If you use a UNC bolt for a sealing cover, it needs a Gasket under the head.

Field Identification Guide

Lost the spec sheet? Here is how to identify your thread in the field.

Correct identification ensures you order the right replacement part from Sunhy.

Step-by-Step Identification Process

- Clean the Threads: Remove grease and dirt. Old thread sealant can look like thread teeth.

- Measure Diameter: Use calipers to measure the O.D. (Major Diameter).

- Example: If it measures ~0.49″, it is likely a 1/2″ nominal size.

- Count the Threads (The TPI Check):

- Use a thread pitch gauge (best method).

- Or, place a ruler against the threads. Count how many threads sit within 1 inch.

- Comparison: If you count 13 threads in an inch (for 1/2″ dia), it is UNC. If you count 20, it is UNF.

Common Identification Errors

- Confusing 1-inch sizes:

Watch out for the 1-inch diameter. Standard UNC is 1″-8. Standard UNF is 1″-12. However, there is a special 1″-14 UNS thread often used in hydraulics. Always measure carefully on large fittings. - Ignoring Thread Class (2A vs 2B):

Fasteners come in classes (1A/B loose, 2A/B standard, 3A/B tight). For standard industrial use, Sunhy supplies Class 2A (External) / 2B (Internal).

Choosing the Right Fitting & Fastener

Selection Matrix

Use this logic to decide between UNC and UNF for your BOM (Bill of Materials).

| Scenario | Best Choice | Reasoning |

|---|---|---|

| Bolting a Flange | UNC | Standard for ANSI flanges; quick assembly; easy to remove even if slightly corroded. |

| Hydraulic Port | UNF | Standard for SAE ports; allows O-ring sealing; resists vibration loosening. |

| High Vibration Motor | UNF | Fine threads have a lower helix angle, creating a self-locking effect. |

| Aluminum/Cast Iron Housing | UNC | Coarse threads are deeper and won’t strip out the soft metal housing. |

Sunhy: Your One-Stop Source

Why buy flanges from one vendor and bolts from another?

Sunhy simplifies your procurement by supplying the complete assembly.

- For Pipeline Projects: We supply the Flanges + Gaskets + UNC Bolt Kits (Studs & Nuts).

- For Instrumentation: We supply UNF Adapters, Tube Fittings, and Valves.

Benefit: Sunhy ensures material compatibility. If you order 316L Stainless Flanges, we automatically recommend B8M Class 2 Stainless Bolts (UNC) to prevent galvanic corrosion.

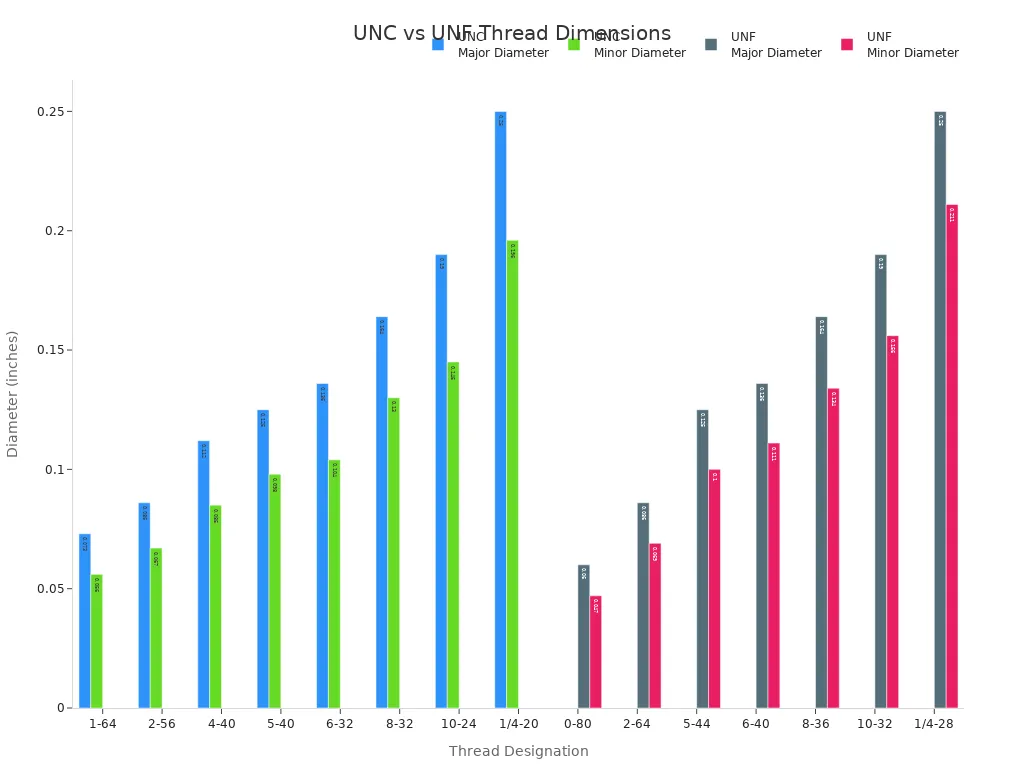

Reference Data: UNC vs UNF Dimensions

Common Size Chart (TPI Reference)

Keep this chart handy for field verification.

| Nominal Diameter | UNC (Coarse) TPI | UNF (Fine) TPI |

|---|---|---|

| 1/4″ | 20 | 28 |

| 5/16″ | 18 | 24 |

| 3/8″ | 16 | 24 |

| 7/16″ | 14 | 20 |

| 1/2″ | 13 | 20 |

| 5/8″ | 11 | 18 |

| 3/4″ | 10 | 16 |

| 7/8″ | 9 | 14 |

| 1″ | 8 | 12 |

FAQ

What is the main difference between UNC and UNF threads?

Pitch and Application. UNC has fewer threads per inch and is the standard for fastening flanges and structures. UNF has more threads per inch, offering higher strength and vibration resistance, making it the standard for hydraulic ports and precision machinery.

Can you use UNC bolts in a UNF hole?

No. The threads will not mesh. Forcing them will strip the threads instantly. Always use a thread gauge to verify TPI (Threads Per Inch) before installation.

Are flange bolts always UNC?

Mostly, but not always. For diameters 1 inch and smaller, standard flange bolts are UNC. However, per ASME B1.1, sizes above 1 inch often switch to the 8-UN series (8 threads per inch constant pitch), not standard UNC. Sunhy ensures you get the correct pitch for your specific flange size.

Why buy bolt kits from Sunhy?

Convenience and Quality Assurance. When you buy flanges and bolts together from Sunhy, we guarantee material compatibility (e.g., matching A193 B7 bolts with A105 flanges) and correct dimensions, saving you procurement time and reducing field errors.

Conclusion

The difference between UNC vs UNF threads defines the safety of your system. UNC threads are the industry standard for heavy-duty flange bolting due to their durability and ease of assembly, while UNF threads are essential for hydraulic connections that demand high tensile strength and vibration resistance.

Don’t risk system failure with incorrect substitutions. Whether you need rugged UNC studs for a pipeline or precise UNF adapters for a hydraulic circuit, Sunhy provides certified stainless steel solutions tailored to your specific engineering requirements.