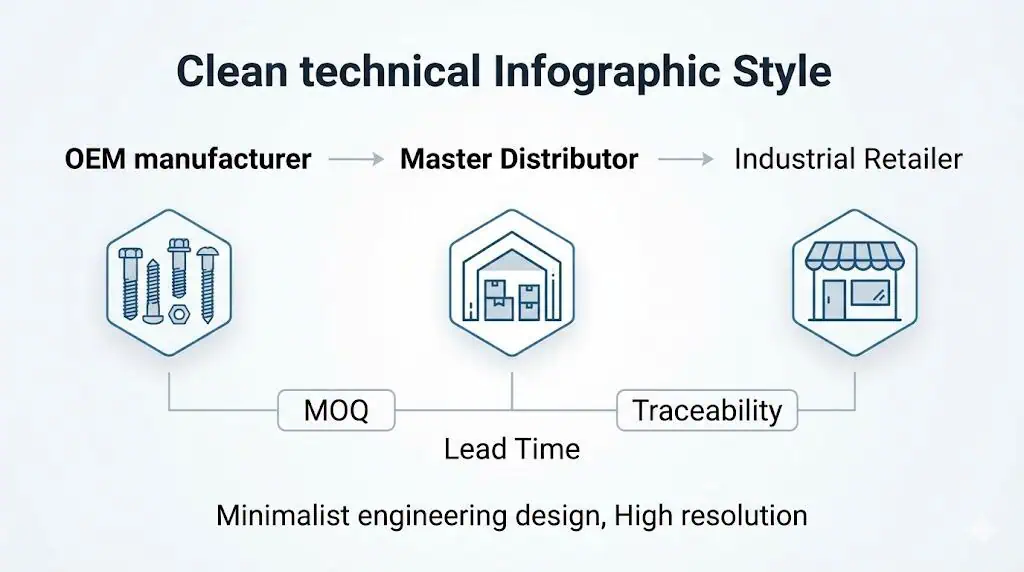

Where to Buy Screws in Bulk? If you buy fasteners like you buy office supplies, you’ll eventually pay for it on the shop floor. A missing screw can stop a line, but a wrong-grade screw can crack a housing, shear in service, or lose clamp load and walk out under vibration. Industrial sourcing usually falls into three lanes: OEM Manufacturers, Master Distributors, and Industrial Retailers—each with different cost, lead-time, and traceability trade-offs.

For procurement officers and project engineers, the job isn’t “find a vendor.” The job is verifying a supply chain that protects mechanical integrity. A simple M12 fastener can become the failure point of a million-dollar machine if the preload is wrong, the heat treatment is off, or the coating process injects hydrogen. Your audit should include compliance to ISO 898-1 (mechanical properties for carbon/alloy steel fasteners), documented lot traceability (Mill Certificates / MTR), and process controls for risks like hydrogen embrittlement and torque scatter. This guide breaks down the sourcing landscape so you can make decisions based on data, not quotes.

Where to Buy Screws: Top Industrial Suppliers

Fast answer (for engineers): Choose the supplier tier based on volume, lead time, and how much control you need over material, process, and documentation. If your joint is safety- or warranty-critical, prioritise traceability, stable friction performance, and verified mechanical properties over piece price—because torque without a controlled friction window is just a guess.

The “best” supplier depends on your volume, lead-time requirements, and engineering customisation needs. Below is a practical breakdown of the common sourcing routes:

- Sunhy (OEM Manufacturer): Best for High-Volume & Custom OEM.

Sunhy operates as a direct manufacturer specialising in Cold Heading, thread rolling, and CNC turning. The value is process control: head forming, thread geometry, heat treatment, and final inspection sit under one roof, so you can lock down mechanical requirements (property class per ISO 898-1), coating specs, and inspection frequency. This model fits automotive, appliance, industrial equipment, and other OEMs where annual usage exceeds 50,000 pieces per SKU and PPAP documentation is required (commonly Level 3, with capability expectations such as Cpk > 1.33 on critical dimensions like pitch diameter and head height). - Fastenal (Logistics Partner): Best for VMI (Vendor Managed Inventory).

Fastenal’s core advantage is logistics and replenishment. Their VMI programmes reduce “C-part chaos” by keeping bins stocked on the shop floor so you don’t go line-down over a missing $0.05 screw. Engineering caution: for load-bearing joints, treat VMI as a delivery method—not a substitute for specs. You still need grade verification, lot control, and certificates for critical parts. - Grainger (MRO Giant): Best for Facility Maintenance.

Grainger is built for urgent MRO needs. If a conveyor guard breaks and you need fasteners tomorrow, their distribution footprint is hard to beat. The trade-off is piece price, and you must validate grade: “bin stock” is often fine for non-critical repairs but may not carry the documentation trail you need for structural, pressure, or fatigue-sensitive applications. - McMaster-Carr (Engineering Resource): Best for R&D & Prototyping.

McMaster is the fastest way for engineers to prototype and de-risk designs because the catalogue data is clean, the SKU info is detailed, and CAD models are easy to pull. For production purchasing, the economics usually don’t work—and engineering teams should avoid copying prototype part numbers directly into mass-production BOMs without a sourcing review. - Fastener Superstore: Best for Mid-Volume Bridge.

This category works when you need “box quantities” (often 500–5,000 pcs) across multiple SKUs. It’s a practical bridge when you are not ready for OEM MOQs but still need consistency beyond consumer retail.

Understanding the Supply Tiers

Quick Guide to Industrial Fastener Sourcing Channels:

- Tier 1: Direct Manufacturers (OEM): Lowest piece price at volume, but higher MOQs (often 10,000+ per SKU or by weight such as 500 kg+). This is the only channel that reliably supports custom alloys (Inconel 718, Monel), non-standard geometry, controlled friction/top-coat systems, and full heat-lot traceability. It is also where you can demand process controls like hydrogen embrittlement prevention and consistent thread rolling rather than cut threads.

- Tier 2: Master Distributors: They buy in container loads and break down to pallet/box quantities. You get moderate pricing, quicker availability on standard DIN/ANSI sizes, and a buffer against market swings. Engineering reality: documentation varies by SKU—ask what comes with EN 10204 3.1 material certification versus “commercial certs” only.

- Tier 3: Industrial Retailers: Convenience and speed. Highest piece price, usually no MOQ, and ideal for unplanned downtime. Treat this channel as “get the line running,” then backfill with engineered supply once the emergency ends.

Leading Online Retailers (MRO & Small Batch)

Where to Buy Screws online for prototyping and emergency maintenance? For down-line situations, online industrial catalogues beat waiting on production. The pitfall is assuming retail fasteners meet structural grades. If the part carries load, verify whether it ships with EN 10204 3.1 Material Certificates or a proper MTR. Without that trail, chemistry and heat treatment are effectively unverified, and your torque spec may not deliver the intended preload.

Shop-floor checklist (60 seconds): confirm standard + grade, confirm thread pitch (Metric coarse vs fine / UNC vs UNF), confirm finish and coating thickness range, and confirm documentation (3.1 / MTR). If any of those are unknown, treat the purchase as non-critical or temporary.

| Retailer | Core Strength | Engineering Value & Risks |

|---|---|---|

| Lowe’s / Home Depot | Immediate retail availability | Risk: Commonly consumer-grade inventory (often equivalent to lower property classes), limited lot traceability, and inconsistent certification. Use for non-critical fixtures; avoid for structural joints, rotating equipment, or anything exposed to vibration/fatigue. |

| Fastenal | VMI (Vendor Managed Inventory) | Value: Local branch support + on-site bin stocking reduces stockouts and admin burden. Engineering check: confirm what SKUs include certificates and whether lots remain segregated in VMI bins. |

| Grainger | Facility Maintenance | Value: Broad SKU coverage and fast fulfilment for MRO. Risk: higher piece price; grade/cert availability varies—verify before using in load-bearing joints. |

| McMaster-Carr | R&D & Prototyping | Gold Standard: Strong product data and CAD models for fast design integration. Risk: pricing often unsuitable for mass production; don’t copy prototype sourcing into production without reviewing grade, coating, and documentation. |

[Engineering Warning]

Retail “bin stock” often lacks heat-lot traceability. For structural steel joints, rotating assemblies, or pressure-related applications, do not rely on general hardware stores. Demand MTRs and confirm the standard callout, mechanical property class (e.g., per ISO 898-1), and process controls—especially if the fastener is plated and high strength (hydrogen embrittlement risk).

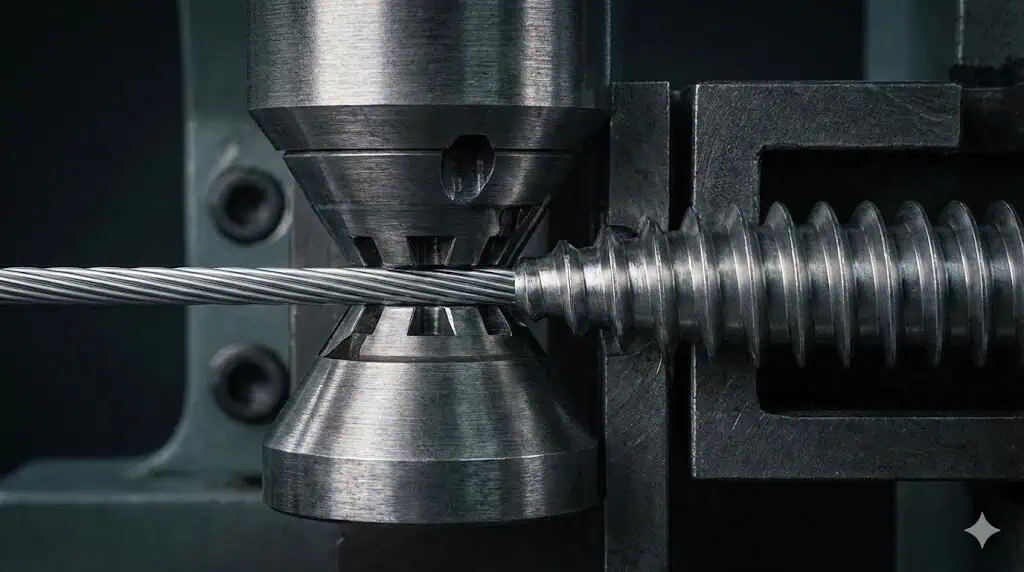

Reputable Manufacturers (OEM & High Volume)

Where to Buy Screws for assembly lines? Once annual usage exceeds ~50,000 pieces per SKU, buying direct from a cold-heading manufacturer becomes the practical route for both cost and consistency. Direct manufacturers control head forming, thread rolling, heat treatment, and the critical post-plating controls that protect high-strength fasteners from delayed hydrogen cracking. For higher property classes (10.9 / 12.9), de-embrittlement baking is not a “nice extra”—it is often the difference between a stable joint and a bolt snapping hours after installation.

Typical de-embrittlement bake windows used in industry: 200–230°C for 4–24 hours, started as soon as possible after electroplating (often within 1–4 hours). The exact requirement depends on hardness/strength class, plating process, and customer specification. If a supplier can’t explain their bake timing and oven control, treat high-strength plated fasteners as high risk.

Working with a manufacturer allows deep technical collaboration:

- Custom Engineering: Modify head styles (add flange to eliminate washers), set thread lengths for correct engagement (avoid bottoming), and select drive types (e.g., 6-Lobe Torx) for automated feeding and higher torque transmission. Small geometry details like chamfer and under-head bearing face flatness directly influence seating and clamp load repeatability.

- Strict PPAP Control: Capability to provide Level 3 PPAP documentation and control plans for automotive clients, with process stability targets (commonly Cpk > 1.33) on critical dimensions and mechanical properties.

- Price Stability: Blanket orders with 12–24 month pricing models, aligning wire purchasing and production scheduling to reduce volatility and avoid “spot-buy surprises.”

Specialized Distributors

Where to Buy Screws for mixed SKUs (Kitting)? Specialised distributors earn their margin when you need 30–100 part numbers in moderate quantities (kitting for furniture, electronics, service packs). “Bag & Tag” services—mixing screws, hex keys, nuts, and washers into a single kit—simplify end-user assembly. The trade-off is unit cost, and you must still control grade and lot segregation if the kit contains load-bearing fasteners.

Evaluating Bulk Fastener Suppliers

Fast answer (audit mindset): Evaluate suppliers the way you evaluate a critical process: confirm the standard callout, verify mechanical properties, confirm traceability, and verify how they control friction and hydrogen risk. If your assembly uses torque control, demand a defined friction window (K-factor) and consistent coating/lubrication—otherwise your clamp load scatter will eat reliability.

Technical Selection Criteria: It’s All in the Details

What technical parameters define a competent supplier?

Beyond price, a supplier must demonstrate control of Torque-Tension relationships. In DC electric nutrunners, friction is the hidden variable. If plating thickness varies or lubricant/topcoat is inconsistent, the same torque setting can deliver wildly different clamp loads. That leads to two ugly outcomes: bolt fatigue if preload is too high (you’re running closer to yield), or vibration loosening if preload is too low.

Practical engineering numbers: many production lines work with K-factor targets roughly in the 0.12–0.20 range for controlled/lubricated assemblies, while dry or poorly controlled surfaces can drift to 0.20–0.35. That swing is enough to turn a “pass” torque into a “fail” clamp load. If preload is critical, request a torque-tension validation report (commonly based on ISO methods) and lock down coating + lubrication as part of the drawing/spec.

Engineering Case Study: The “Torque Was Right” Failure (K-Factor Drift)

The Incident: A line assembling gearboxes reported loosening after vibration testing even though every fastener was torqued to spec. The Investigation: the supplier switched topcoat batches; coating thickness stayed within cosmetic limits, but friction shifted. Result: clamp load dropped, joint slip increased, and loosening followed. The Fix: define a friction/K-factor window in the spec, require consistent topcoat/lube, and validate torque-tension at receiving. The torque value didn’t change—the surface condition did.

Material & Grade Selection Guide (Engineering Data)

Selecting the wrong grade is a fast route to catastrophic failure. Engineers balance tensile strength against ductility and service environment. Higher strength is not automatically better; very high-strength fasteners carry higher hydrogen embrittlement sensitivity and can be less forgiving under shock or poor seating.

| Grade / Material | Yield Strength (Min MPa) | Tensile Strength (Min MPa) | Typical Application & Engineering Notes |

|---|---|---|---|

| Grade 8.8 (Medium Carbon Steel) | 640 MPa | 800 MPa | The “workhorse” class for machinery and general structural joints. Quenched and tempered. Good balance of strength and ductility. Commonly referenced under ISO 898-1 (metric property classes). Approx. equivalent performance band to SAE Grade 5. |

| Grade 10.9 (Alloy Steel) | 900 MPa | 1000 MPa | Used in high-stress joints (automotive chassis, drivetrain, clamping under cyclic loads). Risk: higher sensitivity to hydrogen embrittlement when electroplated; requires strict cleaning/plating/baking controls and lot discipline. Approx. equivalent performance band to SAE Grade 8. |

| A2-70 (304 Stainless) | 450 MPa | 700 MPa | Good corrosion resistance for general outdoor service and food processing. Lower strength than alloy steel; watch preload limits. Can become slightly magnetic after cold work (normal austenite transformation behaviour, not a “fake stainless” indicator). |

| A4-80 (316 Stainless) | 600 MPa | 800 MPa | Preferred in marine/coastal air and chemical exposure where chloride pitting is a concern. Molybdenum improves resistance to pitting/crevice attack. Engineering note: stainless joints also require galling control (anti-seize + controlled RPM). |

Pricing Structure: Cold Heading vs. Machining

Understanding the economics of bulk screws.

Pricing is driven by manufacturing method, coating system, and how much documentation you are buying along with the part. Ask which process the supplier is actually using and whether threads are rolled or cut.

- Cold Heading (The Standard for Bulk): Coil-fed wire, cut slug, head formed by dies. Extremely fast, minimal scrap, and ideal for rolled threads. Tooling is expensive, which drives MOQs. Engineering benefit: consistent head geometry and work-hardened surfaces help fatigue performance and repeatability.

- CNC Machining (For Precision/Low Vol): Bar stock is cut into shape. Great for small batches, odd geometries, and prototype changes. It is slower and wastes material as chips (often a large fraction of input). Engineering caution: cut threads reduce fatigue strength compared with rolled threads; specify rolled threads where the joint is cyclic or safety-critical.

| Pricing Factor | Engineering Impact |

|---|---|

| MOQ (Min Order Qty) | Amortises heading dies and rolling plates. Higher volume lowers unit cost and improves lot-to-lot stability because you avoid “too many small runs” with frequent setup variation. |

| Raw Material (Wire) | Wire cost changes with steel indices and alloy surcharges (10B21, SCM435, 304/316). A competent supplier is transparent about wire grade, heat-lot control, and substitution rules (what can and cannot be changed). |

| Surface Treatment | Finishes change corrosion behaviour and friction. Typical ranges: electro-zinc is often around 5–12 μm on many specs; zinc flake systems commonly target roughly 8–15 μm depending on build; hot-dip galvanising can run much thicker (often 40–80 μm), which can require oversize tapped nuts to avoid thread interference. Coating selection should be tied to service environment and required friction window. |

Logistics: Delivery and Lead Times

Managing Lead Times in Global Supply Chains.

Ocean freight from Asia to the US/EU commonly runs 30–45 days port-to-port, plus customs and inland handling. Manufacturing lead time depends on complexity: many standard screws can run ~30 days; custom parts with heat treatment, controlled topcoats, or patch locking often run 60+ days. If your project is time-sensitive, ask about partial shipments and safety stock strategies.

When discussing logistics, clarify the Incoterms:

- EXW (Ex Works): You pick up from their factory. Maximum control, maximum coordination burden.

- FOB (Free On Board): Supplier handles export customs and loading. You manage the ocean freight. Common for industrial sourcing.

- DDP (Delivered Duty Paid): Supplier delivers to your door including duties/tariffs. Lowest workload for the buyer; pricing often includes a service premium.

Engineering Guide for Procurement

Fast answer (print-first buying): The drawing is the contract. If the print doesn’t define the standard, grade, pitch, finish, and thread fit, you will get “interpretations” across suppliers. That turns into mismatched pitch, thread interference after coating, torque scatter, and expensive rework. Lock down the callout, then lock down inspection and documentation.

Define Your Specs: The Print Matters

Ambiguity creates failures. When ordering, use standard designations and the callout system to define exactly what you need:

- Standard: e.g., “DIN 933” (Hex Head Cap Screw, Full Thread) vs “DIN 931” (Partial Thread). Unthreaded shank length matters in shear joints because you want the shear plane on the shank, not on the threads where shear stress concentrates.

- Material Class: e.g., “Class 8.8 / 10.9” for steel (per ISO 898-1) or “A2-70 / A4-80” for stainless. Avoid mixing metric “property class” language with inch “Grade” language on the same print unless you explicitly define equivalency and test methods.

- Surface Finish: e.g., “Zinc Plated, Trivalent Chromate (Cr3+), 8 μm min thickness”. If the finish is functional (corrosion + friction), define it as a system: coating + topcoat + lubricant, and define a friction window for torque-controlled assembly where necessary.

- Thread Fit: e.g., “6g” (external metric) or “2A” (inch). For thick coatings like hot dip galvanising, specify whether mating threads require oversize tapping to accommodate coating build-up. If you skip this, threads can bind, and installers will “solve” it by over-torquing—destroying preload control.

5 Common Procurement Pitfalls to Avoid

Even seasoned buyers get caught when moving into global sourcing. These five traps show up repeatedly in failure analysis:

- Thread Pitch Confusion: Ordering M10 without specifying pitch. Standard is 1.5 mm but fine pitch like 1.25 mm is common. Mismatched pitch strips immediately and damages the tapped hole. Fine pitch can resist loosening better, but it cross-threads easier and is less forgiving on dirty lines.

- Ignoring Plating Thickness: Thick coatings can create thread interference. Hot dip galvanised builds can exceed 40 μm and often require oversize tapped nuts. If you do not specify fit and coating system together, parts will “not assemble,” and people will force them—guaranteed scrap.

- The “Stainless” Myth: Assuming all stainless steel is non-magnetic. Cold-worked 304 can become slightly magnetic due to austenite transforming under deformation. That does not automatically indicate poor quality; chemistry and certification do.

- Grade Substitution: Replacing 10.9 with 8.8 to save cost reduces allowable preload, increases joint slip, and accelerates loosening under vibration. Going the other way can be worse: dropping 12.9 into a plated system without controlled hydrogen prevention is a recipe for delayed cracking.

- Incomplete Thread Spec: Failing to define full vs partial thread can cause bottoming in tapped holes. If the unthreaded shank enters a short thread depth, the bolt can “feel tight” while delivering near-zero clamp load.

Quality Assurance: Beyond the Visual

Visual inspection doesn’t catch heat treatment errors, hydrogen risk, or thread geometry problems. Robust QA uses both destructive and non-destructive checks. Strong suppliers either run an accredited lab or partner with one (ISO 17025 is the standard benchmark for testing competence). At minimum, confirm they can run:

| Test Method | Purpose |

|---|---|

| Tensile Test / Wedge Loading | Verifies the screw meets rated load and checks head integrity. Wedge tests are useful for confirming head ductility and detecting brittle head failures that visual checks miss. |

| Salt Spray Test (ASTM B117) | Compares corrosion protection systems by hours-to-corrosion onset (white rust vs red rust). Treat this as screening, not a real-life service-life guarantee. |

| Ring & Plug Gauging | Go/No-Go thread gauging confirms pitch diameter and functional fit. This matters more than “OD looks fine,” especially after coating build-up. |

| Vickers/Rockwell Hardness Test | Confirms heat treatment results. Too soft can strip under preload; too hard increases brittleness and hydrogen sensitivity. Use hardness alongside tensile results, not alone. |

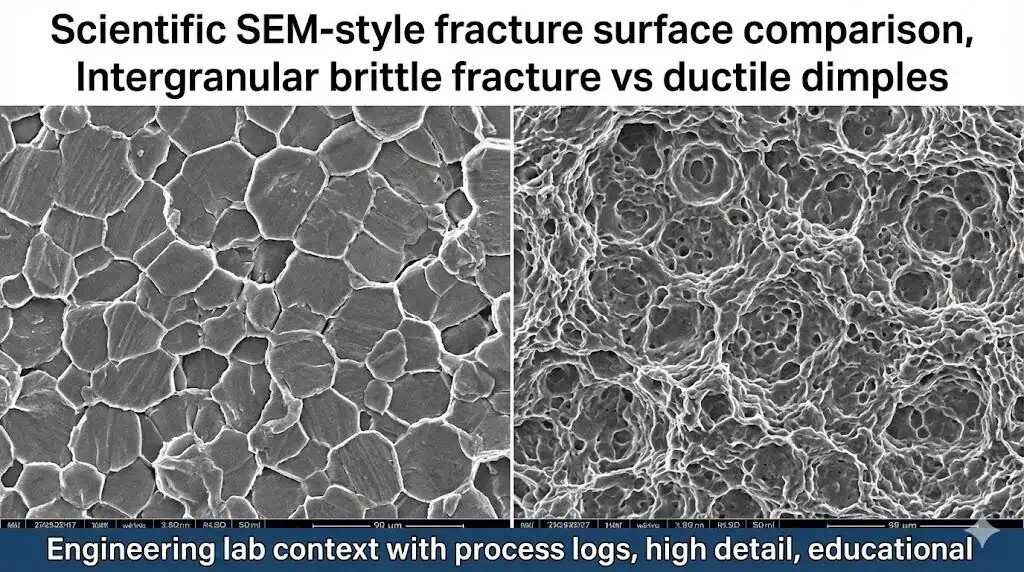

🔧 Engineering Case Study: The Silent Killer (Hydrogen Embrittlement)

The Incident: A heavy equipment manufacturer reported M16 Grade 12.9 bolts snapping 24 hours after installation, while the machine was sitting idle in the warehouse. There was no external load applied.

The Investigation: Our lab analysis using Scanning Electron Microscopy (SEM) revealed intergranular fracture surfaces—a classic brittle failure signature, clearly different from the dimpled pattern of overload failure. The root cause traced back to the electro-galvanising process and the lack of controlled post-plate baking.

The Science: High-strength steel (commonly above ~HRC 39) can trap atomic hydrogen introduced during acid pickling and electroplating. Under preload, hydrogen migrates to grain boundaries and weakens them until a crack starts internally and runs fast—often with no warning.

The Solution: We implemented mandatory De-embrittlement Bake at 200–230°C for 4–24 hours, started within 1–4 hours after plating, with oven logging and lot control. For critical safety parts, we recommended switching to Geomet (Zinc Flake) style coatings where applicable, because non-electrolytic processes reduce hydrogen entry risk compared with electroplating. The key is not the brand name—it is controlling the process window and documenting it.

Negotiating and Building Relationships

Good negotiation goes beyond price per thousand. Spot-buying increases risk: different lots, different friction, different failure behaviour. For industrial buyers, an LTSA with blanket orders lets the manufacturer run longer, more stable production lots (lower unit cost, fewer setup variables) while shipping monthly releases (better cash flow, less warehouse stress). Share your annual forecast and your change-control rules (what can change without approval) so the supplier can plan wire buys and protect you against volatility.

Ensuring Fastener Integrity

Fast answer (documentation wins arguments): Certifications matter, but the document trail matters more. You want traceability from steel heat number to finished lot, and you want proof of mechanical properties, coating system, and inspection results. If a supplier can’t provide that trail, you are buying risk—especially for plated high-strength parts and fatigue-sensitive joints.

Certifications: The Documentation Trail

ISO 9001 is the baseline, not the ceiling. ISO 9001 confirms a quality management system exists, not that the fasteners are correct. For automotive, suppliers with IATF 16949 typically carry stronger process discipline. For testing capability, ISO 17025 accreditation is a strong signal of competent lab practice. The critical document is the Mill Test Report (MTR), which tracks the steel heat number from melt to finished lot. This is how you confirm chemistry and control impurities (Sulphur/Phosphorus) that can affect toughness and brittleness.

Reviews and Audit History

Website reviews don’t stop failures. Ask for evidence: sample inspection reports, certificate examples, and how they handle nonconformities. A supplier who can provide Level 3 PPAP has a working system for control plans, measurement systems, and traceability. If they have a track record in demanding sectors (automotive, aerospace), that discipline usually improves every SKU you buy.

Returns and Non-Conformance

A bad batch can stop a production line. Your contract should require 8D Reports for non-conformance: root cause (tool wear, heat treatment drift, coating thickness variance), corrective action, and verification. For stock items, a 30-day return policy is common. For custom parts, require signed drawing approval and a first-article process so both sides agree on what “good” looks like before volume production. Also confirm the supplier’s procedure for handling NCP (non-conforming product) so rejected lots cannot re-enter the supply chain by accident.

FAQ

What is the difference between Cut Threads and Rolled Threads?

Rolled threads are stronger in fatigue and more consistent for assembly. Rolled threads are formed by cold working, which preserves grain flow and hardens the surface. Cut threads remove material and interrupt grain flow, creating sharper stress risers at the thread root where cracks initiate. For cyclic loads, specify rolled threads whenever possible and validate thread fit with proper gauging.

Why do Stainless Steel bolts seize (Galling)?

Galling is cold welding driven by pressure, friction, and heat. Stainless threads can wipe off the passive oxide film under load, then transfer metal and lock. Prevention is practical: use anti-seize, control installation RPM (avoid high-speed impacts for final torque), and—where the design allows—introduce a hardness/property-class difference between nut and bolt. If the joint is torque-critical, ask for a validated torque table based on your real lubrication condition.

How do I prevent Hydrogen Embrittlement in high-strength bolts?

Control the plating route and bake immediately. Grade 10.9 and 12.9 fasteners can absorb atomic hydrogen during acid pickling and electroplating. A common control approach is baking at roughly 200–230°C for 4–24 hours, started within 1–4 hours after plating, with documented oven logs and lot control. If your application is safety-critical, consider non-electrolytic coating routes where feasible.

What is the typical MOQ for custom Cold Headed screws?

Typically 10,000 to 50,000 pieces per SKU. Cold heading requires punches/dies and rolling plates that must be set and tuned; setup cost is amortised across the run. Below ~5,000 pieces, CNC machining may be the only economical route, but the per-piece cost is higher and cut-thread fatigue performance may be lower than rolled threads.

Where can I verify fastener standards?

Use official standards bodies. Start with ASTM International and ISO Standards, and confirm the exact callout on your drawing (standard + property class + coating system + inspection requirements). Avoid non-technical blogs for dimensions and tolerances—thread fit and coating build-up are where assemblies fail.