Stainless Steel Fittings Manufacturer: From Industrial Piping to Precision Fluid Power

Your Direct Source for ASME B16.9 Butt-Weld Fittings, Hydraulic Adapters, and Pneumatic Components.

Stop sourcing from middlemen. As a specialized pipe fittings factory, Sunhy bridges the gap between heavy-duty infrastructure and precision control. We supply full-schedule (Sch 10S/40S/80S) butt weld fittings and high-pressure connectors manufactured from ASTM A403 WP316L/304L and Duplex Tube materials.

Unlike standard market goods, our products undergo 1040°C solution annealing to ensure maximum corrosion resistance in harsh chemical and marine environments. Experience the reliability of a true pipe and fittings supplier.

Our Focus

Advanced Forming Technology

As a premier pipe fitting manufacturer, we move beyond standard hot extrusion methods. We employ Cold Mandrel Forming for elbows and Hydroforming for tees. These advanced processes guarantee uniform wall thickness across the entire fitting—minimizing the thinning rates often seen in inferior products.

To ensure longevity in corrosive environments, every austenitic stainless steel fitting undergoes strict Solution Annealing at 1040°C followed by rapid water quenching. This critical step restores the material’s grain structure, ensuring full compliance with ASTM A403 and eliminating the risk of intergranular corrosion.

Process

- Elbows: Cold Mandrel Pushing (Consistent Radius)

- Tees: Hydroforming (Seamless Body)

- Result: Smooth internal flow path & consistent Schedule wall thickness.

Heat Treatment

- Temp: Solution Annealing @ 1040°C min.

- Method: Rapid Water Quenching.

- Benefit: Non-magnetic & restored corrosion resistance (Intergranular attack prevention).

Capacity

- Size Range: NPS 1/2" to 48" (DN15-1200).

- Types: Seamless & Welded (100% X-Ray Tested).

- Custom: Spools & Manifolds available per drawing.

Our Products

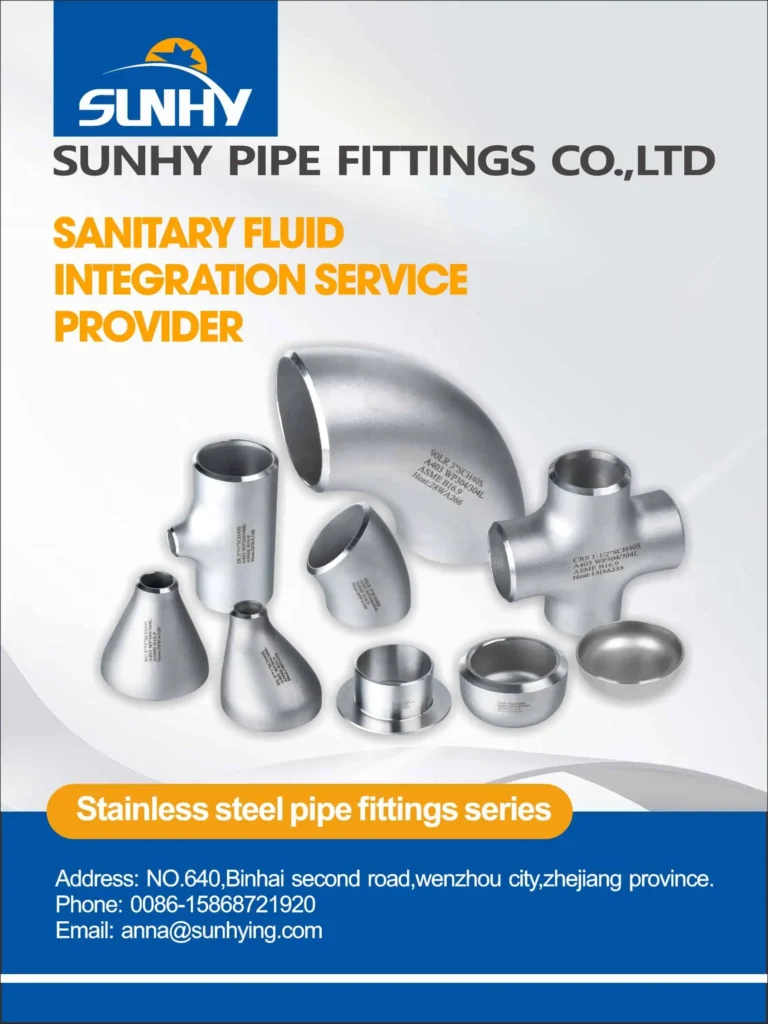

Industrial Process Piping Components (ASME/EN)

Engineered for the heavy industry. Our butt-weld and threaded fittings serve as the backbone for oil & gas, chemical processing, and water treatment facilities. We specialize in difficult-to-source materials including Duplex 2205 and Super Duplex 2507 for superior stress corrosion cracking (SCC) resistance.

Butt-Weld Fittings (ASME B16.9)

Seamless & Welded Elbows, Tees, Reducers (Sch 10S/40S/80S)

Threaded Fittings (ISO 4144 / ASME B1.20.1)

150lb Cast fittings for reliable low-pressure connections.

High-Pressure Forged Fittings (ASME B16.11)

Socket Weld & Threaded (3000lb/6000lb).

Our Products

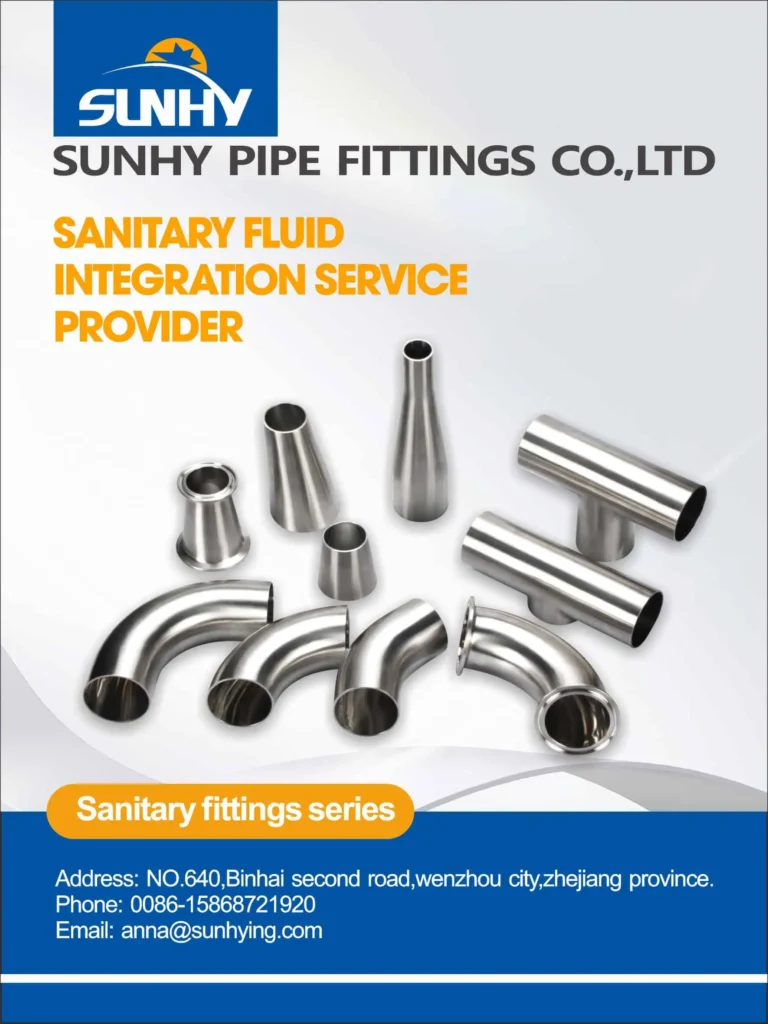

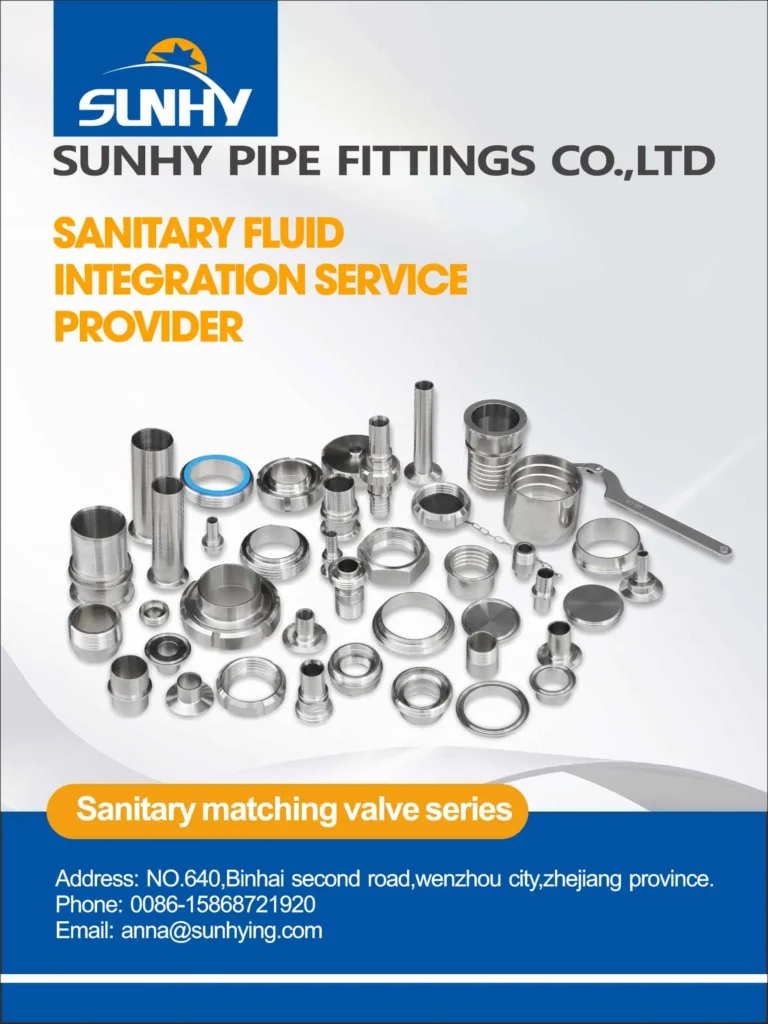

Fluid Power & Instrumentation Connections

Streamline your supply chain with Sunhy’s integrated manufacturing capabilities. We bridge the gap between heavy industrial infrastructure and precision instrumentation. Whether your BOM requires ASME B16.9 butt-weld fittings for process piping or DIN 2353 compression fittings for hydraulic power units, we manufacture them under one quality management system.

Eliminate compatibility risks by sourcing your entire fluid loop—from duplex tube to pneumatic automation components—from a single, certified pipe fittings factory.

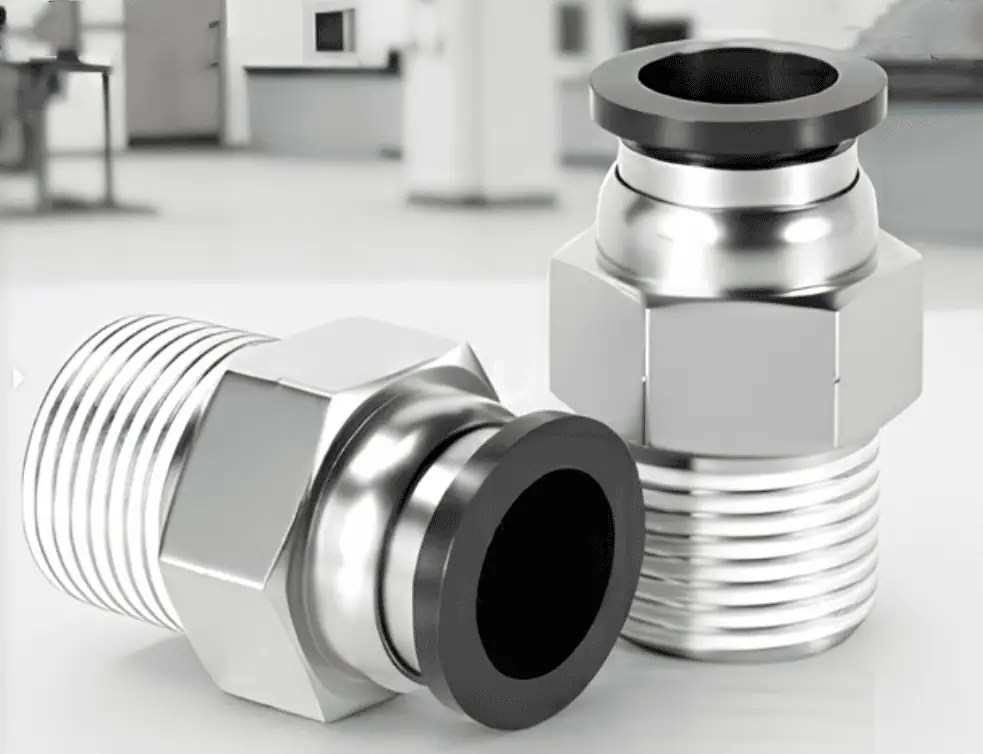

Pneumatic Fittings

Lightweight, corrosion-resistant stainless steel pneumatic fittings for air and gas systems. Designed for quick connection, secure sealing, and long service life.

Hydraulic Adapters

Connect different thread types and hose standards with precision stainless steel adapters. BSP, NPT, JIC, SAE available.

Crimp Fittings

Permanent crimp hose fittings ensuring leak-free hydraulic performance.

Reusable Hose Fittings

Thread-on reusable fittings for field repair and quick maintenance.

Hose Barbs & Push Lock Barbs

Secure hose connections for low-pressure systems. Easy installation, tight seal.

Quick Disconnects (Couplings)

Fast, clean, and secure hose connection/disconnection. Compatible with ISO-A & ISO-B standards.

Metal Hose Weld-On Fittings

Weld-on fittings designed for stainless braided hoses and high-temperature lines.

British Fittings (BSP / BSPT)

Threaded stainless fittings conforming to British Standard Pipe threads for secure hydraulic sealing.

Metric Fittings (DIN / ISO)

DIN 2353 metric fittings for hydraulic and pneumatic applications. Precision-machined for leak-tight performance.

Stainless Metric Tube Fittings (DIN 2353)

Double ferrule compression fittings for metric tubing. Vibration-resistant and reusable.

Stainless Instrumentation Tube Fittings

Single Ferrule & Weld Tube Fittings

Simplified connection for instrumentation lines and small-bore tubing systems.

Our Products

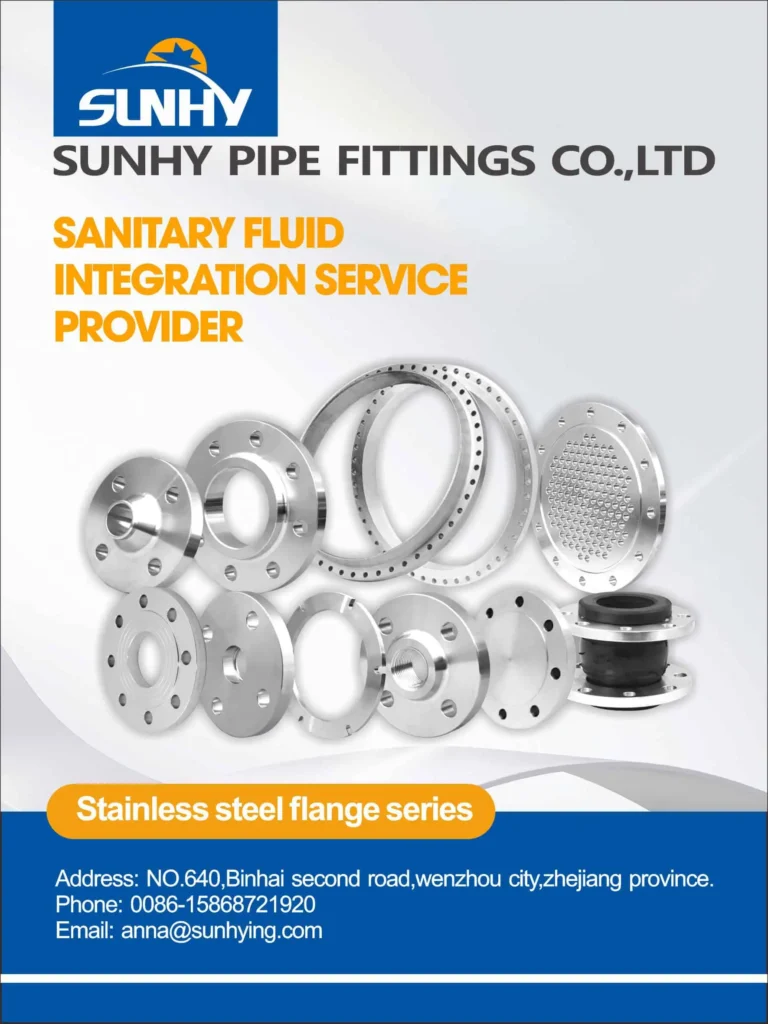

Comprehensive Flange Portfolio (NPS 1/2" - 60")

Sunhy’s reputation for excellence comes from delivering stainless steel flanges of superior quality and value, backed by responsive customer service and reliable delivery. As a vital link in industrial piping systems, our comprehensive range of flanges is engineered to ensure strength, corrosion resistance, and leak-free performance across diverse industries and applications.

Cost-effective solution for low-pressure water lines. Must be used with full-face gaskets to prevent bending stress on cast iron mating parts.

Easy alignment for on-site fabrication. Double fillet welded (inside/outside) for secure joint strength in Class 150-300 systems.

Designed for small-bore high-pressure piping (≤ NPS 2). Counter-bore design ensures smooth flow and reduces turbulence.

No-weld installation for hazardous areas. Precision NPT threads per ASME B1.20.1 ensure tight sealing without hot work.

Used with Stub Ends. The flange rotates for easy bolt alignment. Ideal for systems requiring frequent dismantling or expensive alloy piping.

High-stress forged discs for line termination. Engineered to withstand maximum system pressure and water hammer effects.

Custom drilled precision discs for heat exchangers and boilers. CNC drilling ensures exact hole coordinates for tube bundles.

Heavy-duty long weld necks (LWN) and nozzle flanges designed for ASME Section VIII vessel fabrication.

Tailor-made solutions including Spectacle Blinds, Spacer Rings, and Orifice Flanges machined to your drawings.

Our Solutions

Seamless Connections, Precision Built: Your Risk-Free Manufacturing Partner

Sunhy delivers more than just parts; we deliver operational certainty. As a specialized pipe fittings manufacturer, we utilize advanced CNC machining and a globally trusted quality system to ensure every component—whether for high-pressure hydraulic fluid, sensitive instrumentation, or industrial compressed air—fits perfectly the first time.

Sunhy is your

Complete Fittings System Supplier: Instrumentation, Hydraulic & Piping

Simplify your procurement with a single, integrated source. From Single and Double Ferrule Tube Fittings for precision instrumentation to durable Pneumatic Fittings for air control, our range covers every connection point in your facility.

Instrumentation & Control

- Products: Twin Ferrule Tube Fittings, Compression Fittings.

- Specs: Interchangeable designs, leak-tight seal for gas/liquid.

Hydraulic Power

- Products: High-Pressure Adapters (DIN/JIC/BSP), Crimp Fittings.

- Role: We are verified hydraulic fittings suppliers for OEM machinery.

- Rating: Up to 6000 PSI / 10,000 PSI for heavy-duty cycles.

Industrial Piping

- Products: Threaded (ISO 4144) & Butt-Weld Elbows, Tees, Crosses.

- Material: 304/316L Stainless, Alloy Steel.

- Alloys: 316Ti, 904L, Duplex 2205.

- Service: OEM/ODM Fitting Assemblies tailored to your drawings.

Explore Sunhy

Engineering Capabilities: From Raw Bar to Precision Component

Quality begins with Precision Raw Material Control. We use only high-grade Stainless Steel Round Bars and verified forging methods (Cold Heading & Die Forging) to ensure structural integrity. These materials are shaped in our Advanced CNC Machining Centers, featuring 5-Axis operations for complex geometries and high-precision tolerances.

Precision Forging & Material

- Use of Stainless Steel Round Bar and High-Precision Blank Cutting.

- Strict control over Cold Heading & Free Forging processes.

Advanced CNC Machining

- 5-Axis Complex Part Machining and 4-Axis Centers.

- Precision Laser Cutting for absolute dimensional accuracy.

Surface & Welding Excellence

- Automated Orbital Welding for consistent, flawless joints.

- Internal/External Polishing reaching sanitary or industrial grade requirements.

Traceability & Testing

- 100% PMI (Spectrometry Analysis) to verify chemical composition.

- Full 3.1 MTR Material Records ensuring every fitting is traceable to the heat lot.

- High-Pressure Gas Leak Tests for safety assurance.

Sunhy solutions for

Zero-Leak Guarantee: 3-Point Verification Process

At Sunhy, we don’t assume quality; we prove it. Before any fitting leaves our factory, it must survive our rigorous 3-Point Verification System. We utilize advanced Hydrostatic & Pneumatic Testing Machines (as seen on the left) to subject critical hydraulic and high-pressure fittings to 1.5x their rated working pressure, ensuring absolute structural integrity.

Dimensional accuracy is verified using CMM (Coordinate Measuring Machines) to ensure that every thread pitch and chamfer angle meets ASME B1.20.1 or DIN 2353 tolerances, guaranteeing a hassle-free installation at your job site.

Pressure Test: Hydrostatic testing up to 10,000 PSI / Pneumatic testing for low-pressure leaks.

Dimension Check: CMM verification for thread engagement and sealing surface finish (Ra).

Traceability: Every tested batch is laser-marked with a Heat Code linked to the raw material.

Sunhy Solutions for

Compliance Umbrella: Certified for Global Critical Applications

Minimize your project risk with a partner who understands global compliance. Sunhy manufacturing operates under a comprehensive quality umbrella, anchored by ISO 9001, 14001, and 45001 certifications.

For our European clients, our fittings comply with the Pressure Equipment Directive (PED 2014/68/EU), ensuring legal market access. For the marine sector, we adhere to DNV standards. We enforce strict material control starting with PMI (Positive Material Identification) spectroscopy to verify Nickel and Molybdenum content in 316L and Duplex steels.

Everyone will choose the right choice

Why Choose Sunhy

Sunhy Quality

VS

Low Quality

Materials: Top-tier steel mill source, Full Traceability (MTC).

Materials: Unknown origin, Vague MTC data.

Chemistry: Alloy content strictly controlled (e.g., Ni/Mo), Superior corrosion resistance.

Chemistry: Insufficient alloy (e.g., Low Ni), Poor corrosion resistance.

Accuracy: High-precision CNC finished, 100% Leak-Proof dimensional fit.

Certifications: PED/DNV/TS approved, Strict UT/PT testing on every batch.

Certifications: Only basic ISO, Missing NDT reports.

Finish: Clear stamping, Thorough Passivation, Long-lasting clean surface.

Finish: Blurry mark, Rough finish, Oxide residue.

Experience the Sunhy Difference

Trusted Worldwide, Delivered Anywhere: Export-Ready Logistics

Manufacturing quality is only half the battle; delivering it intact is the other. As a veteran pipe fittings supplier serving 30+ countries, Sunhy understands the complexities of global trade. From FOB Shanghai to DDP delivery at your warehouse in Houston or Hamburg, we handle the logistics so you don’t have to.

Our export packaging is engineered to protect precision threads and machined surfaces during ocean transit. We provide full documentation support, including EN 10204 3.1 Material Certificates, PED 2014/68/EU compliance for Europe, and CRN registration support for Canadian projects.

Dedicated Customer Support Teams

Serving Impressive List Of Long Term Clients!

Our growth is a testament to how much we value our customers. Exceptional customer service has been the key to our success, ensuring satisfaction and fostering loyalty. Thank you for helping us grow together.

Seeing is believing

About Sunhy

See Quality in the Making, Build Trust in Person

Visit Sunhy Factory: See Quality, Build Trust

🏭 Full-Process Tour

See precision machining, assembly, and testing—witness how each stainless steel fitting is born.

🤝 Technical Exchange

Our engineers provide on-site support for selection, customization, and solutions.

Submit your visit request—we’ll contact you within 24h to plan your custom tour.