Sanitary Fittings Manufacturer | 3A & ASME BPE Stainless Steel (304/316L)

In high-purity fluid processing, the integrity of your connection determines the sterility of your product. At Sunhyings, we understand that a sanitary fitting is more than just a connector—it is a critical control point for contamination risks.

With over 30 years of engineering expertise, we supply precision-engineered stainless steel sanitary fittings that meet strict 3-A Sanitary Standards and ASME BPE dimensional tolerances. From standard Tri-Clamp® compatible components to custom fabricated manifolds, our inventory supports the dairy, food & beverage, and pharmaceutical industries with fully traceable 304 and 316L stainless steel materials.

Our Focus

Precision Engineering for Demanding Environments

We manufacture stainless steel fittings with advanced automation and precision control, delivering tight tolerances and perfect sealing performance. Backed by ISO, ASTM, and PED certifications, our production ensures repeatable accuracy for every application.

CNC Machining Equipment

- 120 units of Type 150 CNC lathes

- Over 10 high-precision CNC lathes (Mazak / Doosan)

➜ Ensuring mass production of standard products

➜ Providing customers with high-precision components

Advanced Processing Centers

- 3 five-axis machining centers

- 5 gantry machining centers

- 15 standard vertical machining centers

- 20 customized special-purpose machines

➜ Supporting complex machining for irregular and multi-hole products

Large-scale Machining Capacity

- Maximum machining diameter: 3200 mm

- Maximum workpiece weight: 10 tons

- 32 CNC machines with machining diameter range 680 mm – 2000 mm

➜ Ensuring on-time and perfect delivery for every customer order

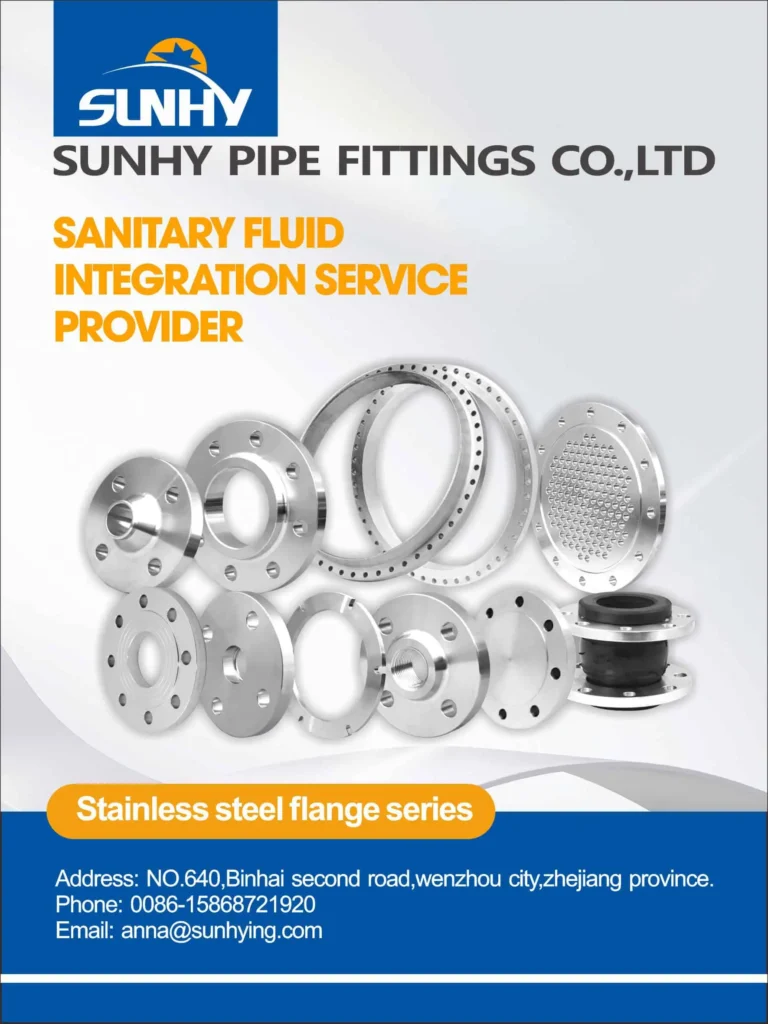

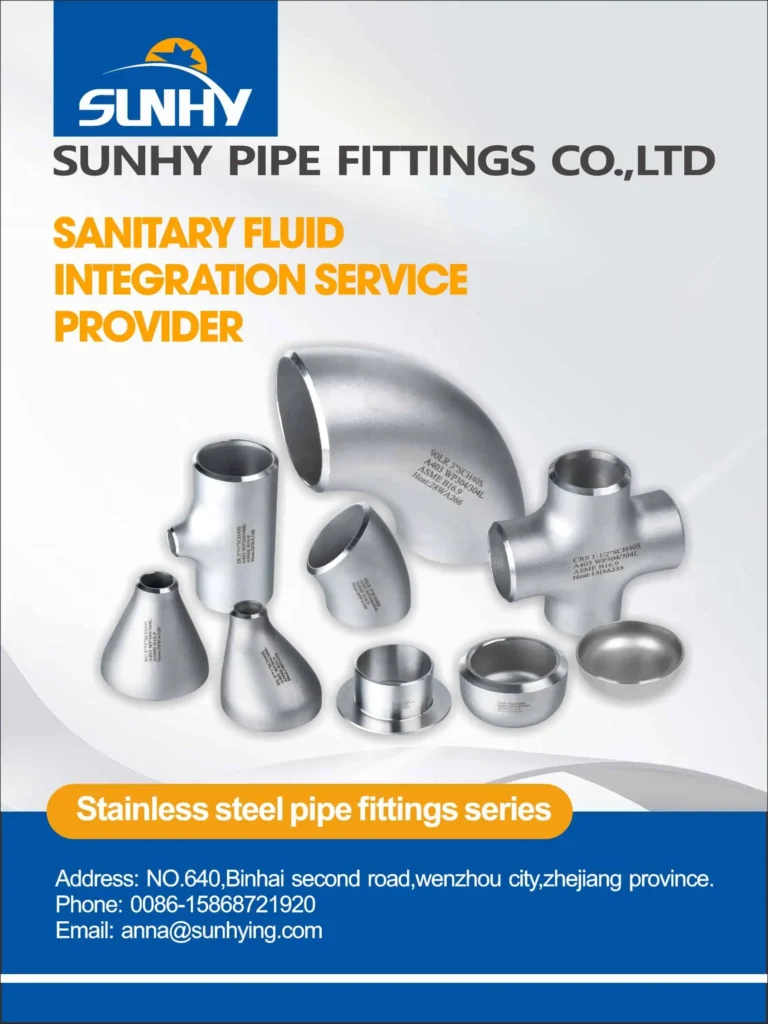

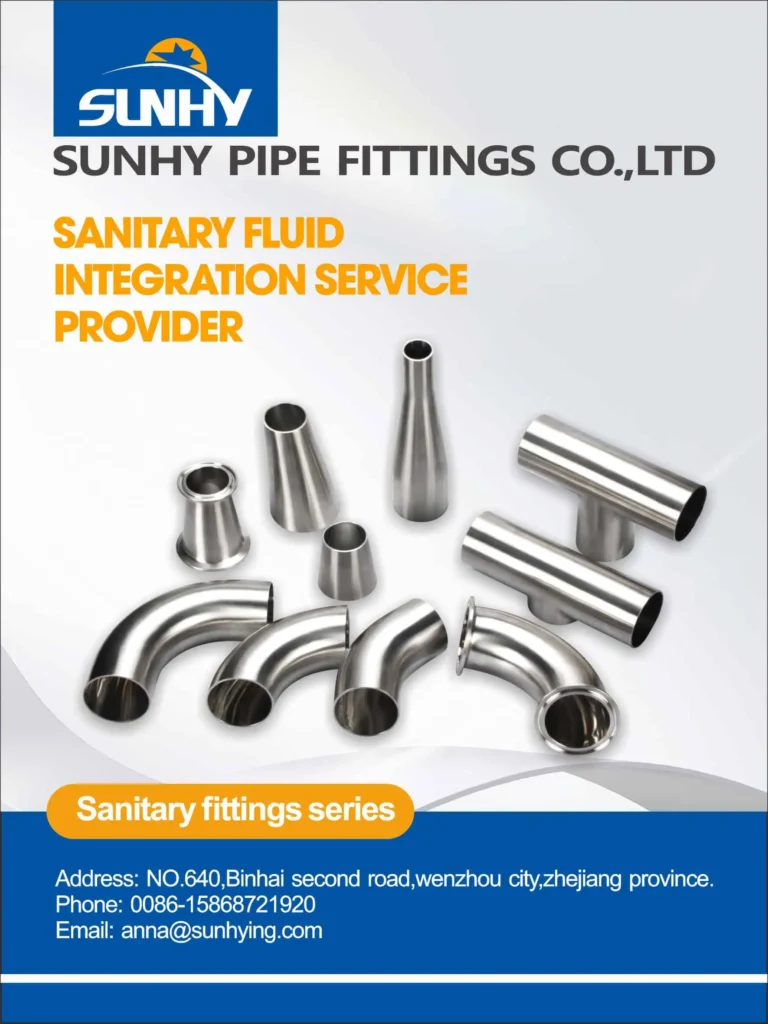

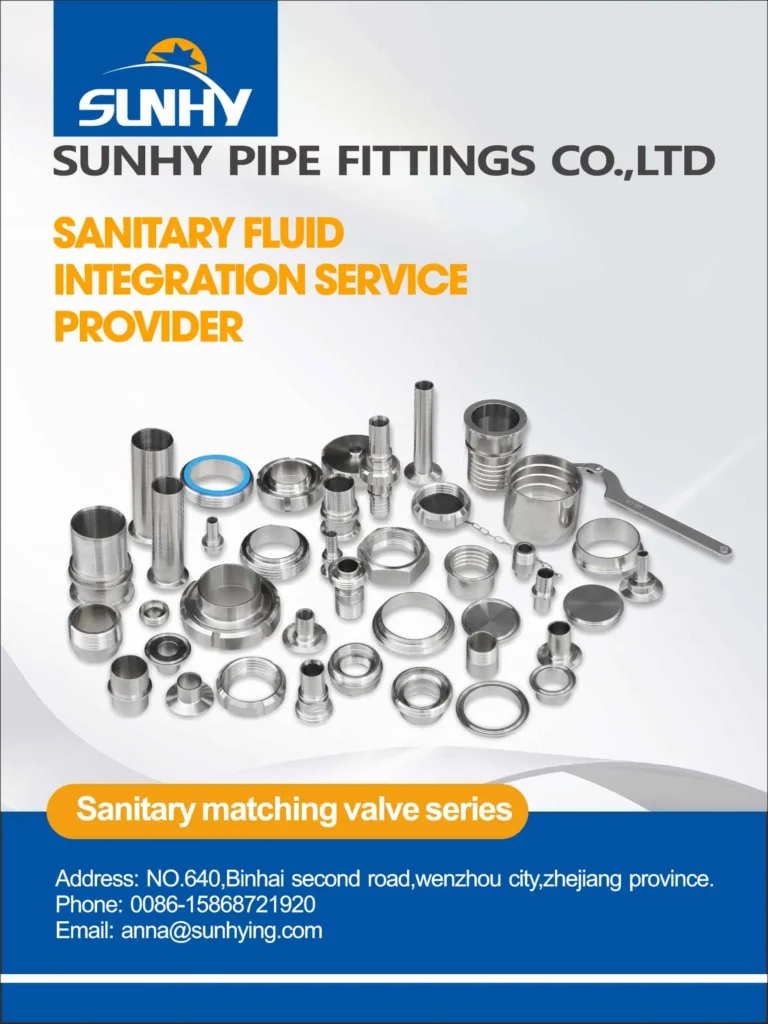

Our Products

Comprehensive Range of Sanitary Fittings

The industry standard for easy assembly and disassembly. Ideal for CIP (Clean-in-Place) systems.

Pneumatic Fittings

Lightweight, corrosion-resistant stainless steel pneumatic fittings for air and gas systems. Designed for quick connection, secure sealing, and long service life.

Hydraulic Adapters

Connect different thread types and hose standards with precision stainless steel adapters. BSP, NPT, JIC, SAE available.

Custom Stainless Steel Fittings

OEM fittings designed per drawing or specification. Available in SS304, SS316, SS316Ti.

Our Solutions

Seamless Connections. Precision Built.

Sunhy provides all the stainless steel fittings you need to keep your systems running smoothly. We use advanced CNC machines and a quality system trusted globally to ensure every single part is built perfectly, right down to the dimensions. Whether you are dealing with hydraulic fluid, pressurized air, or sensitive instruments, our strict process control guarantees easy, perfect assembly and reliable flow. This protects your entire infrastructure investment and ensures dependable performance, no matter how tough the environment is.

Sunhy is your

Complete Fittings System Supplier

Instrumentation Fittings

- Single & Double Ferrule Tube Fittings

- Compression Fittings

- Pipe Fittings (Male/Female Thread)

- Bulkhead & Union Fittings

- Elbows, Tees & Crosses

Industry Applications

- Oil & Gas Instrumentation Lines

- Chemical & Process Control Systems

- Power Generation & Energy Equipment

- Marine & Offshore Installations

- Semiconductor & Clean System Piping

Custom & Specialty Components

- Customized Alloy Fittings (316Ti, 904L, Duplex, etc.)

- High-Pressure Fittings (6,000–10,000 psi)

- Valve Manifolds & Gauge Adapters

- OEM / ODM Fitting Assemblies

Explore Sunhy

Engineering Capabilities

It begins with Precision Raw Material Control—using high-grade Stainless Steel Round Bars and verified forging methods such as Cold Heading and Die Forging.

These materials are shaped in Advanced CNC Machining Centers, including 5-Axis operations and High-Precision Tube Cutting, to achieve complex geometries with exact tolerances.

Post-machining, every component undergoes Automated Orbital Welding and fine Internal/External Polishing for a flawless finish.

The process concludes with Comprehensive Testing, Certification, and Traceability, featuring High-Pressure Gas Leak Tests, Spectrometry Analysis (PMI), and full 3.1 MTR Material Records—ensuring every fitting is certified ready for service.

Raw Material & Precision Forging

- Precision Raw Material Control

- Stainless Steel Round Bar

- High-Precision Blank Cutting

- Cold Heading & Die Forging

- Free Forging

Advanced CNC Precision Machining

- Advanced CNC Precision Machining

- High-Precision Tube Cutting

- Fitting Product Machining

- Threaded Product Machining

- 5-Axis Complex Part Machining

- 4-Axis Machining Center

- Precision Laser Cutting

Welding, Surface Finish & Finish

- High-Standard Welding & Surface Finish

- Automatic Orbital Welding

- Certified Manual Welding

- Internal Precision Polishing

- External Fine Polishing

- Laser Traceability Marking

- Penetrant Testing (PT)

Testing, Certification & Traceabilit

- Testing, Certification & Traceability

- High-Pressure Gas Leak Test

- Spectrometry Analysis (PMI)

- 3.1 MTR Material Traceability

- Surface Roughness Inspection

- Ultrasonic Testing (UT)

- Carbon Content Analysis

- Customized Industrial Packaging

Sunhy solutions for

Testing & Delivery

Sunhy ensures every stainless steel fitting meets exact specifications through a strict three-point verification. Dimensional and thread accuracy are guaranteed using CMM verification. Hydrostatic and pneumatic pressure testing confirms absolute leak-tight performance. Finally, detailed surface inspections and full material traceability ensure consistent, documented quality across every single batch.

Sunhy Solutions for

Quality Control

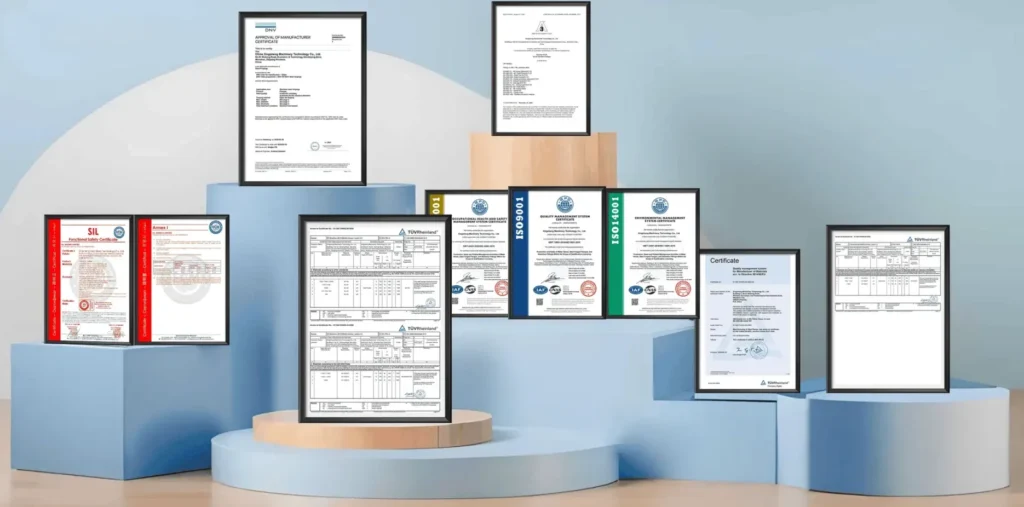

Minimize the risk of premature system failure and reduce your TCO with Sunhy’s fluidic components. Our manufacturing is secured by a comprehensive compliance umbrella, including ISO 9001/14001/45001 and specialized approvals like EU PED and DNV.

We exceed traditional service life expectations in extreme and corrosive environments by mandating strict material control (PMI verified thermal codes) and dimensional perfection (CMM validation). This rigorous, certified process ensures rapid compliance, protects your infrastructure investment, and delivers the predictable, long-lasting performance required to prevent catastrophic losses.

Experience the Sunhy Difference

Trusted Worldwide, Delivered Anywhere

From a single specialty fitting to complex bulk orders of stainless steel components, Sunhy makes global supply simple and reliable. We proudly serve customers in 30+ countries and maintain over 200 ongoing partnerships, proving our logistical strength. This expertise ensures every order—whether large or small—reaches your site on time and in perfect condition, ready for immediate installation into your critical fluid systems.

Dedicated Customer Support Teams

Serving Impressive List Of Long Term Clients!

Our growth is a testament to how much we value our customers. Exceptional customer service has been the key to our success, ensuring satisfaction and fostering loyalty. Thank you for helping us grow together.

Seeing is believing

About Sunhy

See Quality in the Making, Build Trust in Person

Visit Sunhy Factory: See Quality, Build Trust

🏭 Full-Process Tour

See precision machining, assembly, and testing—witness how each stainless steel fitting is born.

🤝 Technical Exchange

Our engineers provide on-site support for selection, customization, and solutions.

Submit your visit request—we’ll contact you within 24h to plan your custom tour.