Stainless Steel Threaded Fittings (Low Pressure) for Pipes, Water Systems & HVAC

Supply consistent, maintenance-friendly stainless steel threaded fittings for low-pressure piping: elbows, tees, couplings, unions, nipples, reducers, crosses, caps, plugs, and bushings—available in NPT or BSPT.

Home / Industrial Pipe Fittings / Low Pressure (Threaded/Class 150)

Types of Threaded Fittings We Supply

Low Pressure (Threaded/Class 150)

Butt Weld (ASME B16.9)

Forged Fittings

Advanced Materials

Stainless Steel Threaded Fittings (Low Pressure) for Pipes, Water Systems & HVAC

Supply consistent, maintenance-friendly stainless steel threaded fittings for low pressure piping: elbows, tees, couplings, unions, nipples, reducers, crosses, caps, plugs, and bushings—available in NPT or BSPT.

Types & Variants (Stainless Steel Threaded Fittings)

For low pressure piping, these stainless steel threaded pipe fittings cover most project needs: threaded elbow fittings, threaded tee fittings, threaded coupling fittings, threaded union fittings, threaded nipple fittings, threaded reducer fittings, threaded cross fittings, and threaded cap fittings.

Threaded Elbow Fittings

90° / 45° elbows for direction changes; street elbows for compact assemblies.

Threaded Tee Fittings

Equal / reducing tees for branching and distribution lines.

Threaded Coupling Fittings

Connect straight runs; reducing couplings adapt sizes quickly.

Threaded Union Fittings

Maintenance breaks for pumps, valves, instruments, and skids.

Threaded Nipple Fittings

Build assemblies; confirm length + Sch requirements (if your project specifies).

Caps, Plugs, Bushings & Reducers

Close end lines, create service ports, and reduce thread sizes.

Quick Selector: Stainless Steel Threaded Fittings Table

Filter by type and thread. All items below are stainless steel.

| SS Item | What it does | Typical use | Search phrases | Notes |

|---|---|---|---|---|

| SS Threaded Elbow (90° / 45°) | Changes direction without welding | Water systems, HVAC, plumbing | threaded elbow fittings, threaded fittings for plumbing | Fast install Avoid over-torque |

| SS Threaded Tee (Equal/Reducing) | Creates a branch from a header | Distribution, equipment tie-ins | threaded tee fittings, threaded pipe connectors | Easy branching |

| SS Threaded Cross | Multi-direction manifold branches | Utility manifolds, test rigs | threaded cross fittings | Mind alignment |

| SS Threaded Coupling | Connects straight runs | Maintenance replacement, extensions | threaded coupling fittings, threaded fittings for pipes | Simple BOM |

| SS Threaded Union | Quick disassembly point | Pumps, instruments, skids | threaded union fittings, threaded fittings supplier | Best for maintenance |

| SS Pipe Nipple | Builds spool assemblies | Skids, equipment hook-ups | threaded nipple fittings, threaded fittings sizes | Confirm length |

| SS Reducer / Bushing | Adapts thread sizes | Instrumentation, compact reductions | threaded reducer fittings, npt threaded fittings | Space-saving |

| SS Cap / Plug | Closes ends and ports | Pressure test ports, drains | threaded cap fittings, threaded metal fittings | Use sealant |

Stainless Steel Only: Grades, Use Cases & Buyer Notes

This page focuses on stainless steel threaded fittings for low pressure service. Stainless is often selected for corrosion resistance, clean utility lines, and long-term maintenance stability.

304 / 304L

General-purpose stainless for water systems, HVAC auxiliaries, and indoor utility lines.

316 / 316L

Preferred for higher chloride exposure and harsher environments (confirm with project spec).

Procurement checklist

Specify grade + thread type (NPT/BSPT) + size + documents. Request MTR if required.

Sizes & Dimensions

Common procurement sizes include 3/4", 1", and 2". Always specify the thread (NPT/BSPT) and any reducer sizes for bushings/reducers.

| Common size | Typical usage | Buyer note |

|---|---|---|

| 3/4" Threaded Fittings | Branches, hose transitions, compact hook-ups | High volume—confirm thread type and grade |

| 1" Threaded Fittings | Utility connections, equipment tie-ins | Use unions for planned maintenance breaks |

| 2" Threaded Fittings | Utility headers, distribution lines | Support piping to reduce joint strain |

| Threaded Fittings Sizes | Reducers/bushings for mixed sizes | Call out both ends: e.g., 1" x 3/4" |

Standards & Quality

To ensure consistent fit-up, specify the thread standard and required documents on the PO. If your project needs certifications (e.g., ISO) or MTR, list them in the RFQ.

| Item | Why it matters | Example PO wording |

|---|---|---|

| Thread standard (NPT or BSPT) | Prevents mismatch, leaks, rework | “Thread: NPT” or “Thread: BSPT” (One standard per system) |

| Material grade (304/316) | Controls corrosion performance | “Material: SS 304/304L (or 316/316L) per datasheet” |

| Inspection & documents | Supports project acceptance | “Provide traceability + packing list; MTR if required” |

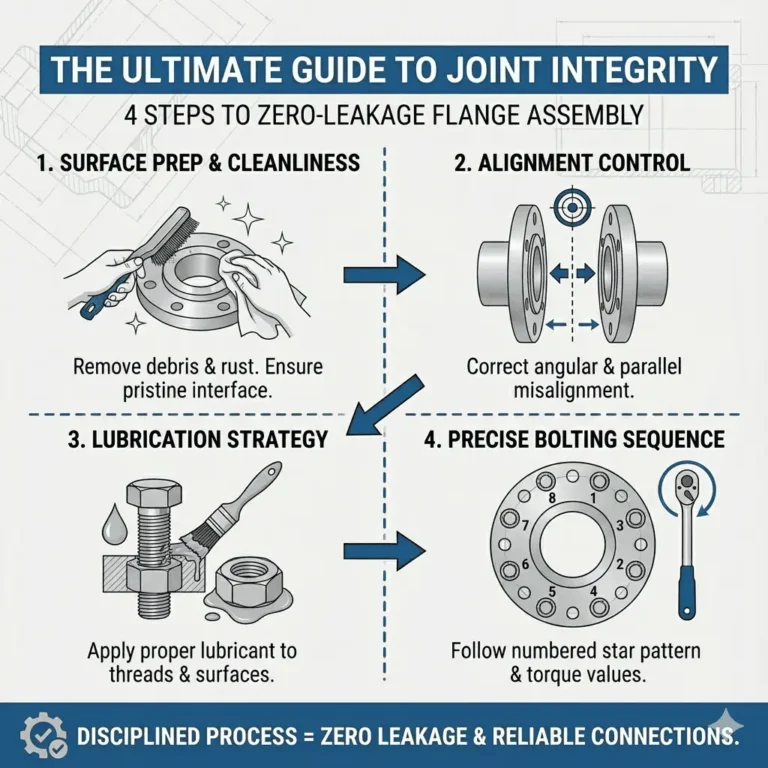

Installation & Usage: How to Install Stainless Steel Threaded Fittings

Stainless threaded connections seal best when the correct thread type, sealant method, and tightening practice are followed.

1) Confirm NPT vs BSPT

Standardize one thread type per system to reduce leak risk.

2) Clean threads

Remove debris/oil; reject damaged threads to prevent cross-threading.

3) Use approved sealant

PTFE tape or sealant compound per project spec. Keep it consistent.

4) Avoid over-torque

Over-tightening can distort threads and increase galling risk on stainless.

5) Remove pipe strain

Support piping so the threaded joint is not carrying load or vibration.

6) Pressure test

Test per project procedure and acceptance criteria.

Images & Video

Replace placeholders with your own stainless product photos, thread close-ups, and inspection/packing shots.

SEO tip: Use unique filenames and alt text for each product photo (type + size + thread + grade).

FAQ

Do you offer 304 and 316 stainless steel threaded fittings?

Yes. For general water/HVAC service, 304/304L is common. For chloride exposure, many projects specify 316/316L. Always follow your project datasheet.

Can I mix NPT and BSPT threads in the same piping system?

Not recommended. Mixing thread standards can cause sealing issues and rework. Standardize one thread type per system and specify it clearly on the PO.

How do I reduce galling risk on stainless threads?

Use project-approved sealant, avoid over-torque, and keep joints aligned without forcing. If your spec allows, a suitable thread lubricant/sealant helps.

What do you need for a fast quote?

Send fitting type, size, thread standard (NPT/BSPT), grade (304/316), quantity, and documentation requirements (MTR if needed).

RFQ Template (Stainless Steel Threaded Fittings)

Copy this template into an email to speed up quoting.