ASME B16.11 Forged Fittings: High-Pressure Socket Weld & Threaded Solutions

Premium manufacturer of Forged Steel Fittings (Class 3000/6000). Certified ASME B16.11 Elbows, Tees & Unions for critical Oil & Gas systems. Get a Fast Quote Today.

Home / Industrial Pipe Fittings / Forged Fittings

Types of Forged Fittings We Supply

Forged Fittings

Butt Weld (ASME B16.9)

Low Pressure (Threaded/Class 150)

Advanced Materials

Forged Fittings: Engineered for Extreme Pressure & Safety

Forged fittings are the backbone of high-integrity piping systems. Manufactured by compressing heated metal under extreme pressure, they offer a dense, non-porous structure that far exceeds the capabilities of cast or welded components. For industries where failure is not an option—such as Oil & Gas, Chemical Processing, and Power Generation—forged fittings (ASME B16.11) provide the ultimate safeguard against leakage and catastrophic failure.

Recommended Alt Text: "ASME B16.11 Forged Steel Fittings Collection - Elbows, Tees, and Unions"

🛠️ Applications & Specification Guide

- Elbows & Tees: Flow direction control for high-velocity fluids.

- Couplings & Unions: Leak-proof joining for maintenance-heavy zones.

- Caps & Plugs: High-pressure system sealing.

- Inserts: Reinforcing branch connections.

✅ Critical Standards & Certifications

We strictly adhere to global manufacturing standards to ensure 100% interchangeability and safety. The primary standard for forged fittings is ASME B16.11, which dictates dimensions, pressure ratings, and markings.

For detailed specifications, you can reference the official ASME B16.11 Standard Page.

| Class Rating | Connection Type | Max Working Pressure (Psi) |

|---|---|---|

| Class 3000 | Threaded / Socket Weld | Up to 3,000 PSI (Standard Hydraulic/Steam) |

| Class 6000 | Threaded / Socket Weld | Up to 6,000 PSI (High-Pressure Gas/Chemical) |

| Class 9000 | Socket Weld Only | Up to 9,000 PSI (Critical Super-High Pressure) |

📊 Proven Performance: Real-World Impact

📌 Case Study: Offshore Drilling Platform

The Challenge: A client in the North Sea experienced frequent corrosion fatigue in their hydraulic lines using standard cast fittings, leading to $15,000 in annual downtime costs per line.

The Solution: Replaced all branch connections with Class 6000 Forged Tees (316L Stainless Steel).

The Result:

📌 Case Study: Chemical Processing Plant

The Challenge: High-vibration steam lines were causing threaded joint loosening.

The Solution: Implemented Socket Weld Forged Fittings to create permanent, sealed joints.

The Result: Eliminated joint leakage completely, passing a 1.5x hydrostatic pressure test with zero failures.

🌟 Trusted by Engineers Worldwide

"We switched to forged fittings for our high-pressure natural gas project last year. The material quality and dimensional accuracy were perfect. We haven't had a single seal failure since installation."

- Senior Piping Engineer, Global Energy Corp.Manufactured in compliance with:

ASME • ASTM • ISO 9001 • APIReady to Upgrade Your Piping System?

Don't compromise on safety. Get certified, high-performance forged fittings for your next project.

🚀 Get a Free Quote Now

Response within 24 hours.

💡 FAQ: Expert Answers

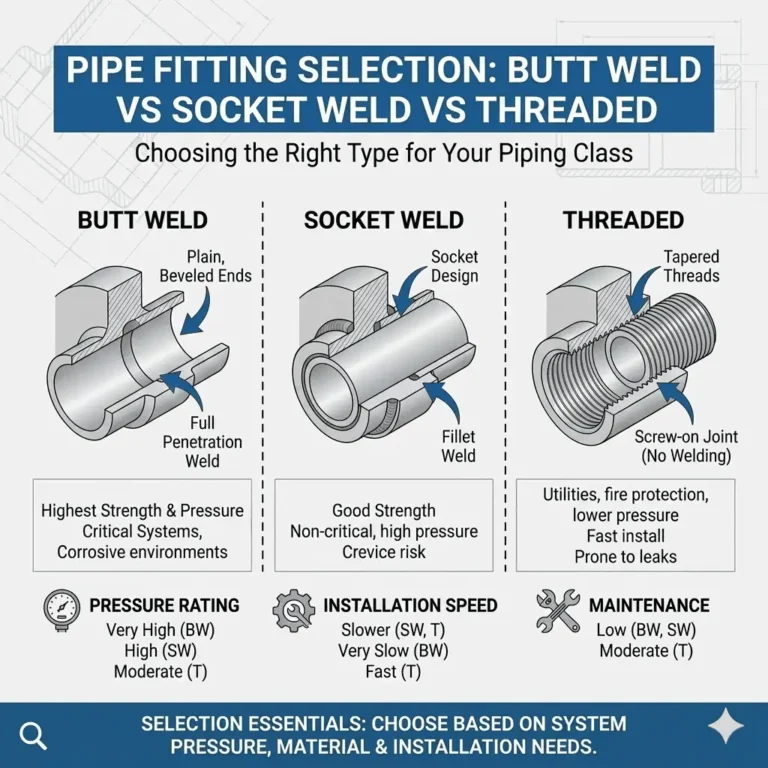

Why choose Socket Weld over Threaded fittings?

Socket Weld fittings provide a permanent, leak-proof connection ideal for high-pressure and high-temperature systems where joint integrity is critical. Threaded fittings are better suited for lower pressures or areas requiring disassembly.

Do you provide Material Test Reports (MTRs)?

Yes, all our forged fittings come with full traceability and Mill Test Reports (MTRs) according to EN 10204 3.1, ensuring the chemical and mechanical properties meet ASTM standards.