Stainless Steel Threaded Flanges (NPT)

Sunhy is a leading manufacturer and supplier of high-quality stainless steel threaded flanges. We engineer these flanges for applications where welding (hot work) is hazardous or prohibited, such as in explosive (ATEX) environments or highly flammable areas.

Unlike welded flanges, this design uses threads (typically NPT per ASME B1.20.1) to form a seal, allowing for easy assembly and disassembly without specialized labor. Our flanges, forged from SS316L and SS304L grades, are ideal for small-bore (NPS 1/2″ to 4″), low-to-medium pressure systems in water treatment, fire protection, and instrumentation.

Home / Stainless Steel Flange / Threaded Flanges

Types of Threaded Flanges We Supply

By Design Type

By Standard & Class

Advanced Materials

4-Bolt Stainless Steel Threaded Flange, NPT Raised Face (RF)

6-Bolt Stainless Steel Threaded Pipe Flange, Raised Face (RF)

Stainless Steel Threaded Flanges: Features & Specifications

When your system requires secure, non-weld integrity and ease of maintenance, we are your specialized Stainless Steel Threaded Flanges manufacturer. Our components are optimized for rapid assembly and disassembly in areas where welding is impractical or prohibited (e.g., ATEX-rated hazardous environments).

Our manufacturing focuses on precision threading to ensure a tight, reliable seal. We produce all common thread types, including:

NPT (ASME B1.20.1)

BSPT (ISO 7-1)

BSPP (ISO 228-1)

Every flange is forged from certified SS316L (for maximum corrosion resistance) or SS304L (for general use) stainless steel and meets stringent ASME B16.5 standards for dimensional accuracy.

Your Factory-Direct Supply

Maximize your project speed and cost efficiency. We stock a ready inventory of standard stainless steel threaded flanges for genuine wholesale pricing and reliable global performance.

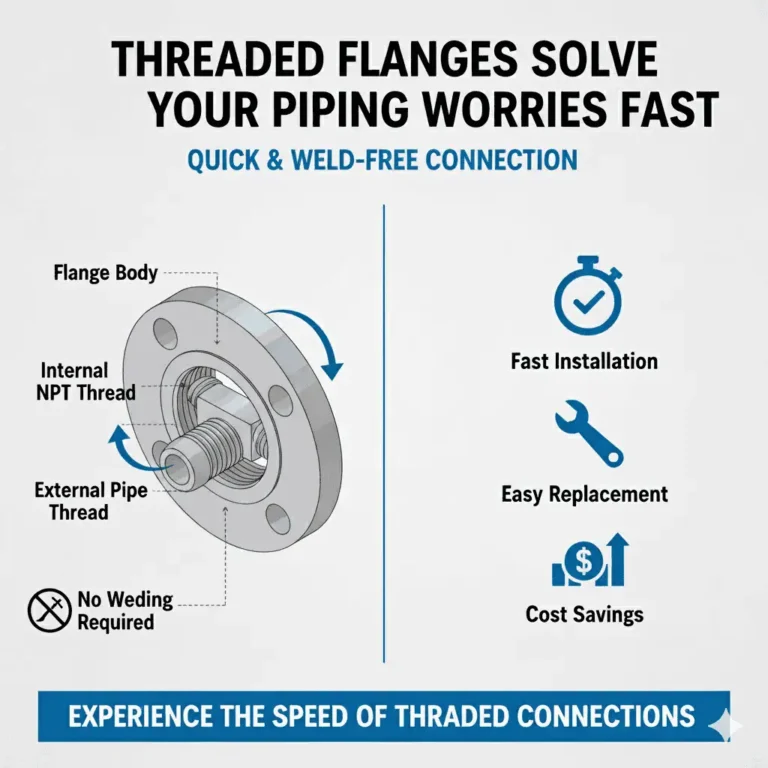

What is a Threaded Flange

A threaded flange is a type of flange that connects to a pipe without welding. It features internal (female) threads, such as NPT, which screw onto the external (male) threads of a pipe. This design is ideal for small-bore piping systems (NPS 4″ / DN100 and smaller) and is essential in hazardous environments (ATEX) where welding (hot work) is prohibited.

Threaded Flanges (TH) Specifications

Standard Compliance

These dimensions strictly conform to ASME B16.5 (Classes 150 & 300) and encompass EN 1092-1 Type 13 specifications.

Thread Standard: All internal threads are machined to ASME B1.20.1 (NPT) standards to ensure a tight, leak-proof seal with standard NPT pipe fittings.

Material & Application

Manufactured from Forged Stainless Steel SS304/304L and SS316/316L.

Welding-Free Solution: Ideal for applications where welding is hazardous (e.g., explosive environments) or difficult to execute.

Assembly: Allows for easy assembly and disassembly of piping connections without thermal distortion.

Dimensional Reference

Refer to the cross-section diagram and the table headers for key measurements:

O: Outside Diameter

Y: Length through Hub (critical for clearance)

BC: Bolt Circle Diameter

Technical Note: Please verify your mating pipe is NPT threaded. Attempting to mate NPT with BSPT/ISO threads will result in seal failure.

Threaded Flange (TH) Dimensions

Standard: ASME B1.20.1 (NPT)ASME B16.5 Class 150 Threaded

| NPS (Size) |

Outside Dia (O) (mm) |

Length (Y) (Through Hub) |

Bolt Circle (BC) (mm) |

Holes (Qty) |

Bolt Size (Inch) |

Thread (Std) |

|---|---|---|---|---|---|---|

| 1/2" | 88.9 | 15.7 | 60.5 | 4 | 1/2" | 1/2 NPT |

| 3/4" | 98.6 | 15.7 | 69.9 | 4 | 1/2" | 3/4 NPT |

| 1" | 108.0 | 17.5 | 79.2 | 4 | 1/2" | 1 NPT |

| 1-1/2" | 127.0 | 22.4 | 98.6 | 4 | 1/2" | 1-1/2 NPT |

| 2" | 152.4 | 25.4 | 120.7 | 4 | 5/8" | 2 NPT |

| 3" | 190.5 | 30.2 | 152.4 | 4 | 5/8" | 3 NPT |

| 4" | 228.6 | 33.3 | 190.5 | 8 | 5/8" | 4 NPT |

| 6" | 279.4 | 39.6 | 241.3 | 8 | 3/4" | 6 NPT |

| 8" | 342.9 | 44.5 | 298.5 | 8 | 3/4" | 8 NPT |

ASME B16.5 Class 300 Threaded

| NPS (Size) |

Outside Dia (O) (mm) |

Length (Y) (Through Hub) |

Bolt Circle (BC) (mm) |

Holes (Qty) |

Bolt Size (Inch) |

Thread (Std) |

|---|---|---|---|---|---|---|

| 1/2" | 95.3 | 22.4 | 66.5 | 4 | 1/2" | 1/2 NPT |

| 3/4" | 117.3 | 25.4 | 82.6 | 4 | 5/8" | 3/4 NPT |

| 1" | 124.0 | 27.0 | 88.9 | 4 | 5/8" | 1 NPT |

| 1-1/2" | 155.4 | 30.2 | 114.3 | 4 | 3/4" | 1-1/2 NPT |

| 2" | 165.1 | 33.3 | 127.0 | 8 | 5/8" | 2 NPT |

| 3" | 209.6 | 42.9 | 168.1 | 8 | 3/4" | 3 NPT |

| 4" | 254.0 | 47.8 | 200.2 | 8 | 3/4" | 4 NPT |

ASME B16.5 Class 600 Threaded

| NPS (Size) |

Outside Dia (O) (mm) |

Length (Y) (Through Hub) |

Bolt Circle (BC) (mm) |

Holes (Qty) |

Bolt Size (Inch) |

Thread (Std) |

|---|---|---|---|---|---|---|

| 1/2" | 95.3 | 22.4 | 66.5 | 4 | 1/2" | 1/2 NPT |

| 3/4" | 117.3 | 25.4 | 82.6 | 4 | 5/8" | 3/4 NPT |

| 1" | 124.0 | 27.0 | 88.9 | 4 | 5/8" | 1 NPT |

| 1-1/2" | 155.4 | 30.2 | 114.3 | 4 | 3/4" | 1-1/2 NPT |

| 2" | 165.1 | 36.6 | 127.0 | 8 | 5/8" | 2 NPT |

Class 900 & 1500 (Instrumentation)

Warning: Threaded flanges in Class 900/1500 are prone to leakage in cyclic environments.

| NPS (Size) |

Class (Rating) |

Outside Dia (mm) |

Min Thread Length (mm) |

Bolt Circle (mm) |

Holes (Qty) |

Thread (Std) |

|---|---|---|---|---|---|---|

| 1/2" | 1500 | 120.7 | 22.0 | 82.6 | 4 | NPT |

| 3/4" | 1500 | 130.0 | 25.0 | 88.9 | 4 | NPT |

| 1" | 1500 | 149.4 | 28.0 | 101.6 | 4 | NPT |

| 1-1/2" | 1500 | 177.8 | 31.0 | 123.9 | 4 | NPT |

| 2" | 1500 | 215.9 | 38.0 | 165.1 | 8 | NPT |

Recommend Weld Neck (WN) or SW for High Pressure Safety.

View Weld Neck FlangesEngineering Note: NPT vs BSPT

- Region: USA, Canada.

- Angle: 60° thread angle.

- Seal: Tapered threads requiring sealant/tape.

- Standard Supply: All Sunhyings ASME flanges come with NPT by default.

- Region: Europe, Asia, Australia.

- Angle: 55° thread angle.

- Incompatibility: NPT and BSPT represent different geometries and cannot be mixed.

- Note: Specify "BSPT Threads" clearly in your RFQ.

Order Threaded Flanges Parameters

To ensure you receive an accurate, factory-direct quote for the correct product, please specify the following key parameters:

| Parameter | Specification |

|---|---|

| Size Range | NPS 1/2″ to NPS 4″ (DN15 to DN100) (Note: Larger sizes are not recommended for threaded flanges) |

| Material Grade | Stainless Steel: SS316/L (F316/L), SS304/L (F304/L) per ASTM A182 |

| Thread Standard | NPT (ASME B1.20.1), BSPT (ISO 7-1), or BSPP (ISO 228-1) |

| Pressure Class (US) | ASME B16.5: Class 150, 300, 600, 900, 1500 |

| Pressure Rating (EU) | EN 1092-1 Type 13: PN10, PN16, PN25, PN40 |

| Flange Face Type | Raised Face (RF) or Flat Face (FF) |

| Certification | Material Test Report (MTR) per EN 10204 3.1 must be supplied. |

Applications & Limitations for Stainless Steel Threaded Flanges

- Stainless Steel Threaded Flanges are a critical solution for small-bore piping systems (NPS 4″ / DN100 and smaller). Their primary advantage is installation without welding (hot work).

This makes them the only choice for applications in hazardous, flammable, or explosive environments (ATEX-rated zones) where welding is prohibited.

Key Applications:

- Hazardous Environments (ATEX): Used in chemical plants, refineries, and offshore platforms where welding poses a fire or explosion risk.

- Easy Assembly & Maintenance: Ideal for temporary systems or lines that require frequent disassembly and maintenance. No certified welder is required for installation.

- Corrosive Low-Pressure Systems: The SS316L grade provides excellent corrosion resistance for water treatment, fire protection systems, and instrumentation lines.

Critical Limitations (Important for Engineers):

You must NOT use threaded flanges in the following applications:

- High-Temperature Services: Temperature cycles (heating and cooling) will cause the threads to expand and contract, leading to leakage.

- High-Pressure Cycles or Vibration: These conditions can cause the threads to loosen over time, compromising the seal.

- Severe Corrosive Services: The thread itself creates a crevice, which can be a point for crevice corrosion.

Threaded Flange Installation Best Practices (Non-Welded)

A successful threaded flange installation requires two key steps: 1. Sealing the Pipe Threads and 2. Bolting the Flange Connection.

1. Sealing the Pipe Threads (The Critical Step)

The thread itself does not create a seal. You MUST use a thread sealant to prevent leaks.

- PTFE Tape (Teflon Tape): This is the most common method. Wrap the male pipe threads (not the flange threads) 3-5 times in the direction of the thread.

- Liquid Pipe Sealant (Pipe Dope): Use a high-quality sealant paste that is rated for your service (e.g., water, gas, oil) and is compatible with stainless steel.

2. Bolting the Flange Connection

Once the flanges are screwed onto the pipes, the connection is bolted just like any other flange.

- Gasket and Alignment: Use a new, correct gasket (e.g., non-asbestos, spiral wound) and ensure the flange faces are perfectly aligned.

- Bolt Lubrication: Crucial for stainless steel. Apply a stainless-steel compatible anti-seize lubricant to the bolt threads and nut faces to prevent “galling” (seizing) during tightening.

- Tightening Sequence: Use a “star pattern” (crisscross) to tighten the bolts. Tighten in three stages (e.g., 50% torque, 80% torque, 100% torque) to ensure the gasket is compressed evenly.

Related blog

FAQ

Do metal threaded flanges leak?

Yes, all threaded flanges can leak if they are installed incorrectly or used in the wrong application.

Leaks are common in high-temperature services (due to thermal expansion/contraction) or high-vibration systems. To prevent leaks, you MUST use a proper thread sealant (like PTFE tape or pipe dope) and NEVER use threaded flanges for high-temperature cyclic services.

When to use threaded or flanged pipe fittings?

This depends on the application, especially on whether welding is allowed.

- Use Threaded Fittings for small-bore pipes (NPS 4″ and smaller) in areas where welding (hot work) is prohibited, such as hazardous or ATEX-rated zones.

- Use Flanged Fittings (Welded) like Weld Neck or Slip-On for larger pipes, high-pressure, or high-temperature systems that require a more robust, permanent, and leak-proof connection.

What is the difference between flanged and threaded?

- A Threaded Connection screws directly onto a pipe (like a nut on a bolt). It is used for small pipes and does not require welding.

- A Flanged Connection uses two flanges (e.g., Weld Neck) that are welded onto the pipes. These two flanges are then bolted together with a gasket in between. This creates a much stronger, more reliable seal for large pipes and high pressures.

Stainless Steel Flanges

Stainless Steel Flanges