Stainless Steel Socket Weld Flanges

High-quality stainless steel socket weld flanges are a specialty of Sunhy, a leading manufacturer and supplier. Our products are engineered for small-diameter piping systems (typically DN50/NPS 2 and below) operating under high pressure, high temperature, and stringent corrosion resistance requirements.

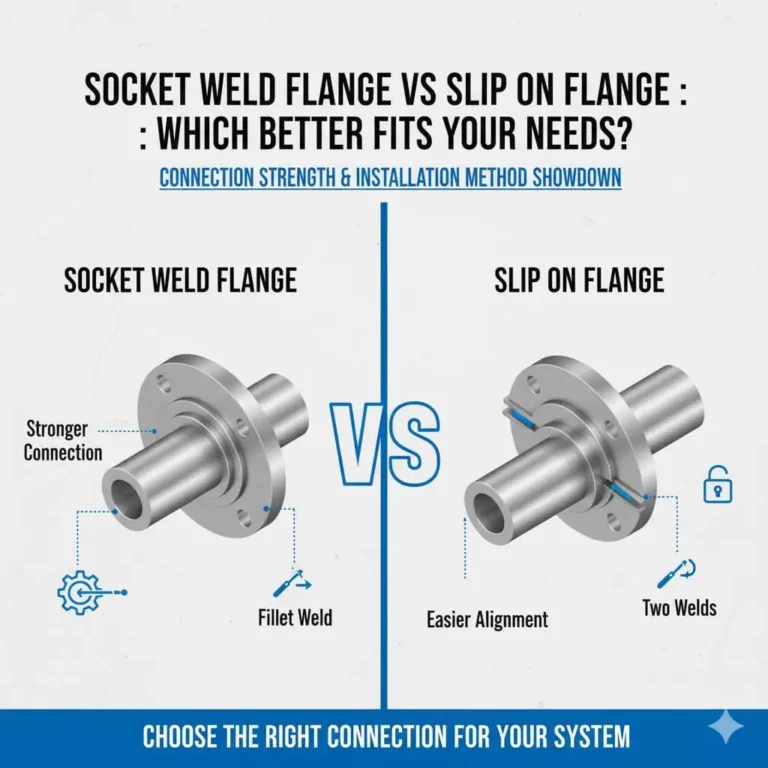

We specialize in SS316/L and SS304/L grades, manufactured in strict accordance with ASME B16.5 standards. The socket weld design (fillet weld) provides greater structural strength and superior leak-proof performance compared to slip-on flanges. This makes them the ideal choice for chemical, pharmaceutical, food processing, and marine engineering applications.

Home / Stainless Steel Flange / Socket Weld Flanges

Types of Socket Weld Flanges We Supply

By Design Type

By Standard & Class

Advanced Materials

304/316 Stainless Steel ISO Socket weld flange

High Quality Socket Weld Flange

- Materials: All flanges are forged from premium SS316/L (for maximum corrosion resistance) and SS304/L (for excellent general-purpose use).

- Standards: We manufacture in strict accordance with ASME B16.5 for dimensions and ASTM A182 for material specifications.

- Quality Assurance: We provide full Material Test Reports (MTRs) and conduct Positive Material Identification (PMI) and 100% dimensional inspections to guarantee chemical composition and tolerance.

| Specification | Details |

|---|---|

| Material Grades | Stainless Steel (SS316/L, SS304/L, F321, F347) |

| Size Range | NPS 1/2″ to NPS 4″ (DN15 to DN100) (Most common: 1/2″ to 2″) |

| Pressure Class | Class 150, 300, 600, 900, 1500 (Note: Class 2500 available by request) |

| Face Type | Raised Face (RF), Flat Face (FF), Ring-Type Joint (RTJ) |

| Applicable Standards | ASME B16.5, ASTM A182, ASME B16.34 |

Your Factory-Direct Wholesale Program

Maximize your project budget by sourcing directly from the factory. Our wholesale program is designed for B2B clients who demand quality and value. We maintain a comprehensive inventory of standard stainless steel socket weld flanges, enabling us to provide fast, reliable global shipping to meet your project timelines.

What is a Socket Weld Flange ?

A Socket Weld Flange (SWF) is a high-pressure pipe flange designed with a “socket” or recessed shoulder. A pipe is inserted into this socket and then secured with an external fillet weld. This design offers superior structural strength and leak integrity over Slip-On flanges, making it ideal for small-bore piping systems (NPS 2″ and smaller).

Socket Weld Flanges (SWF) Specifications

Standard Compliance

The dimensions below are strictly in accordance with ASME B16.5 standards. These specifications ensure global interchangeability and structural integrity for industrial piping systems.

Material & Application

These dimensions apply to our premium range of Forged Stainless Steel flanges, specifically grades SS304/304L and SS316/316L (ASTM A182).

Design: Socket Weld (SW) configuration for reduced risk of leakage in high-pressure systems.

Pressure Classes: Covers Class 150 through Class 600.

Dimensional Reference

Refer to the cross-section diagram to identify key measurements:

OD: Outside Diameter

BC: Bolt Circle Diameter

ID: Inner Diameter

Note: Please ensure the flange bore matches your pipe schedule before installation to prevent flow restriction.

Socket Weld Flange (SW) Dimensions

Unit: Millimeters (mm)ASME B16.5 Class 150 SW (Small Bore)

| NPS (Size) |

Outside Dia (O) (mm) |

Hub Dia (X) (Base of Hub) |

Bolt Circle (BC) (mm) |

Holes (Qty) |

Bolt Size (Inch) |

|---|---|---|---|---|---|

| 1/2" | 88.9 | 30.2 | 60.5 | 4 | 1/2" |

| 3/4" | 98.6 | 38.1 | 69.9 | 4 | 1/2" |

| 1" | 108.0 | 49.3 | 79.2 | 4 | 1/2" |

| 1-1/4" | 117.3 | 58.7 | 88.9 | 4 | 1/2" |

| 1-1/2" | 127.0 | 65.0 | 98.6 | 4 | 1/2" |

| 2" | 152.4 | 77.7 | 120.7 | 4 | 5/8" |

| 2-1/2" | 177.8 | 90.4 | 139.7 | 4 | 5/8" |

| 3" | 190.5 | 108.0 | 152.4 | 4 | 5/8" |

ASME B16.5 Class 300 SW

| NPS (Size) |

Outside Dia (O) (mm) |

Hub Dia (X) (Base of Hub) |

Bolt Circle (BC) (mm) |

Holes (Qty) |

Bolt Size (Inch) |

|---|---|---|---|---|---|

| 1/2" | 95.3 | 38.1 | 66.5 | 4 | 1/2" |

| 3/4" | 117.3 | 47.8 | 82.6 | 4 | 5/8" |

| 1" | 124.0 | 53.8 | 88.9 | 4 | 5/8" |

| 1-1/4" | 133.4 | 63.5 | 98.6 | 4 | 5/8" |

| 1-1/2" | 155.4 | 69.9 | 114.3 | 4 | 3/4" |

| 2" | 165.1 | 84.1 | 127.0 | 8 | 5/8" |

| 2-1/2" | 190.5 | 100.1 | 149.4 | 8 | 3/4" |

| 3" | 209.6 | 117.3 | 168.1 | 8 | 3/4" |

ASME B16.5 Class 600 SW

| NPS (Size) |

Outside Dia (O) (mm) |

Hub Dia (X) (Base of Hub) |

Bolt Circle (BC) (mm) |

Holes (Qty) |

Bolt Size (Inch) |

|---|---|---|---|---|---|

| 1/2" | 95.3 | 38.1 | 66.5 | 4 | 1/2" |

| 3/4" | 117.3 | 47.8 | 82.6 | 4 | 5/8" |

| 1" | 124.0 | 53.8 | 88.9 | 4 | 5/8" |

| 1-1/2" | 155.4 | 69.9 | 114.3 | 4 | 3/4" |

| 2" | 165.1 | 84.1 | 127.0 | 8 | 5/8" |

| 3" | 209.6 | 117.3 | 168.1 | 8 | 3/4" |

High Pressure Socket Weld Use

In practical engineering, socket weld flanges are generally limited to Class 600 and sizes up to NPS 3 (DN80). For Class 900 / 1500 / 2500 service, Weld Neck flanges are typically used due to better performance under cyclic loads and thermal stress.

Looking for Sizes > 3 Inch?

Socket Weld flanges are typically limited to NPS 3 (DN80) and smaller

due to stress concentration at the socket weld in larger pipe sizes.

For larger diameters (4" - 24"), we recommend using

Slip On (SO) or Weld Neck (WN) flanges.

Applications for Stainless Steel Socket Weld Flanges

- Socket Weld (SW) flanges are specified for high-pressure, small-bore piping systems (NPS 2″ / DN50 and smaller). The addition of stainless steel (SS316L & SS304L) makes them essential where both high pressure and high corrosion resistance are required.

Their robust, leak-resistant design makes them superior to threaded or slip-on flanges in demanding environments.

- Chemical Processing & Petrochemical: Ideal for small-diameter (e.g., NPS 1.5″) Class 600, 900, or 1500 service lines carrying corrosive acids, chemicals, or high-pressure steam. The SS316L grade provides critical resistance to chloride and sulfur compounds.

- Pharmaceutical & Food Processing: Used in high-pressure utility lines (like Clean Steam or WFI systems) where the strength of the SW flange is needed, and the SS304L/SS316L material provides the necessary hygiene and corrosion resistance.

- Offshore & Marine (Oil & Gas): Specified for instrumentation and hydraulic control lines that experience high vibration and high pressure. The SS316L grade is critical for resisting saltwater corrosion.

- Power Generation: Used in auxiliary steam lines and high-pressure water systems that require high fatigue strength and resistance to high temperatures.

Technical Limitation (Crevice Corrosion)

Engineers should note that the mandatory 1.6mm installation gap does create a crevice. In highly aggressive or high-purity applications, this crevice can trap fluid and lead to corrosion. For these specific services, a Butt Weld (Weld Neck) flange may be the preferred alternative.

Welding Best Practices for Stainless Steel SW Flanges

Welding stainless steel flanges requires specific procedures to protect their corrosion-resistant properties. Unlike carbon steel, improper welding can lead to “sensitization,” which drastically reduces the material’s integrity.

Key procedures must be followed:

The Weld is EXTERNAL: To be clear, the only mandatory weld is the external fillet weld between the pipe’s outer diameter and the flange socket. An internal seal weld is almost never used and is not standard practice.

The 1.6mm Gap is Mandatory: As per ASME B31.1, the pipe MUST be fully inserted and then pulled back 1.6mm (1/16 inch) before welding. This gap is essential to allow for thermal expansion during welding and prevent stress cracks in the weld root.

Use the Correct Filler Metal: The filler metal must match or exceed the flange material.

For SS316L Flanges: Use ER316L filler rod.

For SS304L Flanges: Use ER308L filler rod.

Control Heat Input (TIG/GTAW): TIG (GTAW) welding is the recommended method. Stainless steel is sensitive to high heat. The welder must use a controlled, low heat input and allow for interpass cooling to prevent carbide precipitation (sensitization), which is the primary cause of weld failure in stainless steel.

Thorough Cleaning is Critical: The flange socket and pipe end must be meticulously cleaned and degreased (using a chloride-free solvent) before welding. Any grease, oil, or contaminants will be “cooked” into the weld, compromising the stainless steel’s passive layer and causing immediate corrosion points.

Post-Weld Verification: After welding, the joint should be visually inspected. For critical applications, Hydrostatic Pressure Testing (typically at 1.5x the design pressure) is performed to confirm the joint’s integrity.

FAQ

What is a Stainless Steel Socket Weld Flange?

A Stainless Steel Socket Weld Flange combines the high-strength socket weld design with the advanced corrosion resistance of grades like SS316L or SS304L. This makes it the ideal choice for small-bore, high-pressure piping systems used in corrosive environments, such as chemical processing, pharmaceutical, and marine applications where both strength and integrity are critical.

do socket weld flanges have a schedule

No, socket weld flanges do not have a “Schedule.” Flanges are rated by Pressure Class (e.g., Class 150, 600, 1500).

However, the bore of the flange is manufactured to match a specific pipe schedule (e.g., SCH 40, SCH 80, SCH 160) to ensure a correct, tight fit for welding. You must specify the pipe schedule when ordering.

how to order socket weld flanges

To order the correct stainless steel socket weld flanges, please provide your supplier with these 6 key specifications for an accurate, factory-direct quote:

Nominal Pipe Size (NPS): e.g., 1.5″ or DN40

Pressure Class: e.g., Class 600, 900, or 1500

Pipe Schedule (for Bore): The schedule of the matching pipe (e.g., SCH 80)

Material Grade: e.g., SS316L or SS304L

Flange Face Type: e.g., Raised Face (RF)

Required Standards: e.g., ASME B16.5

Stainless Steel Flanges

Stainless Steel Flanges