Stainless Steel Lap Joint Flanges (ASME B16.5)

Lap Joint Flanges are the ideal two-piece solution for demanding pipeline projects, specifically designed to address alignment challenges in complex or constrained spaces. Utilizing a separate stub end that is butt-welded to the pipe, this structure ensures that the primary flange ring avoids direct welding stress, significantly extending the component’s service life and minimizing the cost associated with material fatigue.

Manufactured from Stainless Steel in full compliance with ASME B16.5 standards, these flanges ensure superior dimensional accuracy and dependable sealing performance. They are the preferred component for systems requiring frequent dismantling for inspection or routine maintenance. Available in all standard pressure classes, including Class 150, 300, 600, and beyond.

Home / Stainless Steel Flange / Lap Joint Flanges

Types of Weld Neck Flanges We Supply

By Design Type

By Standard & Class

Advanced Materials

6-Bolt Stainless Steel Lap Joint Flange, Flat Face (FF)

Stainless Steel Lap Joint Flange: Specifications & Benefits

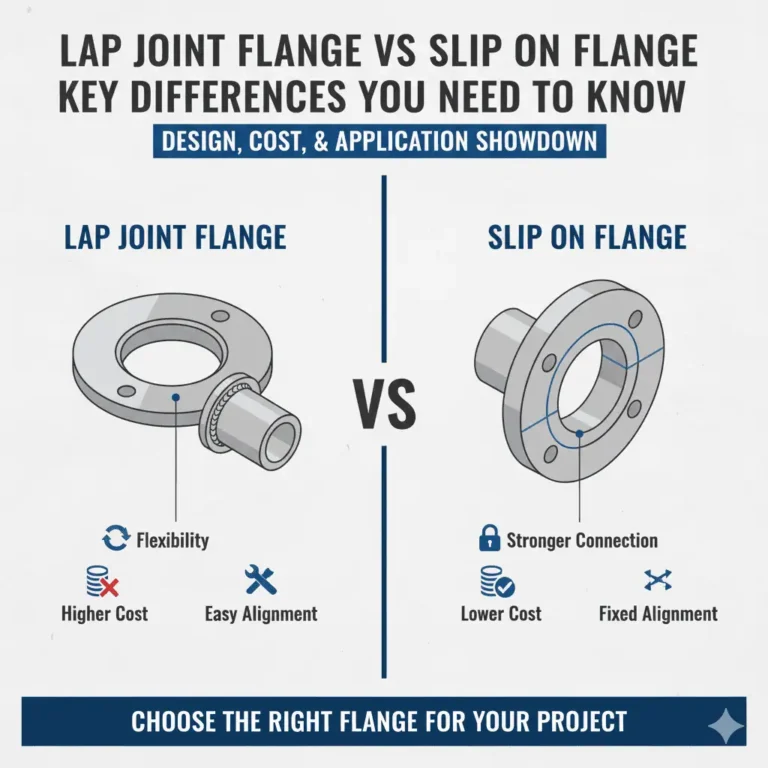

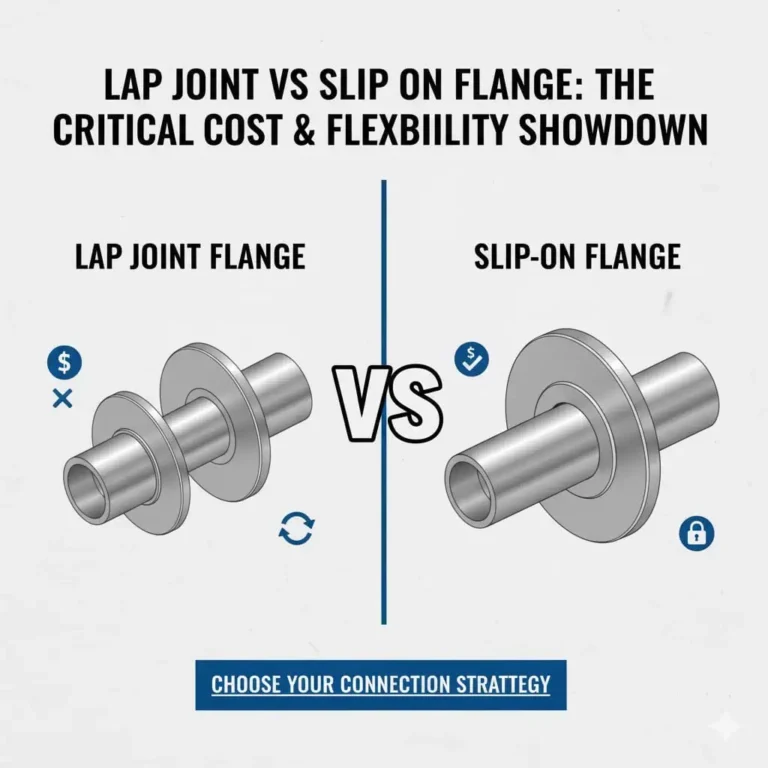

As your dedicated Stainless Steel Lap Joint Flange manufacturer, we understand true project value. The primary advantage of a Lap Joint system is the massive cost savings on high-grade material.

Because the main Flange Ring does not contact the process fluid, you can use a low-cost Carbon Steel Flange Ring (e.g., A105) paired with a corrosion-resistant Stainless Steel Stub End (e.g., SS316L). This drastically reduces material costs on exotic piping systems compared to using a solid SS316L Weld Neck flange.

Furthermore, the free-rotating flange design eliminates the need for precise bolt alignment in the field, ensuring faster project completion and significantly lower installation expenses.

| Specification | Details |

|---|---|

| Size Range | NPS 1/2″ to NPS 48″ (DN15 to DN1200) |

| Pressure Class | ASME B16.5: Class 150, 300, 600, 900, 1500 (Note: Class 2500 by request) |

| Flange Ring Material | Stainless Steel (SS304L) or Carbon Steel (A105) |

| Stub End Material | Stainless Steel (SS316L, SS304L), Duplex, etc. (per ASTM A403) |

| Stub End Type | Type A (for standard Lap Joint) or Type B (for Slip-On Flanges) |

| Standards | ASME B16.5 (Flanges) & ASME B16.9 (Stub Ends) |

Factory-Direct Specifications

We manufacture a full range of Lap Joint Flanges and matching Stub Ends compliant with ASME and EN standards.

What is a Lap Joint Flange

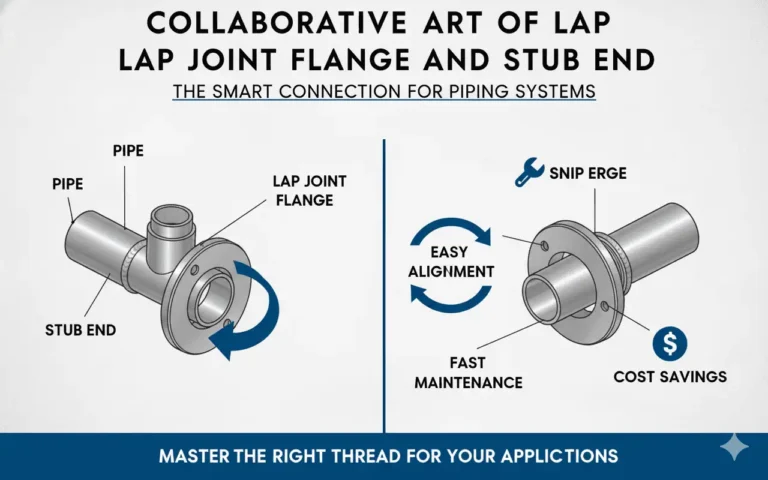

A Lap Joint Flange is a two-piece assembly consisting of a Flange Ring that rotates freely around a Stub End. The Stub End is butt-welded to the pipe, and its face forms the seal.

This design is ideal for easy bolt alignment and massive cost savings, as a low-cost Carbon Steel ring can be used with a corrosion-resistant Stainless Steel Stub End (e.g., SS316L).

Lap Joint Flanges Specifications

System Design & Versatility Our Lap Joint Flanges are engineered for seamless integration with Stub Ends, fully compliant with ASME B16.5 standards for pressure classes 150 through 300.

Two-Component Assembly: Designed to function as a backing ring for ASME B16.9 or MSS SP-43 Stub Ends.

Cost Efficiency: Since the flange ring does not contact the process fluid, high-grade Stainless Steel stub ends can be paired with Carbon Steel flanges to significantly reduce material costs without compromising corrosion resistance.

Engineering Advantages Constructed to facilitate easy installation and maintenance in complex piping systems.

Rotational Alignment: The flange ring rotates freely around the stub end, eliminating issues with bolt hole alignment. This is critical for pre-fabricated piping where rotation is restricted.

Non-Welded Design: The flange itself is not welded to the pipe, allowing for quick dismantling in systems requiring frequent cleaning or inspection.

Dimensional Reference Refer to the schematic diagram to ensure correct fitment between the Flange and the Stub End:

D: Outside Diameter

K: Bolt Circle Diameter (Standardized for mating)

B: Inner Bore (Clearance dimension to slide over the Stub End)

R: Fillet Radius (Critical for seating against the Stub End flare)

Technical Note: Ensure the Radius (R) of the Lap Joint Flange exceeds the radius of the Stub End slightly to ensure the flange face seats flat against the gasket surface. If the flange radius is too small, interference will prevent a proper seal.

Lap Joint (LJ) & Stub End Dimensions

Components: Flange Ring + Stub EndASME B16.5 Class 150 Lap Joint Flange

Dimensions for the backing flange ring only.

| NPS (Size) |

Outside Dia (O) (mm) |

Inner Bore (B) (Clearance) |

Bolt Circle (BC) (mm) |

Holes (Qty) |

Bolt Size (Inch) |

Radius (r) (Fillet) |

|---|---|---|---|---|---|---|

| 1/2" | 88.9 | 22.9 | 60.5 | 4 | 1/2" | 3.0 |

| 3/4" | 98.6 | 28.2 | 69.9 | 4 | 1/2" | 3.0 |

| 1" | 108.0 | 35.1 | 79.2 | 4 | 1/2" | 3.0 |

| 1-1/2" | 127.0 | 50.0 | 98.6 | 4 | 1/2" | 6.0 |

| 2" | 152.4 | 62.5 | 120.7 | 4 | 5/8" | 8.0 |

| 3" | 190.5 | 91.4 | 152.4 | 4 | 5/8" | 10.0 |

| 4" | 228.6 | 116.8 | 190.5 | 8 | 5/8" | 11.0 |

| 6" | 279.4 | 171.5 | 241.3 | 8 | 3/4" | 13.0 |

| 8" | 342.9 | 222.3 | 298.5 | 8 | 3/4" | 13.0 |

ASME B16.5 Class 300 Lap Joint Flange

| NPS (Size) |

Outside Dia (O) (mm) |

Inner Bore (B) (Clearance) |

Bolt Circle (BC) (mm) |

Holes (Qty) |

Bolt Size (Inch) |

Radius (r) (Fillet) |

|---|---|---|---|---|---|---|

| 1/2" | 95.3 | 22.9 | 66.5 | 4 | 1/2" | 3.0 |

| 1" | 124.0 | 35.1 | 88.9 | 4 | 5/8" | 3.0 |

| 1-1/2" | 155.4 | 50.0 | 114.3 | 4 | 3/4" | 6.0 |

| 2" | 165.1 | 62.5 | 127.0 | 8 | 5/8" | 8.0 |

| 3" | 209.6 | 91.4 | 168.1 | 8 | 3/4" | 10.0 |

| 4" | 254.0 | 116.8 | 200.2 | 8 | 3/4" | 11.0 |

| 6" | 317.5 | 171.5 | 269.7 | 12 | 3/4" | 13.0 |

For other pressure classes and facing types, dimensions follow ASME B16.5.

Check Full ASME B16.5 TablesMSS SP-43 / ASME B16.9 Stub End (Short Pattern)

The wetted part. Compatible with both Class 150 & 300 LJ Flanges.

| NPS (Size) |

Pipe OD (mm) |

Length (F) (Short Type) |

Lap Dia (G) (Sealing Face) |

Lap Radius (Corner) |

|---|---|---|---|---|

| 1/2" | 21.3 | 50.8 | 34.9 | 3 |

| 3/4" | 26.7 | 50.8 | 42.9 | 3 |

| 1" | 33.4 | 50.8 | 50.8 | 3 |

| 1-1/2" | 48.3 | 50.8 | 73.0 | 6 |

| 2" | 60.3 | 63.5 | 92.1 | 8 |

| 3" | 88.9 | 63.5 | 127.0 | 10 |

| 4" | 114.3 | 76.2 | 157.2 | 11 |

| 6" | 168.3 | 88.9 | 215.9 | 13 |

| 8" | 219.1 | 101.6 | 269.9 | 13 |

ASME B16.9 Stub End (Long Pattern)

Used when extra length is required for welding clearance. Dimensions per ASME B16.9.

| NPS (Size) |

Pipe OD (mm) |

Length (F) (Long Type) |

Lap Dia (G) (Sealing Face) |

|---|---|---|---|

| 1/2" to 2" | Same length as short pattern (50.8–63.5 mm) | ||

| 2-1/2" | 73.0 | 114.3 | 104.8 |

| 3" | 88.9 | 114.3 | 127.0 |

| 4" | 114.3 | 127.0 | 157.2 |

| 6" | 168.3 | 152.4 | 215.9 |

| 8" | 219.1 | 152.4 | 269.9 |

Need Schedule 10S or 40S Stub Ends?

Check Stock AvailabilityCost Saving Strategy: The Hybrid Assembly

Use Carbon Steel for the heavy flange ring (backing) and expensive Stainless Steel / Alloy only for the stub end (wetted part).

The flange ring can rotate freely around the stub end, making bolt hole alignment effortless during field installation.

Applications & Advantages of Stainless Steel Lap Joint Flanges

The primary advantages of a Stainless Steel Lap Joint Flange system are Cost Savings and Ease of Installation.

Massive Cost Savings (The #1 Benefit): Because the main Flange Ring does not contact the fluid, a low-cost Carbon Steel Flange Ring (e.g., A105) can be used, paired with a corrosion-resistant Stainless Steel Stub End (e.g., SS316L). This drastically reduces material costs on exotic piping systems compared to using a solid SS316L Weld Neck flange.

Rapid Installation & Easy Alignment: The free-rotating flange ring eliminates the need for precise bolt hole alignment in the field. This drastically reduces installation time and labor costs, especially in complex or tight spaces.

Frequent Dismantling & Maintenance: The design is perfect for systems that require frequent inspection or cleaning (e.g., pipelines carrying slurries or abrasive materials in mining or chemical processing).

Flexibility & Vibration Absorption: The two-piece design provides some flexibility, making it ideal for systems with high vibration or potential thermal expansion.

Lap Joint Flange Installation (A 2-Step Process)

Step 1: Welding the Stub End (The Critical Step)

The Stub End (e.g., per ASME B16.9) must be connected to the pipe using a Butt Weld, the same high-integrity weld used for a Weld Neck flange.- For Stainless Steel (e.g., SS316L):

- Method: TIG (GTAW) welding is required for the root pass to ensure a clean, full-penetration weld.

- Filler Metal: Use the correct filler rod (e.g., ER316L) to match the Stub End material.

- Heat Control: Controlled heat input is essential to prevent “sensitization” (carbide precipitation), which can destroy the corrosion resistance of the stainless steel at the weld.

Step 2: Bolting the Flange Ring Connection

After the Stub End is welded and cooled, the Flange Ring (which was slipped onto the pipe before welding) is slid into place.- Gasket & Alignment: Place the gasket on the Stub End face. The rotating ring makes bolt hole alignment simple.

- Critical Step for Stainless Steel: Apply a stainless-steel compatible anti-seize lubricant to all bolt threads and nut faces. This is mandatory to prevent “galling” (seizing) during tightening.

- Tightening: Use a “star pattern” (crisscross) to tighten the bolts in three stages (e.g., 50%, 80%, 100% torque) to ensure even gasket compression.

FAQ

How do you weld a Lap Joint Flange?

A key point is that you do not weld the flange ring. The installation is a 2-step process where you butt-weld the Stub End to the pipe:

Slide the loose Flange Ring onto the pipe before welding.

Align the Stub End (e.g., Type A) with the pipe end.

Perform a full-penetration Butt Weld (e.g., TIG/GTAW for stainless steel) to join the Stub End to the pipe, using the correct filler metal (like ER316L).

The Flange Ring then rotates freely behind the welded Stub End for bolt alignment.

Is a Lap Joint Flange a Raised Face (RF)?

This is a common point of confusion. The loose Flange Ring itself is typically flat.

The actual sealing surface is the face of the Stub End This Stub End face is manufactured to match standard sealing faces, and the most common is a Raised Face (RF), which is what creates the seal with the gasket.

What is a Type A Lap Joint Flange?

A “Type A” refers to the Stub End, not the flange itself.

A Type A Stub End is the industry standard (per ASME B16.9) for use with a standard Lap Joint Flange. It is a short piece of pipe with a flared shoulder and a machined face (the sealing surface). This Stub End is butt-welded to the pipe, and its flared shoulder is what holds the rotating Flange Ring in place.

Stainless Steel Flanges

Stainless Steel Flanges