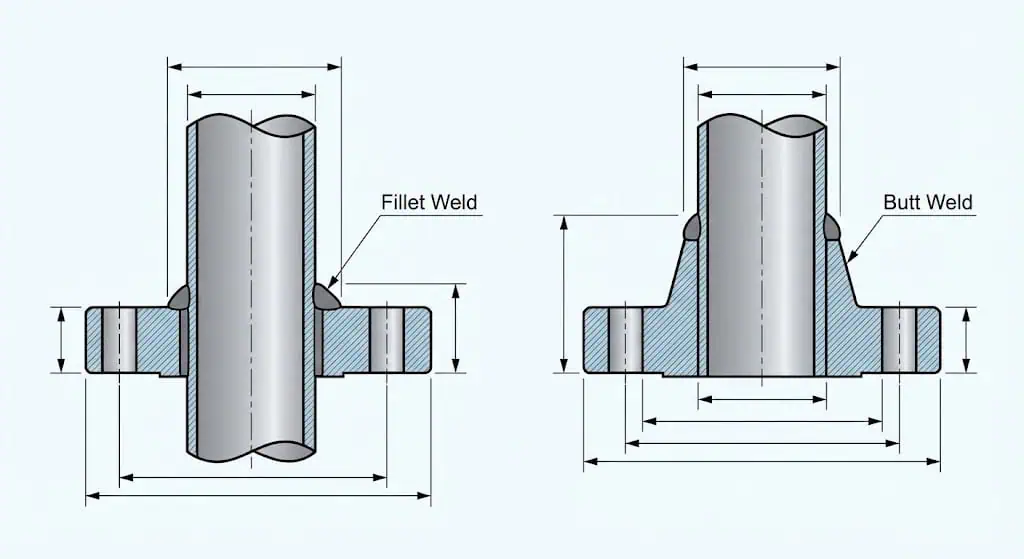

The divergence between a slip-on flange vs weld neck flange centers on structural continuity, fatigue behavior, and what you can realistically inspect after fabrication. A slip-on flange (SO) slides over the pipe OD and is typically secured by fillet welds (often inside + outside), which makes fit-up fast but introduces stress concentration at the weld toes. A weld neck flange (WN) uses a tapered hub and a full-penetration butt weld, creating a smoother load path that tolerates pressure/temperature cycling and vibration far better—especially when volumetric NDT (RT/UT) is specified.

Two practical selection rules used on real piping jobs:

- Use weld neck when the line is safety- or availability-critical: cyclic pressure/temperature, rotating equipment vibration (pump/compressor discharge), hazardous service, or when your QA plan requires meaningful weld inspection (RT/UT).

- Use slip-on for stable utility services: low pressure, limited thermal cycling, non-hazardous fluids, and where the project is schedule-driven and surface NDT is acceptable.

Important note for engineers and buyers: ASME “pressure class” is not a direct PSI value. Actual allowable working pressure depends on material group and temperature (per tables in ASME B16.5). The flange type (SO vs WN) impacts fatigue performance and inspection options more than it changes the B16.5 dimensional interface.

Slip-On Flange vs Weld Neck Flange Comparison

Key Differences Table

Engineering differences show up in geometry, stress distribution, and allowable fabrication/inspection practice. The matrix below frames what actually changes between SO and WN in the field:

| Feature | Slip-On Flanges | Weld Neck Flanges |

|---|---|---|

| Design | Slides over pipe OD; typically fillet welded (often ID & OD) | Tapered hub; full penetration butt welded |

| Load Path | Discontinuity at fillet weld; higher local stress at weld toes | More continuous stress transfer through hub + butt weld |

| Fatigue Performance | Lower under vibration/thermal cycling (stress concentration dominates) | Higher under cyclic loads (reduced stress intensification) |

| Inspection Reality | Mostly surface NDT (VT/PT/MT) on fillet welds; volumetric inspection is limited | RT/UT commonly applied to butt welds when required by QA/spec |

| Typical Use Envelope | Stable utility services; avoid severe cyclic duty | Process-critical lines, high consequence of leak, cyclic duty |

| Installation | Faster fit-up; less sensitive to exact pipe cut length | Requires bevel prep, alignment control, qualified weld procedure |

| Cost Driver | Lower material weight; faster fabrication | More forging/machining; higher welding skill + QA cost |

| Typical Applications | Firewater, cooling loops, low-pressure air/N2 (non-critical) | High-pressure steam, hydrocarbons, corrosive service, rotating equipment discharge |

Summary of Main Points

Slip-on vs weld neck is not a “fits or doesn’t fit” question—both can share the same B16.5 bolt pattern. The decision is about fatigue, weld quality assurance, and leak risk management.

- Design & Fit-up: Slip-on flanges use a bore slightly larger than pipe OD, so the flange can slide into position. This reduces fit-up time on site, but it also creates a fillet-welded joint where local stress concentration and toe quality matter. Weld neck flanges require a beveled pipe end and controlled alignment for a butt weld, which is slower but structurally cleaner.

- Structural Integrity: Weld neck flanges incorporate a long tapered hub that reduces bending stress at the flange-to-pipe transition. In real services (especially near rotating equipment), that hub is what prevents “flange rotation” and slow crack growth at the weld toe.

- Fatigue & Vibration: In pump discharge and compressor piping, slip-on fillet weld toes are a common initiation point for fatigue cracking when supports are poor or vibration is high. Weld neck butt welds—with proper root penetration and alignment—typically survive these conditions far longer. Typical engineering experience: the service life gap can be multiple times under the same vibration spectrum, but it depends heavily on weld profile, misalignment, and support design.

- Pressure Capability (Correct Interpretation): Both flange types are manufactured to ASME B16.5 classes, but the “Class” is a rating system—not a PSI number. The ASME B16.5 flange classes define the interface; allowable pressure must be checked against the specific material group and temperature.

- Total Installed Cost: Slip-on flanges reduce fabrication time (no beveling, faster fit-up). Weld neck flanges usually cost more upfront, but in critical systems they reduce lifecycle cost by enabling robust inspection and minimizing rework after hydrotest or startup leaks.

- Selection Criteria: If the line is cyclic, hazardous, or must be inspectable, weld neck is the default engineering answer. Slip-on is an economical choice for stable utilities when the consequence of leak is low and the spec allows fillet weld construction.

This technical distinction ensures the selected component aligns with real safety margins—not just procurement convenience.

Slip-On Flanges Overview

Design and Construction

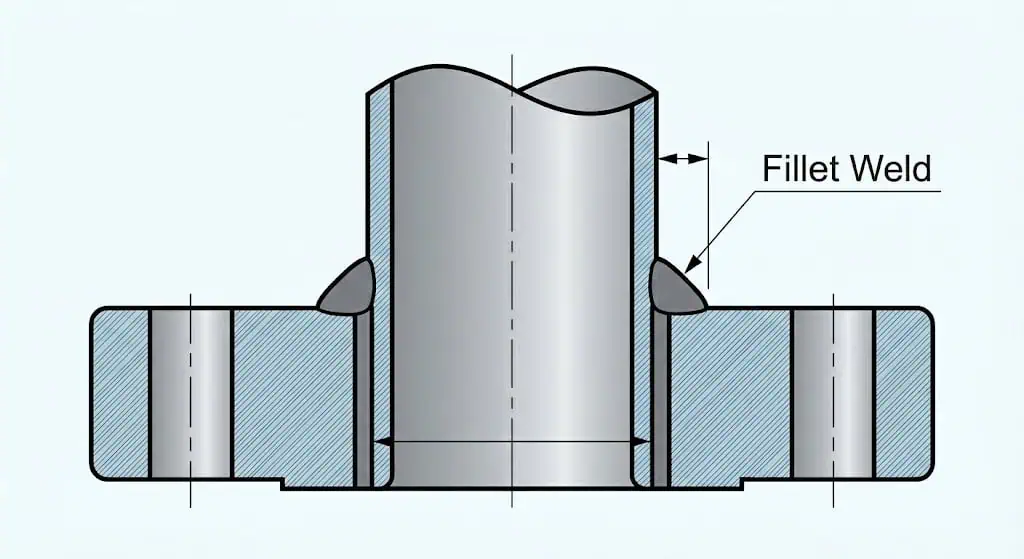

Slip-on flanges are rings with a bore slightly larger than the pipe OD, allowing quick alignment and rotation before welding. In common shop practice, the pipe end is set back a few millimeters from the flange face so the inside fillet weld can be placed without disturbing gasket seating. That “easy fit-up” is the reason slip-ons are popular in utilities—but it also creates a crevice region where corrosion can start if the weld profile is poor or the service is wet and oxygenated.

Common material specifications include (final selection must match code, corrosion, and temperature requirements):

- Carbon Steel (ASTM A105): General industrial service where corrosion allowance and coatings are feasible.

- Stainless Steel (ASTM A182 F304/F316L): Corrosion resistance for chemical, food, and water-related services; also reduces under-deposit corrosion risk around the joint.

- Alloy Steel (ASTM A182 F11/F22): Elevated temperature service (typical power/steam alloys), subject to PWHT requirements depending on thickness and spec.

- Duplex Steel (UNS S31803 / S32205): Higher strength and chloride resistance for offshore, seawater, and desalination—requires qualified welding procedures to control heat input.

Engineering reminder: For stainless systems, consider crevice/under-deposit corrosion risk at the slip-on geometry if the service can stagnate (dead legs, intermittent flow). In those cases, weld neck often performs better long-term even if the pressure class is low.

Welding and Installation

Slip-on flange reliability is dominated by weld execution and fit-up discipline. A common failure pattern is treating slip-ons as “simple,” then skipping key controls like pipe squareness, insertion depth consistency, or inside weld access. In most piping specs, the intent is a fillet weld on the outside plus an additional fillet on the inside when accessible, because the inside weld improves leakage resistance and reduces crevice severity.

Field checklist that prevents rework at hydrotest:

- Confirm pipe end is square and burr-free; out-of-square ends create uneven fillet size.

- Control insertion depth consistently around the circumference; avoid “one-side bottoming.”

- Verify flange face is perpendicular to the pipe axis; mis-squareness drives gasket seating problems later.

- After welding, perform VT + PT/MT as specified; do not assume a smooth-looking toe is crack-free.

Engineering case (installation failure): A cooling-water header repeatedly failed hydrotest at a slip-on flange. Root cause was an incomplete inside fillet weld combined with poor pipe squareness—water tracked through a pinhole at the weld toe. Fix: cut out the joint, re-fit with controlled insertion depth, complete inside weld, then PT inspection before repaint.

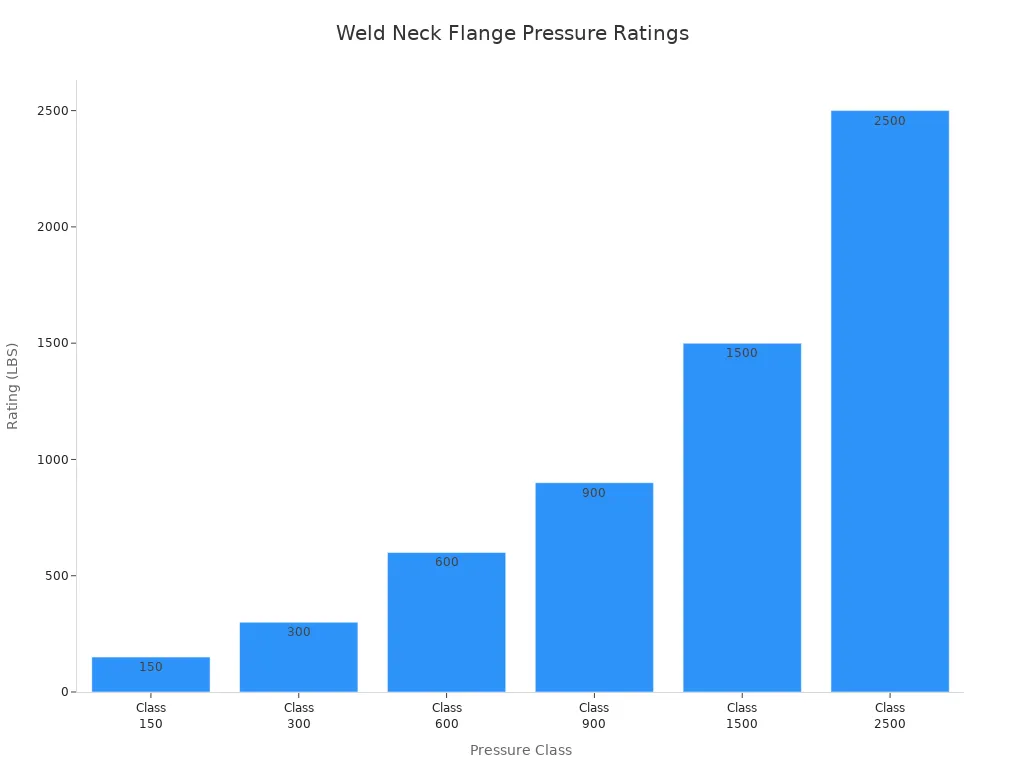

Pressure and Strength

Slip-on flanges can be manufactured in the same ASME B16.5 pressure classes as weld neck flanges, but practical usage is often restricted by fatigue and inspection considerations. For example, in services with vibration, thermal shock, or frequent startups/shutdowns, the fillet weld detail becomes the limiting feature—not the bolt circle.

For reference only: typical allowable working pressures at 38°C (100°F) depend on material group and are taken from ASME B16.5 tables. Always confirm against the actual material group, temperature, and gasket/bolting limits.

| ASME B16.5 Flange Classes | Typical Allowable Pressure at 38°C (100°F) for common carbon steel groups (verify in B16.5) |

|---|---|

| Class 150 | Typical range ~285 psi (material/temperature dependent) |

| Class 300 | Typical range ~740 psi (material/temperature dependent) |

| Class 400 | Typical range ~990 psi (material/temperature dependent) |

| Class 600 | Typical range ~1,480 psi (material/temperature dependent) |

| Class 900 | Typical range ~2,220 psi (material/temperature dependent) |

| Class 1500 | Typical range ~3,705 psi (material/temperature dependent) |

| Class 2500 | Typical range ~6,175 psi (material/temperature dependent) |

Typical engineering guidance (not a code rule): Many owners restrict slip-on flanges to lower classes in cyclic duty because fillet-welded details are more sensitive to vibration, misalignment, and weld profile. If your line is near rotating equipment, treat slip-on as a risk item unless the spec explicitly permits it and supports are robust.

Cost Factors

The economic advantage of slip-on flanges comes from fabrication time and simpler preparation—not only the flange unit price. Pipe ends typically do not require beveling, fit-up is faster, and welding time is often lower than a full-penetration butt weld. However, if repeated leaks occur at startup or if QA requires extensive rework, the “cheap joint” becomes expensive.

Typical cost drivers engineers actually track:

- Preparation: No beveling saves time, but poor squareness increases rework.

- Welding time: Fillet welds are faster, but access for inside weld can be limiting in tight racks.

- Inspection: Surface NDT is cheaper than RT/UT; however, a missed defect often shows up at hydrotest.

- Lifecycle: In wet or corrosive services, crevice behavior can dominate maintenance cost.

Typical Applications

Slip-on flanges are widely used in low-consequence utility and auxiliary systems where vibration and thermal cycling are limited. Common applications include:

- General utility lines: cooling water, compressed air, nitrogen.

- Firefighting water mains (typical lower classes when permitted by the spec).

- Municipal water treatment and wastewater pipelines.

- HVAC chilled water and heating loops.

- Marine ballast systems and non-essential shipboard piping.

- Agricultural irrigation networks.

Where slip-ons often cause trouble: pump discharge headers, compressor piping, and lines with frequent thermal transients. Those services repeatedly produce fatigue cracks at weld toes when supports are marginal.

Recommendation: Specify slip-on flanges for stable, low-consequence utility services where the piping class allows fillet-welded construction and where vibration control is proven by support design.

Weld Neck Flanges Overview

Design and Construction

Weld neck flanges are engineered with a long tapered hub that reduces stress concentration at the flange-to-pipe transition. This is why they dominate in critical service: the hub geometry acts like a stress diffuser, limiting flange rotation and protecting gasket seating under bending moments (misalignment, thermal growth, and vibration).

Key design elements engineers look for during specification and receiving inspection:

| Feature | Technical Function |

|---|---|

| Long tapered hub | Transfers stress smoothly from flange to pipe wall; reduces dishing at the flange face. |

| Bore matching | ID is machined to match pipe Schedule (e.g., Sch 40/80) for stable flow profile and reduced erosion-corrosion risk. |

| Butt weld connection | Allows full penetration welding; enables meaningful volumetric inspection when required by spec. |

| Integral raised face (when specified) | Provides a concentrated sealing surface compatible with common gasket types (verify facing & gasket selection). |

| Bolting capability | Accommodates higher gasket seating stress when required, within the limits of bolting and flange material. |

| Surface finish control | Typical serrated finish helps gasket performance; confirm finish requirements with gasket vendor/spec. |

| Variant geometry | Short hub or long weld neck variants may be specified for layout or stress reasons (project-dependent). |

| Standards interface | Commonly specified to ASME B16.5 or EN 1092-1; verify drilling, facing, and material standard on PO. |

Welding and Installation

Weld neck flange performance is only as good as the butt weld quality and alignment control. In critical systems, the weld procedure is typically qualified (WPS/PQR), and alignment tolerances are controlled because even small high-low (internal misalignment) can become a fatigue hot spot.

Shop/field practices that consistently prevent failures:

- Preparation: Clean bevels; verify bevel angle and land per WPS. Remove scale/oil to prevent lack of fusion.

- Alignment: Control root gap and internal misalignment. Tack sequence should prevent pulling the flange out of square.

- Root Pass: Ensure penetration and a sound root profile. Poor root quality can create a crack starter on the ID.

- Fill & Cap: Build a smooth transition; avoid undercut at the cap toe which drives fatigue cracking.

- PWHT (when required): Apply per material/spec; skipping PWHT on applicable alloys can leave high residual stress.

- NDT Inspection: Apply RT/UT when required by spec; supplement with PT/MT at cap for surface-breaking defects.

Engineering case (fit-up / alignment failure): A high-pressure steam line developed a leak after a short runtime. Investigation showed flange face out-of-square and internal misalignment at the butt weld, causing gasket seating issues plus cyclic bending at the hub. Corrective action: re-cut and re-bevel, align with internal clamp, re-weld to WPS, then RT + flange-face perpendicularity check before final bolt-up.

Pressure and Strength

Weld neck flanges are the default choice when the piping system must tolerate bending moments, thermal cycling, and high consequence of leakage. They do not “increase” ASME class rating by themselves, but they dramatically improve how the joint behaves under real-world load combinations (pressure + bending + vibration).

Correct interpretation of “Class”:

- Pressure Class (150/300/600/900/1500/2500) is a standardized rating framework.

- Allowable working pressure must be taken from ASME B16.5 tables for the specific material group at operating temperature.

- Joint reliability is affected by weld design and QA—this is where weld neck typically outperforms slip-on.

| ASME B16.5 Pressure Class | Engineering Interpretation |

|---|---|

| Class 150–2500 | Dimension + rating framework. Verify allowable working pressure per material group and temperature in B16.5 tables. |

| Critical service | WN is preferred because butt weld quality can be controlled and inspected; hub reduces flange rotation and protects gasket seating. |

This structural continuity is why weld neck joints are routinely specified where leakage is unacceptable under combined loading.

Cost Factors

Weld neck flanges cost more because you pay for forging/machining mass and for butt-weld QA discipline. A weld neck joint often requires bevel prep, alignment control, and qualified welding. If the specification calls for RT/UT, inspection cost can exceed the flange price difference—yet this is usually justified by reduced leak risk and shutdown avoidance.

| Feature | Weld Neck Flange | Slip-On Flange |

|---|---|---|

| Material & Machining | Higher (hub forging + machining) | Lower |

| Installation Labor | Higher (butt weld + alignment control) | Lower (fillet weld fit-up) |

| QA / Inspection | Often higher (RT/UT possible/required) | Often lower (surface NDT only) |

For critical assets, “installed cost” should be compared against the consequence of leak and the probability of rework—not against unit price alone.

Typical Applications

Weld neck flanges are standard in services where process safety, fatigue resistance, and inspection credibility matter. Common use cases include:

- Oil and gas transmission and high-integrity process piping.

- Chemical reactors, high-temperature columns, and corrosive service where shutdowns are costly.

- High-pressure/high-temperature steam lines in power generation.

- Refinery piping for volatile hydrocarbons (LPG/LNG), acid gas, and critical rotating equipment tie-ins.

Engineering case (fatigue near rotating equipment): A pump discharge line originally used slip-on flanges to save fabrication time. Within months, toe cracking appeared at the fillet weld during vibration monitoring. The retrofit to weld neck flanges (with improved supports and alignment control) eliminated recurring weld repairs and stabilized leakage risk.

Comparison of the advantages and disadvantages of Slip-On Flange vs Weld Neck Flange

The trade-off between slip-on and weld neck flanges is speed/cost versus structural durability and inspectability. The right choice depends on piping class, service criticality, and the plant’s risk tolerance—not personal preference.

A detailed engineering assessment highlights the specific pros and cons of each configuration:

Advantages of Slip-On Flanges

- Rapid Installation: Easier fit-up; minor linear misalignments are simpler to manage during positioning.

- Simplified Fit-Up: Flange rotation on pipe helps bolt-hole orientation in tight spool fabrication.

- Lower Skill Barrier: Fillet welds can be executed faster, but still require profile control and inspection discipline.

- Cost Efficiency: Lower material mass and reduced beveling/prep time lower fabrication hours.

- Availability: Widely stocked for standard utility and auxiliary applications.

Advantages of Weld Neck Flanges

- Maximum Structural Robustness: Butt weld provides a cleaner load path and better behavior under bending moments.

- Inspectability: Butt weld configuration is compatible with meaningful RT/UT when specified.

- Fatigue Resistance: Hub transition reduces stress intensification; especially important under vibration and cycling.

- Flow Dynamics: Bore matching reduces turbulence and erosion-corrosion compared with abrupt transitions.

- Extreme Service: Better tolerance to thermal cycling and combined loads that can unseat gaskets.

Disadvantages Matrix

Key limitations to consider during specification:

| Disadvantage | Slip-On Flanges | Weld Neck Flanges |

|---|---|---|

| Fatigue / Vibration | Higher sensitivity to weld toe condition, misalignment, and support quality | More tolerant, but still requires correct alignment and weld quality |

| Inspection | Mostly surface NDT; hidden defects may survive until hydrotest/startup | Volumetric NDT possible when required; higher QA cost |

| Installation Skill | Faster, but still requires disciplined fit-up to prevent gasket seating issues | Requires qualified butt welding and alignment control |

| Maintenance | Crevice geometry can accelerate corrosion in wet/stagnant services | Repair often requires cut-out and re-beveling if weld defects occur |

| Cost | Lower installed cost in stable utilities | Higher installed cost; justified for critical services |

Decision Tip: Use slip-on flanges to control schedule and cost in stable, low-consequence lines. Use weld neck flanges to control risk and lifecycle cost in process-critical lines.

Aligning flange selection with the piping class specification and the inspection plan prevents recurring leaks and rework.

Slip-On Flange vs Weld Neck Flange: Performance & Cost

Strength and Durability

Weld neck flanges usually outperform slip-on flanges in combined loading because the hub reduces stress concentration and protects gasket seating under bending moments. Slip-on joints rely on fillet welds where toe profile, undercut, and fit-up quality heavily influence fatigue life. In corrosive environments, slip-on geometry can also trap moisture and deposits, increasing crevice-driven damage if coating or passivation is poor.

- Weld neck joints are structurally closer to the pipe’s “continuous wall” behavior.

- Slip-on joints introduce a geometric discontinuity that can initiate corrosion and fatigue at the weld toe.

- Typical engineering observation: when vibration exists, support design and weld profile matter more than nominal pressure class for long-term leak performance.

| Flange Type | Reliability Tendency (Typical Field Observation) |

|---|---|

| Slip-On | Good in stable utilities; risk increases with vibration, thermal cycling, and wet/stagnant corrosion |

| Weld Neck | Better tolerance to cyclic load and bending; preferred when leak consequence is high |

Installation Time and Skill

Slip-on flanges offer a logistical advantage in fast-track projects, but they are not “forgiving” of poor workmanship. Faster fit-up can hide squareness and alignment issues that later appear as gasket leaks. Weld neck flanges demand more precision: bevel prep, root gap control, and flange squareness must be controlled to avoid rework and to ensure good gasket seating.

- Slip-on: Faster positioning and bolt-hole orientation; watch insertion depth and flange face squareness.

- Weld neck: Slower fit-up; requires controlled alignment and qualified butt weld execution.

- Labor strategy: Use slip-ons where permitted; reserve WN joints for the highest-risk locations (near equipment, battery limits, tie-ins, high-temperature runs).

Budget Considerations

Slip-on flanges can reduce initial fabrication cost, while weld neck flanges reduce risk-driven cost. If a leak triggers shutdown, environmental reporting, or safety exposure, the economics flip quickly in favor of weld neck and stronger QA. For low-consequence utilities, slip-ons are a rational cost-control choice—when the piping class allows and vibration is managed.

Engineering case (cost vs risk): A plant used slip-ons on a utility header to save time and money—successful for years. The same approach on a cyclic process line caused repeated repairs and lost production. The lesson: apply the flange type based on consequence and cycling, not on procurement habit.

Choosing Between Slip-On and Weld Neck Flanges

Application Scenarios

Flange selection is dictated by the Piping Material Specification (PMS) and the real operating envelope.

For high-pressure steam, hazardous service, or cyclic loads, robust connections and credible inspection become mandatory. A practical selection hierarchy many projects follow:

- Weld neck flanges: Preferred for high consequence of leak, cyclic duty, high temperature, vibration, and where QA requires RT/UT.

- RTJ (Ring Type Joint) flanges: Used for demanding sealing applications; selection depends on facing, gasket, and spec—not just pressure class.

- Socket weld flanges: Sometimes used for small-bore piping where appropriate; depends on code/spec and service conditions.

- Slip-on flanges: Appropriate for stable utilities where the piping class allows and leakage consequence is low.

Slip-on flanges are common in municipal infrastructure and utilities, while weld neck flanges dominate energy and high-integrity process systems.

Factors to Consider

A holistic evaluation prevents mismatch between design intent and real operating risk. Use the table below to align flange type with service and QA requirements:

| Flange Type | Strength & Cyclic Resistance | Cost & Installation Ease | Best Applications |

|---|---|---|---|

| Weld neck flanges | High fatigue tolerance; better under combined pressure + bending + vibration | Higher cost; slower; requires skilled welding and potential RT/UT | Refineries, power plants, offshore, rotating equipment tie-ins |

| Slip on flanges | Adequate for stable utilities; sensitive to vibration and weld toe quality | Lower cost; faster installation; typically surface NDT | Firewater, cooling water, HVAC, low-consequence utility services |

Before finalizing, evaluate fluid toxicity, operating temperature range, startup/shutdown frequency, vibration potential, and the required NDT level. If the spec is written to ASME process codes (e.g., ASME B31.3), follow the project’s piping class rules rather than assuming “utility = slip-on.”

Why Choose Sunhy Stainless Steel Flanges

Sunhy supplies stainless steel flanges with controlled machining, traceable materials, and documentation aligned with common project QA expectations.

For engineering teams, the practical value is consistency: flange dimensions, facing finish, and material identification must match the piping class to prevent onsite fit-up delays and gasket seating problems. Whether the project specifies slip-on flanges for utilities or weld neck flanges for critical service, correct documentation (MTR/PMI as required by the project) reduces receiving-inspection disputes and start-up risk.

| Certification Type | Scope & Assurance |

|---|---|

| ISO 9001 | Quality Management System (QMS) |

| ISO 14001 | Environmental Management System |

| ISO 45001 | Occupational Health and Safety |

| EU Pressure Equipment Directive (PED) | Compliance for EU pressure equipment markets |

| DNV classification | Maritime and offshore type approval |

| Special Equipment Manufacturing License | Regulatory license for pressure piping components |

| Sanitation Permit | Hygienic standards for food/water service |

Final Selection Summary: Select based on consequence of leak, cyclic duty, and inspection plan—not only pressure class. The table below reiterates the functional difference in a procurement-friendly format:

| Feature | Weld Neck Flange | Slip-On Flange |

|---|---|---|

| Design | Long tapered hub (Butt Weld) | Ring with bore (Fillet Weld) |

| Reliability under cycling | Typically higher (better stress distribution) | Lower when vibration/thermal cycling exists |

| Inspection potential | RT/UT often applicable when required | Mostly surface NDT; hidden defects harder to detect |

| Application | Critical & higher consequence service | General utility service |

Choosing a correctly specified flange (standard, pressure class, facing, material, and QA documentation) is what protects schedule and avoids rework during hydrotest and commissioning.

FAQ

What is the main difference between slip on flange and weld neck flange?

The main difference is the weld joint design and the resulting stress/inspection behavior. Slip-on flanges are typically fillet welded (often inside + outside), which makes fit-up faster but increases stress concentration at the weld toes. Weld neck flanges use a full-penetration butt weld with a tapered hub, creating better structural continuity and allowing credible RT/UT inspection when required by the piping class.

When should you use a slip-on flange instead of a weld neck flange?

Use slip-on flanges for stable, low-consequence utility services where the piping class permits fillet-weld construction. Typical examples are cooling water, firewater, compressed air, and nitrogen—provided vibration and thermal cycling are limited and the inspection plan does not require volumetric NDT.

Are weld neck flanges better for high-pressure applications?

Weld neck flanges are generally preferred for high-pressure and cyclic applications because they handle combined loads better and support robust inspection. Pressure rating itself must still be verified by ASME B16.5 tables for the specific material group and temperature (e.g., Class 2500 is a rating framework; allowable pressure is not “2500 psi”).

How do you choose between slip-on flange vs weld neck flange?

Choose based on consequence of leak, cyclic duty, vibration, and required NDT. Use weld neck flanges for severe cyclic conditions, high temperatures, hazardous fluids, and lines near rotating equipment. Use slip-on flanges for low-risk utilities where faster fabrication is valuable and the piping class allows it.

Do Sunhy stainless steel flanges meet international standards?

Sunhy supplies flanges manufactured to common international standards (ASME B16.5 / ASTM / EN 1092-1 as specified on the order). For engineering acceptance, verify the purchase order includes standard, class/PN, facing, material grade, and required documentation (e.g., MTR/PMI per project specification).