Tube Sheet Flanges

Sunhy manufactures high-integrity, precision-engineered tube sheet flanges, the critical heart of shell-and-tube heat exchangers. These components serve a complex dual role: providing rigid structural support for the entire tube bundle while simultaneously acting as a high-pressure flange, sealing the shell-side and tube-side fluids.

As a specialized manufacturer, we produce custom tube sheet flanges from a wide range of materials, including solid alloys, clad composites, and standard steels. Our advanced manufacturing and quality assurance processes, including PAUT inspection, ensure verifiable integrity for the most demanding applications in refining, chemical processing, and power generation.

Home / Stainless Steel Flange / Specialty / Tube Sheet Flanges

Types of Tube Sheet Flanges We Supply

By Design Type

By Standard & Class

Advanced Materials

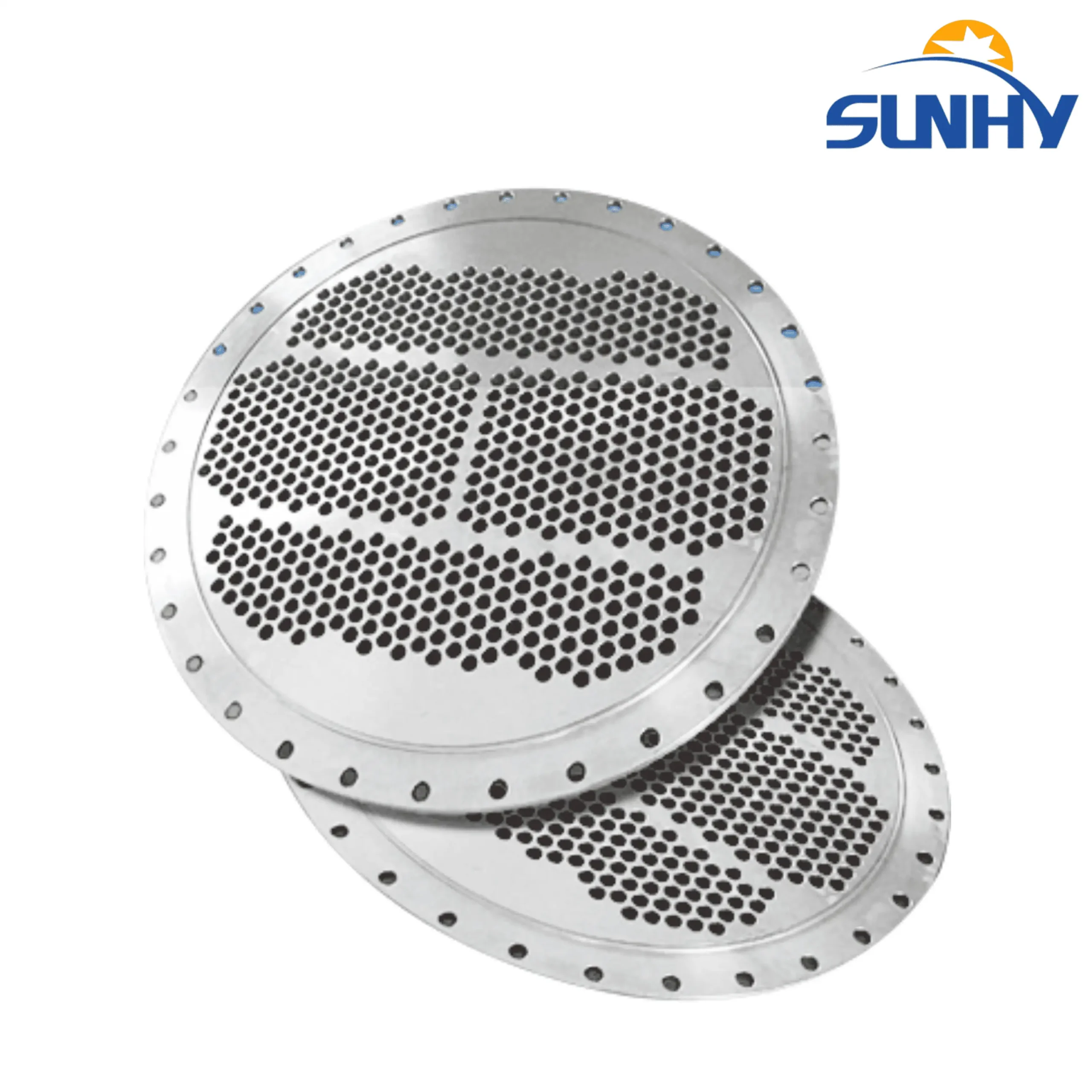

Stainless Steel Flanged Tube Sheet for Heat Exchanger

Precision Stainless Steel Baffle Plate / Tube Sheet

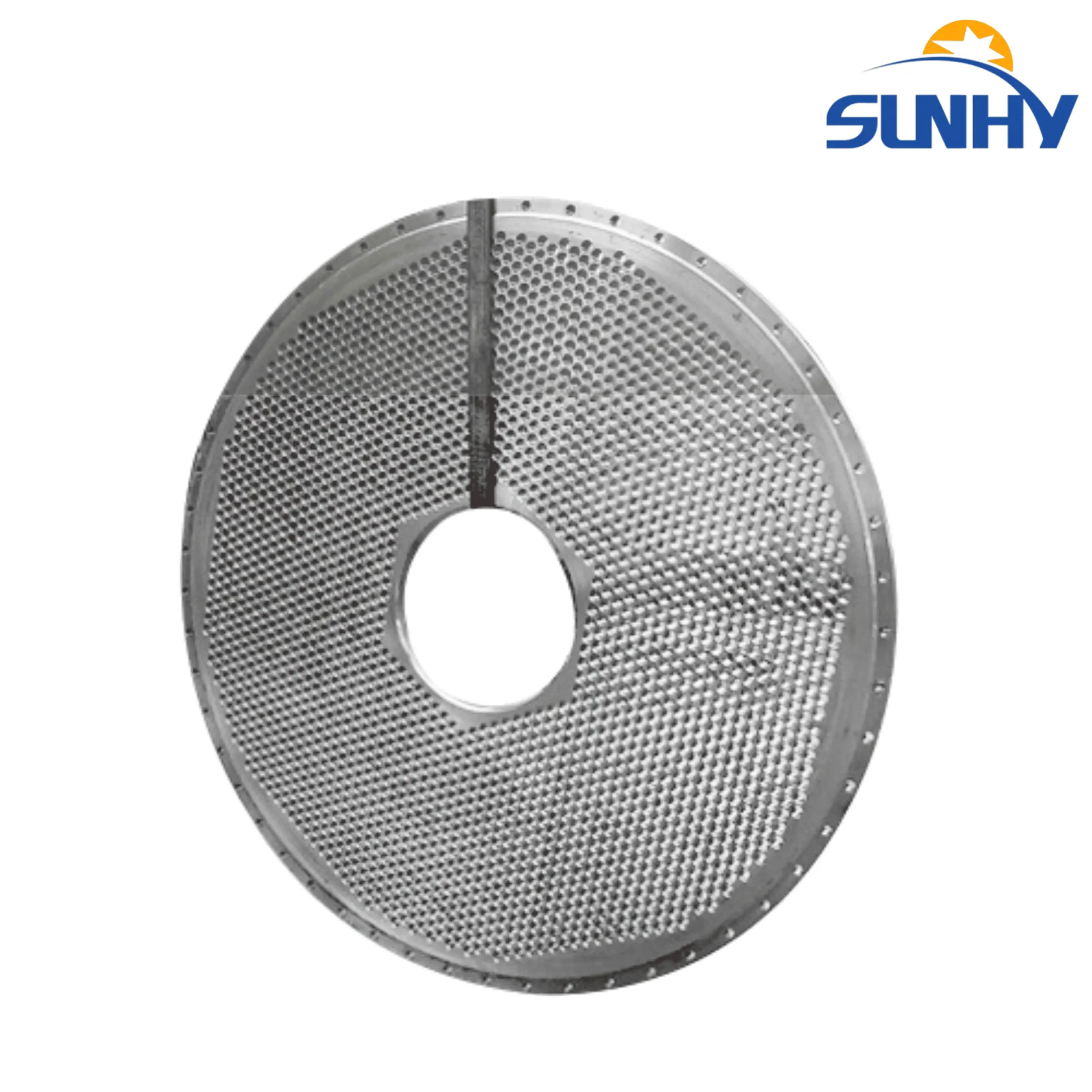

Stainless Steel Perforated Tube Sheet / Screen

Stainless Steel Perforated Plate / Tube Sheet

Bolted Stainless Steel Tube Sheet for Heat Exchanger

Stainless Steel Pocket Orifice Plate (Multi-Hole)

Stainless Steel Core Orifice Plate (Multi-Hole)

Stainless Steel Multi-Hole Plate Flange / Spacer

Stainless Steel Filter Element Support Flange

Stainless Steel Condenser Tube Sheet / Baffle Plate

Stainless Steel Condenser Orifice Plate with Flange

Stainless Steel Filter Bag Flange / Support Plate

Why Partner with Sunhy for Your Tube Sheet Flanges?

Purchasing a tube sheet flange is an investment in your plant’s safety, efficiency, and uptime. We offer more than just a component; we provide an engineering partnership.

Value Engineering Expertise: We don’t just sell expensive solid alloys. Our engineers will review your application to see if a Clad Material or Lap-Joint design can provide the same performance and safety at a significantly lower total cost.

Manufacturing Beyond the Standard: We apply the “manufacturer’s experience” mentioned by TEMA. We don’t just machine a “standard” groove; we design an optimized groove profile for your specific tube material and wall thickness to ensure maximum joint strength and seal life.

Verifiable, Advanced Quality Assurance: We don’t rely on outdated “code compromises” that skip internal weld inspection. We have invested in advanced PAUT systems to prove the volumetric integrity of our TTS welds, giving you traceable, digital quality records and true peace of mind.

What Are Tube Sheet Flanges? The Critical Dual-Role Component

A tube sheet, also known as a tube sheet flange, is one of the most complex and critical components in shell-and-tube heat exchangers, boilers, and pressure vessels. It is a thick, forged plate precision-drilled with hundreds or thousands of holes in a precise pattern to accept and anchor the heat transfer tubes.

Its uniqueness lies in its dual functionality:

Structural Support & Alignment: The tube sheet acts as the “skeleton” for the tube bundle. It holds every single tube in precise alignment, preventing catastrophic failures from flow-induced vibration (FIV) and operational stress.

Fluid Isolation & Sealing: Its most vital function is to serve as an absolute physical barrier. It isolates the “tube-side” fluid (flowing inside the tubes) from the “shell-side” fluid (flowing outside the tubes). This sealing integrity is paramount for process efficiency and safety.

Determining Thermodynamic Performance: The mechanical layout of the tube sheet—its tube count, pitch, and pattern—directly dictates the total heat transfer area (A in the Q = U * A * ΔTlm equation). Our engineers balance the need for maximum thermal efficiency (more tubes) with the need for mechanical integrity (stronger ligaments).

Technical Parameters for Ordering (RFQ Checklist)

To provide an accurate quotation, please include the following information in your RFQ. A technical drawing is always the most effective way to communicate your full requirements.

| Category | Required Information | Notes |

| Basics | 1. Governing Standards: ASME, TEMA Class (R, B, or C)? | This sets the quality, tolerance, and design basis. |

| 2. Technical Drawing: (Most Important) | Please attach if available. | |

| Dimensions & Material | 3. Key Dimensions: Outer Diameter (OD), Thickness. | |

| 4. Base Material Grade: Full ASTM/ASME grade (e.g., SA-516 Gr.70). | ||

| 5. Clad Material (if any): Clad alloy (e.g., SB-265 Gr.1) & min. thickness. | ||

| Flange Specs | 6. Pressure Rating (Class): 150#, 300#, 600#, etc. | Determines flange thickness and bolt pattern. |

| 7. Flange Face Type: RF (Raised Face), FF (Flat Face), or RTJ. | ||

| Tube Hole Details | 8. Total Number of Holes: | |

| 9. For Tube OD: (e.g., D 19.05mm or 0.75 inch). | ||

| 10. Drilled Hole Diameter: The actual finished hole size. | ||

| 11. Tube Hole Layout: Pitch (center-to-center) and Pattern (e.g., 1.25″ Triangle). | ||

| 12. Grooving: Yes/No? Number of grooves? (or “Per TEMA”). | ||

| Quality | 13. NDT Requirements: Standard (PT/MT) or Advanced (PAUT)? | This impacts cost and delivery. |

Tube Sheet Flange Design Types & Selection

- The choice of tube sheet design is dictated by thermal expansion, cleaning requirements, and fluid properties.

1. Fixed Tubesheet (e.g., TEMA BEM, AEM)

This is the simplest design where both tube sheets are welded directly to the shell.

- Pros: Most cost-effective and allows for the maximum number of tubes in a given shell. The straight tubes are easy to clean on the tube-side.

- Cons: Cannot accommodate large thermal expansion differences between the shell and tubes, requiring a bellows expansion joint. The tube bundle cannot be removed, making shell-side cleaning very difficult (chemical cleaning only).

2. U-Tube (e.g., TEMA BEU)

Uses a single tube sheet with U-shaped tubes.

- Pros: The U-bends allow the bundle to freely expand and contract, eliminating thermal stress. The entire bundle can be removed for easy shell-side cleaning and inspection.

- Cons: The U-bends make tube-side mechanical cleaning extremely difficult or impossible. This design is only suitable for clean, non-fouling fluids on the tube-side.

3. Floating Head (e.g., TEMA BES, AET)

The most versatile and robust design. One tube sheet is fixed, while the other “floats” inside the shell, connected only to the tube bundle.

- Pros: Perfectly handles large thermal expansion. The entire bundle can be removed, and the straight tubes allow for easy cleaning of both the tube-side and shell-side.

- Cons: This is the most complex and expensive design due to the internal floating head cover, flanges, and seals.

| Design Type | TEMA Example | Thermal Expansion | Bundle Removable? | Tube-Side Cleaning (Internal) | Shell-Side Cleaning (External) | Relative Cost | Typical Application |

| Fixed Tubesheet | BEM, AEM | Poor (Needs Bellows) | No | Easy (Straight Tubes) | Difficult (Chemical Only) | Low | Low temp differential, clean shell-side fluid. |

| U-Tube Bundle | BEU, AEU | Excellent (Free) | Yes | Difficult / Impossible | Easy (Removable) | Medium | High temp differential, clean tube-side fluid. |

| Floating Head (Split-Ring) | BES, AES | Excellent (Free) | Yes | Easy (Straight Tubes) | Easy (Removable) | High | High temp differential, fouling shell-side fluid (Refinery). |

| Floating Head (Pull-Through) | BET, AET | Excellent (Free) | Yes | Easy (Straight Tubes) | Easy (Removable) | Highest | Similar to BES, but when cleaning convenience is the top priority. |

Special Design: Double Tube Sheet for Critical Applications

For applications where even trace amounts of cross-contamination are unacceptable, the Double Tube Sheet design is used.

This system uses two separate tube sheets (an inner and an outer) separated by a small gap. This gap is vented to the atmosphere.

How it works: If a leak occurs at either tube-to-tubesheet joint, the leaking fluid (either tube-side or shell-side) enters the gap and is safely drained out of the vent. This provides an immediate, detectable signal of a leak before the two process fluids can ever mix.

Key Applications:

Pharmaceutical & Food: Protecting pure products (WFI, beverages) from contamination by utility fluids (steam, cooling water).

Power Generation: Protecting high-purity boiler feedwater from contamination by cooling water (river or seawater).

Nuclear Industry: Ensuring absolute isolation between radioactive and non-radioactive fluids.

Governing Standards: ASME UHX vs. TEMA

Manufacturing a safe and reliable tube sheet flange requires adherence to two complementary standards:

ASME (UHX): The ASME BPVC Section VIII, Div. 1, Part UHX provides the mandatory rules for safety and pressure integrity. It governs the design calculations for pressure-bearing parts like the tubesheet thickness, shell, and channels to ensure the vessel will not fail under pressure.

TEMA: The TEMA (Tubular Exchanger Manufacturers Association) standard provides rules for performance, durability, and manufacturing quality. It covers non-pressure components like baffles and tie rods, as well as manufacturing tolerances and design classes (R, B, C) for different service severities.

A high-quality heat exchanger must be ASME compliant (to be safe and legal) and TEMA compliant (to be efficient and durable).

Manufacturing & Precision Engineering

The performance of a tube sheet is locked in during manufacturing.

Forging (Recommended): We strongly advocate for forged tube sheets over cast. The forging process compacts the metal’s internal structure, eliminating porosity and refining the grain, which results in superior toughness, fatigue strength, and structural integrity.

CNC Drilling & Reaming: All tube holes are laid out in CAD and executed on multi-axis CNC machining centers. This guarantees exacting tolerances for hole diameter, position, and perpendicularity. After drilling, holes can be “reamed” to achieve a highly precise diameter and smooth surface finish, preparing them for a perfect tube joint.

Grooving (Joint Strength): For expanded joints, this is a critical step. We machine one or two precise grooves into the wall of the tube hole. During the tube expansion process, the tube material plastically deforms and “flows” into these grooves, creating a strong mechanical interlock. This dramatically increases the joint’s pull-out strength and sealing reliability, as specified by TEMA.

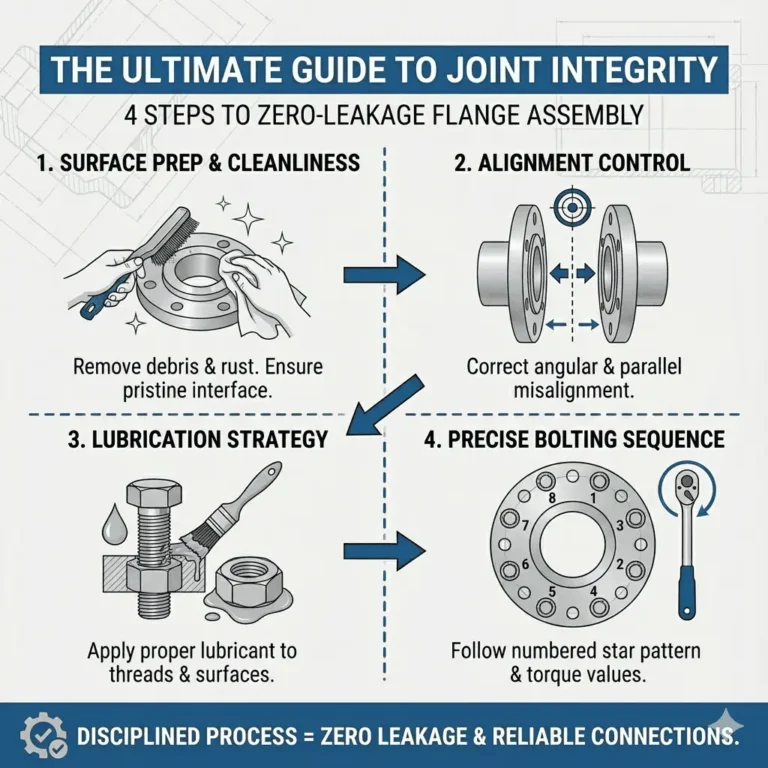

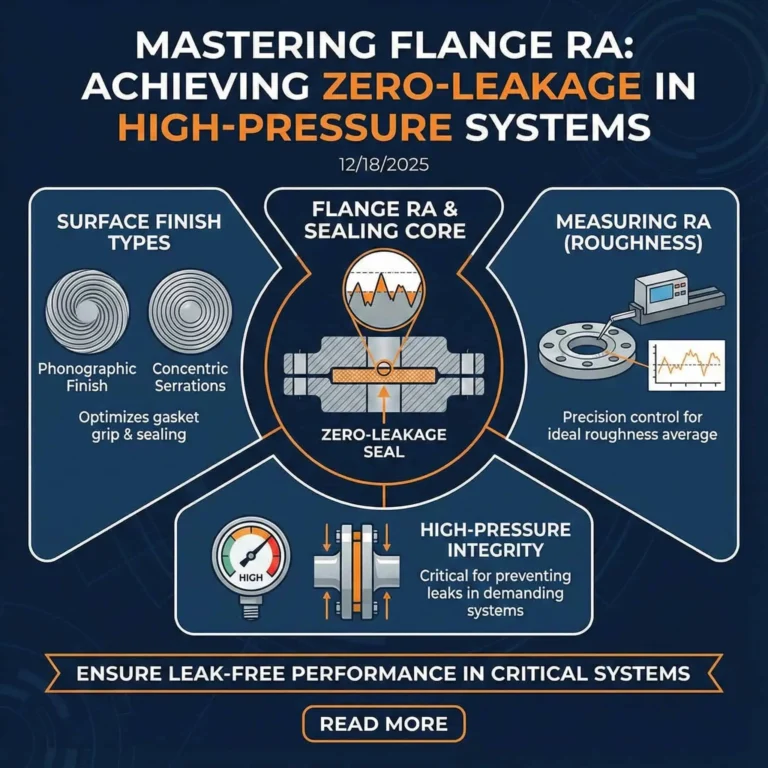

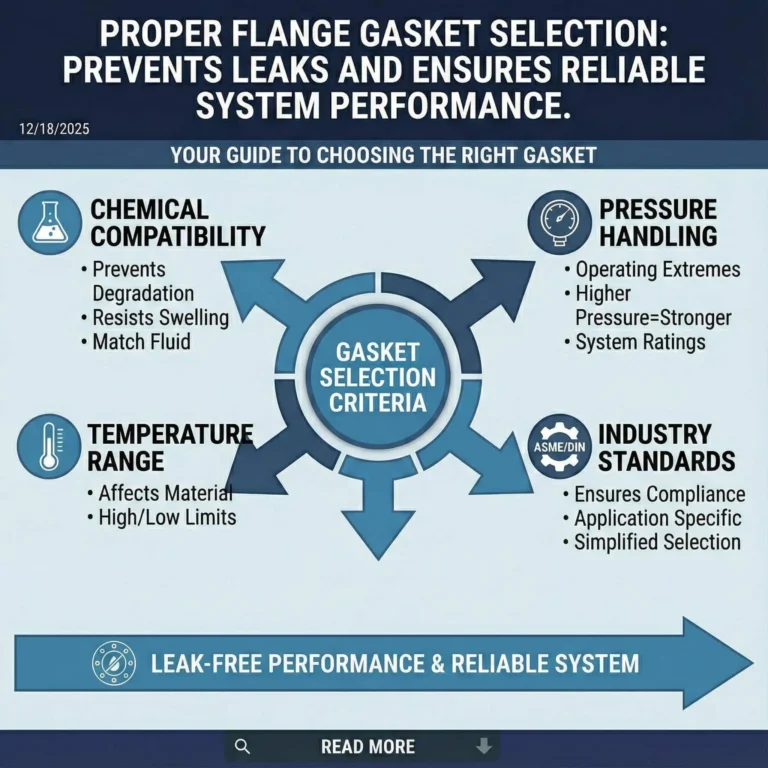

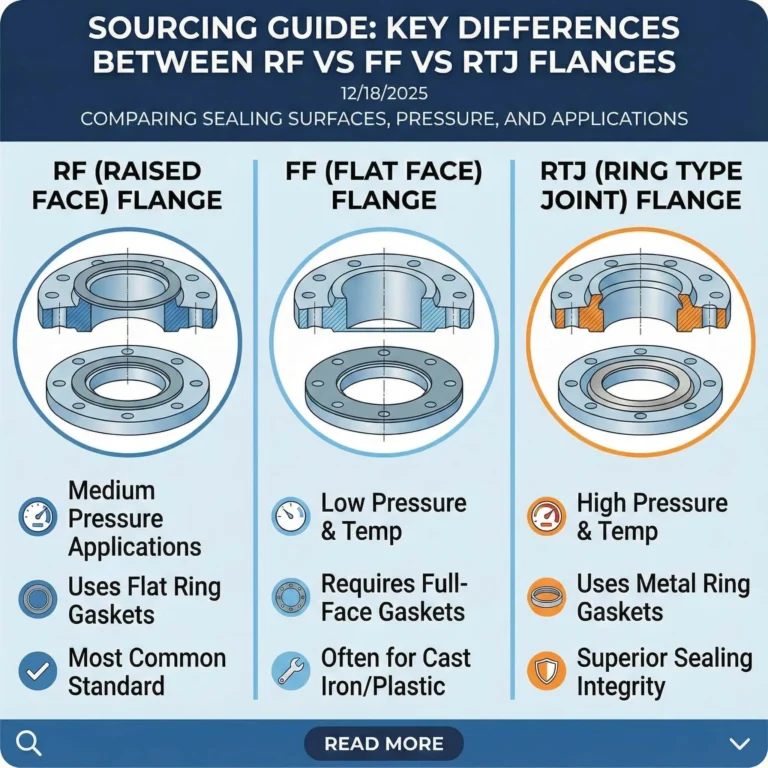

Sealing Integrity: Faces, Gaskets & Assembly

External leakage at the flange face is a common failure point. Preventing it requires a systems approach.

Flange Face Types

Raised Face (RF): The most common type. It concentrates the bolt load on a smaller gasket area, increasing the sealing pressure.

Flat Face (FF): Used for lower pressures or brittle materials. An FF flange must never be bolted to an RF flange, as this will crack the FF flange.

Ring-Type Joint (RTJ): Used for extreme high-pressure and high-temperature services. A solid metal ring gasket deforms into a groove for a metal-to-metal seal.

Advanced Gasketing for Thermal Transients

Heat exchangers frequently experience “thermal transients” (start-ups, shutdowns). As the unit heats and cools, the bolts and flanges expand and contract, causing bolt load to fluctuate. Standard spiral wound gaskets can lose their “spring” and fail to compensate, resulting in a leak.

Solution: Kammprofile (Grooved) Gaskets This advanced gasket features a solid metal core with serrated grooves, covered by a soft sealing layer (like graphite).

The metal core provides high strength and blow-out resistance.

The soft graphite layers have excellent elastic recovery, allowing them to compensate for flange movement and bolt load fluctuations during thermal cycles.

For “problem” exchangers that experience repeated leaks, upgrading to a Kammprofile gasket is a proven, high-reliability solution.

Quality Assurance & Advanced NDT

We provide verifiable quality assurance for every tube sheet we produce.

Standard Inspection:

Visual & Dimensional (VT): 100% check of all dimensions, hole patterns, and surface finishes against the drawing and TEMA tolerances.

Surface NDT: Penetrant Testing (PT) or Magnetic Particle Testing (MT) to detect any surface-breaking cracks or defects.

Final Hydrostatic Test: Performed on the completed vessel to validate the integrity and sealing of the entire assembly under pressure.

Advanced Volumetric Testing for TTS Welds: The Tube-to-Tubesheet (TTS) weld joint is a known weak point, but it is impossible to inspect with traditional X-ray (RT) due to the geometry. This means serious internal defects like “lack of fusion” can be missed.

Sunhyings utilizes advanced NDT methods to solve this problem:

Phased Array Ultrasonic Testing (PAUT): This is the new gold standard. A specialized PAUT probe is inserted inside the tube, scanning the entire weld volume 360°. It creates a clear, cross-sectional image (like a CT scan) that can accurately identify and size any internal weld defects, providing 100% volumetric assurance.

Time of Flight Diffraction (TOFD): A highly accurate ultrasonic method for sizing defect height, providing critical information for “fitness-for-service” assessments.

Eddy Current Testing (ECT): A fast, electromagnetic method ideal for detecting cracks, pitting, and wall thinning in the body of non-ferrous tubes (Stainless Steel, Titanium, etc.).

Applications Across High-Risk Industries

- Petrochemical & Refining: (TEMA R) The most demanding environment. Floating head designs (TEMA S or T) are standard to allow bundle removal for cleaning heavy hydrocarbon fouling. Duplex/Super Duplex materials are common.

- Power Generation: (TEMA B/R) Massive scale. Double tube sheets are often used to protect high-purity boiler feedwater from contamination. Titanium is the standard for seawater-cooled condensers.

- Chemical Processing: (TEMA B) Highly diverse. Material selection (Stainless, Hastelloy) is customized to resist specific corrosive chemicals.

- Pharmaceutical & Food: (TEMA C/B) Absolute purity is the key. Double tube sheet designs are mandatory to prevent contamination. 316L Stainless Steel with polished finishes is standard.

Related blog

FAQ

What are the most common causes of tube sheet flange leaks?

Leaks occur in two main areas.

Internal (Tube-to-Tubesheet Joint): Caused by manufacturing defects (improper expansion, weld defects), thermal cycling, vibration, or corrosion.

External (Gasket): Caused by improper gasket selection (not rated for the temperature/pressure), failure during thermal cycling (common with standard gaskets), or improper bolt-up.

How can Tube-to-Tubesheet (TTS) joint failure be prevented?

It requires a system approach.

Design: Select the correct materials and, for fixed designs, properly account for thermal expansion (use a bellows if needed).

Manufacturing: Use precise, controlled tube expansion (hydraulic or torque-controlled) and optimized hole grooving. For welded joints, 100% volumetric NDT (like PAUT) is essential to eliminate internal defects.

Operation: Minimize severe thermal shocks and monitor for vibration.

What is the fundamental difference between a tube sheet flange and a standard pipe flange (like a Weld Neck)?

A standard pipe flange (ASME B16.5) has one job: connect two things (like pipes or valves). Its design is simple. A tube sheet flange (ASME UHX) is a far more complex component. It must act as a flange on its outer edge while also supporting thousands of tubes and resisting complex bending, thermal, and shear stresses across its perforated face. It follows a completely different and more rigorous set of design rules (ASME UHX).

Stainless Steel Flanges

Stainless Steel Flanges