Compression Fittings have become a top choice for sanitary systems because you need reliable, clean, and simple solutions. The pharmaceutical and food & beverage industries now prefer these fittings for high-purity and contamination-free fluid transport. You can trust Sunhy stainless steel fittings for precision, strong corrosion resistance, and zero-leak performance. Look for practical advice and tips to help you select the best fittings for your needs.

Compression Fittings in Sanitary Systems

What Are Compression Fittings?

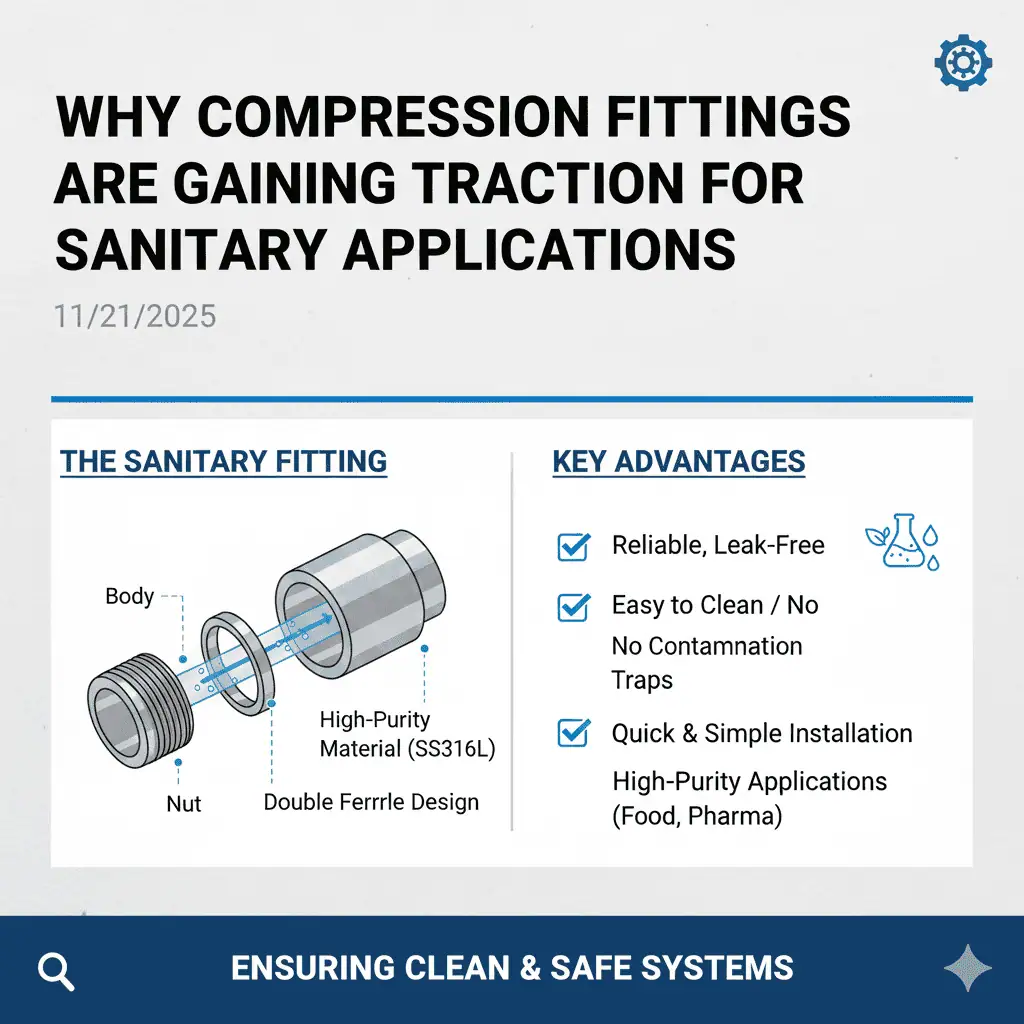

Compression fittings are mechanical connectors that create a tight, leak-free seal between pipes or tubes without the need for heat or adhesives. You use them to join sections of piping quickly and securely. These fittings work by compressing a ring, called a ferrule, onto the pipe as you tighten a nut. This action forms a strong seal that prevents leaks.

Here is a table showing the main components of compression fittings:

| Component | Description |

|---|---|

| Compression Nut | Slides onto the pipe or tubing and is tightened to create a seal. |

| Compression Ring | Also known as a ferrule, it is compressed around the pipe for a tight seal. |

| Compression Seat | The part of the fitting that the pipe is inserted into for compression. |

You can install compression fittings in three simple steps:

- Insert the tubing into the fitting.

- Slide the compression ring onto the tubing.

- Tighten the compression nut to create a secure seal.

Why Use Compression Fittings for Sanitary Applications?

You choose compression fittings for sanitary systems because they offer reliable, clean, and efficient connections. These fittings help you maintain hygiene and prevent contamination in sensitive environments.

Some key advantages include:

- High-pressure and temperature resistance, making them suitable for demanding conditions.

- Reliable, long-term seals that reduce maintenance needs.

- Versatile material compatibility, allowing you to connect different types of pipes.

- Quick and easy installation, with no soldering or gluing required.

- Cost-effective solutions for both new installations and repairs.

You often find compression fittings in places where reliability and cleanliness matter most, such as food processing plants and laboratories. Their robust sealing mechanism ensures that your sanitary systems stay leak-free and safe.

Key Benefits for Sanitary Applications

Hygiene and Cleanability

You achieve superior hygiene and easy cleaning with compression fittings.

- These fittings minimize dead spaces, which helps prevent bacterial growth.

- You benefit from smooth surfaces without threads or crevices, reducing contamination risks.

- Cleaning and sterilization become straightforward, which is essential for maintaining sanitary conditions.

Tip: Choose fittings with polished surfaces for even easier cleaning in sensitive environments.

Leak-Free Performance

You can rely on compression fittings for secure, leak-free connections.

- When you install them correctly, these fittings deliver high reliability.

- You do not need soldering, which means you avoid introducing contaminants.

- Material compatibility and proper installation ensure long-lasting, leak-tight performance.

| Feature | Benefit for You |

|---|---|

| No soldering required | Cleaner, safer connections |

| Secure sealing | Reduced risk of leaks |

| Reliable performance | Fewer maintenance interruptions |

Easy Installation

You save time and effort with the simple installation process of compression fittings.

- You do not need special tools or heat, which makes the process safer.

- The straightforward assembly allows you to complete projects quickly.

- You can easily disassemble and reassemble the fittings for maintenance or system changes.

Note: Always follow manufacturer guidelines for tightening to ensure a proper seal.

Versatility in Sanitary Environments

You gain flexibility because compression fittings adapt to many sanitary applications.

- These fittings maintain cleanliness and minimize contamination, making them ideal for food and beverage production.

- The smooth internal surfaces and high-quality materials support hygiene in pharmaceutical settings.

- You assemble them without heat or extra materials, ensuring a clean, leak-tight seal.

- You find a wide range of sizes and configurations, so you can match different tubing diameters and system needs.

- The design supports future modifications or expansions without major changes to your system.

Remember: Stainless steel compression fittings work especially well in environments that demand both durability and cleanliness.

Cost and Reliability Advantages

Reduced Labor and Maintenance

You save time and money with compression fittings because they require less labor and maintenance.

Compression fittings allow you to assemble and disassemble connections using basic hand tools. You do not need specialized equipment or skilled labor. This simple process reduces installation time and lowers labor costs. You avoid the complexity of welded or flanged fittings, which often need more effort and regular maintenance.

- You connect and disconnect compression fittings quickly.

- You minimize downtime during repairs or upgrades.

- You reduce the risk of errors during installation.

Tip: Choose compression fittings for projects where speed and efficiency matter most.

| Fitting Type | Installation Tools Needed | Labor Skill Level | Maintenance Frequency |

|---|---|---|---|

| Compression Fittings | Basic hand tools | General | Low |

| Welded Fittings | Welding equipment | Skilled | Moderate |

| Flanged Fittings | Wrenches, torque tools | Skilled | Moderate |

Long-Term Value

You gain long-term value with compression fittings due to their durability and reliability.

Compression fittings last longer and require fewer replacements. Their robust design means you experience fewer leaks and breakdowns. You benefit from lower life-cycle costs and improved operational efficiency.

- You avoid frequent shutdowns for repairs.

- You spend less on replacement parts.

- You maintain consistent performance in your sanitary systems.

Compression fittings offer a cost-effective solution for both new installations and ongoing maintenance. You invest in reliability and reduce total ownership costs over time.

Note: Reliable compression fittings help you maintain sanitary standards and keep your operations running smoothly.

Choosing Compression Fittings for Sanitary Needs

Material Selection

You should choose the right material to ensure safety and performance in sanitary systems.

Stainless steel and brass are the most common materials for compression fittings. Stainless steel stands out in sanitary applications because it offers high corrosion resistance, strength, and easy cleaning. This makes it ideal for environments with strict hygiene standards, such as food and beverage production and pharmaceutical production. Sunhy stainless steel fittings provide excellent durability and resist pitting, cracking, and chemical corrosion. You can reuse them for adjustments or repairs, which adds value in sanitary processing industries.

| Material | Advantages |

|---|---|

| Brass | Easy to install, versatile, reusable, but less suitable for harsh conditions |

| Stainless Steel | High corrosion resistance, reusable, strong, ideal for sanitary environments |

Tip: Choose stainless steel for systems that require frequent cleaning and exposure to chemicals.

Sizing and Compatibility

You must select the correct size and ensure compatibility to prevent leaks and failures.

Start by matching the fitting size to your pipe diameter and flow rate. Check the pressure and temperature ratings to make sure the fitting can handle your system’s demands. Always confirm chemical compatibility with the fluids in your process. Sunhy stainless steel fittings come in standard sizes and custom options, making it easy to find the right fit for your sanitary system.

- Match fitting size to pipe diameter and flow rate.

- Check pressure and temperature ratings.

- Confirm chemical compatibility.

- Choose fittings designed for your specific application.

Improper sizing or compatibility can cause leaks, system failures, and safety hazards. You protect your system and maintain hygiene by choosing the right fittings.

Standards and Certification

You need to verify that your fittings meet industry standards for sanitary use.

Look for fittings that comply with 3-A Sanitary Standards, which focus on hygienic design, material quality, and surface finish. Sunhy stainless steel fittings undergo rigorous testing and certification to ensure they meet these requirements. High-grade stainless steel resists corrosion and supports cleaning protocols like Clean-In-Place (CIP) and Sterilize-In-Place (SIP). Internal surfaces should have a smooth finish to prevent microbial buildup.

| Standard/Requirement | Key Points |

|---|---|

| 3-A Sanitary Standards | Hygienic design, material selection, surface finish, cleaning compatibility |

| Material Requirements | High-grade stainless steel, corrosion resistance |

| Surface Finish Standards | Smooth internal surfaces for easy sanitation |

| Cleaning Compatibility | Withstands high temperatures and cleaning agents |

Note: Always choose certified fittings to ensure safety and compliance in sanitary environments.

Compression fittings give you reliable, hygienic, and cost-effective solutions for sanitary systems.

You benefit from:

- Hygiene: Leak prevention keeps your system clean.

- Reliability: Strong connections handle pressure and temperature changes.

- Cost-effectiveness: Fewer interruptions mean lower costs.

- Adaptability: Easy upgrades and changes support your needs.

Choose high-quality fittings like Sunhy stainless steel for the best results. Always match fittings to your system, check environmental factors, and follow manufacturer guidelines. Consult industry experts to ensure your sanitary system performs at its best.

FAQ

What makes compression fittings suitable for sanitary applications?

You get reliable, leak-free connections and easy cleaning.

Compression fittings use smooth surfaces and strong seals. You avoid contamination and maintain hygiene.

How do you install compression fittings?

You follow three steps: insert tubing, slide the ferrule, tighten the nut.

No special tools or heat needed.

Tip: Always check manufacturer instructions for best results.

Can you reuse compression fittings?

You can reuse most stainless steel compression fittings.

Disassemble, clean, and reassemble them.

| Fitting Type | Reusable? |

|---|---|

| Stainless Steel | Yes |

| Brass | Yes |

What standards should you check for sanitary fittings?

You should look for 3-A Sanitary Standards and material certifications.

These standards ensure hygiene, corrosion resistance, and safe cleaning.