A threaded flange is a pipe flange with a tapered internal thread that screws onto a matching threaded pipe end, giving you a pressure-tight, removable joint without welding. In real plant work, threaded flanges are most valuable on small-bore lines where hot work is restricted (permits, ignition risk, coating restrictions) or where you need quick removal for maintenance. From an engineering standpoint, the “speed” advantage only holds if you control three items: (1) thread type compatibility (NPT vs BSPT, etc.), (2) correct sealing practice at the threads and flange face, and (3) vibration/support conditions.

With more than three decades of stainless steel flange manufacturing experience, Sunhy supports engineers from material selection through machining and inspection, so the threaded flanges you receive fit your standards and reduce unplanned downtime. (Engineering note: “removable” does not automatically mean “reusable”—thread condition and galling risk must be assessed during shutdown.)

What are threaded flanges?

Threaded flange definition

A threaded flange is a type of pipe flange that connects to a pipe using internal threads instead of a weld.

The pipe end is machined with external tapered threads; when you screw the flange onto this threaded end, the thread interference provides mechanical engagement and creates a potential sealing path at the thread helix. A gasket is then placed between mating flanges to complete the flange-face seal. Because no welding is required, installation can be done without welding power sources, weld consumables, or post-weld inspection—provided the piping code allows threaded joints for the service.

Threaded flanges are especially common on small diameter lines, utility services, instrument tie-ins, and locations where welding is difficult, restricted, or temporarily not permitted. They are not a “universal substitute” for welded flanges: for severe cyclic loading, high vibration, or frequent thermal cycling, welded connections are often the more reliable long-term choice.

Tip: Threaded flanges are available in ASME rating classes (e.g., 150 through 2500), but allowable working pressure depends on material grade and temperature tables—not class number alone. Always confirm code/service limits before selecting the class.

Key features and standards

Threaded flanges are popular because they combine weld-free installation with standardized dimensions and sealing faces.

From an engineering review perspective, you should tie the flange selection to three standards categories: (1) flange dimensional/rating standard, (2) thread system standard, and (3) assembly/inspection practices (bolting + sealing + workmanship).

- Fast installation and replacement without welding or post-weld NDT.

- Practical on small-bore lines where code permits threaded joints and supports control vibration.

- Multiple facing options (RF, FF, RTJ) to match gasket type and leak tightness requirements.

- Standardized rating classes and sizes for interchangeability when you specify the same standard.

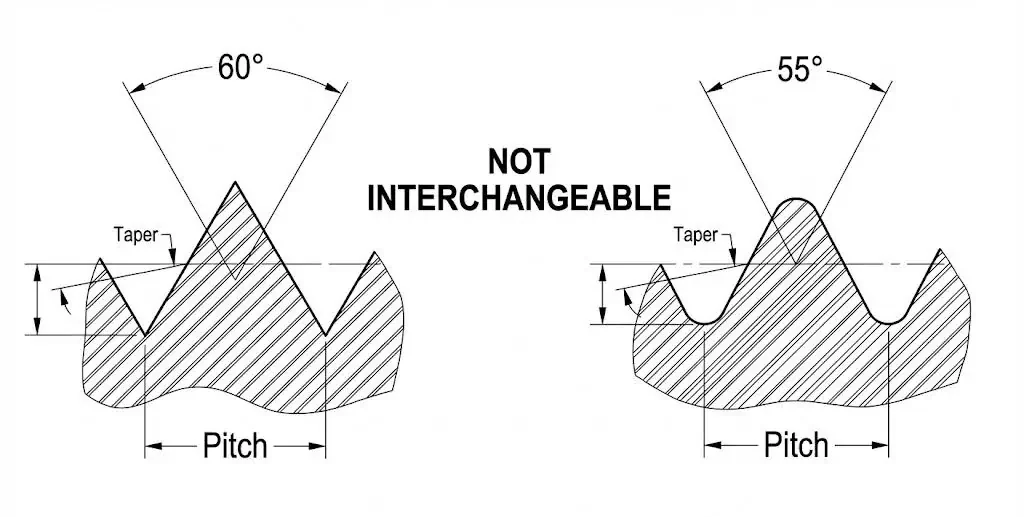

Thread system compatibility matters more than most teams expect. NPT and BSPT are both tapered but are not generally interchangeable; thread angle and pitch differences can create “looks-tight” assemblies that weep under pressure or after temperature cycles. A quick field check is to confirm thread designation on drawings/MTO and verify with gauges during receiving inspection.

Field reference: common pipe thread identification and taper/sealing notes (useful for avoiding NPT/BSPT mix-ups during shutdown work).

Common materials used for threaded flanges and how they affect performance:

| Material Type | Specifications |

|---|---|

| Carbon Steel | ASTM A105, A350, A694; suitable for general utility service and wide temperature ranges. |

| Alloy Steel | ASTM A182; higher strength and improved resistance at elevated temperature and pressure. |

| Stainless Steel | ASTM A182; corrosion resistance for chemical, food, and water lines. For chloride exposure, engineers often favor 316/316L over 304/304L (service-dependent). |

| Duplex Steel | ASTM A182; higher strength and better stress corrosion cracking resistance in tougher environments. |

| Nickel Alloys | ASTM B160, B166, B564; selected for severe corrosion or high-temperature service. |

- The material grade determines mechanical strength, corrosion resistance, and service life.

- For stainless threaded joints, plan for galling control (lubrication/anti-seize, clean threads, correct assembly) and verify thread condition after disassembly.

International standards commonly referenced in engineering projects:

| Standard | Description |

|---|---|

| ASME B16.5 | Flange classes, dimensions, tolerances, materials and guidance related to bolting/gaskets for many common flanges. |

| Thread system (e.g., NPT / BSPT) | Defines thread form, taper, pitch and gauge practice. Confirm NPT vs BSPT on drawings and purchase orders. |

| ASTM | Material standards for forging/plate/bar used in flange manufacturing (e.g., A105, A182). |

| DIN / EN (project dependent) | European flange systems using PN designations and geometry sets; avoid mixing with ASME patterns unless explicitly designed. |

| Project piping code/spec | Defines where threaded joints are permitted and what inspection/seal-weld practices apply. |

Sunhy manufactures stainless steel threaded flanges in accordance with ASME, ASTM, DIN and EN project requirements. Each flange is produced on CNC equipment and verified by dimensional and visual inspection, giving you consistent fit-up, traceable certificates, and reliable sealing performance in the field.

How threaded flanges solve problems

Fast, weld-free installation

Engineers choose threaded flanges when they need a weld-free connection that can be installed with controlled workmanship.

Internal threads in the flange bore match the external threads on your pipe. After confirming thread type and cleaning the threads, apply a compatible sealant, screw the flange into position, and align the mating flange. There is no weld prep, no heat input, and no post-weld NDT planning—advantages that matter during short shutdown windows or when ignition-risk controls restrict hot work.

Engineering reality check: threaded installation is only “fast” when you avoid rework. Rework is commonly caused by thread mismatch (NPT vs BSPT), damaged threads, or gasket face mismatch (RF/FF). If your team does receiving checks (gauges, face type verification) the first-time fit rate improves substantially.

Field example (repair under hot-work restriction): A plant instrument air manifold needed a quick isolation spool replacement in a zone where hot work permits were delayed. The joint was completed using threaded flanges after thread verification and sealant selection; the leak test passed on the first attempt. The key controls were clean threads, correct thread system confirmation, and even bolt loading at the flange face (not “extra torque” on the threads).

Easy maintenance and replacement

Threaded flanges make maintenance easier because removal does not require cutting or weld removal.

When you need access to a valve, strainer, or spool piece, the flange can be unscrewed instead of cut out. This reduces hot work in operating plants, shortens shutdown windows, and limits the amount of new welding and inspection you have to schedule.

The threaded flange design, with internal threads matching the pipe’s male threads, eliminates the need for welding and can reduce replacement time. Practical success still depends on thread condition and anti-galling practice on stainless systems.

Field example (stainless galling during disassembly): On a 316 stainless small-bore drain, a threaded flange seized during removal after multiple heat cycles. Root cause was thread galling from dry assembly and minor contamination. Corrective action: replace the flange and pipe nipple, clean threads, apply a compatible anti-seize/sealant, and control assembly torque. Preventive action: specify assembly lubricant/sealant practice and require clean-thread inspection at installation.

Leak prevention benefits

When correctly specified and installed, threaded flanges provide dependable sealing with low leakage risk on suitable services.

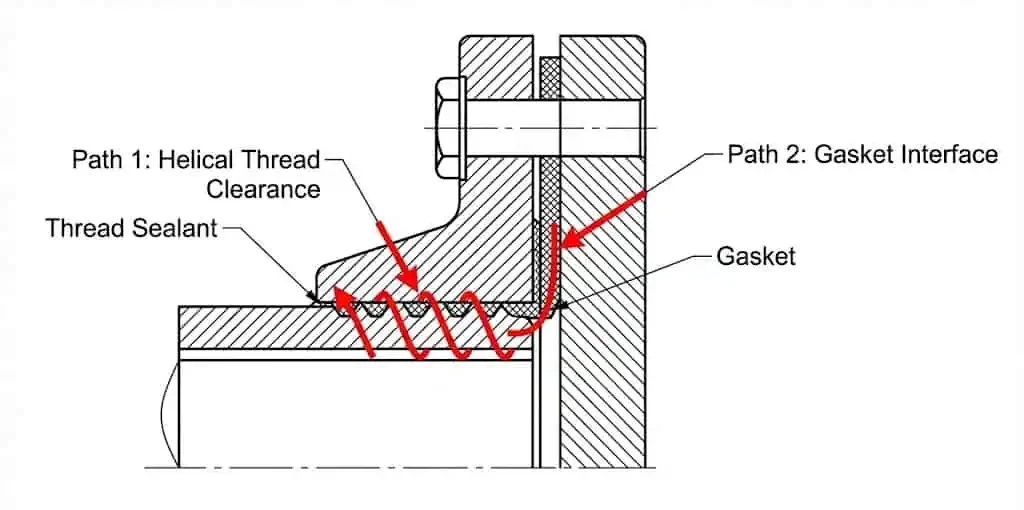

Leak paths exist at (1) the thread helix (pipe-to-flange engagement) and (2) the flange face (gasketed joint). Treat them as two separate sealing problems and control each with the right checks.

- Thread system control: confirm NPT vs BSPT; tapered threads are not automatically interchangeable. Use gauges during receiving and before installation.

- Thread condition: clean, undamaged threads; remove coatings/paint overspray; reject flattened or torn threads.

- Sealant selection: choose PTFE tape or compound approved for your medium and temperature; avoid incompatible materials (project spec governs).

- Face + gasket match: RF/FF/RTJ must match the mating flange and gasket design; never “force fit” mismatched faces.

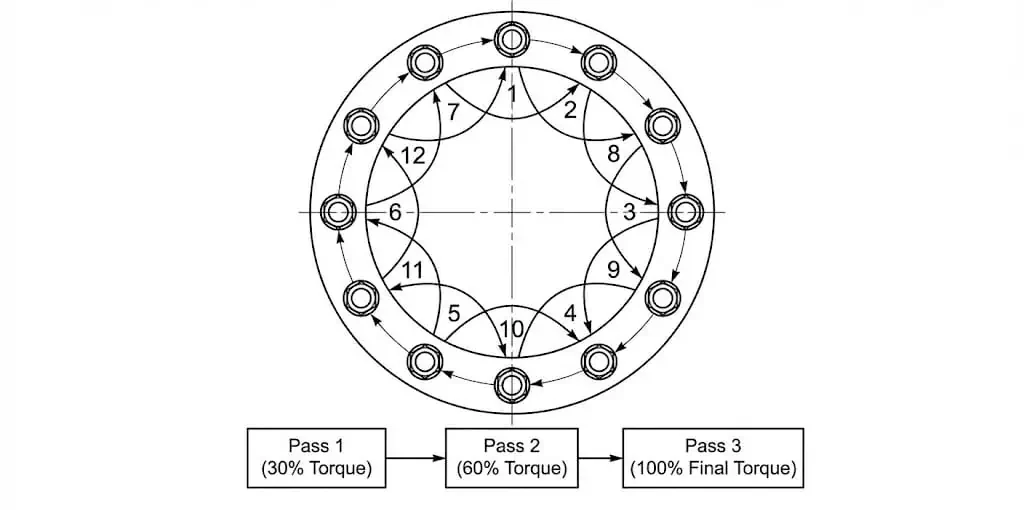

- Bolting method: tighten in a cross pattern in multiple passes; uneven compression is a frequent cause of flange-face seepage.

Workmanship reference (threaded joints): project piping guides based on ASME B31.3 commonly require clean threads and appropriate lubrication/sealant practices; when seal welding is specified, it is treated as a leak-tightness control and must be executed per specification.

Field example (thread mismatch that “almost fit”): A shutdown crew installed a threaded flange that started by hand but weeped during hydrotest. Root cause was mixed thread systems (similar OD but different thread angle/pitch). Fix: replace with correct thread system components and implement a simple receiving gauge check to prevent recurrence.

Versatile piping applications

Threaded flanges are used across many industries because they provide a practical balance between speed and maintainability.

They are often selected for chemical processing, water treatment, oil and gas utilities, and food production systems—especially on small-bore lines where future access is expected.

At the same time, engineering teams should respect the limits of the design in severe conditions:

- Compared with fully welded joints of the same size, threaded joints are more sensitive to vibration and bending loads; support and restraint matter.

- Repeated thermal cycling can relax sealing stress and amplify minor workmanship issues (sealant breakdown, gasket creep, bolt relaxation).

- In stainless systems, galling can make disassembly difficult and reduce reusability if anti-galling practice is not controlled.

Field example (vibration loosening): A threaded flange on a pump-skid instrument line developed intermittent weeping after weeks of operation. Root cause was vibration plus insufficient line support. Corrective action: add proper support/restraint near the connection and replace gasket/sealant. Preventive action: avoid threaded joints on high-vibration zones where welded alternatives are feasible.

For moderate-pressure small-bore systems where vibration is controlled, threaded flanges remain a strong option. Sunhy’s application team can help you check whether a threaded or welded connection is more suitable for each line in your plant.

When to use threaded flanges

Best use cases

Threaded flanges are most suitable when you need reliable, weld-free connections or very fast repairs on small-bore piping.

They are designed for situations where welding is not possible, not safe, or not economical. You can install or remove a threaded flange quickly, which is critical during shutdowns or in areas where hot work is restricted.

Common scenarios where threaded flanges are an excellent choice:

- Emergency repairs that require immediate restoration of flow.

- Piping systems in hazardous or flammable environments where hot work is restricted.

- Temporary installations, test loops, and skid-mounted equipment.

- Small diameter piping where vibration is controlled and code permits threaded joints.

- Projects where welding equipment or skilled welders are not readily available.

Tip: You can request custom threaded flange solutions from Sunhy for special dimensions, materials, or challenging applications. When customizing, confirm thread designation, face type, bolt pattern standard, and inspection requirements on the drawing.

Considerations and limitations

Before selecting a threaded flange, evaluate design conditions and long-term maintenance plans.

The table below summarizes the main factors engineers usually check:

| Consideration | Description |

|---|---|

| Material Selection | Match medium, temperature, corrosion conditions; plan galling control for stainless threads. |

| Dimensions | Verify flange size, schedule compatibility, face type (RF/FF/RTJ), and bolt pattern standard (ASME vs EN/DIN). |

| Quality Assurance | Confirm compliance to project standard; include thread/face inspection, and optional PMI/NDT when specified. |

| Service Severity | High vibration, severe cyclic loading, and frequent thermal cycling often favor welded flanges. |

| Cost | Balance purchase price with maintenance risk, leak criticality, and rework probability. |

Additional tips for optimal performance of threaded flange joints:

- Ensure full compatibility between the pipe thread and flange thread (designation, size, tolerance).

- Specify gasket material and thickness based on medium, pressure and temperature—then match flange facing accordingly.

- Use the recommended bolt tightening sequence and torque controls to avoid uneven gasket loading (multi-pass, cross pattern).

Note: Sunhy’s engineering team can help you select or design the right threaded flange for your project, from material choice to machining details, so that every joint matches your drawing and design code.

Threaded flange installation guide

Preparation and tools

Good preparation and the right tools are essential for a safe, leak-free threaded flange installation.

- Inspect the threaded flange for damage and ensure the internal threads and sealing face are clean (no dents, burrs, paint, or handling damage).

- Check the pipe end for correct thread form and cleanliness; remove rust, coating overspray, and debris. When available, verify with thread gauges (go/no-go) during shutdown work.

- Gather these tools and materials:

- Thread sealant (PTFE tape or compound) approved for your medium

- Appropriate wrench (strap wrench preferred to avoid marking surfaces)

- Wire brush + solvent wipes for thread cleaning

- Correct gasket type/size for the flange facing

- Bolts/nuts suitable for the flange rating class and environment

- Torque wrench when required by spec, plus PPE

Always clean the pipe ends thoroughly and inspect all threads before starting work. This reduces the risk of galling and leakage.

Step-by-step process

Follow these steps to build a reliable, leak-free threaded flange connection:

- Clean the pipe ends to remove rust, dust, paint, and other debris.

- Inspect threads on both the pipe and inside the flange for damage or mismatch; verify thread system (NPT vs BSPT) if there is any doubt.

- Apply PTFE tape or approved thread compound to the male pipe threads in the direction of tightening (avoid “back-wrapping”).

- Align the flange with the pipe and screw it on by hand until snug; do not cross-thread.

- Use a wrench to bring the flange to its final position—tighten firmly but do not apply excessive force that damages threads.

- Insert a new, clean gasket centered on the flange face; confirm facing type matches the gasket design.

- Insert bolts and nuts, then tighten in a crosswise pattern in multiple passes to achieve even gasket compression (typical practice is staged tightening; project specs govern exact % and torque).

- Perform leak testing per project procedure after assembly and again after thermal stabilization if required by service criticality.

Tip: Use bolts that meet specified standards and select gasket/sealant compatible with your medium and temperature to prevent leaks and premature failure.

Maintenance tips

Regular inspection and simple maintenance routines extend the life of threaded flanges and reduce unplanned outages.

- Inspect for weeping at both the threads and flange face; differentiate the leak source before re-torquing bolts.

- Check bolt tightness periodically where vibration exists; gasket relaxation and thermal cycling can reduce load over time.

- Clean flange/bolting surfaces to reveal early corrosion or leak tracks.

- Apply protective coatings on external surfaces in corrosive environments (avoid contaminating sealing faces/threads).

- Replace components if you find cracked faces, distorted sealing surfaces, severe corrosion, or damaged threads.

- After repairs or modifications, pressure test to verify joint integrity.

Troubleshooting (fast field diagnosis):

| Symptom | Likely Cause | Corrective Action |

|---|---|---|

| Weeping at thread area | Thread mismatch, damaged threads, wrong/insufficient sealant | Disassemble, verify thread system, clean threads, reassemble with approved sealant; replace damaged parts |

| Leak at flange face | Uneven bolt load, wrong gasket, face mismatch (RF/FF) | Replace gasket, verify facing, tighten in cross pattern with staged passes |

| Seized during disassembly | Stainless galling, contamination, over-torque | Replace affected parts; enforce clean-thread + anti-galling practice next install |

| Recurring leaks after weeks | Vibration/support issue, thermal cycling | Add support/restraint; reassess joint type and consider welded alternative in severe zones |

| Sunhy Support | Description |

|---|---|

| Timely Service | Fast technical response to keep engineering decisions and procurement aligned with schedule. |

| Quality Inspection | Dimensional and visual inspection; optional PMI/NDT when specified by project documents. |

| Installation Guidance | Practical documentation and guidance for installation/maintenance teams (thread/facing/gasket/bolting checks). |

Sunhy’s team supports you from early design and material selection through delivery and installation, helping you build safer, longer-lasting piping systems.

By choosing suitable threaded flanges and applying good engineering practice, you can solve many piping challenges quickly and reliably. Sunhy’s stainless steel flange products combine proven materials, precise machining, and careful inspection, giving you confidence in every joint from design review to commissioning.

- Sunhy’s quality assurance team inspects each flange against relevant standards and project specifications.

- In repeat-project environments (oil & gas, chemical, water treatment), stable flange fit-up and documentation traceability reduce rework risk during shutdowns.

| Contact Method | Details |

|---|---|

| Contact Form | Name, Phone, Email, Message |

| anna@sunhying.com | |

| Phone | +86 18066318999 |

Reach out to Sunhy to review your threaded flange drawing, confirm thread/facing compatibility, or request machining/inspection documentation for your project package.

FAQ

What are the main benefits of using threaded flanges?

The main benefits are weld-free installation, faster tie-ins on small-bore lines, and easier future removal. In practice, these benefits hold when thread type is verified, sealant is compatible with service, and vibration is controlled.

- Quick installation using controlled workmanship steps.

- Easy removal and reinstallation during shutdowns (when threads are not galled/damaged).

- No welding equipment or hot-work permits required in many cases.

- Reliable sealing when combined with suitable gaskets and sealants.

- Common on small diameter utility and process lines.

Can you use threaded flanges for high-pressure systems?

Threaded flanges can be used in moderate- to high-pressure systems when the piping code allows it and the correct rating class/material/temperature limits are met. For very high pressure, high temperature, severe cyclic service, or high vibration, many engineers prefer welded designs (weld neck or socket weld) for additional margin and robustness.

| Pressure Class | Typical Use |

|---|---|

| 150–600 | Common on small-bore utility and process lines where code permits threaded joints. |

| 900–2500 | Specialized systems where design checks, material/temperature tables, and code rules explicitly permit threaded joints. |

How do you prevent leaks with threaded flanges?

Leak prevention depends on correct thread system, clean threads, proper sealant, correct gasket/facing match, and balanced bolt tightening. Treat thread sealing and flange-face sealing as two controlled items.

Clean threads, verify NPT vs BSPT, use approved PTFE tape/compound for your medium, center a new gasket, and tighten bolts evenly in a cross pattern using staged passes.

What industries use threaded flanges most?

Threaded flanges are widely used on small-bore lines in oil & gas utilities, chemical plants, water treatment facilities, and food & beverage processing. They are especially useful where frequent access is expected or where welding restrictions apply.

- Oil & gas utilities and small-bore process lines.

- Chemical and petrochemical plants.

- Water and wastewater treatment plants.

- Food & beverage systems using stainless piping.

Does Sunhy offer custom threaded flange solutions?

Yes. Sunhy can provide custom sizes, special materials, and project-specific machining details for threaded flanges. For custom work, provide thread designation, face type, bolt pattern standard, material grade, and inspection requirements.

Sunhy’s engineering team works with your drawings, specifications and plant conditions to deliver threaded flanges aligned with your design code and inspection plan.

NPT vs BSPT: how do you avoid thread mismatch on site?

Confirm thread designation on drawings/MTO, verify with gauges during receiving, and do not mix thread systems. NPT and BSPT are both tapered but differ in thread angle/pitch; assemblies may start by hand but leak under pressure or after temperature cycling. If there is any doubt, stop and verify before tightening.

Do you need seal welding on threaded flanges?

Only if your project specification/code practice requires it. Seal welding is sometimes used to reduce the chance of leakage through the thread helix, but it must be executed correctly and can complicate future disassembly. Treat it as a specified workmanship control—not a default step.