You will encounter several main stainless steel flange types in industrial systems:

- Weld neck flange

- Slip-on flange

- Socket weld flange

- Lap joint flange

- Threaded flange

- Blind flange

- Orifice flange

- Ring-type joint flange

Sunhy’s stainless steel flanges set industry standards by combining precision engineering and rigorous quality control. Choosing the right stainless steel flange types impacts both safety and efficiency. A proper selection ensures a tight seal, prevents leaks, and maintains system integrity, especially in high-pressure environments.

Stainless steel flange types

What is a flange?

A flange is a mechanical component that connects pipes, valves, pumps, or other equipment in a piping system. You use flanges to create a secure, leak-proof joint that allows for easy assembly, disassembly, and maintenance. Flanges come in various shapes and sizes to suit different pressure, temperature, and application requirements. When you select the right flange, you ensure the integrity and safety of your system.

Why stainless steel?

Stainless steel offers superior performance for flanges in demanding environments. You benefit from several key advantages when you choose stainless steel flange types:

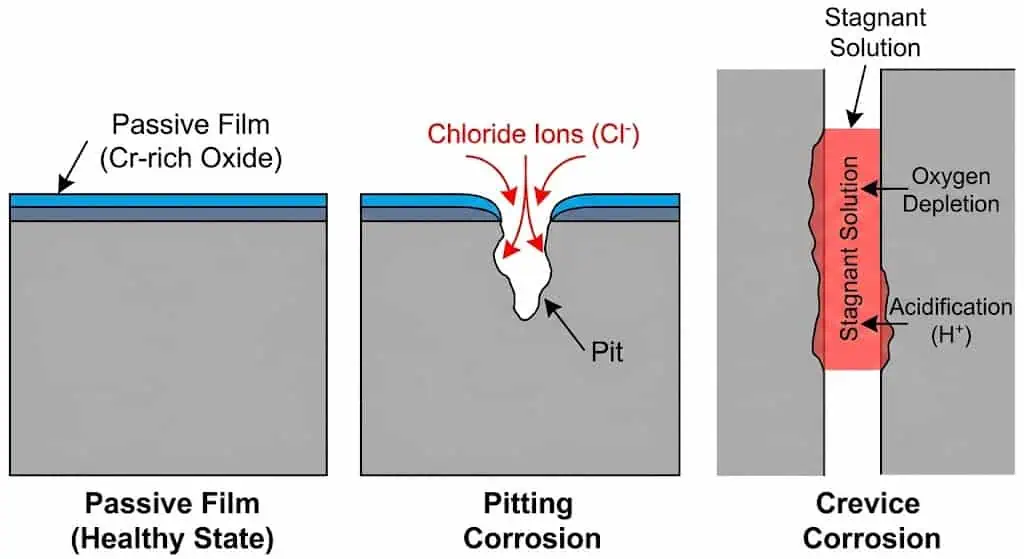

- Excellent corrosion resistance due to the chromium-rich composition, making them ideal for water, chemical, and harsh industrial applications.

- High strength and the ability to withstand elevated temperatures, which makes stainless steel flanges suitable for heavy-duty and high-heat systems.

- Self-healing properties from the protective chromium oxide layer, ensuring long-term durability even if the surface gets scratched.

Tip: Stainless steel flanges maintain their performance and appearance over time, reducing maintenance costs and downtime.

Sunhy stands out as a leading manufacturer of stainless steel flanges. You can trust Sunhy’s products because they meet international standards such as ASME, ASTM, DIN, and EN1092-1. These standards define requirements for materials, dimensions, pressure ratings, and surface finishes, ensuring you receive reliable and consistent quality.

| Standard | What It Covers |

|---|---|

| ASME B16.5, ASTM A182/A182M | Chemical composition, mechanical properties, and pressure classes |

| DIN, EN1092-1 | Dimensions, tolerances, facings, and marking requirements |

Sunhy’s advanced manufacturing uses high-precision CNC machining and strict quality control. Every flange undergoes thorough inspection and testing. Certifications like ISO 9001 and PED approval guarantee that you receive safe, high-quality products for your industrial applications.

Understanding the types of stainless steel flanges helps you make the right choice for your project. When you know the common stainless steel flange types, you can match the flange to your system’s needs and ensure optimal performance.

Main types of stainless steel flanges

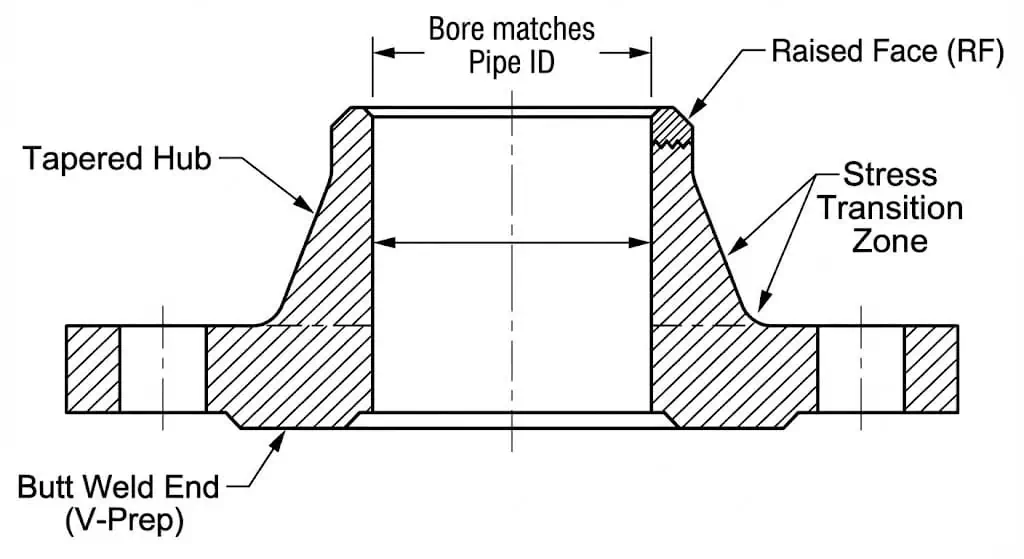

Weld neck flange

Weld neck flanges provide the highest strength and leak resistance for critical piping systems.

You will recognize weld neck flanges by their long, tapered neck that transitions smoothly into the pipe. This design reduces stress and ensures a strong, leak-proof connection through butt-welding. These flanges are ideal for high-pressure and high-temperature environments, such as oil and gas, power generation, and chemical processing.

| Feature | Description |

|---|---|

| Tapered Neck Design | Reduces stress and enhances load distribution |

| Butt-Weld Connection | Ensures a secure, leak-proof joint |

| Pressure Resistance | Handles high pressures and temperatures |

| Material Grades | 304, 304L, 316, 316L |

| Standards | ASME, ASTM, DIN, EN1092-1 |

Typical applications:

- High-pressure pipelines

- Steam systems

- Cryogenic and corrosive environments

Pros:

- Superior strength and durability

- Excellent leak resistance

- Precise alignment and smooth flow

Cons:

- Requires skilled welding for installation

Sunhy offers weld neck flanges in a wide range of sizes and custom options to fit your project needs.

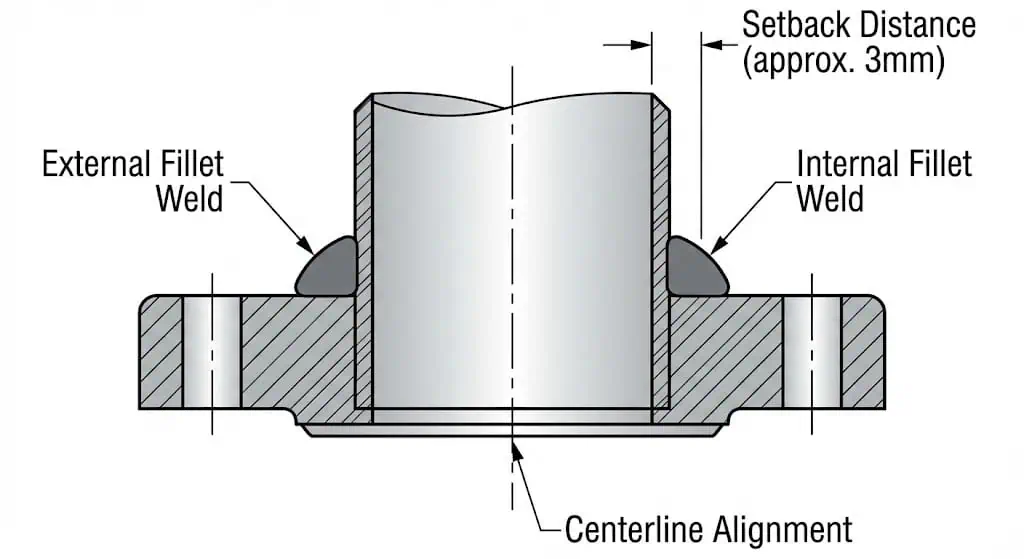

Slip-on flange

Slip-on flanges offer easy installation and cost savings for low- to moderate-pressure systems.

You simply slide the flange over the pipe and weld it in place. This design makes alignment simple and reduces installation time. Slip-on flanges are common in water treatment, HVAC, fire protection, and food processing.

| Characteristic | Description |

|---|---|

| Design | Flat face, slips over pipe, welded in place |

| Installation | Easy alignment, less precise than weld neck |

| Applications | Low- to moderate-pressure piping |

| Material Grades | 304, 304L, 316, 316L |

| Standards | ASME, ASTM, DIN, EN1092-1 |

Typical applications:

- Municipal water systems

- Industrial piping

- Marine and agricultural systems

Pros:

- Cost-effective

- Simple installation

Cons:

- Not suitable for high-pressure or high-temperature use

Sunhy’s slip-on flanges are available in multiple sizes and materials for diverse industrial applications.

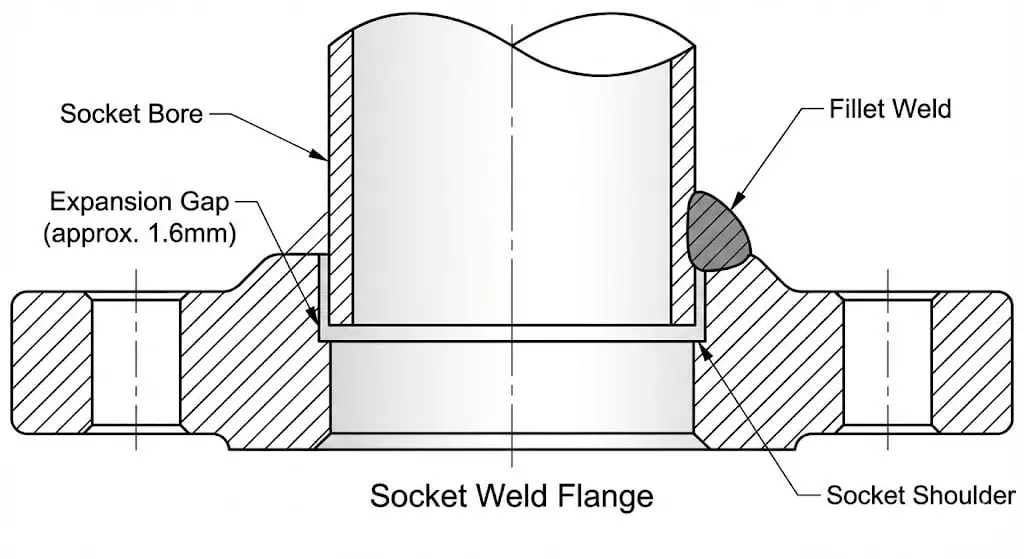

Socket weld flange

Socket weld flanges are best for small-diameter, high-pressure piping where leak prevention is critical.

You insert the pipe into the flange’s socket and secure it with a fillet weld. This method creates a strong, vibration-resistant joint. Socket weld flanges are common in chemical, petrochemical, and hydraulic systems.

| Advantage | Description |

|---|---|

| Leak-Proof Design | Recessed socket minimizes leakage |

| Strong Mechanical Bond | Fillet weld adds strength and vibration resistance |

| Ideal for Small Pipes | Best for pipes 2 inches or less |

| Material Grades | 304, 304L, 316, 316L |

| Standards | ASME, ASTM, DIN, EN1092-1 |

Typical applications:

- High-pressure hydraulic lines

- Chemical processing

- Compact piping systems

Pros:

- Strong, leak-resistant connection

- Easier installation for small pipes

Cons:

- Not recommended for large-diameter pipes

Sunhy manufactures socket weld flanges in a variety of stainless steel grades to meet your system’s requirements.

Threaded flange

Threaded flanges allow for quick, weld-free connections in small-diameter, high-pressure systems.

You screw the flange onto the pipe, making installation fast and safe, especially in hazardous or flammable environments. Threaded flanges are popular in oil and gas, chemical, and water treatment industries. (Reference thread standard: ASME B1.20.1.)

| Feature/Application | Description |

|---|---|

| No Welding Required | Easy installation and removal |

| High-Pressure Suitability | Good for moderate to high-pressure, small-diameter piping |

| Maintenance Friendly | Ideal for systems needing frequent disassembly |

| Material Grades | 304, 304L, 316, 316L |

| Standards | ASME, ASTM, DIN, EN1092-1 |

Typical applications:

- Hazardous environments

- Temporary or removable connections

- Residential and industrial plumbing

Pros:

- Quick installation

- No special tools needed

Cons:

- Not suitable for high temperatures or bending stresses

Sunhy’s threaded flanges are available in standard and custom sizes for your specific needs.

Blind flange

Blind flanges seal the end of a pipe or vessel, allowing for easy isolation and maintenance.

You use blind flanges to close off piping systems, perform pressure tests, or reserve future connections. They provide a strong seal and simplify maintenance in oil and gas, chemical, water treatment, and power generation.

| Benefit | Description |

|---|---|

| Maintenance Access | Quick removal for inspection or repairs |

| System Isolation | Safely isolates pipeline sections |

| Pressure Testing | Closes pipeline for pressure checks |

| Material Grades | 304, 304L, 316, 316L |

| Standards | ASME, ASTM, DIN, EN1092-1 |

Typical applications:

- Pipeline plugging and system isolation

- Pressure testing

- Reserve spare interface

Pros:

- Saves time on installation and maintenance

- Provides a secure, leak-proof seal

Cons:

- Limited flexibility for system modifications

Sunhy supplies blind flanges in a full range of sizes and pressure ratings for all types of stainless steel flanges.

Lap joint flange

Lap joint flanges provide flexibility and easy alignment for systems needing frequent maintenance or quick assembly.

You pair these flanges with a stub end, allowing the flange to rotate freely for bolt alignment. Lap joint flanges are ideal for corrosive environments, cost-sensitive projects, and piping systems with frequent modifications.

| Unique Features | Typical Applications |

|---|---|

| Rotates freely for easy alignment | Corrosive environments |

| Less likely to corrode | Systems needing frequent maintenance |

| Easy to maintain and connect | Cost-sensitive installations |

| Suitable for limited space | Piping in tight spaces |

| Material Grades | 304, 304L, 316, 316L |

| Standards | ASME, ASTM, DIN, EN1092-1 |

Typical applications:

- Removable connections for maintenance

- Temporary piping

- Marine and offshore systems

Pros:

- Quick bolt-hole alignment

- Simplifies assembly and disassembly

Cons:

- Not recommended for high-pressure sealing

Sunhy’s lap joint flanges are engineered for durability and corrosion resistance in demanding environments.

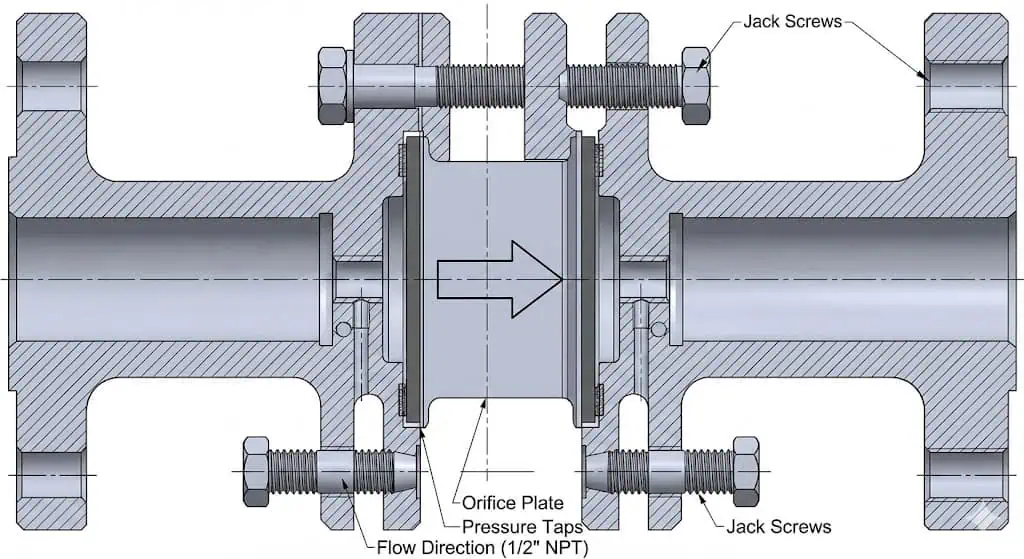

Orifice flange

Orifice flanges enable precise flow measurement and control in process industries.

You use orifice flanges to hold orifice plates, which measure the flow rate of liquids or gases. These flanges are essential in gas distribution, water treatment, and chemical processing for monitoring and controlling process flows. (Reference: ASME B16.36 Orifice Flanges.)

| Feature | Description |

|---|---|

| Flow Measurement | Measures flow rate by monitoring pressure drop across orifice plate |

| Design | Includes holes for pressure taps and jack screws for easy plate replacement |

| Maintenance | Allows quick inspection and replacement of orifice plates |

| Material Grades | 304, 304L, 316, 316L |

| Standards | ASME, ASTM, DIN, EN1092-1 |

Typical applications:

- Gas distribution networks

- Water treatment plants

- Chemical and refinery process control

Pros:

- Accurate flow measurement

- Easy integration into existing systems

Cons:

- Requires precise installation and calibration

Sunhy customizes orifice flanges to meet your flow measurement and control needs.

Ring-type joint flange

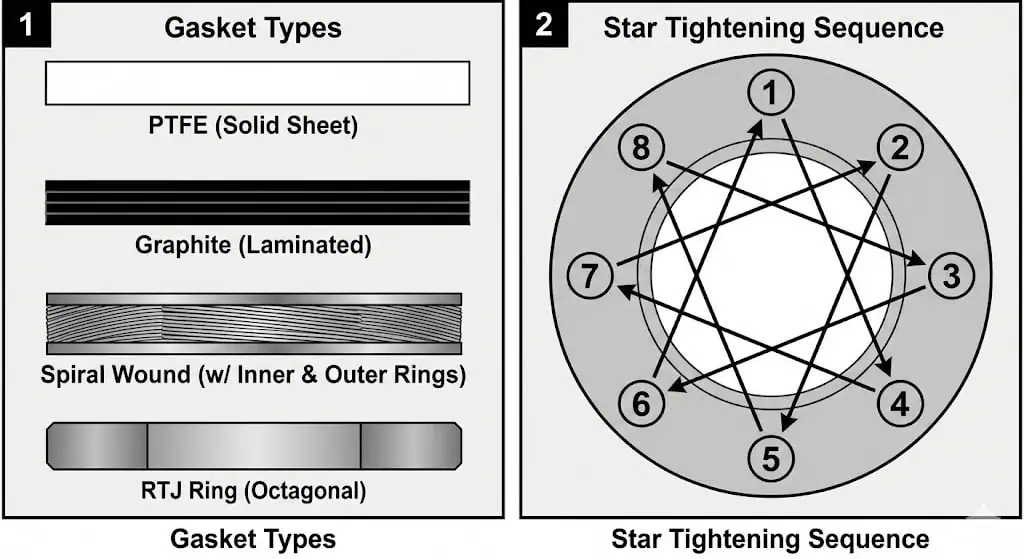

Ring-type joint flanges deliver leak-proof sealing for high-pressure, high-temperature environments.

You will find these flanges in oil and gas, steam, and power generation industries. The design uses a metallic ring gasket compressed into a machined groove, creating a robust metal-to-metal seal.

| Characteristic/Application | Description |

|---|---|

| Sealing Capability | Metal ring gasket ensures leak-proof seal under extreme pressure and temperature |

| Types | Oval and octagonal ring designs for different sealing loads |

| Reusability | Can be reused multiple times without losing sealing effectiveness |

| Pressure Handling | Withstands pressures up to 15,000 psi (103 MPa) |

| Material Grades | 304, 304L, 316, 316L |

| Standards | ASME, ASTM, DIN, EN1092-1 |

Typical applications:

- Oil and gas pipelines

- Steam boilers

- Chemical and power plants

Pros:

- Exceptional leak resistance

- Reliable in extreme conditions

Cons:

- Requires precise installation

Sunhy’s ring-type joint flanges are engineered for the most demanding industrial applications.

Sunhy provides all common stainless steel flange types, manufactured to international standards and available in grades 304, 304L, 316, and 316L. You can request custom sizes and configurations to match your project’s exact requirements. With Sunhy’s expertise, you ensure the right types of stainless steel flanges for every application, maximizing safety, performance, and corrosion resistance.

Types of stainless steel flanges: comparison

Key differences

You need to understand the main differences between the types of stainless steel flanges to make the right choice for your system.

| Flange Type | Key Characteristics | Pressure Suitability | Welding Required | Typical Use |

|---|---|---|---|---|

| Weld neck flanges | Long tapered hub, excellent stress distribution | High | Yes | High-pressure, high-temp |

| Slip-on flanges | Slides over pipe, easy to install, cost-effective | Low | Yes | Low-pressure |

| Socket weld flanges | Pipe fits into socket, strong for small diameters | High (small pipes) | Yes | Compact, high-pressure lines |

| Threaded flanges | Tapered threads, no welding needed | High (small pipes) | No | Quick assembly, maintenance |

| Blind flanges | Solid disc, seals pipe end, no inner diameter | High | No | Capping off lines |

| Lap joint flanges | Rotates for easy alignment, used with stub end | Low | Yes | Frequent maintenance |

| Orifice flanges | Holds orifice plate for flow measurement | Varies | Yes | Flow monitoring |

| Ring-type joint | Metal ring gasket, leak-proof seal for extreme conditions | Very high | Yes | Oil, gas, power plants |

Note: Lap joint flanges offer flexibility but do not hold pressure as well as weld neck or socket weld flanges. Blind flanges stand out because they cap off lines and have no inner diameter.

Best-use scenarios

You should match each flange type to its ideal industrial applications for best results.

- Weld neck flanges: Use these in oil and gas, chemical processing, and any system with high pressure or temperature.

- Slip-on flanges: Choose these for water treatment, food processing, and other low-pressure systems.

- Socket weld flanges: Install these in compact, high-pressure hydraulic or chemical lines with small pipe diameters.

- Threaded flanges: Select these for small-diameter, high-pressure lines where welding is not possible or safe.

- Blind flanges: Apply these to cap off pipelines, perform pressure tests, or isolate sections for maintenance.

- Lap joint flanges: Use these in systems that require frequent disassembly or alignment, such as marine or corrosive environments.

- Orifice flanges: Integrate these into process lines where you need accurate flow measurement and control.

- Ring-type joint flanges: Rely on these for extreme pressure and temperature, especially in oil, gas, and power generation.

Sunhy’s expertise ensures you always get the right flange for your specific industrial applications. You benefit from high corrosion resistance, precise engineering, and reliable performance across all types of stainless steel flanges.

Stainless Steel Flange Quick Selection Guide

Size and Dimensions

Choose the correct size and dimensions to ensure a secure fit and reliable performance.

- Identify the flange type by its features.

- Check the outer and inner diameters for compatibility.

- Select the right thickness for pressure requirements.

- Count and measure bolt holes for proper alignment.

- Confirm the pressure class matches your system.

- Follow industry standards like DIN, ANSI, or JIS.

Material Grade

Select the right material grade for durability and corrosion resistance.

| Material Grade | Corrosion Resistance | Applications |

|---|---|---|

| 304 | Fairly good | General-purpose products |

| 304L | Similar to 304 | General-purpose products |

| 316 | Superior to 304 | Marine fittings, chemical processing |

| 316L | Excellent for chloride environments | Marine, chemical, pharmaceutical manufacturing |

Standards and Certifications

Verify standards and certifications to guarantee safety and quality.

- ASME Certification: Ensures material, dimension, and performance criteria. (See ASME B16.5)

- ISO Certification: Confirms international quality management.

- ASTM Standards: Sets material and dimension requirements. (See ASTM A182/A182M)

- EN Standards: Meets European compliance.

- PED Certification: Required for pressure equipment. (See Directive 2014/68/EU (PED))

- NACE Certification: For corrosive environments. (Reference: ISO 15156-1:2020)

- UL and API Certifications: For safety and oil/gas use.

Always check for ISO 9001, ASME B16.5, PED, and NACE MR0175/ISO 15156 compliance. (External references: ASME / PED / ISO 15156-1:2020)

Gaskets and Bolting

Use the right gaskets and bolts for a leak-proof seal.

- Gaskets fill the gap between flange surfaces to prevent leaks.

- Choose gasket material that allows elastic deformation.

- Select the correct type: non-metallic, metal, or combined.

- Apply proper bolt preload for effective sealing.

- Ensure flange stiffness to avoid warping and seal failure.

Fluid medium

Match the flange material and gasket to the fluid medium.

You need to consider the chemical properties of the fluid. For aggressive chemicals or seawater, use 316 or 316L stainless steel flanges for better corrosion resistance.

Connection/sealing requirements

Pick the flange type based on sealing needs.

Weld neck flanges offer strong, leak-proof joints for high-pressure systems. Slip-on flanges provide easy installation for low-pressure lines. Socket weld flanges suit small, high-pressure pipes. Blind flanges seal pipe ends. Lap joint flanges allow quick alignment and frequent disassembly.

Manufacturer Reliability

Choose a trusted manufacturer for consistent quality.

Sunhy provides stainless steel flanges with strict quality control, advanced CNC machining, and global certifications. You can request custom solutions and rely on responsive customer support.

Application needs

Match the flange type to your application.

For industrial applications, select the flange that fits your system’s pressure, temperature, and maintenance needs. Sunhy offers a full range, including weld neck flanges, slip-on flanges, socket weld flanges, blind flanges, and lap joint flanges.

Pressure and temperature

Check the flange rating for pressure and temperature limits.

Flange ratings (Class 150, 300, etc.) show the maximum pressure and temperature the flange can handle. Higher ratings mean greater resistance.

Installation factors

Plan for installation space, tools, and skills.

Some flanges need welding, while others use threads or bolts. Consider the available space and the skill level of your installation team.

Sunhy’s experts can help you select the right stainless steel flanges for any project. Contact their team for custom solutions and technical support.

You have learned about the main stainless steel flange types and their roles in industrial systems. Each type offers unique benefits, such as strength, easy installation, or corrosion resistance. When choosing flanges, avoid these common mistakes:

- Using bolts that do not meet standards can weaken connections.

- Welding can distort flanges if you do not control heat properly.

Consider your system’s needs and consult Sunhy’s experts for the best solution. Explore Sunhy’s full product range to ensure safe and reliable performance.

FAQ

What standards do Sunhy stainless steel flanges meet?

All Sunhy flanges meet international standards.

You can find products certified to ASME, ASTM, DIN, and EN1092-1. These standards guarantee quality, safety, and compatibility in industrial piping systems.

Can Sunhy provide custom flange solutions?

Yes, Sunhy offers custom sizes and configurations.

You can request flanges tailored to your project’s requirements. Sunhy’s advanced CNC machining ensures precise, reliable results for any application.

How do I ensure proper installation of stainless steel flanges?

Follow manufacturer guidelines and use the correct gaskets and bolts.

- Align flanges carefully

- Apply recommended torque

- Inspect for leaks after assembly

Tip: Sunhy’s support team can guide you through installation best practices.