Stopping flange leakage in high-pressure hydrogen service requires more than just tightening bolts; it demands materials resistant to Hydrogen Embrittlement (HE) and gaskets designed for low-permeation.

Hydrogen molecules are the smallest in the universe (approx. 106 pm kinetic diameter), allowing them to permeate standard sealing materials 8x faster than methane. In high-pressure environments (often exceeding 700 bar), this permeation combined with rapid thermal cycling creates a critical safety hazard. Flange–gasket–bolt assemblies cause more than a third of leaks in hydrogen systems. Flanges fail the most, leading to costly shutdowns and safety incidents. New products like Sunhy’s Stainless Steel Flanges give you the safety compliance needed for these tough jobs.

Root Causes of Flange Leakage in Hydrogen Service

Flange leakage in high-pressure hydrogen service happens because of specific mechanisms like hydrogen attack and elastic interaction.

Unlike natural gas, hydrogen can diffuse into the metal lattice, causing internal pressure buildup known as Hydrogen Embrittlement. This makes the metal brittle and prone to cracking under bolt load. Understanding these technical root causes is vital for compliance with ASME B31.12 (Hydrogen Piping and Pipelines).

| Cause of Leakage | Description |

|---|---|

| Inadequate Bolt Preload | Not enough preload fails to overcome internal pressure, leading to “blowout” conditions. |

| Improper Bolt Tightening Sequence | Incorrect tightening results in gasket pinching and uneven surface stress distribution. |

| Poor Contact Surface Quality | Radial scratches or suboptimal roughness (Ra > 6.3µm) provide direct leak paths for H2. |

| Hydrogen Embrittlement (HE) | H2 atoms diffuse into steel, reducing ductility and causing sudden bolt or flange fracture. |

| Gasket Permeation | Standard polymer gaskets allow H2 to pass through the material itself, not just around it. |

| Bolt Surface Contamination | Rust and debris on bolt threads increase friction (K-factor), resulting in false torque readings. |

Bolt Preload & Relaxation

Incorrect bolt preload is a leading cause of flange leakage.

In high-pressure service, bolts often experience “relaxation” or “creep” within the first 24 hours of operation due to gasket setting. If the initial preload is too low, this relaxation drops the clamping force below the critical sealing threshold. Always calculate target torque based on friction factors (K-values) and follow ASME PCC-1 guidelines.

Improper Tightening Sequence

Improper tightening sequence leads to uneven gasket compression and flange leakage.

You should tighten bolts in a Legacy Star Pattern (Cross Pattern). This helps spread the pressure evenly. Experts recommend a multi-pass approach: 30%, 60%, and 100% of final torque, followed by a final circular “check pass” to ensure all bolts are seated.

Surface Finish Requirements

Poor surface finish or damage increases the risk of fugitive emissions.

For hydrogen, the standard ASME B16.5 finish (125-250 AARH) is usually sufficient, but the path must be free of radial scratches. A concentric serrated finish is often preferred over a phonographic finish for H2 gas to create continuous barriers against leakage.

Corrosion & Hydrogen Attack

Corrosion weakens flange surfaces and creates new paths for flange leakage.

High Temperature Hydrogen Attack (HTHA) can cause decarburization in carbon steels. This is why material selection is critical. Stainless steels with high nickel content resist this degradation better than standard carbon steel.

Gasket Selection Errors

Choosing a porous gasket material causes permeation leakage.

Standard graphite gaskets can be permeable to hydrogen. For high-pressure hydrogen, semi-metallic gaskets (like Spiral Wound with PTFE filler) or solid metal ring joints (RTJ) are required to meet ISO 15848-1 tightness classes.

Contamination

Contamination on bolts, flanges, or gaskets can lead to flange leakage over time.

Debris affects the friction coefficient. If your K-factor is off by just 0.02, your actual bolt load could be 30% lower than intended, leading to immediate leaks upon pressurization.

Fact Check: Hydrogen is flammable at a concentration of just 4% in air, making even “micro-leaks” a serious safety concern.

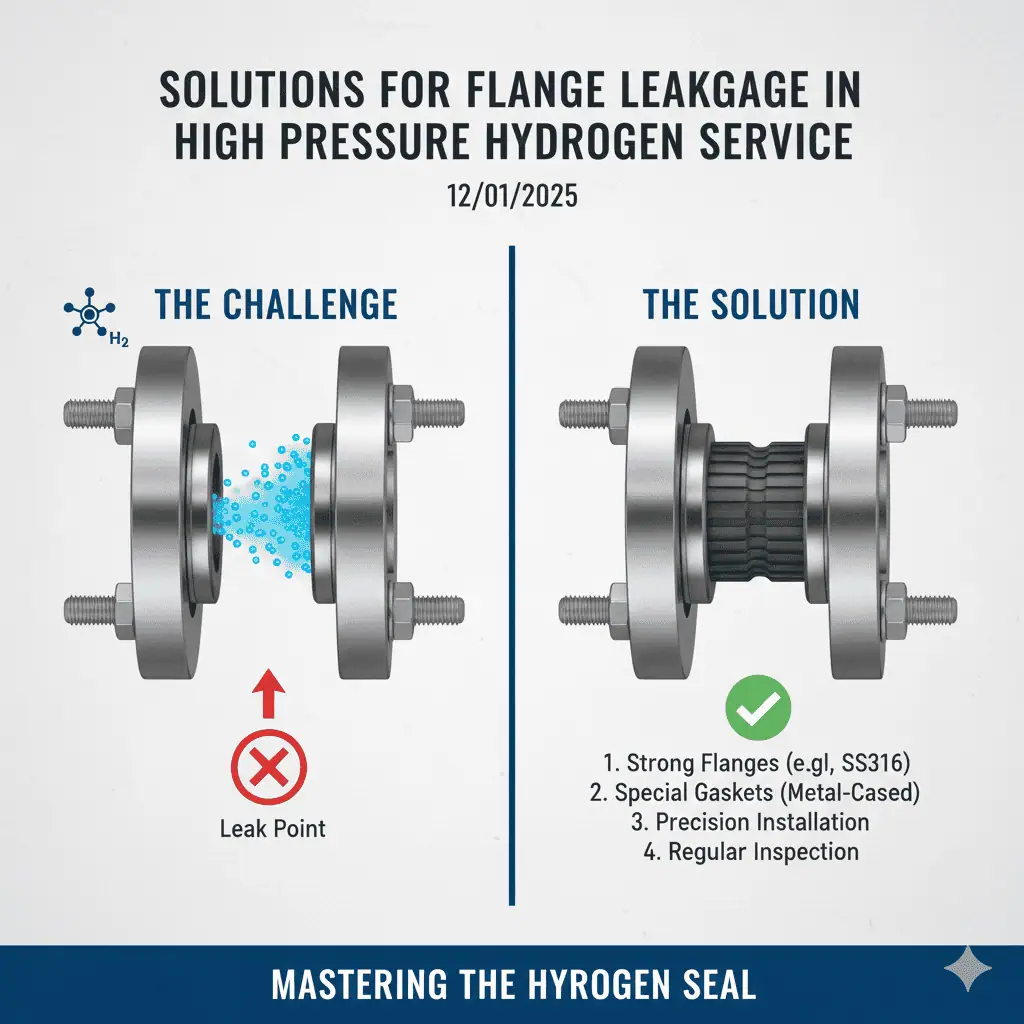

High-Pressure Hydrogen Sealing Solutions

Material Selection: Why 316L Matters

Choose forged stainless steel (316/316L) flanges for the best resistance to hydrogen embrittlement.

Austenitic stainless steels, particularly SUS316L, have a high nickel content (10-14%) which stabilizes the metal structure against hydrogen diffusion. Unlike martensitic or ferritic steels, 316L maintains ductility even at cryogenic temperatures (liquid hydrogen storage) and high pressures.

Sunhy’s Stainless Steel Flanges use solution-annealed 316L forgings. This process relieves internal stresses that could otherwise become initiation sites for hydrogen cracking. This gives you both strength and protection from rust.

Advanced Gasket Technologies

Select advanced metal gaskets and avoid non-metallic types for high-pressure hydrogen flange sealing technology.

For pressures above 100 bar, Ring Type Joint (RTJ) flanges are often preferred because the seal is Metal-to-Metal, virtually eliminating permeation.

| Provider | Description |

|---|---|

| Trelleborg | Offers H2Pro™ materials verified against rapid gas decompression (RGD). |

| Omniseal Solutions | Provides polymer-energized metal seals for cryogenic hydrogen applications. |

| Freudenberg Sealing Technologies | Delivers seals testing to ISO 15848 for fugitive emissions compliance. |

Installation Best Practices

Follow strict installation steps to maximize flange sealing technology and prevent leaks.

- Make sure flanges and gaskets are compatible with hydrogen (Check H2 compatibility charts).

- Use lubricated bolts (K-factor 0.16 or lower) to ensure torque converts to clamping force.

- Clean all parts before you start. Take off any rust, dirt, or oil.

- Put the gasket flat and in the middle.

- Use gaskets made for high-pressure hydrogen, like spiral wound with inner rings.

Real-World Case Study: Thermal Cycling Leakage

Case Background: In 2022, a hydrogen fuel station in Europe experienced repeated flange leakage on a compressor discharge line (700 bar). The system utilized standard 304 stainless steel flanges with graphite gaskets.

The Problem: The system underwent rapid thermal cycling—heating up during compression and cooling down rapidly. The coefficients of thermal expansion between the bolts and the flange caused the gasket to lose compression load (a phenomenon called “thermal unloading”). Furthermore, hydrogen permeated the graphite filler.

The Solution: The maintenance team replaced the flanges with Sunhy 316L Heavy Hex Flanges (for better thermal stability) and switched to a Spiral Wound Gasket with a high-purity PTFE filler and an inner ring. They also implemented live-loading washers on the bolts to maintain tension during thermal cycles.

Result: Zero leakage was detected over the next 12 months of operation, passing the ISO 15848-1 tightness test.

Prevention and Maintenance

Routine Inspection

You can prevent most flange leaks by inspecting your system on a regular schedule using H2 detectors.

Because hydrogen is odorless and colorless, visual inspection isn’t enough. Use portable hydrogen detectors (sniffers) or ultrasonic leak detectors to find micro-leaks. If you find a leak, mark the spot and fix it right away. You should also use pressure tests to find small leaks that you cannot see.

Inspection Checklist:

- Check for visible corrosion or condensation (ice formation due to expansion).

- Use a handheld Hydrogen Gas Detector (LEL meter).

- Listen for ultrasonic noise (high-pressure leaks create high-frequency sound).

- Verify bolt torque after the first thermal cycle (Hot Bolting).

- Record every finding.

Staff Training

You stop leaks by training your staff to spot and fix problems early.

You must teach your team how to find a leak and what steps to take. Show them how to use torque wrenches correctly and follow the ASME PCC-1 tightening sequence. Make sure they know how to clean parts before assembly. Hold training sessions often. Review real leak cases and discuss what went wrong. When your staff knows what to do, you lower the risk of leaks.

Documentation

You reduce leaks by keeping good records of every inspection and repair.

Write down every leak you find and how you fix it. Keep track of the date, location, and what you did. Use a table or logbook for easy reference. Good records help you see patterns and prevent future leaks. You can also show these records to suppliers like Sunhy to get better support and advice.

| Date | Location | Leak Found | Action Taken | Staff Name |

|---|---|---|---|---|

| 2024-05-01 | Flange #12 | Yes (Micro) | Replaced with 316L RTJ Gasket | J. Smith |

| 2024-05-10 | Flange #7 | No | Routine Ultrasonic Check | L. Brown |

Note: Reliable suppliers and quality products make leak prevention easier and more effective.

You can stop flange leakage in high-pressure hydrogen service by picking the right materials, putting them together the right way, and checking them often.

- Pick forged stainless steel flanges (316L) because they resist Hydrogen Embrittlement.

- Use advanced metal gaskets or PTFE-filled spiral wound gaskets.

- Teach your team what to do and check flanges a lot.

- Write down every check and repair so you remember what was done.

For important jobs, ask experts for help and pick trusted products like Sunhy’s Stainless Steel Flanges.

FAQ

What is the best gasket for high-pressure hydrogen service?

The best gasket is typically a metal gasket or semi-metallic composite.

For pressures >100 bar, Ring Type Joints (RTJ) or Spiral Wound Gaskets with Inner Rings (PTFE filler) are recommended. They resist permeation better than fiber or graphite gaskets. Always use a gasket that matches your flange pressure rating (Class 150-2500).

How do you prevent gasket failure during installation?

You prevent gasket failure by following strict installation steps like ASME PCC-1.

Clean every surface to remove debris. Verify flange alignment (parallelism). Tighten bolts in a star pattern using a calibrated torque wrench. Do not use “Cheater Bars” or impact guns for final tightening.

Why do gaskets leak in hydrogen systems?

Hydrogen leaks due to its tiny molecular size and permeation capabilities.

Hydrogen (H2) is 8 times smaller than methane molecules. It can permeate through the body of porous gasket materials. Additionally, Hydrogen Embrittlement can relax bolts, reducing the clamping force that holds the seal.

How often should you inspect gaskets in hydrogen service?

You should inspect flange connections every 3-6 months or after thermal cycles.

Use ultrasonic leak detectors or hydrogen sniffers, as H2 is invisible. Check bolt torque values after the first operational cycle (retorquing) to account for gasket relaxation.

Can you reuse a gasket after disassembly?

No, never reuse a gasket in critical hydrogen service.

Once compressed, a gasket loses its recovery properties. Reusing it will result in a failure to seal against the high-mobility hydrogen molecules. Always install a fresh gasket during maintenance.