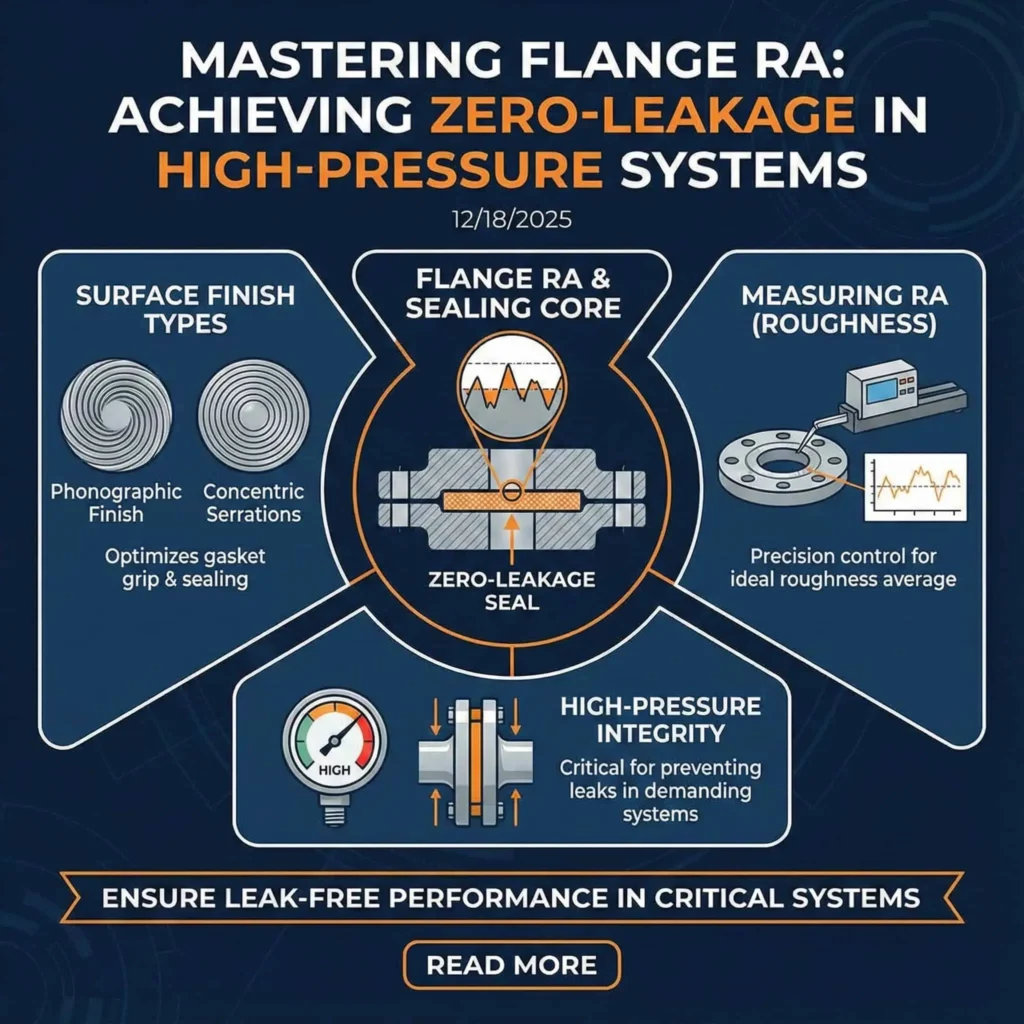

Mastering flange Ra sets the foundation for zero-leakage in high-pressure systems. Precision engineering controls the Phonographic Finish and Concentric Serrations, optimizing the Interface between flange and gasket. Quality assurance ensures each flange resists Micro-imperfections, achieving reliable Sealing Integrity. Sunhy’s advanced manufacturing delivers consistent surface roughness, critical for leak-free performance.

The right contact pressure will make the plastic deformation happen on sealing surface and block micro leakage paths. Therefore, the contact pressure is essential for the optimal sealing performance of SPMC.

Combining these precise bolting techniques with the appropriate flange design and material minimizes the risks of gasket failure and fluid leakage, which is essential for maintaining system integrity in high-pressure environments.

Engineers and decision-makers rely on correct flange ra to ensure every connection maintains integrity under demanding conditions.

Flange Ra and Leak-Proof Pipeline Connections

What Is Flange Ra in Flange Engineering?

Flange Ra measures the arithmetic average of the absolute values of profile height deviations from the mean line, defining the surface finish quality on flange faces.

Engineers use Ra to evaluate the Phonographic Finish and Concentric Serrations on the Interface between flange and gasket. This measurement helps control Micro-imperfections that can compromise Sealing Integrity.

| Term | Definition |

|---|---|

| Ra | The arithmetic average of the absolute values of the profile height deviations from the mean line, used to define typical facing finishes in flange engineering standards. |

How Surface Roughness Affects Gasket Sealing

Surface roughness directly impacts gasket performance and leak-proof pipeline connection reliability.

- Surface finish is critical in gasket design, affecting seal performance and longevity.

- A well-prepared surface should be consistent and within the recommended roughness range for the gasket type.

- Excessive roughness can lead to leak, while overly smooth surfaces may cause gasket creep and blow-out.

- Measuring both Ra and Rz provides a comprehensive understanding of sealing surfaces, allowing for better gasket material selection.

- Ra is useful for general machining control, but Rz offers a more detailed view of surface texture, especially in the presence of irregularities.

- Softer, more compressible gasket materials perform better on rough or damaged surfaces, adapting to irregularities and maintaining contact pressure.

Typical Ra Ranges for Common Flange Face Types

Industry standards specify Ra ranges to ensure leak-free flanges and zero-leak requirements.

The following table shows typical Ra values for common flange face types:

| Flange Face Type | Typical Ra Range (µin) | Typical Ra Range (µm) |

|---|---|---|

| Raised Face (RF) | 125 – 250 | 3 – 6 |

These values help maintain Sealing Integrity and support leak-proof pipeline connection in high-pressure environments.

Common Leakage Problems Caused by Incorrect Ra

Incorrect flange ra can result in several leakage problems at the pipeline connection.

- Too rough a surface creates Micro-imperfections that allow fluid to escape, reducing pressure and risking system failure.

- Overly smooth surfaces prevent proper gasket compression, leading to blow-out or loss of Sealing Integrity.

- Inconsistent Ra across the Interface can cause uneven torque distribution and compromise gasketing performance.

Tip: Always verify flange ra during inspection to ensure reliable leak-proof pipeline connection and maintain zero-leak requirements.

Industry Standards and Ra Specification

International Standards That Define Flange Ra

International standards set clear guidelines for flange ra to ensure Sealing Integrity and zero-leak requirements.

Organizations such as ASME, EN, and ISO publish specifications for Phonographic Finish and Concentric Serrations on flange faces. These standards help engineers achieve consistent Interface quality and control Micro-imperfections. The most referenced standards include:

- ASME B16.5: Covers pipe flanges and flanged fittings, specifying surface finish for different pressure classes.

- EN 1092-1: Defines requirements for steel flanges in Europe, including Ra values for sealing surfaces.

- ISO 4287/4288: Provides methods for measuring and evaluating surface roughness parameters.

Note: Following these standards ensures every connection meets global expectations for safety and performance.

Ra Requirements for RF, FF, and RTJ Flanges

Each flange face type requires a specific Ra range to maintain Sealing Integrity and prevent leaks.

The table below summarizes typical Ra values for common flange types:

| Flange Face Type | Ra Range (µin) | Ra Range (µm) | Typical Application |

|---|---|---|---|

| Raised Face (RF) | 125–250 | 3–6 | General service |

| Flat Face (FF) | 125–250 | 3–6 | Low-pressure |

| Ring Type Joint (RTJ) | 63–125 | 1.6–3.2 | High-pressure |

These values support proper gasket seating, optimal torque application, and reliable gasketing techniques.

Specifying Ra in Datasheets, Drawings, and Purchase Orders

Clear Ra specification in project documents ensures manufacturers deliver the correct surface finish for every Interface.

Engineers should always include Ra values on datasheets, technical drawings, and purchase orders. This practice eliminates ambiguity and guarantees that the Phonographic Finish or Concentric Serrations meet project needs. A typical specification might look like:

Flange Face Finish: Phonographic Finish, Ra 125–250 µin (3–6 µm), per ASME B16.5

Tip: Consistent documentation helps suppliers like Sunhy deliver flanges that meet zero-leak requirements and maintain Sealing Integrity throughout the system.

Measuring Flange Ra in Practice

Surface Roughness Parameters (Ra, Rz, and Others) Explained

Ra and Rz are the primary parameters for assessing flange surface quality.

Ra, or Arithmetic Mean Roughness, measures the average height of surface asperities, providing an overall view of smoothness. Rz, the ten-point height of irregularities, focuses on the difference between the highest peaks and lowest valleys. This distinction is essential for quality control in flange manufacturing, especially for maintaining Sealing Integrity at the Interface.

| Parameter | Definition | Measurement Method | Application |

|---|---|---|---|

| Ra | Average roughness of a surface | Overall average of surface asperities | General surface quality assessment |

| Rz | Ten-point height of irregularities | Difference between highest peaks and lowest valleys | Identifying extreme surface irregularities |

- Sealing applications: Ra ensures a good sealing surface, while Rz identifies potential leak paths caused by Micro-imperfections.

- Gasketing and coatings: Ra supports proper gasketing, while Rz highlights areas where coatings might not adhere.

Measurement Tools and Setups for Flange Faces

Precision tools ensure accurate measurement of flange ra and surface finish.

Technicians use portable surface roughness testers, stylus profilometers, and optical instruments to measure Phonographic Finish and Concentric Serrations. These tools scan the Interface and record both Ra and Rz values. For high-pressure pipeline connections, inspectors often use calibrated reference specimens to verify instrument accuracy. Proper setup includes cleaning the flange face, aligning the tool perpendicular to the grooves, and recording multiple readings across the surface.

Tip: Always measure at several points on the flange face to detect any variation in Micro-imperfections.

Inspection Frequency, Sampling Plans, and Acceptance Criteria

Consistent inspection routines maintain quality and prevent leak risks.

Manufacturers establish inspection frequency based on batch size, flange type, and pressure class. A typical sampling plan involves checking the first and last pieces of each batch, plus random samples throughout production. Acceptance criteria require Ra and Rz values to fall within specified ranges for the flange face type. If any reading falls outside the range, the batch undergoes further review or corrective action.

- Inspectors document all results and compare them to project specifications.

- Acceptance ensures the flange will achieve proper torque, optimal sealing, and reliable connection in service.

Controlling Ra in Manufacturing

Machining and Finishing Processes That Set Ra

Precision machining and finishing techniques determine the final Ra on flange faces.

Manufacturers use specialized processes to achieve the required Phonographic Finish or Concentric Serrations at the Interface. These processes create uniform grooves that address Micro-imperfections and support Sealing Integrity.

- Turning on CNC lathes produces consistent Phonographic Finish.

- Milling and grinding refine the surface to the target Ra.

- Lapping ensures smoothness for critical sealing applications.

| Finish Type | Roughness (Ra) | Application/Notes |

|---|---|---|

| Serrated Finish | 125 – 500 micro inches | Enhances sealing with soft gaskets; interlocks at the Interface. |

| Smooth Finish | 3.2 – 6.3 micrometers | Used in machinery; needs higher pressure for sealing. |

| Stock Finish | 250 – 500 AARH | Suitable for soft gaskets; too smooth may cause a leak. |

A precise finish increases friction and grip, ensuring the gasket remains stable under varying torque and pressure.

Achieving Consistent Ra Across Batches and Sizes

Strict process control and inspection maintain consistent Ra for every flange, regardless of size or batch.

Manufacturers set clear surface finish requirements and flatness tolerances. They use dimensional inspection and advanced testing to verify each flange meets zero-leak requirements.

- Inspectors check the Phonographic Finish and Concentric Serrations for uniformity.

- Hydrostatic, ultrasonic, and magnetic particle testing confirm structural integrity.

- Flatness tolerance typically stays within 0.002 inches to support reliable gasketing.

| Key Aspect | Details |

|---|---|

| Surface Finish Requirements | Face Roughness must meet specific Ra values. |

| Flatness Tolerance | Typically within 0.002 inches. |

| Quality Control Measures | Dimensional inspection and testing procedures are essential. |

| Testing Procedures | Hydrostatic, ultrasonic, and magnetic particle testing ensure quality. |

Quality Control, MTRs, and Third-Party Inspection

Material test reports (MTRs) and third-party inspections verify that every flange meets industry standards for Ra and Sealing Integrity.

MTRs confirm that each component matches the required chemical and mechanical properties. Inspectors review these certificates and compare them to the Inspection Test Plan. Third-party inspections add an extra layer of assurance, helping prevent costly failures in pipeline systems. These steps guarantee that every flange delivers reliable performance and meets all safety and compliance regulations.

Tip: Always request MTRs and third-party inspection reports to confirm compliance with project specifications and industry standards.

Flange Sealing Techniques for Zero-Leakage

Matching Gasket Type to Flange Face Ra

Selecting the right gasket for the job ensures Sealing Integrity at the Interface.

- The finish of the flange face, measured by Ra, directly affects how well the gasket seals, especially under high pressure.

- Metallic gaskets require a smoother Phonographic Finish to minimize Micro-imperfections and maintain leak tightness.

- Semi-metallic and nonmetallic gaskets tolerate rougher Concentric Serrations, adapting to surface irregularities.

- The interaction between gasket material and flange surface determines the effectiveness of the seal in pipeline applications.

Bolt Torque, Lubrication, and Tightening Patterns

Applying consistent torque and proper lubrication prevents leaks and supports optimal flange sealing techniques.

| Recommendation | Description |

|---|---|

| Torque Sequence | Use a controlled three-step torque approach (30 %, 60 %, 100 %). |

| Surface Finish | Maintain flange surface finish between 125–250 µin Ra for reliable sealing. |

| Lubrication | Apply compatible lubricant to bolts and nuts to reduce friction and galling. |

- Accurate torque application ensures each bolt achieves the correct preload for consistent gasket seating.

- Lubricants help bolts reach specified torque values, reflecting true preload and supporting sealing integrity.

Assembly Best Practices for High-Pressure Systems

Following best practices for sealing flanges reduces leakage risk and improves system reliability.

- Train assembly personnel to understand flange sealing techniques and torque and tightening best practices.

- Clean flange faces and fasteners to remove contaminants and Micro-imperfections.

- Align flanges precisely to protect the Interface and maintain sealing integrity.

- Select corrosion-resistant materials such as stainless steel for high-pressure pipeline service.

- Use calibrated torque wrenches and follow standard tightening sequences for consistent torque.

- Conduct pressure and tightness tests to verify the seal before commissioning.

Avoiding Common Installation and Handling Errors

Preventing installation errors protects the Phonographic Finish and Concentric Serrations, ensuring leak-free performance.

| Error Type | Description |

|---|---|

| Improper Gasket Selection | Using incorrect or old gaskets can compromise sealing integrity. |

| Inadequate Surface Prep | Dirty or damaged flange faces create leak paths at the Interface. |

| Misalignment | Off-center flanges stress joints and threaten sealing integrity. |

| Incorrect Torque Application | Failing to apply consistent torque can prevent proper gasketing and sealing. |

| Incompatible Materials | Unsuitable materials may cause corrosion or mechanical failure. |

- Corrosion pitting and contaminants like dirt or weld spatter introduce Micro-imperfections that undermine the seal.

- Using the correct gasket and maintaining clean, undamaged flange faces are essential for reliable flange sealing techniques.

Troubleshooting Ra-Related Leaks

Diagnosing Whether Ra Is the Root Cause

Engineers determine if Ra is the root cause of a leak by using targeted diagnostic methods.

A systematic approach helps identify issues at the Interface and ensures Sealing Integrity. The following table outlines common diagnostic techniques:

| Diagnostic Method | Description |

|---|---|

| Visual Inspection | Engineers examine the sealing surface for Micro-imperfections, damage, or irregularities. |

| Surface Roughness Measurement | Technicians use specialized tools to assess the Ra of the flange face, verifying Phonographic Finish. |

| Replication Techniques | Teams create physical imprints of the flange face for microscopic analysis of Concentric Serrations. |

Tip: Surface roughness measurement often reveals if improper bolt torque or a damaged flange surface has compromised the seal.

Repair Options for Damaged or Over-Rough Flange Faces

Repairing a damaged flange surface restores Sealing Integrity and prevents leaks.

Engineers select from several proven methods:

- Quick, cost-effective repair services use polymer composite materials to rebuild the flange face.

- In situ repairs minimize downtime and avoid hot work or machining.

- These solutions isolate dissimilar metals, preventing galvanic corrosion.

- Remove the corroded flange and weld a new one.

- Machine the sealing face or ring groove on-site within flange tolerance.

- Add material through weld buttering runs, then machine the sealing face.

- Apply polymer composite repair materials to restore the Interface.

When to Re-Machine, Lap, or Replace the Flange

Engineers re-machine, lap, or replace a flange when Ra exceeds optimal levels or corrosion damages the Interface.

Corrosion increases Ra, creating irregularities that harm gasketing and reduce Sealing Integrity. Grinding and honing restore proper Ra values, ensuring compatibility with gasket types. Replacement becomes necessary when damage is extensive or repairs cannot achieve the required Phonographic Finish or Concentric Serrations.

Preventive Maintenance and Re-Inspection Intervals

Regular preventive maintenance and scheduled re-inspection maintain Sealing Integrity and prevent future leaks.

Teams inspect flange faces for Micro-imperfections, measure Ra, and verify the condition of the Interface. Maintenance schedules depend on system pressure, media, and environmental factors. Early detection of surface changes allows timely intervention, reducing the risk of leaks and costly downtime.

Note: Consistent monitoring and maintenance protect high-pressure systems and support long-term reliability.

Practical Ra Checklists and Engineering Tips

Pre-Fabrication Ra Checklist for Engineers and Buyers

A comprehensive pre-fabrication checklist ensures every flange meets Sealing Integrity standards before leaving the factory.

Engineers and buyers should verify each item to guarantee compliance with project requirements and industry standards. The following table outlines essential checks:

| Item | Description |

|---|---|

| ES-4 | Hydrostatic testing |

| ES-16 | Radiographic inspection of welds |

| ES-20 | Ultrasonic wall thickness measurement |

| ES-21 | GTAW root pass fit-up |

| ES-22 | Color coding of piping materials |

| ES-25 | Random radiography of girth welds |

| ES-26 | Welded load-bearing attachments |

| ES-27 | Visual examination scope & limits |

| ES-29 | Abrasive blast cleaning |

| ES-30 | Ultrasonic examination of butt welds |

| TB-1 | Pressure–temperature ratings of seamless pipe |

| TB-3 | Roles & responsibilities of engineers |

Tip: Always confirm that Phonographic Finish and Concentric Serrations meet specified Ra values to prevent Micro-imperfections at the Interface.

Site Installation and Commissioning Checklist

Proper installation and commissioning protect the Interface and maintain Sealing Integrity in high-pressure systems.

Teams should follow these steps:

- Inspect flange faces for damage or contamination.

- Measure Ra to confirm Phonographic Finish and Concentric Serrations fall within specification.

- Clean all contact surfaces to remove debris and prevent Micro-imperfections.

- Select the correct gasket type for the application, considering gasketing compatibility.

- Apply calibrated torque in the recommended sequence.

- Perform pressure testing to verify leak-free performance.

Note: Consistent documentation and inspection at each stage reduce the risk of leaks and ensure long-term reliability.

Working With SUNHY for Ra-Controlled Flange Supply

Partnering with Sunhy guarantees precise Ra control and reliable Sealing Integrity for every project.

Sunhy uses advanced CNC machining to deliver consistent Phonographic Finish and Concentric Serrations. The company provides full traceability, rigorous testing, and third-party inspection for every flange. Engineers receive detailed documentation, including Ra measurements and material test reports, ensuring each Interface meets zero-leak requirements.

Sunhy’s commitment to quality and customer support makes them a trusted supplier for high-pressure pipeline applications.

Mastering flange Ra ensures zero-leakage in high-pressure systems.

Key steps include:

- Understanding that flanges prevent leaks by creating uniform pressure at the Interface.

- Recognizing that Sealing Integrity depends on maintaining pressure above internal fluid pressure.

- Identifying factors that inhibit this pressure, such as Micro-imperfections.

Quality manufacturing and precise measurement drive long-term reliability.

High-grade materials, Phonographic Finish, and Concentric Serrations support durability and compliance.

A practical checklist for leak-proof connections includes:

| Checklist Item | Description |

|---|---|

| Proper site preparation | Specify technical requirements and hydraulic needs. |

| Corrosion protection | Implement measures to prevent degradation. |

| Continuous monitoring | Regularly check operating pressure and integrity. |

Ongoing inspection and adherence to standards like ASME PCC-1 sustain Sealing Integrity and system performance.

FAQ

What is the ideal Ra value for a Phonographic Finish on a flange?

The ideal Ra value for a Phonographic Finish ranges from 125 to 250 µin (3 to 6 µm).

This range supports Sealing Integrity at the Interface and helps eliminate Micro-imperfections.

How do Concentric Serrations improve gasket sealing?

Concentric Serrations create uniform grooves that enhance gasket grip and block Micro-imperfections.

They increase friction at the Interface, improving Sealing Integrity in high-pressure systems.

Why does Sunhy measure both Ra and Rz on flange faces?

Sunhy measures both Ra and Rz to ensure the Phonographic Finish and Concentric Serrations meet strict standards.

This dual measurement detects Micro-imperfections and confirms Sealing Integrity at the Interface.

What tools verify Ra on stainless steel flanges?

Technicians use portable surface roughness testers and stylus profilometers.

These tools scan the Interface, recording Ra values to confirm the quality of the Phonographic Finish and Concentric Serrations.

When should engineers re-machine a flange face?

Engineers re-machine a flange face when Ra exceeds specification or corrosion creates Micro-imperfections.

This process restores Sealing Integrity and prepares the Interface for reliable service.