Lap Joint Flange and Stub End create a practical connection for industrial piping—especially where alignment, frequent disassembly, and material cost control matter. You gain easy alignment, cost savings, and faster maintenance with this pairing. In real piping work, this combination is often selected when you want the corrosion-resistant alloy only where the fluid touches (the stub end), while using a more economical backing flange for bolting.

Here’s why this combination stands out:

| Advantage | Description |

|---|---|

| Easy Alignment | The backing flange rotates, making bolt alignment simple—even when spool pieces are slightly off-angle. |

| Cost-Effective | Only the stub end is wetted; you can use expensive alloy on the stub end and a lower-cost backing flange. |

| Maintenance Efficiency | Quick disassembly supports inspection, gasket replacement, and equipment tie-ins with less downtime. |

Sunhy’s stainless steel flanges are manufactured with CNC machining and inspection controls to support secure, repeatable, leak-resistant flange joints.

Lap Joint Flange and Stub End Basics

Lap Joint Flange Overview

What is a Lap Joint Flange?

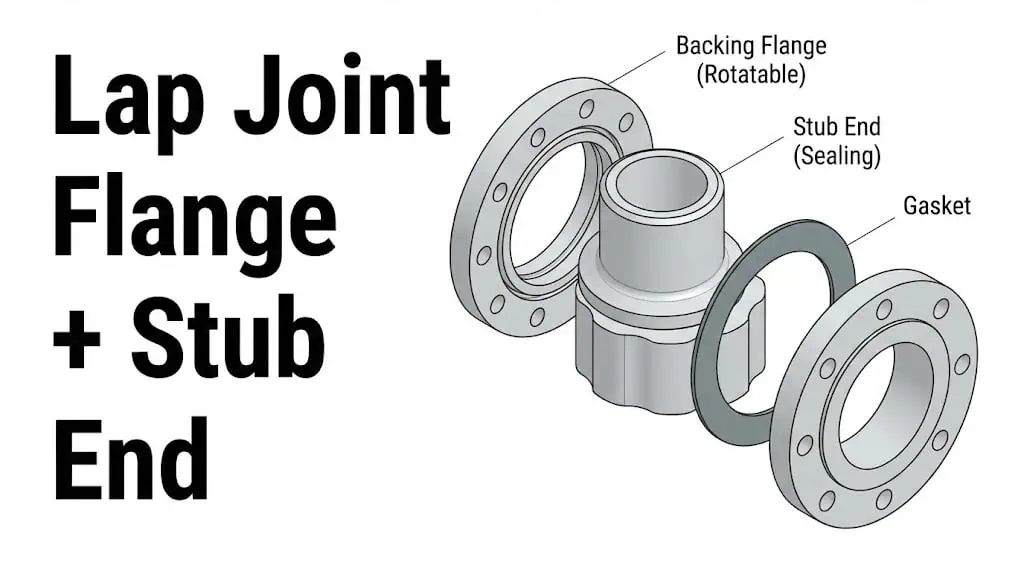

A lap joint flange is a loose, rotatable ring (backing flange) that fits over a pipe and works with a stub end. You do not weld the backing flange to the pipe. Instead, the stub end is welded to the pipe, and the backing flange provides the bolting force.

Why engineers choose a lap joint flange (typical field reasons):

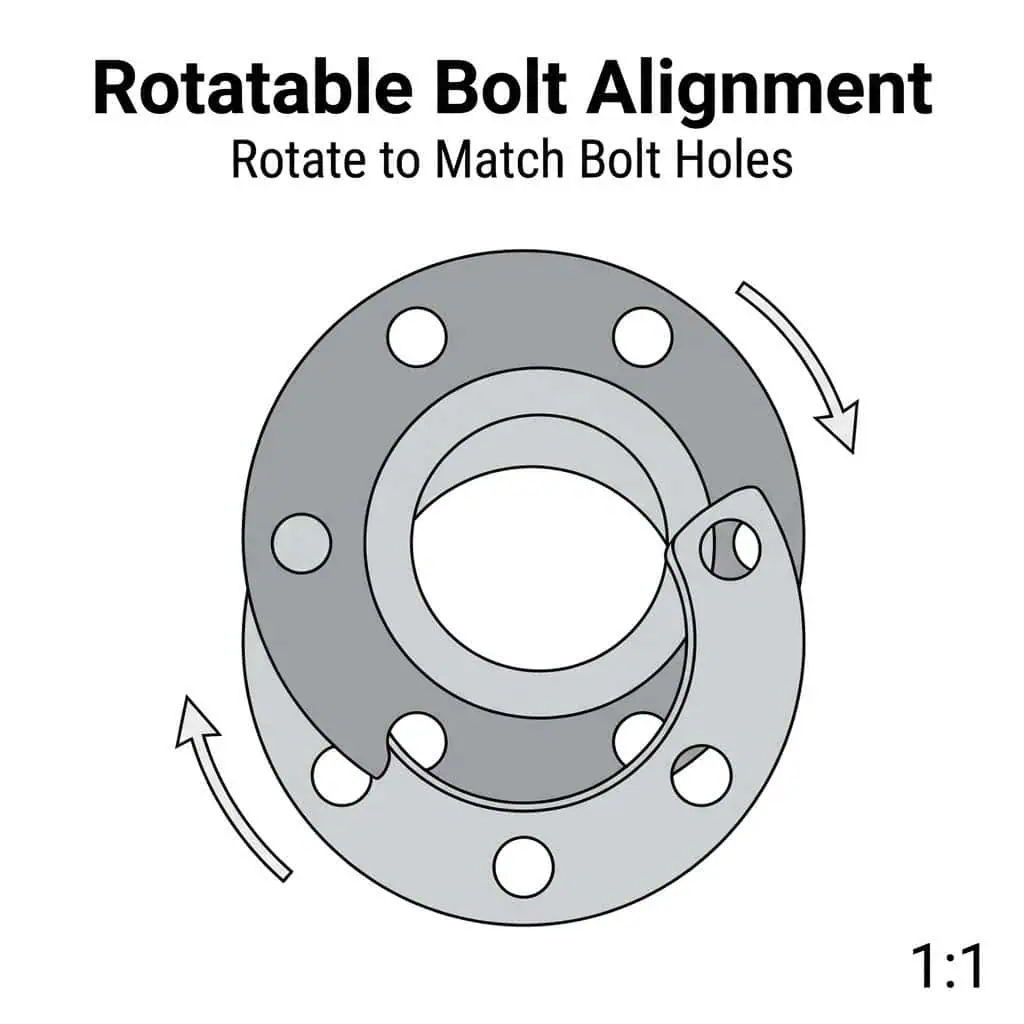

- Alignment tolerance: You can rotate the backing flange to match bolt holes quickly, which is helpful for large spools, tight racks, and retrofit work.

- Maintenance access: Frequent dismantling is easier because the backing flange is not welded to the pipe.

- Material strategy: The backing flange can be carbon steel or another economical grade, while the stub end matches the process media requirement.

How Sunhy controls quality

Sunhy manufactures lap joint flanges using CNC machining and dimensional inspection to meet international standards such as ASME, ASTM, DIN, and EN1092-1. For projects that require traceability, request MTC/heat numbers and inspection records as part of procurement documentation.

Tip: If your joint will be opened frequently, focus on repeatable fit-up: smooth seating surface, correct gasket selection, and controlled bolt tightening sequence.

| Standard | Coverage |

|---|---|

| ASME, ASTM | Chemical composition, mechanical properties, pressure classes |

| DIN, EN1092-1 | Dimensions, tolerances, facings, marking requirements |

Stub End Overview

What is a stub end?

A stub end is a short butt-weld fitting welded to the end of a pipe. The flared lap of the stub end forms the seating surface that compresses the gasket. In a lap joint assembly, the backing flange provides load, but the stub end provides the seal interface.

Important detail for selection: stub ends are available in different patterns (commonly short pattern vs long pattern). Your pattern choice affects face-to-face and alignment with mating equipment.

- Short pattern: common for many general service systems where compactness is desired.

- Long pattern: often selected when you need additional length for alignment, heavier wall, or specific matching requirements.

Sunhy stub ends (product reference): You can review size range, materials, and patterns here: Stub Ends (Butt Weld Fittings). This page is useful for procurement alignment and ensuring your stub end matches the flange rating and facing expectations.

Standards and compatibility:

Stub ends are typically produced to butt-weld fitting standards (commonly ASME B16.9 dimensions for many applications). In stainless light-wall systems, many projects reference MSS SP-43 for dimensional guidance (especially where Schedule 5S/10S is used). Always confirm the exact standard and wall thickness schedule with your piping class and the mating flange standard.

Why stub ends are used with lap joint flanges in corrosive service:

Only the stub end touches the media. That means you can specify 316/316L, duplex, or nickel alloy for the stub end while using a less expensive backing flange, reducing total cost without sacrificing corrosion resistance where it matters.

Typical engineering uses:

- Corrosive or chloride-bearing service where the wetted surface must be stainless or duplex

- Systems requiring frequent dismantling (filters, strainers, exchangers, inspection points)

- Skid packages and retrofit tie-ins where bolt-hole alignment needs flexibility

How Sunhy meets standards for stub ends

Sunhy provides stub ends manufactured for industrial piping applications (material options and compliance depend on project requirements). For documentation-driven projects, specify MTC, PMI (if needed), dimensional reports, and NDT scope in your purchase order.

| Function/Roles | Description |

|---|---|

| Joining expensive materials | Stub end matches alloy requirement; backing flange can be economical. |

| Frequent dismantling | Good for systems needing regular inspection or maintenance. |

| Quick alignment | Backing flange rotation simplifies bolt-hole alignment. |

| Cost efficiency | Only the stub end requires expensive material. |

| Rotatable flange | Backing flange rotates for proper orientation during installation. |

Lap Joint Flange and Stub End work together to give you flexibility, durability, and cost control in industrial piping—when properly specified and assembled.

Assembly and Working Principle

How Lap Joint Flange and Stub End Connect

You assemble a Lap Joint Flange and Stub End using a repeatable field sequence. In practice, the goal is to maintain alignment, protect the seating surface, and apply uniform gasket compression.

- Slip the backing flange over the pipe and position it behind the stub end lap.

- Weld the stub end to the pipe spool with an approved WPS and qualified welder.

- Place the gasket between the mating faces (stub end lap to mating flange face) and insert bolts.

- Align bolt holes by rotating the backing flange, then tighten in a controlled sequence.

Tip: Treat the stub end lap like a sealing face—keep it clean, protected from impacts, and free of deep scratches that can create leak paths.

Field detail that prevents leaks:

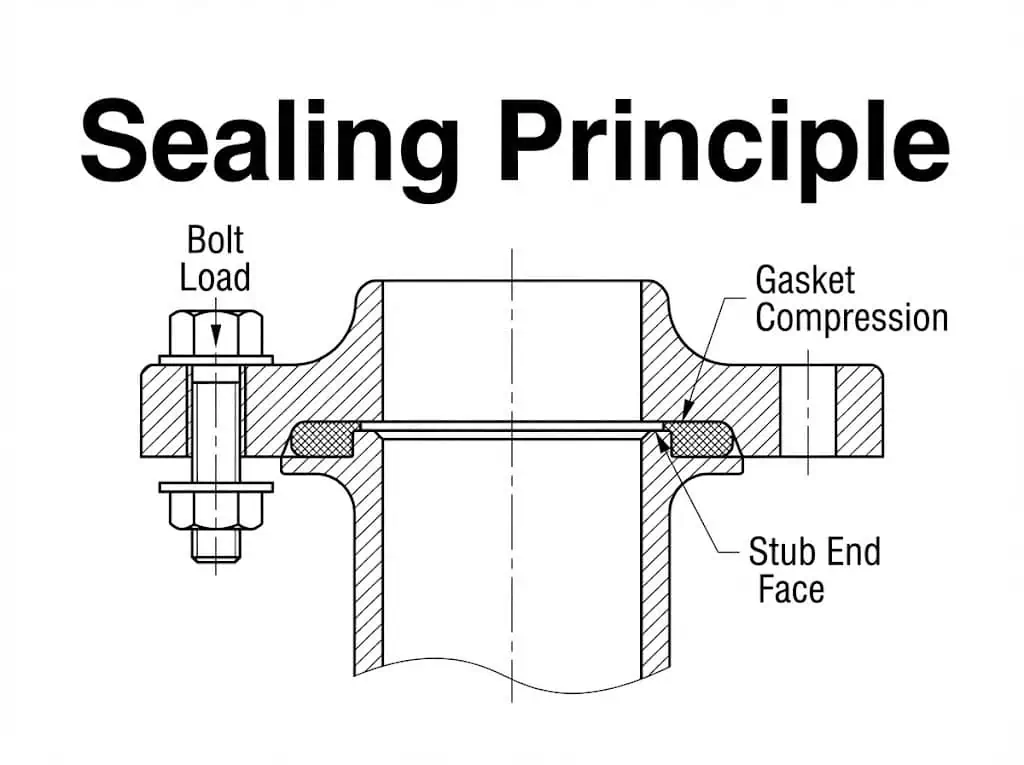

Most gasket failures in lap joint assemblies are not “because lap joint is weak”—they happen because of uneven compression (poor tightening pattern), misalignment, damaged seating surfaces, or wrong gasket selection for the media/temperature.

Sealing and Alignment Process

You achieve the seal at the stub end lap + gasket interface.

The backing flange applies bolt load, pressing the stub end lap against the gasket. A reliable seal depends on:

- Correct gasket type and thickness

- Clean, undamaged sealing surfaces

- Uniform bolt load (tightening sequence + staged torque passes)

| Step | Action |

|---|---|

| Gasket Placement | Center the gasket and confirm correct ID/OD for the flange facing. |

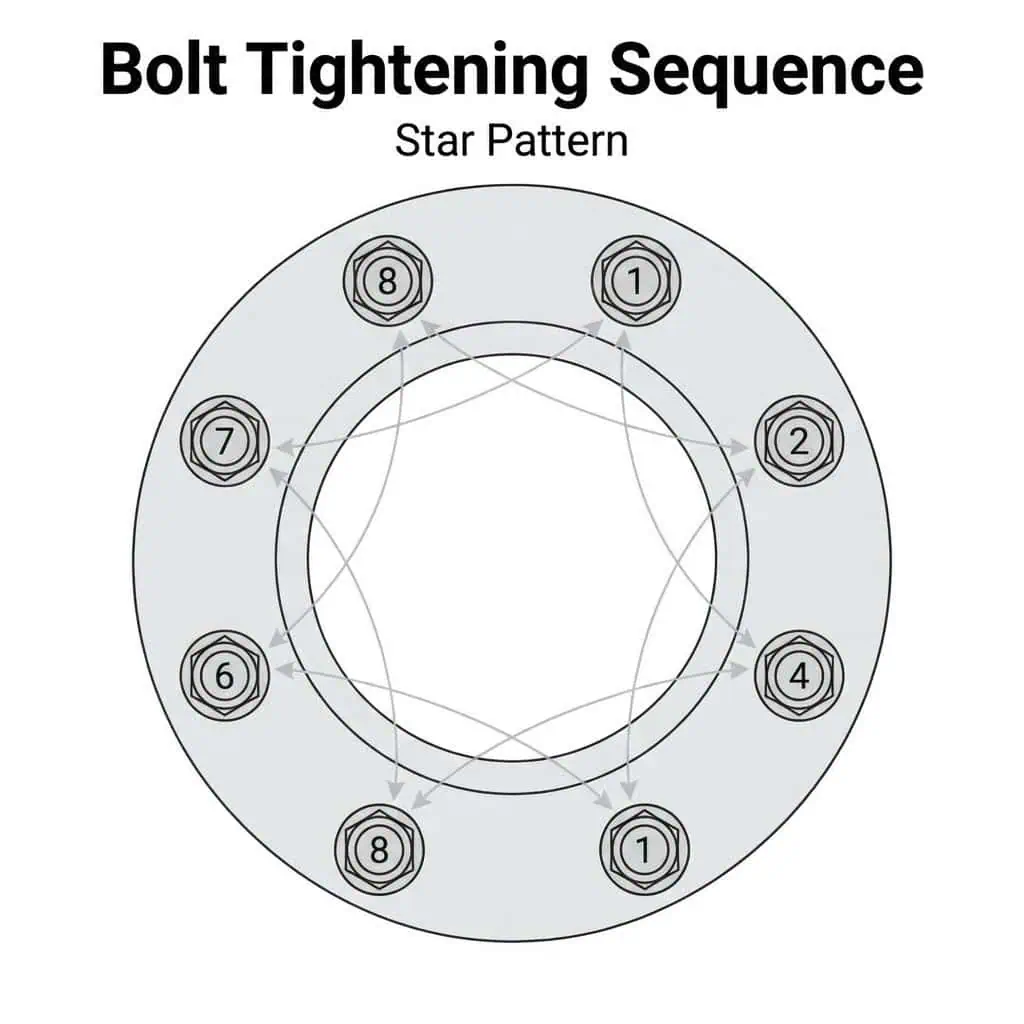

| Bolt Tightening | Tighten in a star/cross pattern with staged passes for uniform compression. |

| Flange Rotation | Rotate the backing flange for bolt-hole alignment before final tightening. |

What are the mechanical benefits?

Using Lap Joint Flange and Stub End lets you save costs in stainless steel or nickel alloy systems. The backing flange can be carbon steel, while the stub end matches the piping material and process media. You get a connection that is easier to disassemble and inspect, with strong sealing performance when assembled correctly.

Controlled tightening recommendation: use a star-like crossing pattern and staged tightening passes to compress the gasket uniformly (especially on larger bolt circles or critical service).

Key Advantages of Lap Joint Flange and Stub End

Installation Efficiency

You achieve faster fit-up with Lap Joint Flange and Stub End because the backing ring rotates.

This saves time when bolt-hole alignment is difficult (large diameter spools, crowded pipe racks, or retrofit tie-ins). However, speed only helps if the stub end lap and gasket selection are correct.

- Rotate flange for bolt-hole match without rework

- Remove/replace spools faster during maintenance windows

- Reduce on-site correction time for minor spool misalignment

Tip: If you see recurring leaks, don’t “just tighten more.” Verify gasket type, surface condition, and tightening sequence first.

Cost Savings

You lower project cost because the backing flange does not contact the process fluid.

This is a common strategy in corrosive service: specify the wetted stub end in 316/316L (or higher alloy as needed), while keeping the backing flange economical.

- Use high-grade materials only where needed

- Reuse backing flanges during maintenance (when condition allows)

- Reduce replacement frequency by selecting correct wetted alloy

| Cost-Saving Feature | Benefit |

|---|---|

| Selective Material Use | Only stub end needs expensive alloy |

| Reusable Flange | Backing flange can be reused multiple times |

| Reduced Maintenance | Lower long-term repair and replacement costs |

Note: Cost savings should never override compatibility—confirm alloy selection against chloride level, temperature, and media chemistry.

Corrosion Resistance

You protect the system by matching stub end material to the media.

Because the stub end is the wetted part, it drives corrosion performance. Backing flange material mainly affects external corrosion and mechanical integrity, not internal corrosion resistance.

| Media Type | Recommended Materials | Key Considerations |

|---|---|---|

| Water, Low-Pressure Steam | Carbon Steel / 304 / 316 (as needed) | Coatings for external corrosion; verify oxygen/chemistry |

| Oil, Natural Gas | Carbon Steel / CRA as required | Confirm H2S/CO2; sour service may require special material rules |

| Oxidizing Acids | Stainless Steel (304L, 316L) | 316L typically improves chloride resistance |

| Non-Oxidizing Acids, Seawater | 316L, Duplex Stainless Steel | Control pitting/crevice corrosion; verify temperature/chlorides |

You can further optimize your system by selecting from common stainless steel grades:

| Material | Typical Use Case | Key Advantage | Relative Cost |

|---|---|---|---|

| 304 Stainless Steel | General-purpose piping | Good corrosion resistance | Low |

| 316/316L Stainless Steel | Chemical, marine environments | Improved chloride resistance | Medium |

| Duplex Stainless Steel | High-chloride / aggressive media | Higher strength + corrosion resistance | High |

Engineering note: if your failure mode is crevice/pitting, material upgrade alone may not solve it—gasket selection, drainage, and surface condition also matter.

Lap Joint Flange and Stub End give you a flexible, cost-effective, and durable solution for modern piping systems—when standard compatibility, material selection, and assembly discipline are handled correctly.

Applications in Industry

Where Lap Joint Flange and Stub End Excel

You find Lap Joint Flange and Stub End excel in systems needing frequent maintenance, corrosion resistance, and cost efficiency.

This connection is common where you expect periodic inspection, spool replacement, or equipment tie-ins—especially in corrosive media lines where the wetted alloy needs to be higher grade.

Tip: For frequent dismantling points (filters/strainers/exchangers), lap joint assemblies can reduce downtime—if gasket control and tightening procedures are standardized.

Top industries where this solution delivers the most value:

- Oil and Gas: easy disassembly for inspection and tie-ins

- Petrochemical Refineries: maintenance efficiency for equipment connections

- Water Treatment: corrosion control and easier spool changes

- Food Processing: hygiene-driven dismantling and cleaning

- Power Generation: selected non-critical services with scheduled maintenance

| Industry | Benefits |

|---|---|

| Oil and Gas | Easy maintenance, flexible alignment |

| Chemical Processing | Cost control for corrosion-resistant systems |

| Water Treatment | Cleaning access, long service life |

| Food and Beverage | Hygienic dismantling and cleaning |

| Marine | Material strategy for corrosive environments |

Common Use Cases

You use Lap Joint Flange and Stub End in piping systems that require flexibility, durability, and cost savings.

This connection adapts to applications where material pairing is needed (wetted vs non-wetted) and where frequent access is expected.

- Simplifies assembly and disassembly

- Allows quick access for maintenance

- Enables use of economical backing flange materials

- Protects backing flange faces from internal erosion/chemical attack (because it is not wetted)

- Helps manage alignment in large pipe racks and retrofit work

| Industry | Use Case Description |

|---|---|

| Chemical | Corrosive liquids: upgrade stub end alloy, keep economical backing flange |

| Petrochemical | Equipment connections requiring periodic opening |

| Water Treatment | Potable/wastewater chemical dosing and maintenance access points |

Where you should be cautious:

If the joint will see high cyclic bending, strong vibration, or severe external corrosion, review pipe supports, bolt material, and joint design carefully. Lap joint assemblies are not “wrong” for demanding service, but they are less forgiving to poor tightening control and surface damage.

Selection and Maintenance Tips

Choosing the Right Materials

Select materials based on fluid compatibility, pressure/temperature, and corrosion mechanism.

The stub end should match the process media and operating conditions, while the backing flange can be selected for mechanical needs and external environment. If you’re specifying stainless/duplex, confirm not only “corrosion resistance,” but also the likely failure mode (pitting, crevice, SCC).

| Material Type | Material Grades |

|---|---|

| Carbon Steel | ASTM A105, A350 LF2 (commonly for backing flange) |

| Stainless Steel | ASTM A182 F304, F304L, F316, F316L, F321 |

| Alloy Steel | ASTM A182 F11, F22 |

| Nickel Alloys | Inconel, Monel, Hastelloy (application-dependent) |

| Duplex Stainless Steel | 2205 |

| Super Duplex Steel | 2507 |

| Copper Alloys | Brass, Bronze |

Tip: If you’re selecting between 304 and 316L for a stub end, confirm chloride exposure and temperature—316L is often chosen when chloride pitting risk increases.

Installation Best Practices

Follow precise installation steps to prevent leaks and ensure repeatable performance.

For lap joint assemblies, most leak events trace back to gasket misfit, surface damage, or uneven bolt load. Make your installation process auditable and repeatable:

- Verify stub end pattern (short/long) and flange rating before fit-up.

- Inspect the stub end lap for dents, deep scratches, and weld spatter.

- Center the gasket and confirm correct gasket dimensions (ID/OD) for the joint.

- Use a star/cross tightening sequence with multiple staged passes (do not torque around in a circle).

- Check bolt engagement length and use suitable lubrication where required by your bolting procedure.

- Recheck bolt load after initial pressurization/thermal cycle if required by your plant procedure.

Note: “Tighten more” is not a root-cause fix. If you see repeated leaks, verify gasket type, tightening method, and surface condition first.

Maintenance and Troubleshooting

Inspect, clean, and verify connections regularly to maximize service life.

Routine inspection should include: gasket condition, seating surface marks, bolt corrosion/galling, backing flange distortion, and alignment. When you encounter leaks or alignment issues, use the troubleshooting strategies below.

| Strategy | Description |

|---|---|

| Proper gasket selection | Choose gasket compatible with fluid + temperature; verify size and facing match. |

| Controlled bolt tightening | Use star/cross pattern + staged passes to avoid uneven compression and leaks. |

| Alignment verification | Check spool alignment before tightening; avoid pulling misalignment in with bolts. |

| Surface preparation | Clean and inspect stub end lap; remove debris that creates leak paths. |

| Check bolt length & condition | Ensure correct engagement and replace corroded/galling bolts and nuts. |

Real-world engineering examples (problem → cause → fix/prevention)

- Example 1: Repeat leak after gasket change → gasket centered poorly and tightened in a circular pattern → reassemble with correct gasket ID/OD + star pattern + staged torque passes; inspect stub end lap for scratches.

- Example 2: “We fixed it by over-torquing” and then studs failed → over-torque used to compensate for uneven load and poor surface condition → restore correct procedure: replace studs if yielded, verify surfaces, use correct tightening method and lubrication rules.

- Example 3: Crevice corrosion around lap in chloride service → 304 stub end used where chlorides + temperature accelerated pitting/crevice attack → upgrade stub end alloy (often 316L/duplex depending on conditions), improve drainage/cleaning, review gasket material.

- Example 4: Alignment “pulled in” by bolts caused flange distortion → spool misalignment forced into position by tightening → correct supports/alignment, re-fit spool, then tighten normally to avoid bending stress on the joint.

Sunhy’s support team can assist with matching flange type, stub end pattern, and documentation requirements for Lap Joint Flange and Stub End assemblies.

You gain flexibility, cost savings, and easy maintenance with Lap Joint Flange and Stub End—when selection and assembly discipline are in place.

- Match materials correctly (wetted vs non-wetted).

- Standardize gasket + bolting procedure to avoid repeat leaks.

- Inspect seating surface condition and bolt condition during each opening.

For product specification alignment, review Sunhy’s stub end range here: Stub Ends (Butt Weld Fittings).

FAQ

What is the main benefit of using a Lap Joint Flange and Stub End?

Easy bolt alignment and cost control in corrosion-resistant systems.

You rotate the backing flange for quick bolt-hole alignment. You use expensive material only for the stub end (wetted part), which reduces overall cost while keeping corrosion resistance where it matters.

Can you reuse Lap Joint Flanges?

Yes—often, if inspection confirms the backing flange is in good condition.

The backing flange rarely contacts process fluid. In maintenance work, it is commonly reused if bolt holes, flatness, and external corrosion condition remain acceptable.

How do you select the right material for a stub end?

Match the stub end alloy to the process fluid and corrosion mechanism.

Select stainless steel, duplex, or nickel alloys for corrosion resistance when required. Use carbon steel for non-corrosive service. If chloride pitting/crevice corrosion is a risk, validate that 304 is sufficient—often 316L/duplex is chosen depending on conditions.

Tip: If you are unsure, specify your media chemistry (chlorides, temperature, cleaning chemicals) and let engineering confirm the minimum acceptable alloy.

Where do Lap Joint Flange and Stub End connections work best?

Best for systems needing frequent maintenance and flexible alignment.

You commonly find them in chemical, petrochemical, water treatment, and food processing industries—especially at inspection points, filters, and equipment tie-ins.

| Industry | Benefit |

|---|---|

| Chemical | Corrosion resistance strategy (wetted stub end) |

| Water Treatment | Easy cleaning and maintenance access |

| Food Processing | Hygienic dismantling and cleaning |

How do you prevent leaks in Lap Joint Flange assemblies?

Use correct gasket + clean seating surface + controlled bolt tightening.

Center the gasket, keep the stub end lap clean and undamaged, and tighten bolts in a star/cross pattern with staged passes. Avoid pulling misalignment in with bolt force.

- Clean flange faces and stub end lap

- Verify alignment before tightening

- Use star/cross tightening sequence + staged torque passes

Short pattern vs long pattern stub end: which should you use?

Choose based on dimensional matching and installation needs.

Short pattern is commonly used for compact layouts. Long pattern is used when additional length is required for matching, alignment, or specific project standards. Confirm the pattern requirement in your piping class and with the mating flange/equipment.

Does the backing flange face type matter in a lap joint assembly?

Yes—because the backing flange transfers load, but sealing happens on the stub end lap.

The backing flange must match bolt circle and rating, and remain flat enough to deliver uniform load. The gasket and sealing face relationship is driven by the stub end lap + mating flange, so verify compatibility of gasket and mating face condition.

What documentation should you request when buying stub ends?

For controlled projects, request traceability and inspection records.

Typical requests include MTC/heat number traceability, dimensional inspection, PMI (if required), and NDT scope if the project specification requires it. This prevents mixed materials and reduces commissioning risk.