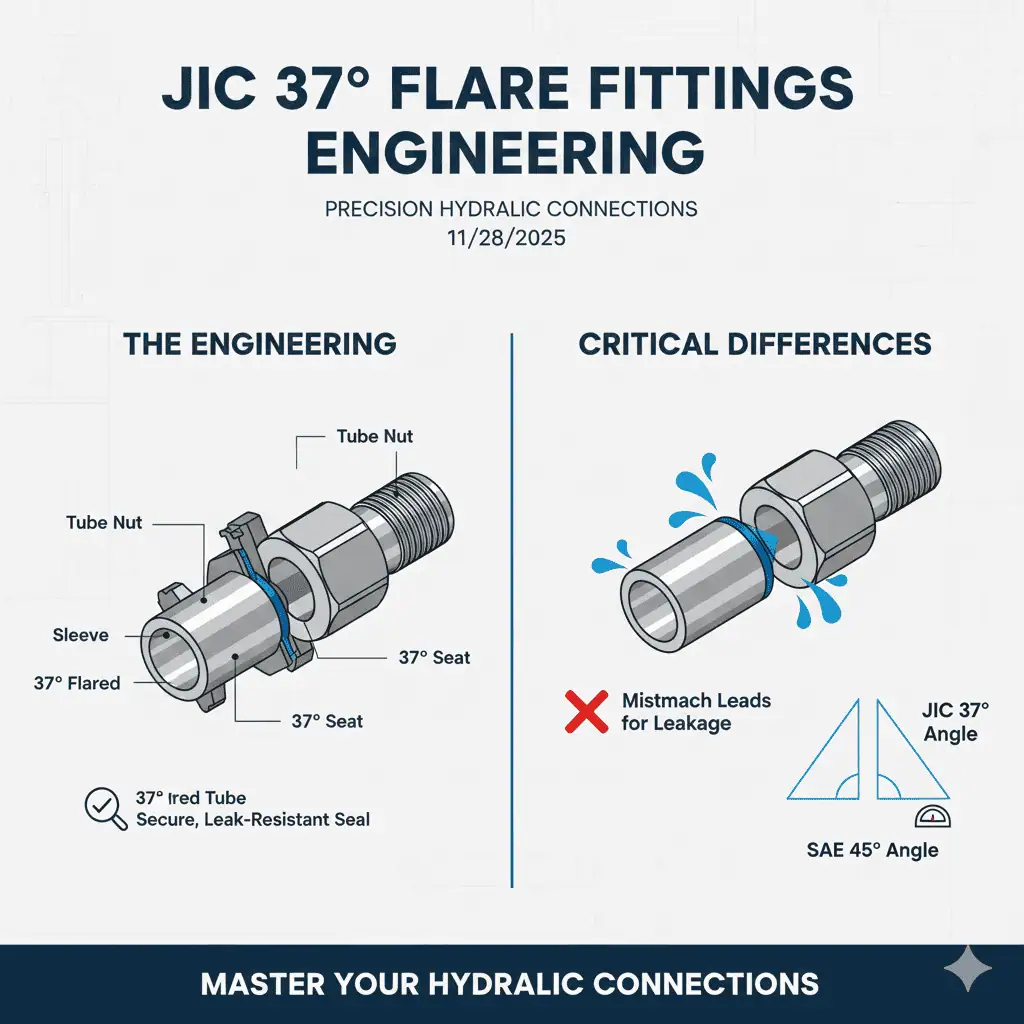

JIC 37° flare fittings create secure, leak-resistant hydraulic connections using a 37-degree flared seat. You rely on these fittings to maintain safety and performance in demanding fluid power systems. JIC fittings help prevent leaks and failures, which can lead to costly downtime or hazards. Selecting the correct fitting matters. For example, using a JIC (37°) male with an SAE (45°) female may cause leaks under pressure.

| Mismatched Pair | Result of Mismatch | How to Identify |

|---|---|---|

| JIC (37°) Male into SAE (45°) Female | Leaks under pressure or vibration | Use a seat angle gauge to check seat |

You safeguard your system by choosing the right fittings and understanding their unique engineering role.

What Are JIC 37° Flare Fittings

37° Flare Fittings Design

JIC 37° flare fittings use a precise 37 degree flare to create strong, leak-resistant connections in hydraulic systems.

You see these fittings in many industries because they offer reliability and easy installation. The design includes three main parts: the body, the sleeve, and the nut. Each part works together to form a tight seal under pressure.

- The body has a 37° flared seat.

- The sleeve supports the tube and helps distribute pressure.

- The nut secures the sleeve and tube to the fitting body.

Tip: You can quickly identify 37° flare fittings by measuring the angle of the seat with a gauge.

The historical development of these fittings began during World War II. The Joint Industry Council wanted to solve problems with inconsistent hydraulic components. In the late 1940s, they created unified specifications. By 1950, the SAE J514 standard made these fittings reliable and interchangeable. Later, ISO 8434-2 helped standardize them worldwide.

You benefit from these standards because they make repairs and replacements simple. The standardized dimensions mean you can use fittings from different manufacturers without worry.

Here is a comparison table to help you understand how 37° flare fittings differ from other common hydraulic fittings:

| Feature | JIC 37° Flare Fittings | AN Fittings |

|---|---|---|

| Manufacturing Tolerances | Looser tolerances for general use | Tighter tolerances for high performance |

| Material and Durability | Made from carbon steel, less durable | Made from stainless steel or aluminum, more durable |

| Applications | Used in agriculture, construction, and industrial systems | Used in aerospace, military, and high-pressure systems |

| Cost | More cost-effective for less demanding environments | Higher cost due to stringent standards |

Flare Connection Principle

The 37° flare connection principle relies on metal-to-metal contact to create a reliable seal.

You achieve a leak-proof joint by tightening the nut, which presses the sleeve and tube against the 37° flared seat. This action forms a strong seal that can handle high pressure and vibration.

- The flare fitting works with both metric and inch tubes. You only need to change the sleeve for compatibility.

- The design reduces the number of parts you need, making installation faster and easier.

- You can use these fittings in extreme working conditions because the seal remains effective under high pressure.

Here is a table that explains the key engineering principles behind the 37° flare connection:

| Key Feature | Description |

|---|---|

| Design | The 37° flare fitting consists of a body, sleeve, and nut, ensuring a perfect seal under pressure. |

| Material Options | Made from cold-drawn bar stocks for straight fittings and forgings for angular fittings, enhancing reliability. |

| Sealing Capabilities | The design allows for effective sealing even under high pressure and extreme working conditions. |

| Compatibility | Can accommodate both metric and inch tubes with a simple change in sleeves, reducing costs. |

| Manufacturing Ease | Simplifies manufacturing requirements and reduces part count due to various fitting configurations. |

Note: You should always check the flare angle before installation. Using the wrong angle can cause leaks and system failures.

You rely on 37° flare fittings because they offer a proven solution for hydraulic and fluid power systems. Their design and connection principle make them a top choice for engineers who value safety, reliability, and performance.

Materials and Manufacturing of 37° Flare Fittings

Stainless Steel and Other Materials

You find stainless steel as the most popular material for JIC 37° flare fittings because of its excellent corrosion resistance and strength. Other materials like nickel alloys, brass, and carbon steel also play important roles in different environments.

| Material | Description |

|---|---|

| Stainless Steel | Commonly used for its corrosion resistance. |

| Nickel Alloys | Known for high strength and resistance to heat. |

| Brass | Valued for machinability and corrosion resistance. |

| Carbon Steel | Often used for strength and durability. |

Stainless steel, especially grades like ASTM A403 WP316L/304L and Duplex, stands out in harsh chemical and marine environments. You benefit from its chromium content, which forms a protective oxide layer and prevents rust.

| Material | Corrosion Resistance Description |

|---|---|

| Stainless Steel | Highly resistant in harsh environments due to a protective oxide layer. |

| Brass | Good in mild environments, less effective in acidic or alkaline conditions. |

| Aluminum | Decent resistance, but not as robust as stainless steel in aggressive environments. |

Manufacturing Techniques

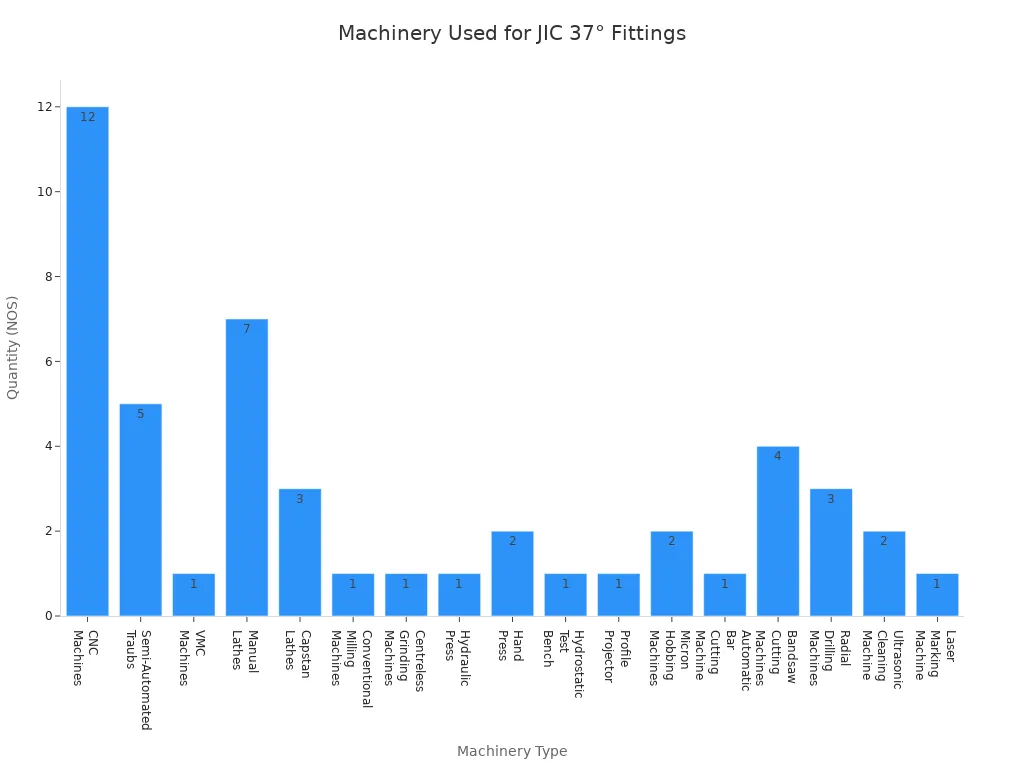

You rely on advanced manufacturing techniques to ensure the quality and performance of 37° flare fittings. Sunhy uses solution annealing at 1040°C to restore grain structure and maximize corrosion resistance. Cold Mandrel Forming and Hydroforming create elbows and tees with uniform wall thickness and high strength.

- CNC machines and semi-automated equipment shape fittings with precision.

- Hydrostatic and pneumatic tests verify leak-proof performance.

- Ultrasonic cleaning and laser marking ensure cleanliness and traceability.

You can trust fittings made with these methods to withstand high pressure, vibration, and corrosion.

Quality Standards

You should always look for fittings manufactured to international standards for safety and reliability. The most important standards for JIC 37° flare fittings are SAE J514 and ISO 8434-2. Sunhy’s stainless steel fittings meet these requirements through strict quality control, including hydrostatic and pneumatic testing.

- SAE J514 and ISO 8434-2 ensure global compatibility and interchangeability.

- Rigorous inspections and testing guarantee each fitting meets high safety standards.

Choosing fittings that meet these standards helps you maintain system integrity and avoid costly failures.

Performance and Reliability

Pressure Ratings

JIC 37° flare fittings deliver high pressure performance across a range of sizes and materials. You can rely on these fittings for demanding hydraulic systems because they maintain integrity under pressure. The table below shows typical pressure ratings for different fitting sizes:

| Fitting Size | Pressure Rating (psi) |

|---|---|

| 1/4 inch | 6000 |

| 1 inch | 3000 |

| Specialized | Up to 10,000 or more |

You see that smaller fittings handle higher pressures. Specialized designs can reach even greater ratings. JIC fittings are engineered for high-pressure applications. They outperform many alternatives, such as compression fittings, in leak resistance and durability. You benefit from their precision engineering, which reduces the risk of system failure due to leakage. Many industries, including aerospace and military, choose these fittings for their reliability in critical systems.

- JIC 37° flare fittings are designed for high-pressure use.

- They offer superior leak resistance compared to other types.

- The 37-degree flare angle creates a strong connection.

- You find them in industrial, aerospace, and military applications.

Tip: Always check the pressure rating for your specific fitting size before installation.

Sealing and Leak Prevention

You achieve reliable sealing with JIC 37° flare fittings because of their metal-to-metal contact and robust design. The 37-degree flare creates a tight seal that resists leaks, even under vibration and pressure changes. However, you must pay attention to several factors to maintain leak-free performance.

- Wear and tear on sealing surfaces can cause leaks. Regular inspection and maintenance help you catch problems early.

- Temperature and pressure variations affect seals. Select fittings rated for your system’s conditions to minimize risks.

- Chemical compatibility matters. Choose materials that resist the chemicals in your hydraulic fluid to prevent leaks.

You can trust these fittings to minimize leaks when you follow proper installation and maintenance practices. Their design helps you avoid common issues found in other fitting types.

Note: Inspect sealing surfaces for scratches or wear before assembly. This simple step prevents most leaks.

Durability and Corrosion Resistance

JIC 37° flare fittings provide long-lasting durability and excellent corrosion resistance, saving you time and money. You benefit from their robust construction, which means less frequent replacement and lower maintenance costs. These fittings meet strict safety standards and system requirements, making them a preferred choice in many industries.

- Durability ensures you do not need to re-flare or replace fittings often.

- You experience significant savings and reliable service over time.

- Consistent performance meets customer expectations and ensures safety.

Many users favor these fittings for their exceptional results in harsh environments. You can count on them to deliver excellent service, even in challenging conditions.

Reminder: Choose stainless steel or duplex grades for maximum corrosion resistance in chemical or marine environments.

Applications of JIC 37° Flare Fittings

Industrial Sectors

You use JIC 37° flare fittings in many key industries because they offer reliable, leak-resistant connections. These fittings help you maintain safety and performance in demanding environments.

- Oil & Gas: You find these fittings in drilling rigs, pipelines, and refineries. They handle harsh chemicals and high pressures.

- Chemical Processing: You rely on them for transferring corrosive fluids. Stainless steel options, like those from Sunhy, resist chemical attack.

- Marine: You use JIC fittings on ships and offshore platforms. They stand up to saltwater and vibration.

- Water Treatment: You install these fittings in filtration systems and pumping stations. They prevent leaks and ensure clean water delivery.

- Construction and Agriculture: You see them in heavy machinery and hydraulic equipment.

Note: Sunhy’s stainless steel fittings provide extra corrosion resistance, making them a top choice in these sectors.

System Examples

You benefit from JIC 37° flare fittings in a wide range of high-pressure systems. These fittings help you build safe and efficient fluid power networks.

| System Type | Application Example | Why Use JIC 37° Flare Fittings? |

|---|---|---|

| Hydraulic Power Units | Excavators, cranes, loaders | Withstand high pressure and vibration |

| Chemical Transfer Skids | Acid and solvent handling | Resist corrosion and leaks |

| Marine Fuel Lines | Ship engines, fuel transfer systems | Prevent leaks in harsh environments |

| Water Treatment Plants | Filtration and dosing systems | Ensure clean, reliable connections |

| Oil & Gas Wellheads | Pressure control and safety systems | Handle extreme pressure and chemicals |

You choose these fittings when you need strong, dependable connections. Sunhy’s products give you confidence in critical applications.

Tip: Always match the fitting material to your system’s fluid and environment for best results.

Selection Criteria for 37° Flare Fittings

Sizing and Compatibility

You must select the correct size and ensure compatibility to achieve a leak-free and reliable connection.

JIC fittings come in a wide range of sizes, from 1/8 inch to 2 inches in diameter. These sizes give you flexibility for many hydraulic applications. The SAE J514 standard defines the thread specifications, so you can use fittings from different manufacturers without worry.

To choose the right size, follow these steps:

- Confirm the fitting’s 37-degree flare seat with a flare gauge.

- Measure the outer diameter (O.D.) of the male threads using a caliper.

- Use a thread pitch gauge to find the number of threads per inch (TPI).

- Check a JIC sizing chart with your O.D. and pitch to find the correct dash size.

Tip: Always double-check the flare angle and thread size before installation to avoid leaks.

Environmental Factors

You need to consider pressure, temperature, and chemical compatibility when selecting flare fittings.

These factors have a big impact on performance and safety. The material of your fitting must match the fluid in your system. For example, corrosive chemicals or high temperatures require stainless steel or special alloys to prevent damage.

- High pressure can stress fittings, so always check the pressure rating.

- Extreme temperatures may cause expansion or contraction, affecting the seal.

- Chemical exposure can lead to corrosion or failure if you use the wrong material.

Note: Sunhy’s stainless steel fittings offer excellent resistance in harsh environments.

Standards and Interchangeability

You ensure system compatibility and safety by choosing fittings that meet recognized standards.

JIC fittings follow SAE J514 and ISO 8434-2 standards. These standards guarantee that fittings from different brands will work together. AN fittings, made to MIL-F-5509, also use a 37-degree flare, so they are mechanically compatible with JIC fittings. However, AN fittings have tighter tolerances and use higher-grade materials for aerospace and military uses.

| Standard | Application Area | Key Feature |

|---|---|---|

| SAE J514 | Industrial, hydraulic | Interchangeable, cost-effective |

| ISO 8434-2 | Global compatibility | Standardized dimensions |

| MIL-F-5509 | Aerospace, military | Stricter tolerances, high-grade |

Always check the standard before mixing fittings to maintain safety and performance.

Installation and Maintenance

Installation Steps

You achieve a leak-free and reliable connection by following these installation steps for JIC 37° flare fittings:

- Visual Inspection: Check the flare for cracks, irregularities, or deformation.

- Surface Cleanliness: Clean all fitting surfaces to remove debris.

- Deburring Tool Selection: Pick a tool designed for both inside and outside of the tube.

- Inside Deburring: Insert the tool into the tube end and rotate to remove sharp edges.

- Outside Deburring: Smooth the outer edge of the tube with the tool.

- Select the Flaring Tool: Choose a tool that matches your tube size and material.

- Insert the Tube: Place the tube into the flaring tool’s clamp.

- Tighten the Clamp: Secure the tube by tightening the clamp.

- Create the Flare: Rotate the handle to press the tube end into the flaring cone.

- Inspect the Flare: Remove and check the flare for uniformity.

- Hand-Tightening the Fitting: Thread the nut onto the fitting body by hand.

- Flats Method for Torque: Mark a flat side of the hex nut and tighten by the specified number of flats.

Tip: Always inspect the flare before final assembly to prevent leaks.

Inspection and Maintenance

You extend the life of your fittings by using regular inspection and maintenance routines:

- Regularly check for wear, corrosion, or leaks, especially on O-rings and threads.

- Clean fittings with a lint-free cloth to remove dirt and debris.

- Apply manufacturer-approved lubricant to threads to reduce friction.

- Replace damaged or worn fittings or O-rings immediately.

- Monitor system pressure for unusual changes that may signal fitting issues.

| Task | Purpose |

|---|---|

| Inspection | Detect wear, corrosion, or leaks |

| Cleaning | Prevent contamination |

| Lubrication | Reduce friction and galling |

| Replacement | Avoid leaks and failures |

| Pressure Monitoring | Spot fitting problems early |

Safety Tips

You protect yourself and your system by following these safety guidelines:

- Handle high-pressure systems with caution.

- Wear gloves and safety glasses to guard against hazards.

- Inspect fittings for wear, damage, or leaks before use.

- Clean and lubricate fittings with suitable products.

- Store fittings in a dry, clean place to prevent contamination.

- Replace any fitting that shows signs of wear or damage.

Remember: Safety gear and regular checks help you avoid accidents and keep your system running smoothly.

Troubleshooting Common Issues

Leak Detection

You can detect leaks in JIC 37° flare fittings using several effective methods.

Quick identification helps you prevent system failures and maintain safety. Here are the most common ways to spot leaks:

| Method | Description |

|---|---|

| Visual Inspection | Look for fluid around the fitting and check for physical damage or corrosion. |

| Pressure Testing | Attach a pressure gauge, pressurize the system, and watch for any drop in pressure. |

| Leak Detection Spray | Spray the area and look for bubbles, which show the exact location of a leak. |

Tip: Always inspect fittings after installation and during routine maintenance.

Failure Causes and Solutions

You can solve most fitting failures by understanding their main causes and applying the right solutions.

The table below shows common problems and how you can fix them:

| Primary Cause | Recommended Solution |

|---|---|

| Loosening from vibration | Tighten fittings to the correct torque. Use a backup wrench for stability. |

| Temperature changes | Use lock washers or thread locking compounds to keep fittings secure. |

| Improper installation | Perform regular maintenance and check for correct assembly. |

| Material compatibility issues | Choose materials that match your system’s environment and control temperature. |

Note: Always follow manufacturer guidelines for installation and maintenance.

Preventive Measures

You can prevent most issues with JIC 37° flare fittings by following best practices.

Use these steps to keep your system running smoothly:

- Avoid over-tightening. Tighten the nut just enough to seal, not more.

- Use a backup wrench. Hold the fitting body steady while tightening.

- Skip sealants. Do not use Teflon tape or pipe dope on JIC threads.

- Measure carefully. Use a thread gauge and double-check your results.

- Verify the flare angle. Confirm it is 37 degrees before assembly.

- Tighten with a torque wrench. Follow manufacturer specifications.

- Lubricate lightly. Apply a small amount of clean system fluid to threads and flare surfaces.

- Inspect before assembly. Check for damage or contamination on all surfaces.

Remember: Careful installation and regular checks help you avoid leaks and extend the life of your fittings.

You gain reliable, leak-free performance by choosing jic 37° flare fittings for your systems. Quality fittings reduce downtime and improve safety. Regular inspection and correct installation help you avoid problems. The table below highlights why these fittings matter:

| Benefit | Impact on Your System |

|---|---|

| Leak-proof seal | Prevents fluid loss |

| High pressure rating | Handles demanding applications |

| Easy maintenance | Saves time and effort |

You can look forward to new materials and smart features that make fittings like Sunhy’s even more efficient and durable.

FAQ

What is the main advantage of JIC 37° flare fittings?

You get a strong, leak-resistant connection that works in high-pressure systems.

- Easy installation

- Reliable sealing

- Wide compatibility

Can you reuse JIC 37° flare fittings?

You can reuse them if the sealing surfaces show no damage or wear.

Always inspect the flare and threads before reassembly.

How do you identify a JIC 37° flare fitting?

You measure the seat angle. JIC fittings have a 37-degree flare.

| Fitting Type | Flare Angle |

|---|---|

| JIC | 37° |

| SAE | 45° |

Where should you use stainless steel JIC fittings?

You should use them in corrosive or harsh environments.

- Chemical plants

- Marine systems

- Oil & gas facilities