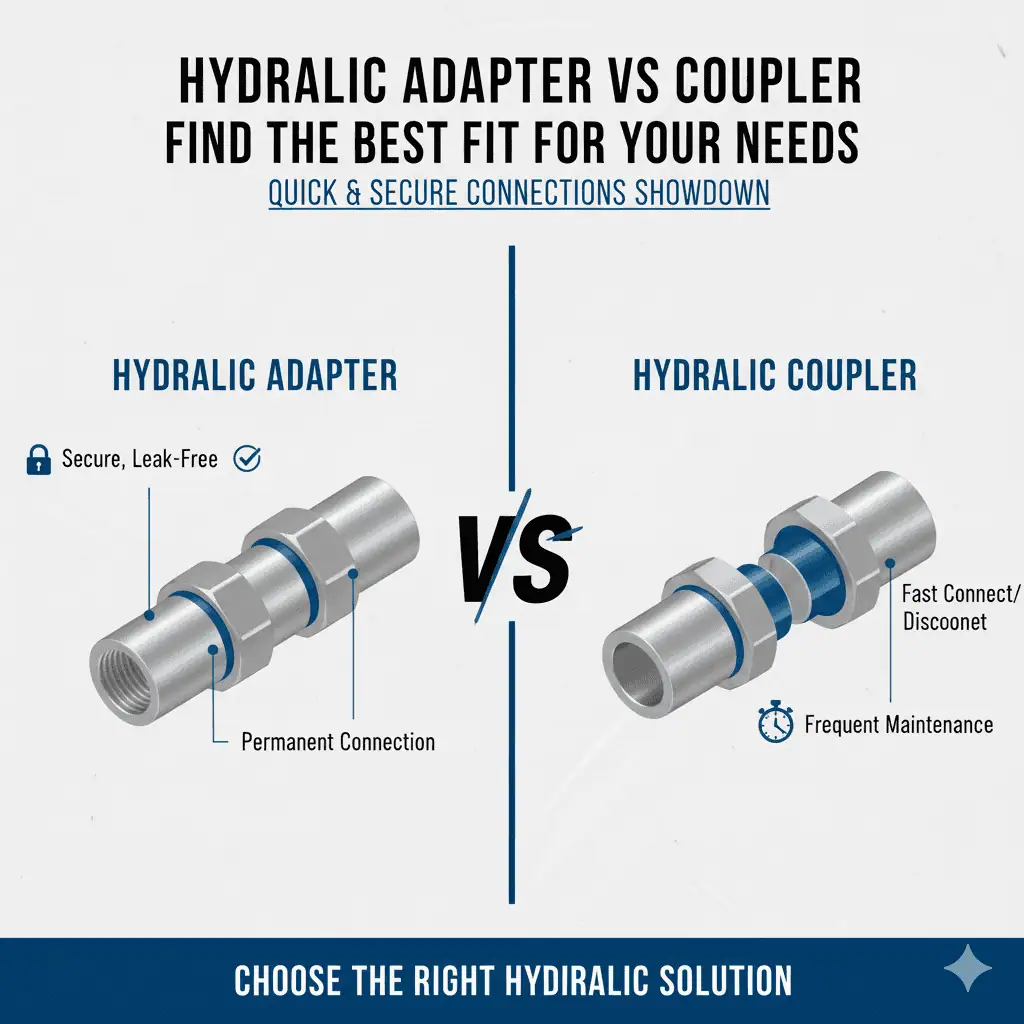

You should choose a hydraulic adapter when you need secure, leak-free connections; opt for a coupler when fast changes or frequent maintenance are required. Imagine working in a busy industrial setting where every minute of downtime impacts productivity. The right decision between hydraulic adapter vs coupler can change your system’s efficiency and reliability.

- Hydraulic adapters maintain system integrity by preventing leaks.

- Couplers allow quick connections and disconnections, improving maintenance speed.

Quality and compatibility matter most. Sunhy offers trusted hydraulic solutions to match your specific needs.

Hydraulic Adapter vs Coupler Overview

What Is a Hydraulic Adapter

A hydraulic adapter connects different types or sizes of hydraulic fittings, hoses, or pipes, ensuring system compatibility and leak-free operation.

You use hydraulic adapters when you need to join components with incompatible threads or sizes. These specialized connectors help you maintain efficient fluid flow and system integrity. You can find hydraulic adapters in many forms, such as straight, elbow, tee, and cross adapters. Each type serves a unique purpose in your hydraulic system.

- Connect hydraulic equipment of different specifications and types.

- Improve system efficiency by optimizing fluid transmission paths.

- Enhance safety by ensuring firm and sealed connections.

- Simplify maintenance and upgrades of hydraulic systems.

- Adapt to diverse application needs with various designs.

- Improve system stability by reducing the impact of vibration and shock.

Hydraulic adapters come in a range of materials. Stainless steel offers corrosion resistance and high strength. Brass provides excellent machinability and works well in lower-pressure systems. Aluminum is lightweight and ideal for mobile machinery. Carbon steel delivers robust performance for heavy-duty applications. Special alloys handle extreme temperatures and chemical exposure.

| Type of Adapter | Description |

|---|---|

| Female Threaded | Standard in many industries, compatible with various systems. |

| Male Threaded | Popular in construction, mining, and manufacturing. |

| Welded | Used for permanent, leak-proof connections in high-pressure environments. |

| Soldered | Suitable for low-pressure systems with specific bonding needs. |

| Straight Adapter | Connects two hoses in a straight line. |

| Elbow Adapter | Creates a 90-degree or 45-degree angle between hoses. |

| Tee Adapter | Allows for a three-way connection. |

| Cross Adapter | Enables a four-way connection. |

| Bulkhead Adapter | Passes through a panel or wall to connect hoses on both sides. |

| SAE Standards | J514 covers hydraulic tube fittings and adapters. |

| ISO Standards | ISO 8434-1 and ISO 8434-2 ensure precision and consistency. |

What Is a Hydraulic Coupler

A hydraulic coupler allows you to quickly connect or disconnect hydraulic lines without tools, making it ideal for systems that require frequent changes or maintenance.

You rely on hydraulic couplers when you need to swap attachments or perform maintenance fast. These components consist of a male and female half that join together to create a secure, leak-resistant connection. Hydraulic couplers prevent fluid loss and maintain pressure during connection and disconnection. This feature is essential in time-sensitive environments.

Hydraulic couplers, including iso 16028 couplers, serve a wide range of industries. You see them in construction, agriculture, automotive, manufacturing, and even healthcare. For example, you might use couplers on excavators, tractors, or hospital beds. Their design supports quick changes and reduces downtime.

| Industry | Applications |

|---|---|

| Construction | Excavators, bulldozers, cranes, concrete pumps |

| Agriculture | Tractors, harvesters, irrigation systems |

| Automotive | Production presses, braking systems, hydraulic steering |

| Manufacturing | Presses, injection molding machines, automation systems |

| Healthcare | Hospital beds, surgical tables, patient lifts |

| Energy | Wind turbines, power station valves, offshore drilling |

| Aerospace | Landing gear, flaps, cargo doors |

| Defence & Military | Tanks, submarines, aircraft weapon systems |

| Entertainment | Rollercoasters, water rides, stunt equipment |

| Waste Management | Collection vehicles, recycling balers, compactors |

Key Differences

Hydraulic adapter vs coupler: Adapters connect incompatible fittings for permanent or semi-permanent use, while couplers enable fast, tool-free connections and disconnections.

You need to understand the main differences to choose the right component for your system. The table below highlights the most important distinctions:

| Feature | Hydraulic Adapters | Hydraulic Couplers |

|---|---|---|

| Design | Simple, cylindrical components designed to connect incompatible thread types. | More complex, designed for quick connections and disconnections. |

| Functionality | Connects components with different thread types or sizes, ensuring seamless operation. | Allows for easy connection/disconnection without tools, ideal for frequent changes. |

| Example Usage | Connecting a hose with BSP thread to a pump with NPT thread. | Quick-disconnect couplers in construction equipment for switching attachments. |

Tip: When you need permanent, leak-proof connections and maximum compatibility, choose hydraulic adapters. When you need speed and flexibility, couplers or adapter couplings are your best option.

Hydraulic adapter vs coupler selection depends on your system’s requirements for pressure, leak prevention, and compatibility. Hydraulic adapters handle high-pressure systems and ensure tight, leak-free connections. Couplers excel in applications where you need to change attachments or perform maintenance quickly. Both play a vital role in hydraulic fittings and system performance.

Hydraulic Coupler Adapters Explained

Purpose and Function

Hydraulic coupler adapters provide secure, leak-free connections between hydraulic components. You rely on these adapters to maintain system reliability and prevent fluid escape, which is essential for efficient operation. Hydraulic coupler adapters bridge the gap between different coupler types or sizes, allowing you to connect equipment that would otherwise be incompatible.

- Ensure a tight seal between hydraulic lines.

- Prevent leaks that can reduce system pressure and efficiency.

- Allow you to connect components with different thread types or diameters.

- Support quick changes without compromising safety.

Hydraulic coupler adapters play a vital role in fluid power systems. You use them to maintain consistent performance, especially when your equipment operates under high pressure or in demanding environments. The design focuses on durability and ease of use, so you can install or replace them quickly.

| Feature | Benefit |

|---|---|

| Leak Prevention | Maintains system pressure |

| Compatibility | Connects different coupler types |

| Quick Installation | Reduces downtime |

| Durability | Withstands harsh conditions |

Note: You should always select hydraulic coupler adapters that match your system’s pressure rating and material requirements to ensure long-term reliability.

When to Use Coupler Adapters

You should use hydraulic coupler adapters when you need to connect hydraulic lines with different coupler styles or sizes. These adapters are ideal for situations where you frequently change attachments or need to adapt equipment for various tasks.

- You work in construction and need to switch tools on an excavator.

- You operate agricultural machinery with attachments that use different coupler types.

- You maintain hydraulic systems in manufacturing and require fast, reliable connections.

- You handle repairs and upgrades, adapting older equipment to modern hydraulic standards.

Hydraulic coupler adapters help you save time and reduce maintenance costs. You avoid fluid loss and keep your system running smoothly, even when working with diverse equipment.

Tip: Always check compatibility before installation. Using the right hydraulic coupler adapters improves safety and extends the life of your hydraulic system.

Comparing Couplers and Adapters

Design and Construction

Couplers feature specialized mechanisms for fast, secure connections, while adapters focus on compatibility and durability.

You notice that couplers use ball-lock systems, push-to-connect designs, and flat-face surfaces to ensure reliable operation and minimize fluid loss. Adapters rely on robust materials and precise engineering to connect hydraulic fittings with different threads or sizes. The table below highlights the main design differences that affect durability and compatibility:

| Coupler Type | Connection Method | Durability Features | Compatibility Aspects |

|---|---|---|---|

| Push-to-Connect | Ball-lock mechanism | Reliable and efficient connection | Standard compatibility with hydraulic systems |

| Push-Pull | Enhanced ball-lock | Convenient hands-free operation | Ideal for quick coupling changes |

| Flat-Face | Ball-lock, minimal fluid loss | Reduces contamination, ideal for cleanliness | Suitable for hydraulic systems requiring reliability |

| Screw-to-Connect | Manual threading | Superior holding strength under extreme conditions | Used in heavy-duty applications requiring stability |

Hydraulic fittings use O-rings, gaskets, and thread sealants to prevent leaks and contamination. These sealing mechanisms maintain fluid transfer integrity and system efficiency.

How They Work

Adapters connect components for permanent or semi-permanent use, while couplers enable quick-release coupling for fast changes.

You use adapters to join hydraulic fittings of different sizes or types, ensuring compatibility and secure flow. Couplers allow you to connect and disconnect lines rapidly, which is essential for maintenance or switching attachments. The table below explains the working principle:

| Component Type | Function |

|---|---|

| Fittings | Connect hoses and tubes to major components, ensuring secure flow of hydraulic fluid. |

| Adapters | Connect components of different sizes/types, allowing for compatibility between them. |

Flat face hydraulic couplers provide clean, efficient, and secure connections by preventing leaks during connection and disconnection. This design protects your system from contamination.

Typical Applications

You choose couplers for quick couplings and frequent changes; you select adapters for permanent connections and system compatibility.

Couplers excel in mobile equipment, construction, and agriculture where you need fast attachment changes. Adapters work best in industrial settings, oil and gas, and material handling where system integrity is critical. Hydraulic couplers, adapter couplings, and quick-release coupling solutions support efficient maintenance and upgrades.

- Hydraulic couplers: Used in excavators, tractors, and manufacturing presses.

- Adapter couplings: Connect hydraulic fittings in oil rigs, heavy machinery, and industrial plants.

- Quick couplings: Enable fast tool changes in automotive and construction equipment.

- Hydraulic fittings: Ensure leak-proof connections in all hydraulic systems.

Tip: Always match the sealing mechanism and material to your application to maximize durability and prevent contamination.

Pros and Cons of Hydraulic Adapters

Advantages

Hydraulic adapters offer secure, leak-proof connections and unmatched flexibility in hydraulic systems. You can rely on these components to maintain high performance, even under demanding conditions. The following table highlights the main advantages you gain when using a hydraulic adapter:

| Advantage | Description |

|---|---|

| Leak-proof connections | O-ring end face seal fittings eliminate leakage in high-pressure systems. |

| High pressure ratings | Can handle pressures up to 6,000 psi. |

| Ease of assembly | Components can be easily assembled or disassembled on-site. |

| Flexibility in design | Allows for connection of mismatched fittings, enhancing system versatility. |

| Excellent vibration resistance | Designed to withstand vibrations, ensuring reliability in operation. |

You improve the overall efficiency of your hydraulic system by connecting mismatched hydraulic fittings. You also reduce downtime and operational costs because you avoid modifying existing components. By using adapter couplings, you extend the lifespan of your equipment and create a cost-effective solution for your operation.

Tip: Choose hydraulic adapters when you need to connect different thread types or sizes without sacrificing system integrity.

Limitations

You must consider several factors before selecting an adapter for your hydraulic application. The right choice ensures safety and long-term performance. The table below outlines the key limitations you should keep in mind:

| Limitation Type | Description |

|---|---|

| Material Compatibility | Ensure the adapter’s material matches the hydraulic fluid and operating environment. |

| Pressure and Temperature Ratings | Verify that the adapter’s ratings meet or exceed your system requirements. |

| Thread Types and Standards | Identify and match the thread type in your system to prevent leaks or failures. |

| Size and Fit | Accurate measurement of dimensions is crucial for a secure connection and to avoid leaks. |

You need to check the compatibility of hydraulic fittings, pressure ratings, and thread standards before installation. This step helps you avoid leaks and system failures. Always measure carefully and select the right adapter for your specific needs.

Pros and Cons of Hydraulic Couplers

Benefits

Hydraulic couplers deliver fast, reliable connections and improve system efficiency. You gain several advantages when you choose couplers for your hydraulic fittings and equipment:

- You reduce downtime. Couplers eliminate lost time when hoses refuse to reconnect due to trapped pressure. This feature allows you to operate equipment faster.

- You improve operator safety. Hydraulic couplers prevent high-pressure oil spray and lower physical strain, which reduces the risk of injuries.

- You avoid risky workarounds. Couplers provide a controlled pressure equalization method, so you do not need to use unsafe practices.

- You extend component service life. Couplers reduce stress on hoses and hydraulic fittings, leading to fewer leaks and lower maintenance costs.

- You achieve faster attachment changeovers. Couplers streamline the process of switching attachments, which increases productivity in mobile and stationary equipment.

Tip: Hydraulic couplers are essential for applications that require frequent changes or maintenance. You can rely on them to keep your hydraulic system running smoothly.

Drawbacks

You must consider several limitations before selecting couplers for your hydraulic system. While couplers offer many benefits, you may encounter some challenges:

- Choosing the wrong seal for hydraulic fluid or temperature conditions can cause premature failure. You need to match seals to your system’s requirements.

- Leakage and contamination may occur if you select improper hydraulic couplers or install them incorrectly. Always check compatibility with your hydraulic fittings.

- Hoses and fittings connected by couplers are prone to wear and failure. Aging, abrasion, and exposure to extreme temperatures can shorten service life.

Note: You should inspect couplers and hydraulic fittings regularly. Proper selection and maintenance help you avoid common issues and maximize performance.

Choosing the Right Fit

Decision Checklist

You should use this checklist to decide between a hydraulic adapter and a coupler for your system.

| Criteria | Description |

|---|---|

| Operating Pressure | Confirm the component can handle your system’s maximum pressure. |

| Thread/Connector Compatibility | Check that threads and connectors match your equipment. |

| Flow Rate | Ensure the fitting supports your required fluid flow. |

| Material Compatibility | Select materials that resist corrosion and match your hydraulic fluid. |

Tip: Review each criterion before making your final selection. This approach helps you avoid leaks, downtime, and costly repairs.

Use-Case Examples

You should choose based on your industry’s needs and how often you change attachments or perform maintenance.

- Automotive:

You work in a busy auto shop. You need to connect hoses with different threads. A hydraulic adapter vs coupler decision comes down to permanence. Use an adapter for a permanent connection between mismatched fittings. Use couplers when you need to swap out tools or test systems quickly. - Construction:

You operate heavy machinery like excavators. You often switch between hydraulic attachments. Couplers let you change tools fast and keep your equipment running. Adapters help when you need to connect hoses with different thread types or sizes. - Oil & Gas:

You manage high-pressure pipelines. System integrity is critical. Hydraulic adapters provide secure, leak-proof connections for permanent installations. Couplers allow for quick maintenance or emergency repairs, minimizing downtime. - Material Handling:

You maintain forklifts and conveyor systems. You need both flexibility and reliability. Use adapters to connect different hydraulic components. Use couplers for fast equipment changeovers or routine maintenance.

Sunhy offers a wide range of adapters and couplers for every industry. You can request custom sizes, thread types, or surface treatments to match your exact requirements.

Factors to Consider

You must evaluate several factors before choosing between a hydraulic adapter and a coupler.

| Factor | Description |

|---|---|

| Compatibility | Make sure the fitting matches the size and type of your hoses and equipment. |

| Pressure Rating | Select components that can handle your system’s highest pressure. |

| Temperature Range | Choose materials that withstand your operating temperatures. |

| Fluid Type | Ensure compatibility with your hydraulic fluid (oil, water, or synthetic). |

| Material | Pick materials like steel, stainless steel, or brass for durability. |

- Every fitting has a pressure rating. Always check manufacturer specifications to ensure safety.

- The temperature of your hydraulic fluid affects performance. Select fittings that can handle temperature extremes.

- The viscosity and type of hydraulic fluid influence your choice. Make sure your fittings allow for smooth fluid movement.

Sunhy’s product range covers all major standards and materials. You can customize adapters and couplers for unique applications, ensuring a perfect fit for your hydraulic system.

In summary:

- Choose a hydraulic adapter when you need a permanent, leak-proof connection between different thread types or sizes.

- Choose a coupler when you need to connect and disconnect lines quickly for frequent changes or maintenance.

- Sunhy provides both standard and custom solutions, helping you optimize your system for safety, efficiency, and reliability.

Hydraulic Adapter and Coupler Applications

Industrial Use

Hydraulic adapters and couplers ensure reliable connections and leak-free performance in industrial environments.

You often face demanding conditions in factories, chemical plants, and material handling facilities. Sunhy’s adapters deliver durability and precision, helping you maintain system integrity. You can choose from stainless steel, brass, or aluminum to match your needs. Stainless steel resists corrosion and chemicals, making it ideal for chemical processing and marine equipment. Brass works well for smaller fittings in lower-pressure systems. Aluminum offers a lightweight solution for low-pressure applications.

| Material | Characteristics | Typical Applications |

|---|---|---|

| Stainless Steel | High strength, corrosion resistance | Chemical, marine, industrial |

| Brass | Good corrosion resistance, moderate strength | Compression fittings |

| Aluminum | Lightweight, corrosion resistant | Low-pressure, mobile systems |

Tip: Select the right material and sealing option to maximize performance and lifespan in harsh environments.

Mobile Equipment

Adapters and couplers play a vital role in mobile equipment by enabling quick changes and maintaining leak-free connections.

You rely on hydraulic systems in excavators, bulldozers, and cranes to connect cylinders, pumps, and motors. These machines experience extreme vibrations and heavy loads. Sunhy’s adapters withstand these stresses, ensuring safe and efficient operation. Agricultural machinery, such as tractors and harvesters, uses adapters to connect implements and hydraulic lines. Quick-connect adapters help you change attachments fast, saving time in the field.

- Construction equipment uses adapters for secure connections under vibration and load.

- Agricultural machinery benefits from quick-connect adapters for frequent attachment changes.

- Reliable adapters prevent leaks and reduce downtime during maintenance.

Note: You must inspect connections regularly to avoid leaks and failures caused by dirt, vibration, or residual pressure.

Construction and Agriculture

You face unique challenges in construction and agriculture, including exposure to dirt, chemicals, and moisture.

Adapters and couplers must be compatible with various equipment and withstand harsh conditions. Maintaining leak-free connections is essential for safety and efficiency.

| Challenge | Description |

|---|---|

| Exposure to harsh conditions | Dirt, chemicals, and moisture degrade components over time. |

| Compatibility with equipment | Adapters and couplers must fit different machines and implements. |

| Risk of leaks and failures | Environmental factors increase the need for regular inspection and maintenance. |

- Frequent implement changes can make connecting couplers difficult due to residual pressure.

- Forcing connections under pressure risks equipment damage and operator injury.

- Leak-free connections protect your system from contamination and vibration.

Sunhy’s precision engineering and sealing options, such as O-rings and flat seals, help you maintain system reliability in the toughest environments.

Choose hydraulic adapters for permanent, leak-free connections between different thread types or sizes. Select couplers when you need fast, frequent changes.

You should always match pressure rating, temperature compatibility, fluid resistance, and thread type to your system.

- For adapters: check pressure, temperature, fluid, and thread compatibility.

- For couplers: consider pressure, flow rate, seal material, port size, environment, and frequency of use.

Consulting Sunhy’s experts helps you customize solutions for complex systems, ensuring seamless integration and peak performance.

FAQ

What is the main difference between a hydraulic adapter and a coupler?

A hydraulic adapter connects different thread types or sizes for permanent use. A coupler lets you quickly connect or disconnect hydraulic lines.

| Adapter | Coupler |

|---|---|

| Permanent connection | Quick connection/disconnection |

When should you use a hydraulic adapter?

Use a hydraulic adapter when you need a secure, leak-proof connection between mismatched fittings.

You should choose adapters for permanent installations or when joining different thread types.

Can you use hydraulic adapters and couplers together?

Yes, you can use both in the same system.

You often connect an adapter to match thread types, then attach a coupler for quick changes.

How do you select the right material for hydraulic adapters or couplers?

Choose materials based on pressure, fluid type, and environment.

- Stainless steel: Corrosion resistance

- Brass: Lower pressure

- Carbon steel: Heavy-duty use

What maintenance do hydraulic adapters and couplers require?

Inspect for leaks, wear, and proper fit regularly.

Clean connections, replace damaged seals, and check for corrosion to keep your system reliable.