To choose blind flanges, evaluate the service purpose (isolation, future tie-in, pressure test), size/standard, material compatibility, pressure-temperature class, gasket-facing match, and bolting/assembly discipline. A blind flange is not just a “cap”—it is a pressure boundary that must carry bolt load and resist plate bending. Sunhy’s stainless steel flanges focus on repeatable machining and inspection to keep faces, bolt patterns, and fit-up consistent in demanding environments.

Use the decision factors below as your baseline, then confirm against the applicable dimensional standard (for example, ASME B16.5 / ASME B16.47 or EN 1092-1) and your plant’s bolted-joint assembly practice (many sites align to ASME PCC-1 concepts). For an engineering reference on flange types and typical usage, see: Wermac flange type overview. For assembly discipline guidance, see: ASME PCC-1 overview.

| Decision Factor | Description |

|---|---|

| Pipeline Size and Standard | Confirm the flange standard (ASME/EN/DIN/JIS/AWWA) and bolt pattern. Mixing standards is a common cause of site rework. |

| Flange Material | Driven by fluid corrosivity, temperature, and external environment (CUI, marine, chemicals). Consider sour service requirements where applicable. |

| Flange Dimensions | OD, thickness, bolt circle, bolt holes, facing type. Verify against the governing standard and the mating flange. |

| Pressure-Temperature Rating | Class/PN rating is not “psi by name.” Use the pressure-temperature tables for the specific material and temperature range. |

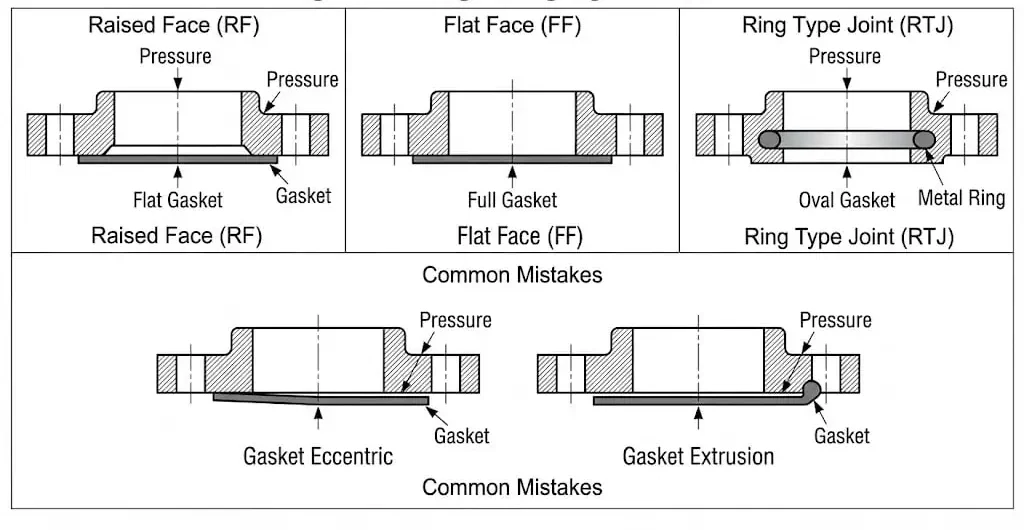

| Compatibility With Gaskets & Bolting | Gasket type + facing (RF/FF/RTJ) + bolt/stud grade + tightening method control sealing reliability. |

Application Needs For Blind Flanges

Purpose And Function

You should select blind flanges based on their ability to isolate, protect, and maintain pipeline systems. In real plants, blind flanges are used in three high-frequency situations: (1) temporary isolation for maintenance, (2) permanent closure points reserved for future tie-ins, and (3) hydrostatic or pneumatic testing boundaries. Each case changes what matters most (reusability, corrosion allowance, test pressure, and assembly controls).

Blind flanges serve several essential functions in industrial piping:

- Isolation and shutdown: Used to isolate sections during maintenance, preventing uncontrolled release. This is a pressure boundary—confirm LOTO, depressurization, and vent/drain steps before loosening any studs.

- Pressure testing boundary: Used to seal off spools for hydrotest/pneumatic test. Your test plan must confirm class rating, gasket type, and bolt-up method.

- Contamination prevention: Prevents ingress of debris, moisture, and oxygen—important for stainless systems where crevice corrosion can start in stagnant areas.

- Equipment protection: Shields open pipe ends and valves from impact, dust, and weather during storage/transport.

Field example (maintenance isolation): A unit shutdown replaced a valve downstream of a blind flange. The flange was reused, but the gasket seating face had deep radial scratches from a previous scrape tool. The joint wept during start-up until the face was refinished and a compatible gasket was installed. Lesson: reuse decisions must include face condition inspection—not just “no cracks.”

You should identify your specific use case—seal a pipeline, isolate equipment, create a test boundary, or protect an opening—before choosing the blind flange standard, facing, thickness, gasket, and bolting plan.

Pressure And Temperature Requirements

You must match the pressure-temperature rating of blind flanges to your operating conditions. The “Class 150 / 300 / 600 …” designation is a rating system, not a direct psi value. Allowable pressure depends on material group and temperature (ratings generally drop as temperature rises). When temperature increases, bolt relaxation and gasket creep become more likely, so assembly discipline matters as much as nominal class.

The table below is a practical way to think about class selection. Treat it as selection logic—not a substitute for the official pressure-temperature tables.

| Flange Class / Rating System | What It Controls | Engineering Note |

|---|---|---|

| ASME Class (150/300/600/900/1500/2500) | Pressure-temperature envelope per material group | Use the official ASME B16 pressure-temperature tables for the exact material and temperature range. |

| EN/DIN PN (PN 6/10/16/25/40…) | Pressure rating system commonly used in Europe | PN is a nominal rating; confirm temperature derating and bolt pattern compatibility with mating parts. |

| JIS K (5K/10K/16K…) | Japanese rating system | Confirm dimensions/bolt circle; do not assume direct equivalence to ASME class without verifying. |

If you exceed the recommended pressure-temperature rating, you risk leakage, bolt overload, or plate bending. In higher temperature duty, also watch for:

- Thermal expansion mismatch between studs, flange, and piping.

- Bolt relaxation and gasket creep that reduce sealing stress after heat-up.

- Cyclic temperature swings that can warp faces or loosen bolting if the joint is not assembled consistently.

Tip: Select the pressure class based on your maximum operating pressure and temperature, then confirm the exact allowable rating using the applicable standard tables for your flange material. Do not “overspec by habit” without checking bolt load and gasket suitability.

Environmental And Industry Standards

You need to consider external environment and industry standards when selecting blind flanges. External corrosion (including corrosion under insulation, CUI) can attack carbon steel blind flanges quickly in wet insulation. For stainless, chloride exposure can drive pitting/crevice corrosion—especially when stagnant water remains at the gasket interface after washdowns.

Material selection by environment is usually more predictive than “industry name.” Use the table below as a starting point and then confirm against your project spec.

| Material | Corrosion Resistance | Suitable For |

|---|---|---|

| Carbon Steel (e.g., ASTM A105) | Low without coatings | Non-corrosive media, dry indoor environments, controlled corrosion programs |

| Stainless Steel (e.g., ASTM A182 F304/L, F316/L) | Good to very good | Corrosive media, washdown service, marine atmosphere (316/316L preferred when chlorides are present) |

| Alloy Steel (e.g., ASTM A182 F11/F22) | Service dependent | Higher temperature duties where strength retention is needed; corrosion resistance depends on the alloy and environment |

You should also ensure blind flanges comply with recognized standards for dimensions, tolerances, facing, and marking. Commonly referenced standards include:

- ASME B16.5 / ASME B16.47 for flange dimensions, facing, and rating system (Class).

- EN 1092-1 for European flange dimensions and PN ratings.

- ASTM material standards (e.g., A105, A182) to control chemistry, mechanical properties, and traceability.

Engineering pitfall (standard mismatch): ASME and EN flanges may be the “same size” by name, but bolt circle diameter and hole count can differ. If you are closing a line for a shutdown, a mismatch becomes schedule-critical. Always verify standard + size + rating + facing on both mating parts before ordering blind flanges.

Note: Sunhy’s stainless steel blind flanges can be supplied to common international standards (ASME/ASTM/DIN/EN1092-1) with documentation aligned to project requirements.

By considering purpose, pressure-temperature rating, and environment/standards, you reduce the most common blind flange failures: wrong bolt pattern, wrong gasket-facing match, and unsuitable material selection.

Size, Material, And Pressure Rating

Flange Dimensions And Fit

You must match flange dimensions precisely to your pipeline specifications to ensure a secure, leak-free connection. With blind flanges, fit is not only bolt holes. Plate thickness, facing type, gasket OD/ID, and stud length determine whether the joint can develop and retain sealing stress.

When you select blind flanges, focus on these measurements and checks:

- Nominal pipe size (NPS/DN) and the governing standard (ASME/EN/AWWA/JIS)

- Outer diameter and thickness (plate stiffness matters for larger sizes)

- Bolt circle diameter, number of bolt holes, bolt hole diameter

- Facing type (RF/FF/RTJ) and surface finish expectations

- Stud size/length and nut engagement (insufficient engagement is a quiet but real failure mode)

If you choose the wrong size or standard, you risk leaks and compromised integrity. Typical site problems include:

- Gasket coverage errors (wrong OD/ID) leading to blowout paths or inward extrusion

- Bolt pattern mismatch between ASME and EN flanges, causing rework or unsafe “field drilling” attempts

- Non-parallel faces after welding distortions on the mating flange, creating uneven compression

Always verify the mating flange standard, rating, and facing before ordering blind flanges. A “same size” label is not enough.

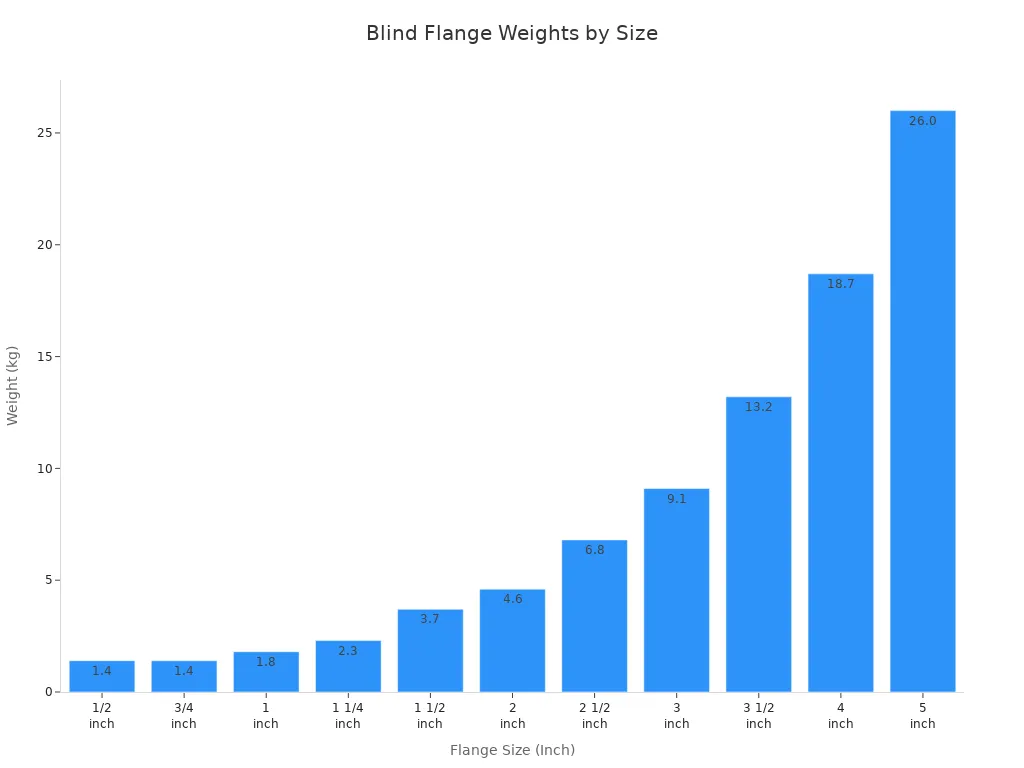

Here is a table of standard blind flange dimensions used in some water treatment facilities. Treat this as an example pattern only—waterworks standards (often AWWA-based) can differ from ASME/EN patterns. Always follow the project specification.

| Size in Inch | Size in mm | Outer Dia. | Flange Thick. | No of Bolts | Weight in kg |

|---|---|---|---|---|---|

| 1/2 | 15 | 95 | 14.3 | 4 | 1.4 |

| 3/4 | 20 | 115 | 15.9 | 4 | 1.4 |

| 1 | 25 | 125 | 17.5 | 4 | 1.8 |

| 1 1/4 | 32 | 135 | 20.7 | 4 | 2.3 |

| 1 1/2 | 40 | 155 | 22.3 | 4 | 3.7 |

| 2 | 50 | 165 | 25.4 | 8 | 4.6 |

| 2 1/2 | 65 | 190 | 28.6 | 8 | 6.8 |

| 3 | 80 | 210 | 31.8 | 8 | 9.1 |

| 3 1/2 | 90 | 230 | 35 | 8 | 13.2 |

| 4 | 100 | 275 | 38.1 | 8 | 18.7 |

| 5 | 125 | 330 | 44.5 | 8 | 26.0 |

Field example (standard mismatch): A DN100 blind flange was ordered to EN 1092-1 and arrived on site for a Class 150 ASME line. The bolt circle and hole count did not match, causing a schedule slip. Lesson: always specify standard + rating system + facing in the PO, not only size.

Material Selection For Blind Flanges

You should choose flange material based on the fluid type, environment, and required durability. For blind flanges, material selection has two corrosion vectors: internal media exposure (at the gasket interface and any trapped crevices) and external environment exposure (CUI, marine spray, chemical vapors).

The most common materials for blind flanges include:

| Material | Corrosion Resistance Properties | Engineering Use Note |

|---|---|---|

| Stainless Steel (304L/316L) | Excellent general corrosion resistance; 316/316L improves chloride pitting resistance due to Mo content. | Prefer 316/316L for marine/coastal exposure or chloride-bearing water; control crevice conditions at the gasket. |

| Duplex Stainless (e.g., 2205) | Higher strength and strong chloride resistance in many services. | Useful where strength and corrosion resistance are both needed; welding procedure control matters. |

| Alloy Steel (F11/F22) | Strength retention at temperature; corrosion resistance depends on environment. | Selected for higher-temperature duties; corrosion strategy still required. |

| Carbon Steel (A105) | Prone to rust without protection. | Economical for non-corrosive service with coatings/painting and controlled environment. |

| Nickel Alloys (e.g., Inconel) | High strength and strong corrosion resistance in severe environments. | Selected for aggressive chemistry or high temperature; cost justifies only for severe duty. |

| Non-metallic (PVC/PTFE lined) | High corrosion resistance but limited by pressure/temperature. | Use only where the piping class allows; confirm temperature and bolt load limits. |

Stainless steel stands out for corrosion resistance and lower maintenance in wet, washdown, coastal, or chemical environments. Where carbon steel must be used, external corrosion control (coatings, insulation design, drainage) often determines whether the joint lasts years or fails early.

| Material | Corrosion Resistance | Maintenance Requirements | Typical Selection Trigger |

|---|---|---|---|

| Stainless Steel | Superior | Lower | Chlorides, washdown, marine exposure, chemical vapors |

| Carbon Steel | Lower | Higher | Dry, non-corrosive duty with corrosion control program |

- Stainless steel blind flanges reduce the probability of external corrosion-driven replacement in wet environments.

- Material selection must consider gasket crevice conditions; even stainless can pit if chlorides + stagnation persist at the joint.

- If failure cost is high (unit downtime, safety risk), material conservatism is usually cheaper than repeated shutdown work.

Field example (CUI): A painted carbon steel blind flange under insulation corroded through while the line was out of service (water trapped in the insulation). The blind flange looked fine externally until removal. Lesson: external environment can be more aggressive than internal media; treat CUI as a primary design condition.

Pressure Rating And Standards

You must select blind flanges with a pressure-temperature rating that matches or exceeds your maximum operating conditions, and follow recognized standards. “Class” ratings are applied through pressure-temperature tables by material group. The same class number has different allowable pressures depending on material and temperature. For a general engineering reference on rating concepts and common flange limitations, see: Wermac flange ratings overview.

Here is an example-style snapshot many engineers use during early screening (your final selection must still follow the official tables for your specific material and temperature range):

| ASME B16.5 Flange Classes | Example Maximum Pressure (at 100°F / 38°C for common carbon steel groups) | Selection Reminder |

|---|---|---|

| Class 150 | Example values vary by material group | Confirm material group + temperature table; don’t equate “150” to psi. |

| Class 300 | Example values vary by material group | Verify bolt/stud grade and gasket suitability for the service. |

| Class 600 | Example values vary by material group | Higher class increases bolt load demand; assembly method becomes more critical. |

| Class 900 | Example values vary by material group | Check flange thickness and plate deflection risk at larger sizes. |

| Class 1500 | Example values vary by material group | Use a disciplined multi-pass tightening and verified bolting procedure. |

| Class 2500 | Example values vary by material group | Ensure joint design and assembly method are controlled and documented. |

You will encounter different standards worldwide. The most common include:

| Standard | Pressure Rating Type | Examples |

|---|---|---|

| ASME/ANSI | Class Ratings | Class 150, 300, 600… |

| DIN / EN | PN Ratings | PN 6, 10, 16, 25… |

| JIS | K Ratings | 5K, 10K, 16K… |

Always check your project specification and the mating flange details (standard + rating + facing). If the mating flange is already installed, field measurement and verification prevent expensive surprises.

By considering flange dimensions, flange material, and pressure-temperature rating, you ensure blind flanges deliver safe, reliable performance—especially when the blind flange is serving as a test boundary or long-term closure point.

Compatibility And Longevity

Gasket And Component Matching

You ensure reliable sealing and system integrity by matching blind flanges with compatible gaskets and bolting. Blind flanges are often used on dead-ends where trapped media can sit at the gasket line. That increases the importance of gasket material compatibility and facing selection (RF/FF/RTJ). A good general reference for gasket types and selection logic can be found from major gasket manufacturers, for example: Flexitallic technical resources and Garlock technical resources.

Key matching checks you should make before installation:

- Facing vs gasket type: Spiral wound gaskets are common on raised face (RF) flanges; ring-type joints require RTJ grooves and correct ring numbers.

- Temperature and chemical compatibility: PTFE is excellent for many chemicals but limited by temperature and creep; graphite handles temperature but must match media and oxidation conditions.

- Bolting grade and lubrication: Bolt load consistency changes with friction. A “same torque” can produce different clamp loads if lubrication differs.

- Stud length and nut engagement: Insufficient thread engagement reduces usable bolt load and increases loosening risk.

| Service Condition | Common Facing | Typical Gasket Strategy (verify against spec) | Engineering Watch-Out |

|---|---|---|---|

| General water service | FF/RF | CNAF or EPDM (per spec) | Don’t overtighten soft gaskets; avoid flange rotation damage. |

| Steam / higher temperature | RF | Graphite or spiral wound | Plan for bolt relaxation; use disciplined tightening. |

| Chemical duty | RF/FF | PTFE envelope or compatible composite | Confirm chemical compatibility and temperature limits. |

| High pressure / severe duty | RF/RTJ | Spiral wound or RTJ | Assembly method is critical; verify flange and groove details. |

Tip: When leaks repeat, investigate clamp load uniformity first (tightening sequence, multiple passes, friction control). Many “gasket problems” are actually bolt load problems.

Maintenance And Service Life

You extend the service life of blind flanges by using repeatable installation practice and routine inspections. Blind flanges are often installed “once and forgotten,” so corrosion, vibration loosening, and gasket aging can progress unnoticed—especially on dead-legs and standby lines.

Routine care and correct installation help prevent common causes of failure. Use these best practices:

- Inspect before reuse: Check for face damage, warping, corrosion, and bolt hole elongation. Replace any flange with questionable flatness.

- Clean and protect: Keep faces clean, protect with face covers during storage, and prevent chloride contamination on stainless faces.

- Use a controlled tightening method: Tighten in a cross/star pattern in multiple passes; align with your site practice (many sites reference PCC-1 concepts).

- Control external corrosion: Manage CUI risk through insulation design, coatings, and drainage.

- Document: Record gasket type, bolt grade, torque method, and any re-torque steps permitted by your procedure.

Common causes of premature failure include improper installation, material mismatch, skipping inspection, corrosion (including CUI), thermal cycling, vibration loosening, gasket misfit, and excessive piping loads. The table below summarizes these factors:

| Cause of Failure | Description | What You Check On Site |

|---|---|---|

| Improper Installation | Incorrect tightening or uneven clamp load causes leakage. | Cross-pattern, multi-pass, consistent lubrication, stud engagement. |

| Improper Material Selection | Incompatible materials corrode or lose strength at temperature. | Media + temperature + external environment review. |

| Inadequate Inspection | Minor face damage or corrosion grows into failure. | Face condition, flatness, corrosion, bolt hole condition. |

| Corrosion / CUI | External corrosion under insulation attacks flange body. | Coatings, insulation condition, moisture traps, drainage. |

| Thermal Cycling | Temperature swings reduce bolt load or warp faces. | Leak history after heat-up/cool-down, gasket selection. |

| Mechanical Vibration | Vibration loosens bolts and degrades sealing stress. | Support condition, proximity to rotating equipment. |

| Improper Gasket Installation | Wrong gasket size or misplacement creates leak paths. | Correct OD/ID, centered placement, no folds/tears. |

| Excessive Piping Loads | External bending distorts the joint. | Alignment, supports, nozzle loads, pipe strain. |

| Wear and Fatigue | Repeated cycles degrade joint components. | Trend leaks, bolt condition, flange face wear. |

Material choice, operating conditions, and external environment define service life. Stainless steel blind flanges improve durability in corrosive or marine environments, while disciplined assembly and inspection reduce the real-world leak rate over time.

To choose blind flanges, follow a clear process for safety and reliability.

- Identify the purpose and function (isolation, future tie-in, test boundary).

- Assess pressure and temperature needs using the correct rating tables.

- Select the right material for internal media and external environment.

- Confirm dimensions/standard/facing compatibility with the mating flange.

- Plan bolting, gasket selection, and maintenance/inspection practices.

Choose high-quality options like Sunhy’s stainless steel flanges, and align purchasing specs to your piping class (standard, rating, facing, material, documentation). For gasket and bolting practice details, reference reputable manufacturer resources and your site procedure.

FAQ

What is the main purpose of a blind flange?

You use a blind flange to seal the end of a pipeline, valve, or nozzle.

This prevents leaks and provides a safe boundary for maintenance, future tie-ins, or pressure testing—provided the correct rating, gasket, and bolting method are used.

How do you select the correct material for a blind flange?

You choose material based on fluid type, temperature, and external environment (CUI/marine/chemicals).

Use this table as a quick screen, then confirm against the project spec:

| Condition | Typical Direction | Engineering Note |

|---|---|---|

| Corrosive media / washdown | Stainless Steel (often 316/316L) | Watch for chloride crevice conditions at gasket interface. |

| Non-corrosive, dry environment | Carbon Steel | Coatings and corrosion control determine actual life. |

| Higher temperature strength need | Alloy Steel (F11/F22) | Corrosion resistance is not automatic—review environment. |

Can you reuse a blind flange after removal?

You can reuse a blind flange if it shows no damage, corrosion, or warping.

Inspect face flatness, gasket seating surface condition, bolt holes, and any pitting/crevice corrosion before reinstalling. If the face has deep radial scratches or measurable distortion, replacement is usually cheaper than repeat leak work.

Why does a blind flange leak after start-up even when it passed the initial pressure test?

Most repeat leaks come from bolt load loss, gasket creep, or uneven clamp load.

Heat-up can relax studs and compress the gasket. Corrective actions typically include verifying gasket type vs temperature, using a multi-pass cross-pattern tightening method, controlling lubrication/friction, and confirming faces are clean and parallel.

How do you avoid ordering the wrong blind flange standard?

Specify standard + rating + facing, not only size.

Example: “ASME B16.5, NPS 4, Class 300, RF, ASTM A182 F316L.” Standard mismatches (ASME vs EN) often fail at bolt circle and hole count even when the nominal size looks similar.

What gasket type is commonly used with blind flanges?

It depends on service severity and facing.

RF flanges often use spiral wound, graphite, or compatible composites; chemical services may use PTFE-based options within temperature limits; severe duty may require RTJ where specified. Always match gasket to media + temperature + facing type and follow your site installation procedure.