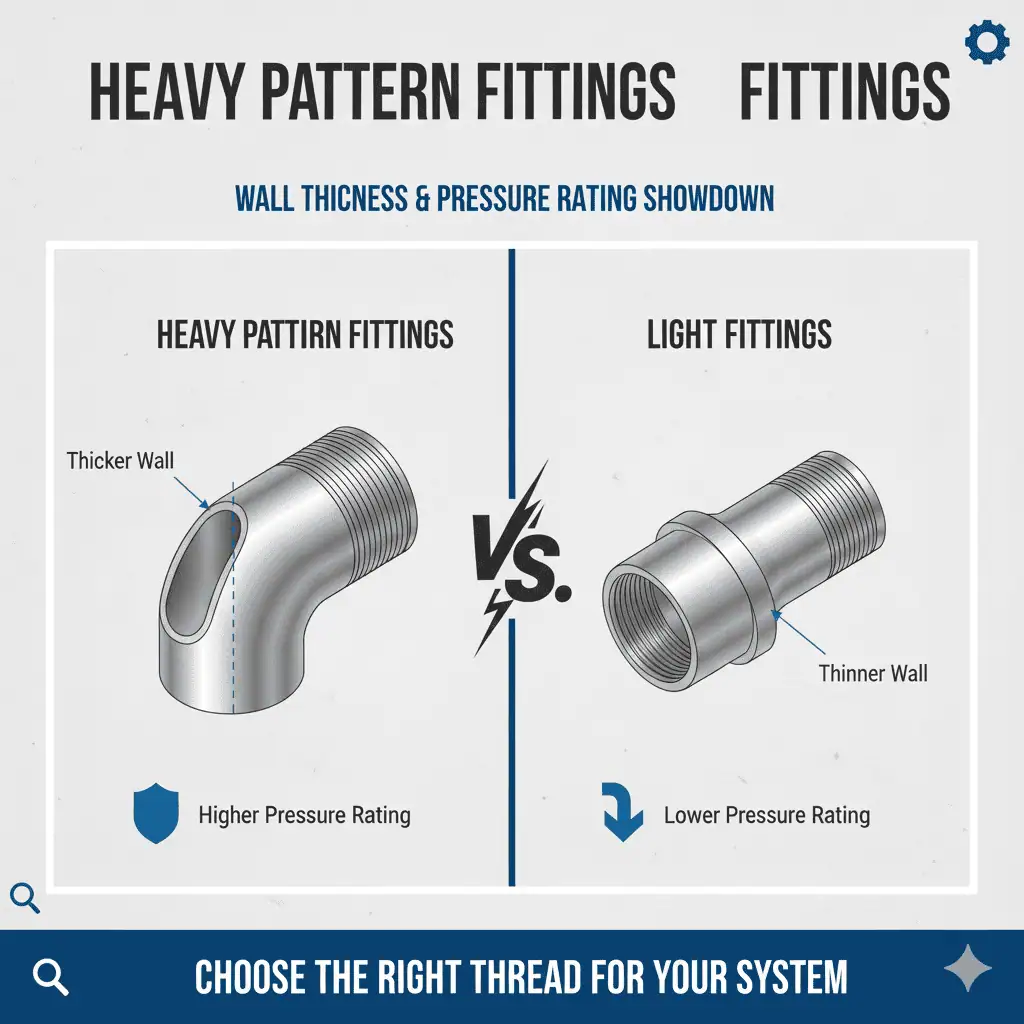

The main difference between heavy pattern fittings vs light pattern fittings is wall thickness and pressure rating. Heavy pattern fittings have thicker walls and handle higher pressures, while light pattern fittings work best in lighter duty systems. You often see both types in industrial applications where safety and reliability matter. Sunhy stands out as a trusted manufacturer of stainless steel fittings, known for quality and compliance with strict standards. Choosing the right fitting helps you improve safety, control costs, and boost system performance.

Heavy Pattern Fittings vs Light Pattern Fittings OverviewKey Differences at a Glance

The main difference between heavy pattern fittings vs light pattern fittings is the wall thickness and pressure rating. You will notice that heavy pattern fittings have thicker walls and support higher pressures. Light pattern fittings use less material and work best in systems with lower pressure demands.

You should choose heavy pattern fittings when you need reliability in industrial processes. These fittings meet strict compliance standards and handle tough environments. Light pattern fittings suit residential or non-critical plumbing where high pressure is not a concern.

Tip: Always check the pressure rating and compliance before selecting fittings for your project. This helps you avoid safety risks and ensures your system works as expected.

Here are the main differences you need to know:

- Heavy pattern fittings have a heavy-duty wall thickness and larger diameter.

- Light pattern fittings use thinner walls and less material.

- Heavy pattern fittings meet CRN registration and strict standards.

- Light pattern fittings do not have CRN registration.

- Heavy pattern fittings work best in industrial applications.

- Light pattern fittings fit residential and light-duty uses.

Comparison Table

You can use this table to compare heavy pattern fittings vs light pattern fittings quickly:

| Feature | Heavy Pattern MSS-SP-114 | Light Pattern |

|---|---|---|

| Wall Thickness | Heavy duty wall thickness, larger diameter | Thinner wall, less material |

| Pressure Rating | Class 150 (300 psi @ 150°F) | 150 PSI |

| Compliance | CRN Registered | Not CRN Registered |

| Applications | Industrial Processes | Residential, non-critical plumbing |

This table shows you how heavy pattern fittings offer more strength and compliance for demanding jobs. Light pattern fittings provide a cost-effective solution for lighter tasks. When you select stainless steel fittings, you should match the pattern to your system’s needs for safety and performance.

Heavy Pattern Fittings Explained

Features and Material Grades

Heavy pattern fittings deliver superior strength and reliability because of their robust design and premium material grades.

You get fittings made from 304 stainless steel fittings, 316 stainless steel fittings, and Duplex stainless steel fittings. Sunhy uses advanced manufacturing methods like solution annealing at 1040°C and rapid water quenching. This process restores the grain structure and boosts corrosion resistance properties. You benefit from uniform wall thickness and consistent performance due to Cold Mandrel Forming and Hydroforming.

Recent advancements in heavy pattern fittings include:

- Enhanced corrosion resistance properties for longer service life.

- Advanced surface treatments for improved cleanability.

- High-purity designs for industries like food processing, pharmaceuticals, and semiconductors.

- Strict hygiene standards to meet growing regulatory demands.

You can choose from a wide range of 304 stainless steel fittings, 316 stainless steel fittings, and Duplex grades. These materials offer excellent durability and resist harsh chemicals, making them ideal for demanding environments.

Industrial Applications

You should use heavy pattern fittings in high-pressure, critical industrial systems.

These fittings meet MSS SP-114 compliance, which means you can trust them in applications where safety and reliability matter most. Sunhy’s 304 stainless steel fittings and 316 stainless steel fittings work well in oil and gas, chemical processing, water treatment, and food production.

Common uses for heavy pattern fittings:

- Oil and gas pipelines

- Chemical plants

- Water treatment facilities

- Food and beverage processing

- Pharmaceutical manufacturing

- Semiconductor fabrication

You see heavy pattern fittings in places where contamination-free connections and high-pressure resistance are essential. The demand for hygienic and high-purity fittings continues to grow, especially in industries with strict cleanliness standards.

Durability and Benefits

Heavy pattern fittings offer unmatched durability, stability, and long-term value.

You get exceptional load-bearing capacity, which supports heavy structures and challenging soil conditions. These fittings adapt to various construction needs, such as bridge foundations and retaining walls. You benefit from high corrosion resistance properties, which minimize maintenance and extend the lifespan of your system.

Key benefits of heavy pattern fittings:

- Exceptional load-bearing capacity for critical infrastructure

- Versatility for different industrial and construction needs

- Durability and corrosion resistance properties for long service life

- Stability in soft or unstable soils

- Environmental friendliness by reducing excavation needs

- Cost efficiency due to reduced maintenance and longer lifespan

- Quick installation that saves time on projects

- Reduced vibrations, which is important in sensitive environments

- Proven reliability in demanding applications

You can rely on Sunhy’s 304 stainless steel fittings and 316 stainless steel fittings for consistent performance and compliance with industry standards. Heavy pattern fittings vs light pattern fittings show clear advantages in durability, safety, and long-term value. When you choose heavy pattern fittings, you invest in the stability and reliability of your entire system.

Light Pattern Fittings Explained

Features and Material Grades

Light pattern fittings offer a cost-effective solution for systems with lower pressure requirements. You will find these fittings use thinner walls and less material than heavy pattern fittings. This design makes them lighter and easier to handle during installation. Manufacturers often use stainless steel grades like 304 and 316 for these fittings, which provide good corrosion resistance for most environments. You benefit from a simple, straightforward fitting that works well in non-critical applications.

Typical Uses

You should choose light pattern fittings for residential plumbing, irrigation, and other light-duty systems. These fittings work best in places where high pressure is not a concern. Many contractors use them in water supply lines, HVAC systems, and general plumbing projects. You can also find them in some commercial settings where the system does not require strict compliance or high-pressure resistance.

Tip: Light pattern fittings help you save on material and installation costs when your application does not demand heavy-duty performance.

Limitations and Considerations

Light pattern fittings have limitations in pressure rating and compliance. You should not use them in critical or high-pressure industrial systems. Regulated industries often require fittings that meet strict standards. Light pattern fittings may not always comply with these requirements.

Here is a table showing common compliance issues you might encounter with light pattern fittings in regulated industries:

| Compliance Issue | Description |

|---|---|

| Dark-sky ordinances | Regulations that limit upward light spill and glare to minimize environmental impact. |

| Energy efficiency standards | Requirements that ensure lighting systems are designed to use energy efficiently. |

| Accessibility in lighting design | Ensuring that lighting solutions are accessible to all users, including those with disabilities. |

| Cybersecurity standards for smart lighting | Compliance with standards to protect smart lighting systems from cyber threats. |

| Interoperability requirements | Ensuring that different lighting systems can work together seamlessly. |

| Evolving regulatory frameworks | Continuous updates in regulations that require ongoing education and adaptation by engineers. |

Sunhy offers both heavy and light pattern options to meet your needs. For critical applications, you should select heavy pattern fittings vs light pattern fittings to ensure safety and compliance.

Standards and Certifications for Fittings

MSS SP-114, ASTM, and ISO

You need to know which standards guarantee the safety and reliability of your fittings. Heavy pattern fittings, such as 316 stainless steel fittings, must meet strict standards like MSS SP-114 and ASTM A351. These standards set requirements for wall thickness, pressure rating, and material quality. MSS SP-114 covers threaded and socket-weld fittings for high-pressure systems. ASTM A351 defines the chemical and mechanical properties for cast fittings, including 316 stainless steel fittings.

International certifications help you compare products from different manufacturers. Here is a table showing the most recognized certifications for 316 stainless steel fittings:

| Certification | Description |

|---|---|

| ASTM A312 | Describes the chemical composition, mechanical properties and test methods for stainless steel welded and seamless tubes. Ideal for high temperature and pressure applications. |

| ASTM A358 | Determines the properties of stainless steel pipes produced by electric resistance welding (ERW). It is widely used in the chemical and petrochemical industries. |

| ISO 1127 | Provides detailed information about the dimensions (diameter, thickness, length) and tolerances of stainless steel pipes. |

| ISO 14343 | Regulates the chemical composition and welding compatibility of the materials used in the production of welded pipes. |

You should always check these certifications before choosing 316 stainless steel fittings for your project. This step helps you avoid safety risks and ensures your system meets global standards.

Sunhy’s Quality Assurance

You can trust Sunhy to deliver 316 stainless steel fittings that meet or exceed international standards. Sunhy holds ISO certifications, which prove that every fitting meets strict quality requirements. The company uses a 3-Point Verification Process to test each fitting for structural integrity and dimensional accuracy. This process includes:

- Material verification for every batch of 316 stainless steel fittings

- Dimensional checks to ensure uniform wall thickness

- Pressure testing to confirm safe operation in demanding environments

You benefit from consistent quality and reliable performance. Sunhy’s commitment to quality means you receive 316 stainless steel fittings that work in critical applications, such as chemical processing, oil and gas, and water treatment. You can simplify your supply chain and reduce risk by choosing a manufacturer with proven quality assurance.

Tip: Always ask for documentation of standards and certifications when you order 316 stainless steel fittings. This step protects your investment and ensures compliance with industry regulations.

Cost and Value Considerations

Price Differences

Heavy pattern fittings cost more than light pattern fittings at the start. You pay a higher price because heavy pattern fittings use more material and advanced manufacturing. Light pattern fittings offer a lower initial cost, which helps you save money on small projects or residential jobs.

Here is a table that shows the price differences for commercial projects:

| Type | Initial Cost | Best Use Case |

|---|---|---|

| Heavy Pattern | Higher | Large commercial, industrial |

| Light Pattern | Lower | Small commercial, residential |

You should choose light pattern fittings for basic commercial plumbing or irrigation. Heavy pattern fittings work best in commercial settings that need high pressure and strict safety standards.

Long-Term Value

Heavy pattern fittings give you better long-term value in commercial systems. You get longer service life and fewer replacements. This means you spend less on repairs and downtime. Light pattern fittings may need more frequent maintenance in commercial environments.

Sunhy’s manufacturing process improves cost-effectiveness for commercial users. You benefit from solution annealing and water quenching, which increase durability. Cold Mandrel Forming and Hydroforming create uniform wall thickness. These steps help you avoid leaks and failures in commercial applications.

Tip: If you manage a commercial facility, invest in heavy pattern fittings for critical systems. You will reduce long-term costs and improve reliability.

You should always consider the total cost, not just the initial price. Heavy pattern fittings help you protect your commercial investment and keep your systems running smoothly.

Choosing the Right Fittings

Application-Based Guidance

You should select heavy pattern fittings for high-stress industrial environments and light pattern fittings for general plumbing or residential systems.

When you work in industrial settings like chemical processing or steam systems, heavy pattern fittings provide the strength and reliability you need. These fittings handle high pressure and meet strict compliance standards. You see them used in industrial plants, manufacturing facilities, and other places where safety is critical.

Light pattern fittings work best in non-critical applications. You find them in residential plumbing, irrigation, and light-duty commercial projects. These fittings offer a cost-effective solution when your system does not require high pressure or advanced compliance. If you manage an industrial project, always consider the demands of your system before choosing a fitting type.

Tip: Match the fitting to your application. Industrial systems need heavy pattern fittings for durability and safety. Residential or light-duty systems can use light pattern fittings to save on costs.

Decision Checklist

Use this checklist to help you decide between heavy and light pattern fittings for your industrial project:

- Payback or break-even point

- Impact on organization’s growth (such as customer volumes)

- Contribution to innovation

- Involved risk

- Availability of resources (time, budget, infrastructure, expertise)

- Cost/benefit ratio

You should review each item before making your choice. Industrial projects often require a higher investment in fittings, but you gain long-term reliability and safety. If you have questions or need help, Sunhy experts can guide you. They understand industrial requirements and can recommend the best stainless steel fittings for your application.

😊 Note: Consulting with Sunhy ensures you select the right fitting for your industrial needs. Their team provides tailored advice based on your project’s requirements.

Heavy pattern fittings offer higher strength and compliance. Light pattern fittings provide a cost-effective choice for lighter tasks.

When you select fittings, always match them to your system’s pressure and safety needs.

- Choose heavy pattern for industrial or high-pressure jobs.

- Use light pattern for residential or non-critical systems.

You can trust Sunhy for quality stainless steel fittings.

For expert advice or more information, contact the Sunhy team today.

FAQ

What is the main difference between heavy pattern and light pattern fittings?

Heavy pattern fittings have thicker walls and higher pressure ratings. Light pattern fittings use thinner walls and suit low-pressure systems.

| Feature | Heavy Pattern | Light Pattern |

|---|---|---|

| Wall Thickness | Thick | Thin |

| Pressure Rating | High | Low |

When should you choose heavy pattern fittings?

You should choose heavy pattern fittings for industrial, high-pressure, or critical applications.

- Oil and gas pipelines

- Chemical plants

- Water treatment systems

Tip: Always check your system’s pressure requirements before selecting fittings.

Are light pattern fittings safe for industrial use?

Light pattern fittings are not recommended for high-pressure or regulated industrial systems.

You can use them in residential plumbing, irrigation, or non-critical commercial projects.

What material grades do Sunhy fittings offer?

You can select from 304, 316, and Duplex stainless steel grades.

These grades provide excellent corrosion resistance and durability for various environments.

How do you verify fitting compliance and quality?

You should request documentation for MSS SP-114, ASTM, and ISO certifications.

Sunhy uses a 3-Point Verification Process to ensure every fitting meets strict standards.