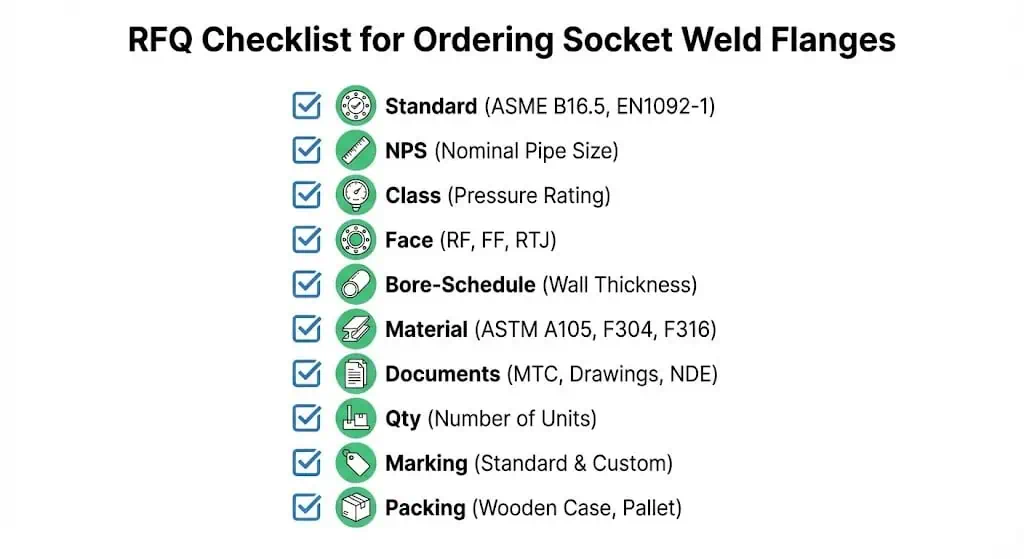

To understand how to order socket weld flanges, you need to provide precise specifications to ensure a successful purchase. Begin by specifying the correct size, material, pressure rating, face type, and pipe schedule. For your convenience, many customers choose from the following combinations:

| Material | Pressure Rating |

|---|---|

| 304/304L Stainless Steel | 300# |

| 316/316L Stainless Steel | 300# |

| Carbon Steel (ASTM A105) | 150# |

Engineer’s note (what usually goes wrong): Most “wrong flange” cases are not about the flange type—they happen because the buyer did not lock down one or more of these fields: (1) bore/schedule, (2) face type, (3) drilling standard, (4) document level (EN 10204 3.1 vs 3.2), or (5) special service requirements (e.g., NACE). If any of those are missing, you risk re-quote, rework, or site rejection.

Quick RFQ line template you can copy:

Socket Weld Flange / Standard: ASME B16.5 / NPS: __ / Class: __ / Face: RF or FF / Bore for: Sch __ / Material: ASTM A182 F__ / Qty: __ / Docs: MTC EN10204 3.1 (or 3.2) / Marking: Heat No. + Size + Class + Material / Packing: export seaworthy.

When you’re ready to learn how to order socket weld flanges, trust Sunhy to deliver flanges with proven quality, advanced manufacturing, and international certifications. Our expertise ensures you receive the right components for your piping system every time.

Identifying Socket Weld Flange Requirements

Application and Pressure Rating

You must identify the application and pressure rating before ordering socket weld flanges. Different industries require socket weld flanges for various uses, such as chemical processing, oil and gas refineries, power generation, and wastewater treatment. Each application has unique demands for pressure and temperature.

| Key Factor | Description |

|---|---|

| Standards | ASME B16.5 covers pressure ratings, tolerances, and marking. |

| Pressure Ratings | Choose the correct class (e.g., 150, 300, 600) for your system’s needs. |

| Applications | Match the flange to your industry and process requirements. |

Selecting the right pressure rating ensures the flange can withstand system conditions. If you choose a rating that is too low, you risk leaks or system failure.

Engineering checklist (before you pick class):

- Design pressure and design temperature (not only operating values).

- Fluid type (water/steam/hydrocarbon/acid/alkali), corrosion allowance, and cleaning method.

- Thermal cycling, vibration, and whether the joint will be dismantled frequently.

- Whether your project spec requires a specific gasket style and seating stress (this can influence face type and finish).

Field case #1 (pressure class under-specified): A Class 150 small-bore utility line was later reclassified to hotter service after commissioning. The flange did not fail immediately, but repeated thermal cycling led to bolt relaxation and a small persistent seep at the joint. Fix: re-rate the joint, upgrade to the correct class, and verify gasket/bolt set. Prevention: lock down the final service conditions at RFQ stage and document “design vs operating” values.

Size, Pipe Schedule, and Face Type

You need to match the flange size, pipe schedule, and face type to your piping system. Proper fitment prevents leaks and ensures safe operation.

- Always use industry standards like ASME, ANSI, or EN 1092 for sizing.

- Match the flange bore to the pipe’s outer diameter and schedule.

- Select the correct face type (raised face, flat face, or ring-type joint) for gasket compatibility.

Engineer’s note (socket weld fit-up): For socket weld joints, many site practices require a small axial clearance between the pipe end and the bottom of the socket before welding. This helps reduce high restraint and weld cracking risk in service. Always follow your project code/spec and welding procedure (WPS).

Tip: Mismatched flange and pipe dimensions can cause leakage, blowout risks, low flow rates, and energy waste. Always double-check measurements.

Field case #2 (wrong schedule/bore causes fit-up failure): Buyer ordered “NPS 2, Class 300” but did not specify bore/schedule. The supplier delivered standard bore, but site pipe was heavier wall. Pipe could not seat properly, weld root profile became inconsistent, and RT/VT failed. Fix: replace with correct bore for the pipe schedule or re-machine bore under controlled procedure. Prevention: always specify “bore for Sch __” in the RFQ line.

Field case #3 (mixing standards: ASME vs EN drilling): A maintenance job mixed an EN1092-1 mating flange with an ASME B16.5 flange of “similar size.” Bolt holes did not align, leading to site rework and delay. Fix: use matched standard pairs or specify drilling explicitly. Prevention: include “standard + drilling pattern” in the order and request a drawing for approval.

Material Selection: Stainless Steel and More

You should select the material based on your application’s environment and required durability. Sunhy offers a wide range of flanges in stainless steel, carbon steel, alloy steel, duplex, and nickel alloys.

| Material Type | Common Grades |

|---|---|

| Carbon Steel | ASTM A105, A350 LF2, A694 F52 |

| Stainless Steel | ASTM A182 F304, F316, F316L, 904L |

| Alloy Steel | ASTM A182 F11, F22, F91 |

| Duplex Steel | Duplex 2205, Super Duplex S32750 |

| Nickel Alloy | Inconel 600, Incoloy 800, Hastelloy C276 |

Sunhy’s flanges meet international standards and hold certifications such as ISO 9001, ISO 14001, ASME B16.5, and CE Marking. These certifications guarantee quality, safety, and global compatibility. When you choose certified flanges, you ensure reliable performance and easy market entry.

Material reality check (engineering perspective):

- 304/304L is common for general service, but chloride exposure (washdown, coastal air, seawater splash) can shift you toward 316/316L.

- 316L is often chosen for better pitting resistance and weldability (lower carbon helps reduce sensitization risk).

- For aggressive chlorides, higher temperatures, or tight corrosion margins, duplex or nickel alloys may be justified—especially when downtime cost dominates material cost.

Field case #4 (corrosion-driven upgrade): A plant used 304L in a washdown area (chloride cleaning). After a period of service, rust staining and localized pitting appeared near the joint. Fix: upgrade to 316L and control crevice areas with proper gasket selection/torque. Prevention: specify environment details (chlorides/cleaning chemicals) in the RFQ and require MTC plus PMI if critical.

How to Order Socket Weld Flanges: Step-by-Step

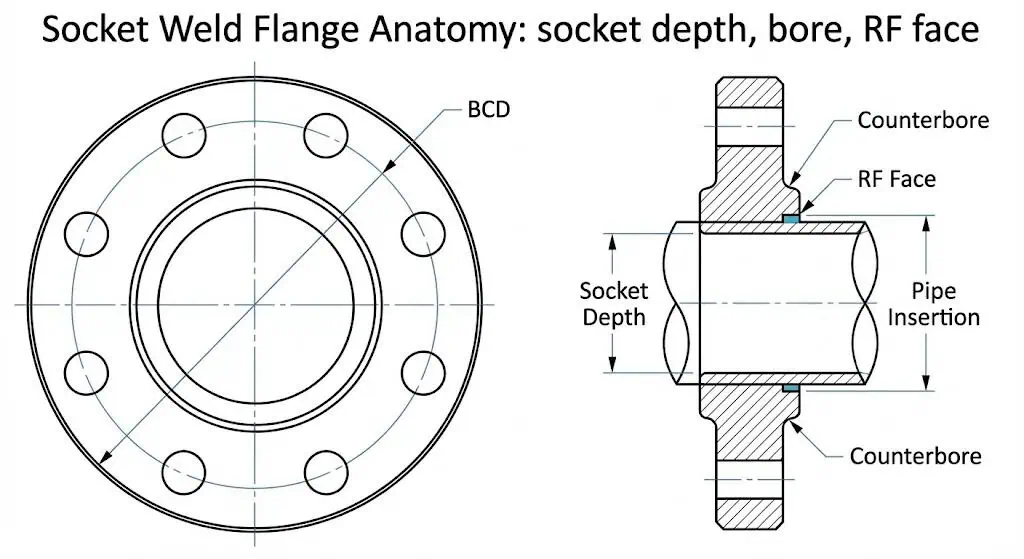

Specifying Dimensions and Standards

You must specify precise dimensions and standards to ensure compatibility and safety.

When you want to know how to order socket weld flanges, start by gathering all necessary measurements and documentation. This step helps you avoid mismatches and ensures a smooth installation.

- Nominal diameter of the flange

- Material grade and certification papers

- Type of flange and face (such as raised face or flat face)

- Pressure rating or class

- Number and diameter of bolt holes

- Bolt circle diameter

- Flange thickness

- Outside diameter

- Socket depth and bore diameter

Tip: Always request documentation that confirms these specifications. This includes dimensional drawings and tolerance sheets.

| Dimension | Tolerance |

|---|---|

| Diameter of Bolt Circle (P) | ±1.6 mm (±1/16 inch) |

| Diameter of Bolt Holes (Q) | +3 mm (1/8 inch) oversized |

| Flange Thickness (T) | ±3 mm (±1/8 inch) |

| Outside Diameter of Flange (O) | ±1.6 mm (±1/16 inch) |

| Socket Depth (D) | Specific tolerances apply |

| Bore Diameter (B) | Allows slight clearance |

| Counterbore Diameter (G) | Specific tolerances apply |

| Facing Finish | Specified in terms of Ra |

When ordering socket weld flanges, you should also check the straightness and alignment of bolt holes. These details help you install a socket weld flange without issues.

Practical acceptance checks (what the site actually measures):

- Drilling alignment with mating flange (a quick bolt-up trial with 2–4 bolts catches many issues early).

- Face condition and finish (especially on RF faces): no deep dents, radial tool marks within spec, no corrosion staining before packing.

- Socket/bore dimensions vs actual pipe schedule (fit-up verification before welding starts).

- Marking legibility (heat no., material, size/class) to ensure traceability after painting/insulation.

Communicating with Suppliers

You need to communicate your requirements clearly to your supplier for a successful order.

When you reach out to Sunhy or another certified manufacturer, provide all specifications and ask about custom options. Sunhy’s advanced CNC machining and forging capabilities allow you to request both standard and custom flanges.

- Share your application details and environment

- Specify all dimensions and standards

- Request information about available materials and finishes

- Ask for certification papers and inspection reports

- Discuss delivery timelines and packaging needs

Note: Sunhy can produce flanges up to 3200 mm in diameter and handle workpieces up to 10 tons. If you need a unique design, mention it early in the process.

Engineering communication tip: If your project is critical, ask the supplier to confirm an inspection plan (ITP) before production starts: dimensional check, material verification, marking, and any NDE/PMI scope. This avoids “assumed inspections” that don’t match the client’s acceptance criteria.

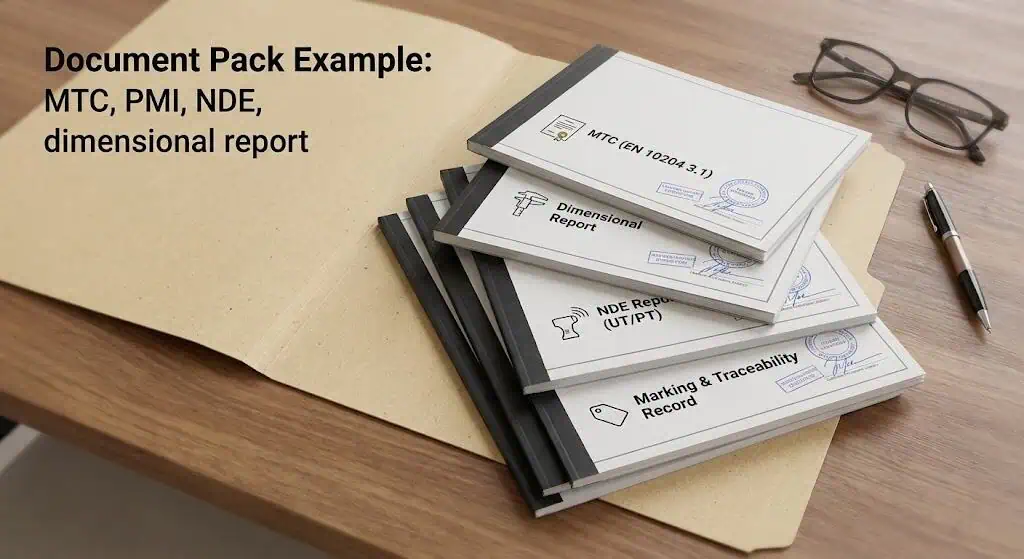

Reviewing and Confirming Your Order

You must review and confirm every detail before finalizing your order socket weld flanges.

Double-check all specifications, documentation, and certifications. This step ensures you receive the correct flanges and prevents costly mistakes.

| Certification Type | Description |

|---|---|

| Material Test Certificates (MTC) | As per EN 10204 3.2 and EN 10204 3.1 |

| NACE MR0175, NACE MR0103 | Test Certificates certifying compliance |

| 100% Radiography Test Report | EN 10204/3.1B |

| Raw Materials Certificate | Certification of raw materials used |

| Third Party Inspection Report | Verification by an independent third party |

- Review all drawings and tolerance sheets

- Confirm material grades and pressure ratings

- Check for required certification papers

- Verify inspection and test reports

- Approve the final quotation and delivery schedule

Tip: If you are unsure about any detail, ask Sunhy for clarification or request a sample specification sheet. This step helps you avoid errors when ordering socket weld flanges.

Fast “PO confirmation” checklist (engineer-friendly):

- PO line includes: standard, NPS, class, face, bore/schedule, material grade, quantity.

- Document list is explicit: EN10204 level + any NACE/PMI/NDE requirements.

- Marking requirements are explicit: heat number + size + class + material.

- Drawing approval required? If yes, add “production only after drawing approved.”

By following these steps, you will know how to order socket weld flanges with confidence. You will receive high-quality flanges that meet your project’s requirements and international standards. Sunhy’s expertise and quality assurance make ordering socket weld flanges a straightforward process.

Tips and Mistakes to Avoid When Ordering Socket Weld Flanges

Common Specification Errors

You can prevent costly errors by understanding the most frequent specification mistakes.

- Ordering flanges made by casting instead of forging can lead to early failure.

- Selecting materials with incorrect chemical composition, such as high carbon in AISI 316L, causes embrittlement.

- Failing to match the flange material to the required standards results in poor performance.

Extra errors engineers see on-site (often missed in RFQ):

- Face type mismatch (RF vs FF) leading to improper gasket seating.

- Missing “bore for schedule” and “drilling standard,” causing fit-up failures.

- Document level not defined (3.1 vs 3.2), triggering client rejection even if dimensions are correct.

Tip: Always verify that your flanges meet the correct standards and manufacturing processes. Sunhy’s quality control team uses ultrasonic, radiographic, and chemical analysis testing to ensure every flange meets strict requirements.

Ensuring Clear Communication

You ensure a smooth order process by communicating clearly with your supplier.

- Provide a complete technical package with detailed specifications and dimensioned drawings.

- Maintain ongoing dialogue with your supplier. Ask questions and clarify any ambiguous requirements.

- Expect regular updates, including photos and test results, throughout production.

- Confirm that your supplier understands your project before manufacturing begins.

- Insist on proactive communication about any issues and solutions.

Note: Sunhy’s team keeps you informed at every stage, providing documentation and updates so you always know the status of your flanges.

Double-Checking Order Details

You reduce mistakes by reviewing every detail before finalizing your order.

| Step | What to Check |

|---|---|

| Specifications | Confirm size, schedule, pressure rating, and face type for all flanges. |

| Documentation | Review material certificates and inspection reports. |

| Drawings | Double-check all dimensions and tolerances. |

| Certification | Ensure all flanges comply with ASME B16.5 or other relevant standards. |

Tip: Download specification sheets or contact Sunhy’s experts for support. For example:

| Flange Type | Size | Link |

|---|---|---|

| ISO-KF Socket Weld Flange | NW-50-SW | Product Spec Sheet |

Sunhy’s inspection process includes mechanical, tensile, and hardness testing, as well as marking each flange for traceability. You can trust that your flanges will meet your project’s needs when you follow these steps.

Maximizing Value: Pros & Cons of Sourcing Socket Weld Flanges from China

You gain significant cost savings when you source socket weld flanges from China. Many Chinese manufacturers offer competitive pricing, which helps you reduce project expenses without sacrificing quality.

You benefit from advanced quality assurance protocols. Suppliers in China use thorough inspection and testing methods to ensure each flange meets international standards.

- Cleaning and inspection remove contaminants and verify weld joints.

- Pressure and leak testing confirm the integrity of the welded joint.

- Post-weld treatment and defect inspection guarantee reliability.

- Final inspection and approval ensure compliance with required standards.

- Chemical composition analysis checks essential elements.

- Microstructure analysis examines internal structure.

- Non-destructive testing, such as ultrasonic examination, detects internal flaws.

- Tensile strength, yield strength, and hardness tests assess material performance.

You should consider lead times when placing orders. Standard flanges usually ship within 2 to 4 weeks. Custom orders may take longer, so you need to ask about production schedules and urgent request options.

Engineer’s sourcing control points (to avoid “cheap but risky”):

- Require traceability: heat number marking must match MTC.

- Define inspection scope: dimensional + marking + document review as minimum.

- For critical service: add PMI (positive material identification) and third-party inspection.

- Confirm packing: face protection, rust prevention, and clear labeling to prevent mix-ups.

| Pros | Cons |

|---|---|

| Cost-effective pricing | Limited direct comparison to other regions |

| High-quality flanges available | Custom orders may require longer lead times |

| Advanced quality assurance protocols | Communication barriers can occur |

| Wide range of material and size options | Shipping times may vary |

Tip: You maximize value by working with certified suppliers who provide documentation and inspection reports for every batch of flanges.

You should always communicate your requirements clearly and confirm all details before finalizing your order. This approach helps you avoid misunderstandings and ensures you receive flanges that meet your specifications.

You ensure a successful order by following each step with precision and attention to detail.

Review the essential steps below:

| Key Step | Description |

|---|---|

| Pipe Size Compatibility | Match the flange socket weld diameter to your pipe size. |

| Pressure Rating | Select the correct pressure class for your system. |

| Material Verification | Confirm the material grade for your application. |

| Compliance Standards | Use ASME or EN benchmarks for accuracy. |

| Quality Assurance | Choose Sunhy for non-destructive testing and full documentation. |

You can request a quote or download specification sheets by contacting Sunhy:

- 📞 Phone: +86 18066318999

- 📧 E-mail: anna@sunhying.com

Trust Sunhy to deliver reliable, certified socket weld flanges for your next project.

FAQ

What information do you need to order socket weld flanges?

You need to provide size, material, pressure rating, face type, pipe schedule, and quantity.

- Application details

- Required standards (ASME, EN, etc.)

- Delivery location

How do you ensure the quality of Sunhy socket weld flanges?

You receive flanges tested with ultrasonic, radiographic, and chemical analysis methods.

Sunhy provides full certification, inspection reports, and traceability for every order.

Can you request custom socket weld flanges?

Yes, you can request custom sizes, materials, and finishes.

- Share your technical drawings

- Specify unique requirements

- Confirm with Sunhy’s engineering team

What certifications do Sunhy flanges have?

You get flanges certified to ISO 9001, ISO 14001, ASME B16.5, and CE.

| Certification | Description |

|---|---|

| ISO 9001 | Quality Management |

| ISO 14001 | Environmental System |

| ASME B16.5 | Flange Standards |

| CE | European Compliance |

How long does delivery take for socket weld flanges?

Standard orders ship in 2–4 weeks. Custom orders may take longer.

You should confirm lead times with Sunhy when placing your order.