Selecting the right gasket depends on material compatibility, pressure, temperature, and adherence to industry standards. Chemical compatibility remains essential, as exposure to incompatible substances can cause degradation or swelling. Understanding the chemical composition of process liquids helps maintain long-term sealing reliability. The International Society of Automation reports that improper gasket selection leads to nearly 30% of mechanical failures in piping systems. SUNHY delivers trusted quality and compliance, providing precision fluid control solutions for demanding environments.

- Chemical compatibility

- Pressure and temperature ratings

- Certification and standards

Quick Answer: How to Select a Flange Gasket

Match Gasket Material to Media and Temperature

Select a gasket material that matches the fluid and temperature conditions.

Flange gasket selection begins with understanding the process media and temperature range. The wrong material can lead to leaks or rapid degradation.

- Pressure and temperature ratings determine the suitability of each gasket type.

- Chemical compatibility ensures the gasket resists attack from process fluids or gases.

- Gasket thickness must fit the application’s operating conditions and compression needs.

Selecting a flange gasket for high-temperature steam requires materials like graphite or metal. For aggressive chemicals, PTFE or specialized elastomers offer better resistance. Always review the selection criteria for gaskets before making a decision.

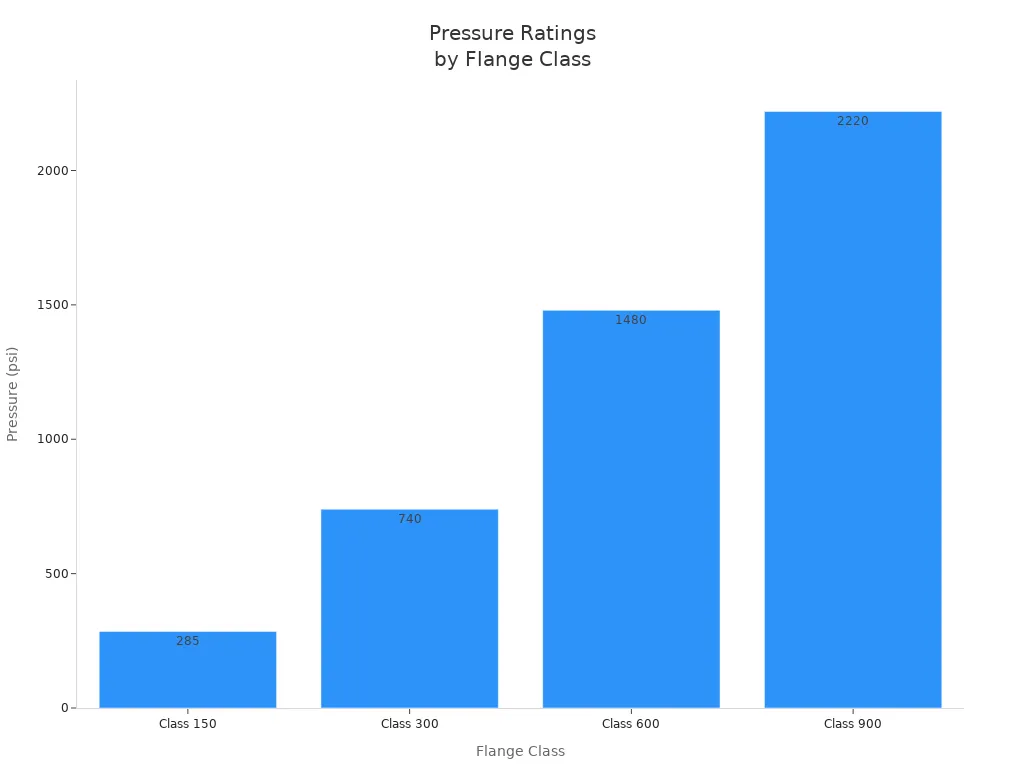

Match Gasket Type to Flange Face and Pressure Class

Choose a gasket type that fits the flange face and pressure class.

Gasket selection depends on flange design and system pressure.

- Flange face finish and flatness affect sealing performance.

- Some gaskets, such as ring-type joint (RTJ), need grooved flanges. Others, like flat gaskets, work with smooth faces.

- Pressure class guides the choice of gasket type for safe operation.

| Flange Class | Approx. Pressure at 100°F (Carbon Steel) | Common Application |

|---|---|---|

| Class 150 | 285 psi | Water, HVAC, low-pressure steam |

| Class 300 | 740 psi | Chemical, refinery, oil & gas |

| Class 600 | 1480 psi | Power generation, high-temp steam |

| Class 900–2500 | 2220–6170 psi | Specialty, offshore or high-pressure systems |

Verify Standards, Bolt Load, and Surface Finish

Confirm compliance with industry standards and proper installation conditions.

Flange gasket selection must meet regulatory and application requirements.

- Industry standards such as ASME, API, and ISO ensure safety and reliability.

- Certifications like API 6A and NACE MR0175/ISO 15156 confirm suitability for oil, gas, and sour service.

- Bolt load and flange surface finish affect the ability to achieve a tight seal.

| Certification | Description |

|---|---|

| API 6A (ISO 10423) | Suitable for high pressure and temperature in petroleum applications. |

| NACE MR0175/ISO 15156 | Ensures material compatibility for sour service environments. |

Tip: Using the wrong gasket type causes leaks and equipment failure. Over 30% of flange leak incidents in chemical plants result from incorrect gasket selection.

Flange gasket selection requires careful attention to each factor. By following these steps, engineers can reduce risk and improve system reliability.

Flange Gasket Basics

The Hidden Cost of Gasket Failure

Gasket failure leads to significant financial and operational consequences.

When a gasket fails, companies face more than just a simple leak. The impact extends across several areas:

- Expensive downtime halts manufacturing processes and disrupts schedules.

- Operational hazards and safety risks increase, especially with pressurized systems.

- Regulatory penalties may result from environmental harm caused by leaks.

- Leakage through failed gaskets can cause substantial operational losses.

- Environmental damage often brings additional financial consequences.

- Safety risks from leaks can lead to costly incidents and injuries.

A single gasket failure can trigger emergency shutdowns, lost product, and increased maintenance costs. These events reduce profits and threaten worker safety. Companies must address these risks to maintain reliable operations.

Why Proper Selection Matters

Proper gasket selection ensures long-term reliability and reduces maintenance costs.

Choosing the right gasket type and material directly affects gasket performance and system integrity. The main types of flange gaskets include:

- Full-face gaskets cover the entire flange surface and suit low-pressure water systems.

- Ring gaskets fit inside the bolt circle and provide strong sealing for higher pressures.

- Rubber flange gaskets offer flexibility for plumbing and water treatment.

- Spiral wound gaskets handle high-pressure and high-temperature service.

- Corrugated metal gaskets deliver durability and can be reused in some cases.

- Kammprofile gaskets use a precision-machined core for fluctuating pressures.

- Ring-type joint (RTJ) gaskets serve extreme oil, gas, and petrochemical conditions.

Proper selection improves the gasket performance factor, which measures the ability to maintain a seal under varying loads and conditions. Reliable gasket selection prevents leaks, reduces shutdowns, and lowers maintenance costs. This approach supports efficient operations and protects both assets and personnel.

Types of Flange Gaskets

There are three main types of flange gaskets: non-metallic, semi-metallic, and metallic. Each type serves specific service conditions and system requirements.

| Type of Gasket | Materials/Structure | Characteristics/Applications |

|---|---|---|

| Non-Metallic | Rubber, graphite, PTFE, non-asbestos fiber | Good flexibility, low cost, suitable for low-pressure and low-temperature environments. |

| Semi-Metallic | Non-metallic core + metal reinforcement | Balances flexibility and strength; excellent elasticity, high pressure/temperature resistance. |

| Metallic | Pure metal (copper, aluminum, stainless steel, etc.) | Used in extreme conditions; high-pressure and high-temperature systems. |

Non-Metallic Gaskets

Non-metallic gaskets offer flexibility and cost-effectiveness for low-pressure and low-temperature applications.

They use materials such as rubber, PTFE, graphite, and non-asbestos fiber. These gaskets seal well on flanges with minor imperfections. Operators often choose non-metallic gaskets for water lines, HVAC systems, and general industrial service. Their ease of installation and affordability make them a popular choice among the types of flange gaskets.

Semi-Metallic Gaskets

Semi-metallic gaskets combine the best features of metal and non-metallic materials for enhanced performance.

They use a composite structure, often with a non-metallic core and metal reinforcement. This design provides both conformability and strength. Common types include spiral wound and metal jacketed gaskets. Semi-metallic gaskets excel in high-pressure, high-temperature, and corrosive environments.

- They seal reliably under fluctuating loads.

- They handle a wide range of operating conditions.

- Industries use them in refineries, chemical plants, and power generation.

Semi-metallic gaskets are preferred over non-metallic or metallic gaskets when systems face extreme temperatures, pressures, or hazardous substances. This versatility makes them one of the most common types of flange gaskets in demanding service.

Metallic and Metal-Reinforced Gaskets

Metallic gaskets deliver maximum strength for the harshest service conditions.

Manufacturers use pure metals such as stainless steel, copper, or aluminum. These gaskets withstand very high pressures and temperatures. Operators install metallic gaskets in critical applications like oil and gas pipelines, steam lines, and reactors.

- They require precise flange surface finish and bolt load.

- They resist blowout and maintain integrity under severe stress.

Selecting the right types of flange gaskets ensures safe, leak-free operation in any system.

Flange Gasket Materials

Compressed Fiber Gaskets

Compressed fiber gaskets provide reliable sealing for moderate pressure and temperature applications.

Manufacturers create these gasket materials by combining fibers such as aramid or cellulose with rubber binders. This blend results in a durable gasket material that resists many chemicals and withstands high temperatures. Chemical resistance varies based on the fibers and binders used.

| Gasket Type | Chemical Resistance Properties | Advantages | Disadvantages |

|---|---|---|---|

| Compressed Fiber Gaskets | Good chemical resistance, withstands aggressive fluids (varies by composition). | High temperature resistance, excellent sealability, durability. | Moderate pressure and temperature limitations. |

- Compressed fiber gasket materials seal well in water, steam, and mild chemical services.

- They offer high temperature resistance and durability.

- Chemical resistance depends on the specific formulation.

PTFE and Graphite Gaskets

PTFE and graphite gaskets excel in harsh chemical and high-temperature environments.

PTFE gasket materials resist nearly all chemicals except molten alkali metals and fluorine gas. These gaskets adapt perfectly to flange surfaces and provide very dense sealing. Graphite gasket materials handle extreme temperatures, operating up to +1000°C in non-oxidizing environments.

| Gasket Type | Chemical Resistance Properties | Advantages | Disadvantages |

|---|---|---|---|

| PTFE Gaskets | Excellent chemical resistance, only attacked by molten alkali metals and fluorine gas. | Extremely chemical resistant, adapts to flange, low leak rates. | Limited temperature resistance, creeping. |

| Graphite Gaskets | Outstanding temperature resistance, suitable for aggressive media. | Handles thermal cycling, high compressibility. | Not suitable for strong oxidizers. |

- PTFE gasket materials offer low leak rates but may creep under load.

- Graphite gasket materials maintain sealing under thermal cycling and fluctuating loads.

Rubber and Elastomer Gaskets

Rubber and elastomer gaskets suit low-pressure, low-temperature, and water service.

These gasket materials include natural rubber, nitrile, neoprene, EPDM, and silicone. Each type has a specific temperature limit.

| Material Type | Maximum Temperature (°C) |

|---|---|

| Rubber | up to +300 |

| Elastomer | up to +260 |

| Graphite | up to +1000 |

- Natural rubber gaskets work up to 82°C.

- Nitrile and butyl gaskets handle up to 121°C.

- Silicone gasket materials withstand up to 260°C.

- Elastomer gaskets provide flexibility and good sealing for plumbing and HVAC systems.

Note: Rubber and elastomer gasket materials have lower temperature limits than graphite.

Metal and Spiral-Wound Gaskets

Metal and spiral-wound gaskets deliver strength for high-pressure and high-temperature service.

Metal gasket materials include stainless steel, copper, and other alloys. Spiral-wound gasket materials combine metal windings with filler materials such as graphite or PTFE.

- Spiral-wound gasket materials handle thermal cycling but may lose sealing if exposed to rapid temperature changes.

- Metal gasket materials resist blowout and maintain integrity under severe stress.

- These gasket materials require precise flange surfaces and correct bolt loads.

Tip: Choose spiral-wound gasket materials for systems with fluctuating temperatures and pressures.

The S.T.A.M.P. Method for Gasket Selection

The S.T.A.M.P. method provides a structured approach for selecting the right gasket for any application. Each parameter addresses a critical aspect of gasket performance and reliability.

| Parameter | Description |

|---|---|

| Size | Importance of contact dimensions and fasteners in calculating contact area and assembly stress to prevent premature failure. |

| Temperature | Need to consider temperature spikes and thermal cycling, which affect gasket performance due to expansion and contraction. |

| Application | Details about the equipment and end-use that influence material selection beyond basic dimensions. |

| Media | The significance of chemical compatibility and emissions compliance when sealing fluids or gases. |

| Pressure | Consideration of constant and fluctuating pressures, including surging, hammering, and thermal expansion, which can impact gasket integrity. |

Size and Flange Facing

Always match gasket size and flange facing to the system’s dimensions.

Engineers measure the flange diameter, bolt circle, and facing type before selecting a gasket. Proper sizing ensures the gasket fits securely and distributes stress evenly. Incorrect sizing can lead to leaks or premature failure in any gasket application.

Temperature and Thermal Cycling

Select materials that withstand operating temperatures and thermal cycling.

Gasket performance depends on the ability to handle temperature spikes and repeated heating and cooling. Materials like graphite and PTFE resist expansion and contraction, making them suitable for demanding applications of flange gaskets.

Application and Mechanical Loading

Consider the equipment and mechanical loads in every application.

The type of machinery, vibration, and assembly stress influence material choice. Heavy-duty applications require gaskets with higher strength and resilience. For example, spiral-wound gaskets perform well in high-pressure environments.

Media (Fluid and Chemical Compatibility)

Choose gasket materials compatible with the process media.

Chemical compatibility prevents degradation and ensures emissions compliance. The table below shows recommended materials for common media:

| Media Type | Recommended Gasket Material |

|---|---|

| Oil/Fuel | NBR or Viton |

| Brake Fluid/Steam | EPDM (Never use NBR) |

| Food/Pharma | FDA-grade Silicone |

Selecting the correct material for each application protects the system and maintains safety.

Pressure and Pressure Class

Verify that the gasket matches system pressure and pressure class.

Constant and fluctuating pressures, including surges and hammering, can affect gasket integrity. Engineers select gaskets rated for the maximum pressure in the application to prevent blowouts and leaks.

Tip: The S.T.A.M.P. method improves accuracy and reliability in gasket selection for every application.

Key Engineering Considerations

Working, Design, and Test Pressures

Engineers must match gasket pressure rating to system requirements for safe operation.

Selecting a gasket involves evaluating working, design, and test pressures. The gasket must withstand the highest expected pressure without losing integrity. The following table summarizes key considerations for selecting a flange gasket in high-pressure applications:

| Design Factor | Description |

|---|---|

| Material Selection | Choose materials compatible with process media. |

| Joint Design | Coordinate gasket design with flange geometry and surface finish. |

| Installation Practices | Apply uniform bolt loading within calculated torque values. |

| Temperature Resistance | Ensure the gasket resists operational temperatures. |

| Pressure Containment | Confirm the gasket pressure rating meets system demands. |

| Chemical Compatibility | Select materials like PTFE for harsh chemicals. |

| Mechanical Movement | Model joint stress and relaxation under load and thermal conditions. |

| Long-term Sealing Integrity | Use modeling software for consistent field performance. |

Temperature Limits and Cycling

Gasket design considerations must address both maximum temperature and thermal cycling.

Temperature extremes and repeated heating or cooling can cause gasket degradation. Engineers select materials that maintain sealing properties throughout temperature fluctuations. Graphite and PTFE gaskets perform well under cycling, while rubber and elastomers suit lower temperature ranges.

Regulatory and Industry Standards

Compliance with standards ensures gasket related considerations meet safety and reliability requirements.

Industry standards such as ASME, ISO, and API guide material selection, surface finish, and installation practices. Recommended practices include:

- Match flange surface finish to gasket material.

- Use torque accuracy for consistent bolt loading.

- Avoid fabrication errors that distort flange surfaces.

- Assess surface texture with profilometry equipment.

- Follow ISO 4287 and ASME B46.1 for surface parameters.

- Use portable testers for real-time quality control.

Application-Specific Requirements

Unique industry needs influence gasket design and selection.

Different sectors require specialized materials and documentation. The table below highlights how application-specific requirements affect gasket selection:

| Industry/Application | Requirements | Impact on Gasket Selection |

|---|---|---|

| Aerospace | Extreme temperature, flammability, outgassing | Materials must ensure reliability in harsh conditions |

| Medical Devices | Biocompatibility, sterilization compatibility | FDA-approved materials and extensive testing |

| General Industry | Varies by application | Influences material choice and quality protocols |

Quality control requirements may affect manufacturing lead times. Engineers ensure gasket performance matches specific needs, guiding inspection and testing protocols.

Common Causes of Gasket Failure

Material Mismatch and Chemical Attack

Material mismatch and chemical attack remain leading causes of gasket failure.

Selecting the wrong gasket material for the process media exposes the gasket to corrosion, erosion, and permeation. Chemical processing plants often report failures due to inappropriate material selection. When the gasket cannot resist the chemicals in the system, it degrades quickly and loses sealing integrity.

- Corrosion from improper materials

- Erosion and permeation

- Incorrect gasket selection for the application

- Changes in application function

Operators must match gasket material to the fluid and temperature conditions. Using the correct material prevents chemical attack and extends gasket life.

Installation and Bolt Load Errors

Improper installation and bolt load errors frequently lead to premature gasket failure.

Poor installation practices create uneven pressure and weak points in the seal. Common mistakes include misalignment, over-torquing, and inadequate surface preparation. Dirt or remnants of old gaskets can hinder effective sealing. Incorrect torque application causes irregular compression, which results in leaks.

- Misalignment during installation

- Over-torquing or under-torquing bolts

- Inadequate surface preparation

- Improper shimming

- Insufficient load from improper installation

Technicians must follow proper installation procedures and use calibrated tools to apply the correct torque. Consistent bolt loading ensures the gasket maintains a reliable seal.

Tip: Always clean flange surfaces and check alignment before installing a new gasket.

Flange Surface Damage and Misalignment

Flange surface damage and misalignment compromise gasket performance.

Damaged or misaligned flanges create uneven stress on the gasket, leading to deformation or crushing. Excessive flange damage, poor gasket cut quality, and incorrect gasket size also contribute to sealing failures.

| Common Issues | Impact on Gasket Performance |

|---|---|

| Excessive flange damage | Creates leak paths |

| Misaligned flanges | Causes uneven stress and deformation |

| Poor gasket cut quality | Reduces sealing area |

| Incorrect gasket size | Prevents proper fit |

Regular inspection of flange surfaces and careful alignment during assembly help prevent these issues. Maintaining flange integrity supports long-term gasket reliability.

Step-by-Step Flange Gasket Selection Process

Gather Service and Piping Data

Start by collecting all relevant service and piping information.

Engineers review the operating temperature, pressure, fluid type, and flange specifications. This data forms the foundation for selecting a suitable gasket.

- Record maximum and minimum temperatures.

- Note system pressure and pressure class.

- Identify fluid or gas composition.

- Document flange size, facing, and surface finish.

A clear understanding of these parameters helps prevent material mismatch and ensures reliable sealing.

Shortlist Gasket Type and Material

Select gasket types and materials that match the application requirements.

Professionals consider temperature, pressure, and fluid compatibility.

- Solid metal gaskets suit high-pressure flanges.

- Hollow metal gaskets work for extreme temperature ranges.

- Corrugated metal gaskets fit pumps, valves, and heat exchangers.

- Semi-metallic gaskets perform well in boilers and autoclaves.

- Non-metallic gaskets, such as rubber or PTFE, serve general industrial needs.

- Liquid gaskets withstand a wide temperature range.

A shortlist allows engineers to focus on options that meet both technical and operational demands.

Consult Manufacturer Data and Data Sheets

Review manufacturer data sheets for detailed material properties and performance ratings.

Data sheets provide information on chemical resistance, temperature limits, and pressure ratings.

- Manufacturer data sheets help select the most suitable gasket for the operational environment.

- Informed decisions lead to optimal sealing performance and longer service life.

- Consulting with manufacturers ensures recommendations align with specific project needs.

Tip: Always compare manufacturer data to system requirements for best results.

Verify Standards, Certification, and Compliance

Confirm that the selected gasket meets all required standards and certifications.

Engineers check for compliance with ASME, API, and ISO standards.

- Review documentation for gasket testing and certification.

- Ensure the gasket meets industry and regulatory requirements.

- Verify that the product includes proper certification for the intended application.

A thorough review of gasket testing and certification guarantees reliability and safety in critical systems.

| Step | Purpose |

|---|---|

| Gather Service Data | Define operating conditions |

| Shortlist Type/Material | Match to application needs |

| Consult Manufacturer Data | Confirm material suitability |

| Verify Standards/Compliance | Ensure safety and reliability |

Flange Gasket Selection Checklist

Service Conditions Checklist

Always verify service conditions before selecting a flange gasket.

- Maximum operating pressure must not exceed gasket rating.

- Temperature range should match gasket material limits.

- Gasket material must be compatible with system fluids.

- Gasket type must fit the flange design.

- Thickness must maintain seal integrity under stress.

- Regulatory compliance is required for all applications.

- Maintenance needs should be considered for systems with frequent service.

Tip: Reviewing these points helps prevent leaks and extends gasket life.

Design and Standards Checklist

Design and standards ensure the gasket meets safety and quality requirements.

| Selection Criteria | Importance |

|---|---|

| Application Use | Understanding the role of the gasket in the production process helps in selecting the right type. |

| Environmental Factors | Identifying conditions the gasket will face ensures durability and compliance. |

| Production Standards | Meeting safety and quality requirements is crucial for compliance. |

Note: Matching design criteria with standards supports reliable operation and regulatory approval.

Installation and Maintenance Checklist

Proper gasket installation and maintenance protect system integrity.

- Inspect flange surfaces for damage or debris before installation.

- Confirm gasket size and type match flange specifications.

- Use calibrated tools to apply correct bolt torque.

- Follow manufacturer guidelines for gasket installation and maintenance.

- Schedule regular inspections to detect wear or leaks early.

- Replace gaskets at recommended intervals to avoid unexpected failures.

Regular maintenance and correct installation reduce downtime and improve safety.

Matching gasket material to service conditions ensures system reliability and leak prevention.

| Gasket Material | Key Properties | Benefits |

|---|---|---|

| PTFE | Chemical resistance | Safe sealing in aggressive environments |

| Viton® | High temperature resistance | Maintains integrity under heat |

| EPDM | Weather and ozone resistance | Durable in outdoor applications |

| Silicone | Flexibility, temperature | Versatile for various conditions |

| Buna-N | Oil resistance | Effective in oil-based applications |

Engineers should use the checklist and step-by-step process for every selection. SUNHY delivers precision fluid control solutions with proven reliability. For complex or critical projects, consulting with experts provides custom solutions and ensures optimal performance.

- Experts guide material selection and design.

- They deliver reliable, leak-free operation in demanding environments.

Choosing the right gasket protects assets and supports safe, efficient operations.

FAQ

What factors determine the best flange gasket material?

Chemical compatibility, temperature, and pressure ratings determine the best material.

Engineers review process media, operating temperature, and system pressure. They select materials that resist corrosion and maintain integrity under service conditions.

How does flange surface finish affect gasket performance?

A smooth, clean flange surface improves gasket sealing.

Operators inspect flange surfaces for damage or irregularities. They use profilometry tools to measure roughness. Proper surface finish prevents leaks and ensures long-term reliability.

Which standards apply to flange gasket selection?

ASME, API, and ISO standards apply to flange gasket selection.

These standards specify material properties, dimensions, and installation practices. Engineers verify compliance to ensure safety and reliability in critical systems.

What are common signs of gasket failure?

Leaks, pressure drops, and visible damage indicate gasket failure.

Technicians look for fluid seepage, loss of system pressure, and deformation around the flange. Regular inspections help detect issues early.

When should an engineer consult a gasket manufacturer?

Engineers consult manufacturers for complex or critical applications.

They seek expert advice when facing unusual media, extreme temperatures, or high pressures. Manufacturers provide data sheets, certifications, and custom solutions.