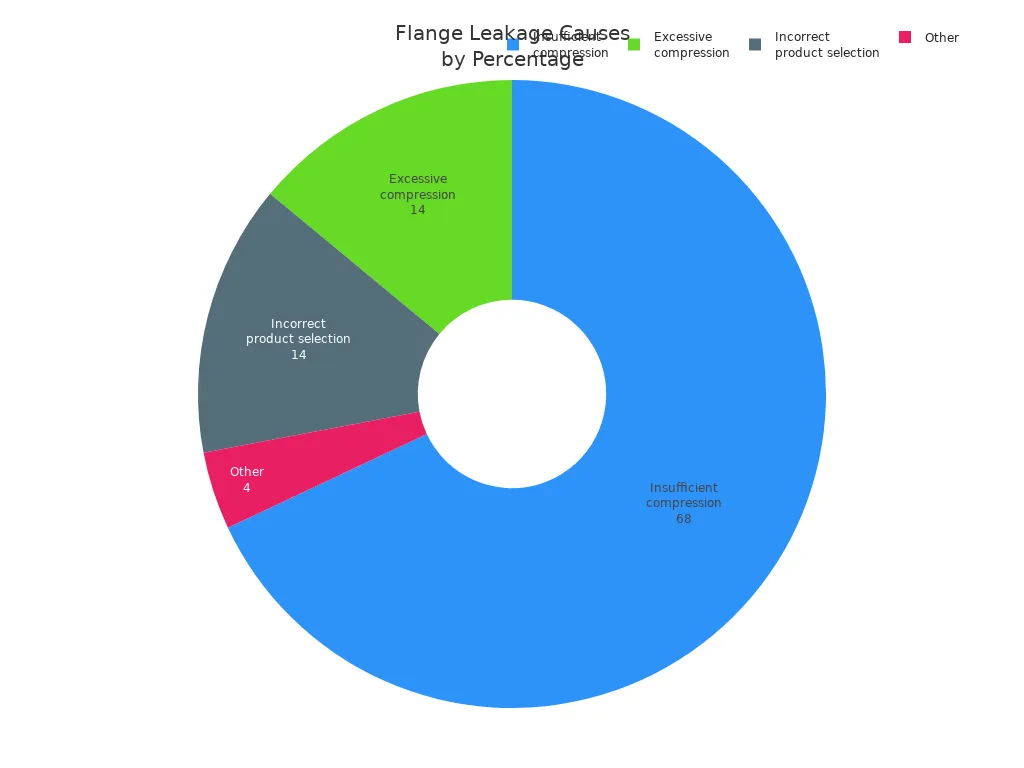

Achieving zero-leakage in flange assembly is not just a goal; it’s a safety mandate requiring a disciplined, four-step process. These critical steps include precision surface preparation and cleanliness, strict alignment control, a calculated lubrication strategy, and a verified installation and bolting sequence. Industry data consistently shows that most flange joint integrity issues stem from improper installation protocols rather than material or gasket failure.

| Cause of Flange Leakage | Percentage |

|---|---|

| Insufficient compression (Low Bolt Load) | 68% |

| Excessive compression (Gasket Crush) | 14% |

| Incorrect product selection | 14% |

| Other | 4% |

The ASME PCC-1 standard highlights process control as essential for joint integrity management. Advanced flange joint integrity management treats the joint assembly as a precise engineering discipline, not just simple bolt tightening, ensuring reliable, leak-free operation and minimizing fugitive emissions.

Step 1: Precision Surface Preparation in Flange Assembly

Cleaning and Critical Inspection

Cleanliness is critical for flange joint integrity and effective leak prevention. Contaminants like rust, scale, dust, or old gasket residue can create micro-paths for fluids to escape, making it impossible for the gasket to seal correctly. This drastically increases the risk of leak and catastrophic joint failure. Surface cleanliness ensures that flange surfaces mate properly and that the gasket material flows into the flange serrations as intended.

Expert Tip: Always perform a thorough visual and tactile inspection before starting flange assembly. Early detection of pitting or damage during plant inspection helps prevent costly repairs and shutdowns.

Recommended inspection protocols include:

- Visual examination of the flange face for dirt, rust, paint, grease, or moisture.

- Checking for old gasket residue (graphite or PTFE) or foreign materials.

- Looking for early warning signs such as radial scoring, pitting, or scratches that cross the sealing surface.

Gasket Seating Surface Finish

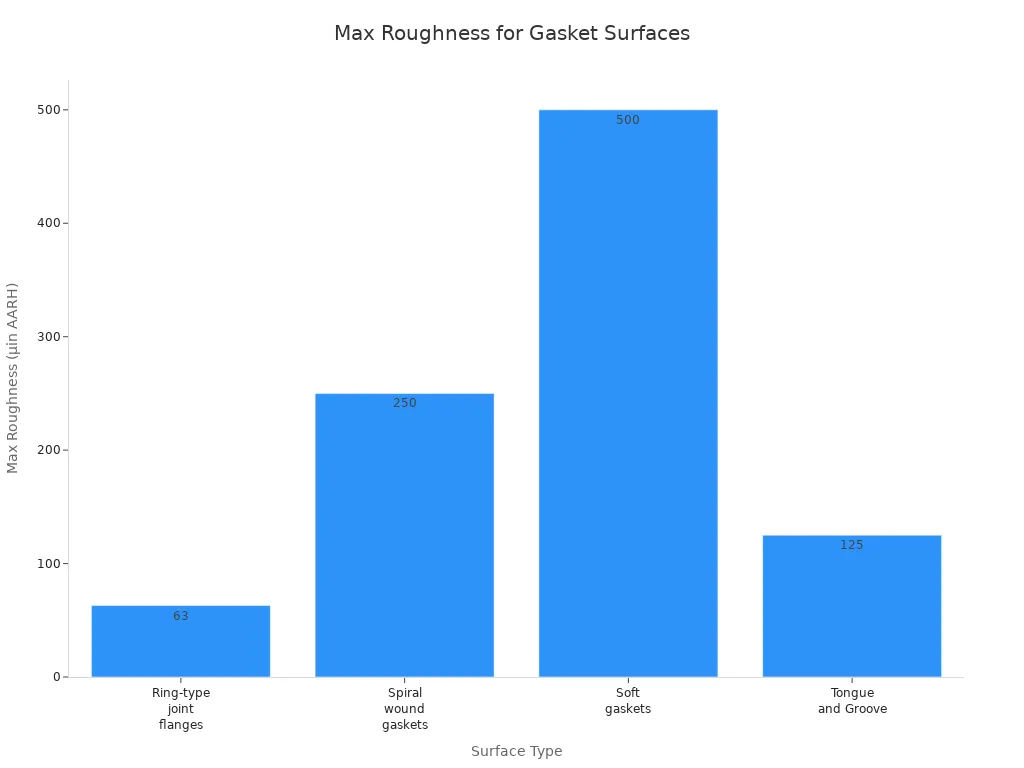

A proper gasket seating surface is essential for achieving zero-leakage. The ASME B16.5 code specifies that the flange face must have a specific roughness (Ra) to ensure friction (“bite”) with the gasket and provide a high-quality seal. Typically, a serrated finish (phonographic or concentric) with 30 to 55 grooves per inch and a roughness between 125 and 500 micro inches (AARH) is required for standard piping.

| Flange Joint Type | Maximum Roughness Value (Ra) |

|---|---|

| Tongue and Groove / Small Male and Female | 3.2 µm (125 µin) |

| Ring Joint (RTJ) | 1.6 µm (63 µin) |

| Other Flange Facings (RF/FF) | 3.2 to 6.3 µm (125 to 250 µin) |

Proper gasket selection and understanding gasket factors (m and y factors) are vital for critical flanges. Always match the surface finish to the gasket type (e.g., smoother finishes for spiral wound gaskets vs. rougher for soft gaskets) to avoid common flange joint failure mechanisms.

Bolt and Nut Condition Verification

Bolts and nuts must be in optimal condition to translate torque into bolt load accurately. Damaged or corroded fasteners increase friction, leading to false torque readings and joint separation. The “Free Run” test is a mandatory simple check: the nut should spin freely by hand along the entire length of the stud thread. If it jams or requires tools, replace the bolt or nut immediately.

| Factor | Description |

|---|---|

| Bolt Load | Directly influences leakage and joint stiffness; optimal load distribution is crucial for integrity. |

| Temperature | Affects axial joint stiffness and can lead to load relaxation (creep), impacting sealing performance. |

| Loading History | Cyclic variations in loading can alter failure criteria and the long-term load-bearing capacity of the joint. |

Checklist for surface preparation:

- Inspect flange face for scratches, gouges, or pits.

- Ensure bolts and nuts are free of corrosion, debris, and burrs.

- Perform the “Free Run” test on 100% of fasteners.

- Confirm the gasket seating surface matches the required roughness specification.

- Document findings for leak testing and future risk-based inspection (RBI).

Proper surface preparation forms the non-negotiable foundation for successful flange assembly, reliable leak testing, and long-term joint integrity.

Step 2: Alignment Control for Flange Joint Integrity

Types of Flange Misalignment

Proper alignment is essential for maintaining flange joint integrity and preventing leaks. Misalignment in flange assembly often results from poor piping design, inadequate pipe support, or incorrect fabrication. These issues introduce severe shear stress and bending moments on the joint, which can lead to uneven gasket compression (pinching) and create leak paths. Misalignment occurs when the pipe and flange do not align concentrically. This situation can prevent bolts from entering bolt holes freely, reducing effective clamping force. Plant inspection teams frequently observe three main types of misalignment:

- Parallelism error: Flange faces are not parallel to each other.

- Rotational misalignment: Bolt holes do not line up (Two-holing issues).

- Axial offset: Flange centerlines are offset from each other.

Alignment Tolerance Standards (ASME)

ASME standards define strict alignment tolerances to ensure structural and leak integrity. Exceeding these tolerances can compromise the gasket seal (causing blowout) and lead to structural failure. The following table summarizes key alignment standards used in the industry:

| Standard | Section | Tolerance Description |

|---|---|---|

| ASME B31.3 | 335.1(c)(1) | Mating gasket contact surfaces must align within 1 mm in 200 mm (1/16 in./ft) |

| ASME PCC-1 | Appendix E | Angular misalignment ≤ 0.2 degrees; offset misalignment ≤ 1.5 mm (1/16 inch) |

Note: Always verify alignment using squares or laser alignment tools during inspection and before gasket installation, especially for high-pressure critical flanges.

Avoiding Bolt-Induced Alignment

Never use bolts to force flanges into alignment. Forcing alignment with bolts introduces “stored energy” and shear stress that can distort the flange. This unsafe practice leads to inaccurate bolt load, uneven gasket compression, and a significantly increased risk of leak during hydrostatic testing. Instead, use proper mechanical lifting tools (come-alongs, chain blocks) to achieve correct alignment before inserting bolts. This approach preserves flange joint integrity and reduces the chance of joint failure.

Tip: Document alignment checks during plant inspection to support future maintenance, reliability audits, and leak prevention efforts.

Step 3: Lubrication Strategy & Torque Coefficients

Lubricant Application Points

Proper lubricant application is the single most important factor in converting torque to bolt load. Lubrication reduces the coefficient of friction and allows bolts to stretch evenly, which is essential for maintaining flange joint integrity. Without it, up to 50% of your torque effort is lost to friction rather than stretching the bolt. During flange assembly, technicians should focus on these application points:

- Fill all valleys of the stud bolt threads with lubricant where the nut will travel.

- Apply a thin, even coat of lubricant to the nut bearing surface (face).

- Confirm a bead of lubricant extrudes from beneath the nut after hand-tightening to verify coverage.

- Cover every thread so the valley of the stud is full, but avoid over-lubricating the flange face itself.

These steps help prevent galling and make both assembly and future disassembly smoother. Inspection teams should verify lubricant presence during each stage of controlled bolting, especially on critical flanges.

Consistency and Friction Factor (K-Factor)

Consistent lubricant application is vital for achieving uniform bolt load and preventing leak. Lubricant consistency directly affects the friction factor, also known as the Nut Factor (K factor), in the assembly process. High-quality lubricants (such as Molybdenum Disulfide or Nickel-based pastes) maintain their properties under high loads, while lower-quality options may break down, causing variability in bolt loads. The following points highlight best practices:

- Use lubricants specified for flange joint integrity management (check temperature ratings).

- Ensure all bolts receive equal lubricant coverage to avoid uneven torque distribution.

- Lubricated studs provide more consistent bolt stretch than dry studs; dry torquing is unpredictable.

- Regular inspection of lubrication effect extends the service life of flange facing machines and fasteners.

Technicians should avoid standard greases that could impact gasket selection or sealing performance. Always check compatibility with flange materials and opt for anti-seize treatments recommended by gasket manufacturers.

Torque Formula and Preload

The relationship between torque, friction factor, and bolt preload determines joint integrity. The torque applied during controlled bolting stretches the bolt (spring effect) and compresses the flange, creating the initial clamp load. The fundamental formula for torque is:

T = K × D × F

(Torque = Friction Factor [K] × Bolt Diameter [D] × Desired Preload [F])

Lubrication directly influences the “K” value. A change in lubrication can double the required torque or halve the resulting load. Proper lubrication ensures the clamp load remains consistent, reducing the risk of joint failure and improving the reliability of leak testing. Inspection teams should document torque values and lubrication methods for all critical flanges to support advanced flange joint integrity management.

Step 4: Bolting Sequence & Controlled Tightening

Hand Tightening and Seating

Hand-tightening all bolts ensures the flange seats evenly and prevents early gasket crush.

Technicians should insert all bolts and tighten them by hand in a crisscross pattern until the nuts contact the flange face. This step aligns the joint and prepares it for controlled bolt up. Proper seating is essential for critical flanges, as uneven seating can cause non-uniform gasket stress, leading to leaks or joint failure during testing.

Star Pattern Tightening (ASME PCC-1)

The Legacy Star Pattern distributes load evenly across the flange, preventing localized stress and gasket damage.

The recommended tightening sequence prevents “pinching” one side of the gasket. The sequence for common flange sizes is as follows:

| Number of Bolts | Bolt Tightening Sequence (Cross-Pattern) |

|---|---|

| 4 | 1, 3, 2, 4 |

| 8 | 1, 5, 3, 7, 2, 6, 4, 8 |

| 12 | 1, 7, 4, 10, 2, 8, 5, 11, 3, 9, 6, 12 |

This sequence ensures uniform compression and supports advanced flange joint integrity management.

Multi-Pass Torqueing Procedure

Multi-pass torqueing achieves uniform preload and reduces the risk of joint integrity loss due to crosstalk.

The ASME PCC-1 compliant process involves several passes:

- Pass 1: Torque all bolts to 30% of the final value in a star/cross pattern.

- Pass 2: Increase to 60% of target torque using the same pattern.

- Pass 3: Apply 100% of the target torque, again in a star pattern.

- Pass 4 (Check Pass): Apply final torque in a circular (clockwise) pattern until no further nut movement occurs.

Multi-pass torqueing minimizes preload reduction from elastic interaction and ensures even load distribution, which is critical for joint integrity management.

Final Check and Elastic Interaction

A final circular check compensates for elastic interaction (bolt relaxation) and confirms uniform preload across the joint.

Elastic interaction can cause variations in bolt tension; tightening one bolt often loosens its neighbor. A rotational check at the final torque value ensures all bolts—not just the last one tightened—reach the specified preload. This step is vital for maintaining integrity in critical joint assemblies and supports a leak-free start-up.

Note: ASME PCC-1 defines preload as the primary clamping force that keeps the joint in compression. Controlled bolting and process control are more important than simply applying high torque, as they prevent gasket selection errors, flange deformation, and bolt yielding.

Disciplined flange assembly and joint integrity management make zero-leakage achievable.

A four-step process—precision surface preparation, alignment, lubrication, and controlled bolting—prevents joint failure and supports leak-free start-up. Key takeaways include:

- Correct torque application verified by calculations.

- Meticulous surface preparation and inspection.

- Consistent workflow following ASME PCC-1 guidelines.

| Benefit | Description |

|---|---|

| Consistent performance | Ensures uniformity in operations and pressure containment. |

| Risk reduction | Minimizes leakage events and fugitive emissions. |

| Operational Efficiency | Reduces rework during start-up and maintenance. |

A printable bolting checklist improves site compliance and supports effective testing. Teams should review current joint practices and commit to operational excellence for long-term integrity.

FAQ: Flange Joint Integrity

What causes most flange leaks?

Improper installation is the primary cause of most flange leaks.

- 80% of leaks result from incorrect assembly practices, not gasket failure.

- Common mistakes include poor surface preparation (rust/debris), misalignment, and uneven bolt load distribution.

How does ASME PCC-1 support joint integrity?

ASME PCC-1 provides the industry standard guidelines for pressure boundary bolted flange joint assembly.

- It offers detailed guidelines for surface preparation, alignment, lubrication, and bolting patterns.

- It trains technicians to ensure consistent, leak-free flange management and safety.

Why is the star pattern tightening sequence important?

The star pattern (or cross pattern) distributes the clamping load evenly across the gasket.

- It prevents gasket crush on one side and potential gaps on the other.

- It significantly reduces the risk of leaks and joint failure during pressurization.

What is the “Free Run” test for bolts and nuts?

The “Free Run” test verifies the condition of the fastener threads before installation.

- The nut should spin freely by hand along the entire length of the bolt thread.

- Any jamming indicates damaged threads or corrosion, requiring immediate replacement to ensure accurate torque readings.

Which factors affect bolt preload consistency?

Lubrication quality, torque application method, and fastener condition are the top factors affecting preload.

| Factor | Impact on Preload |

|---|---|

| Lubrication (K-Factor) | Reduces friction, allowing more torque to convert to clamping force. |

| Torque Method | Controlled tools (Hydraulic/Pneumatic) ensure uniform load compared to manual wrenches. |

| Bolt Condition | Rust or damage increases friction, reducing actual preload on the gasket. |