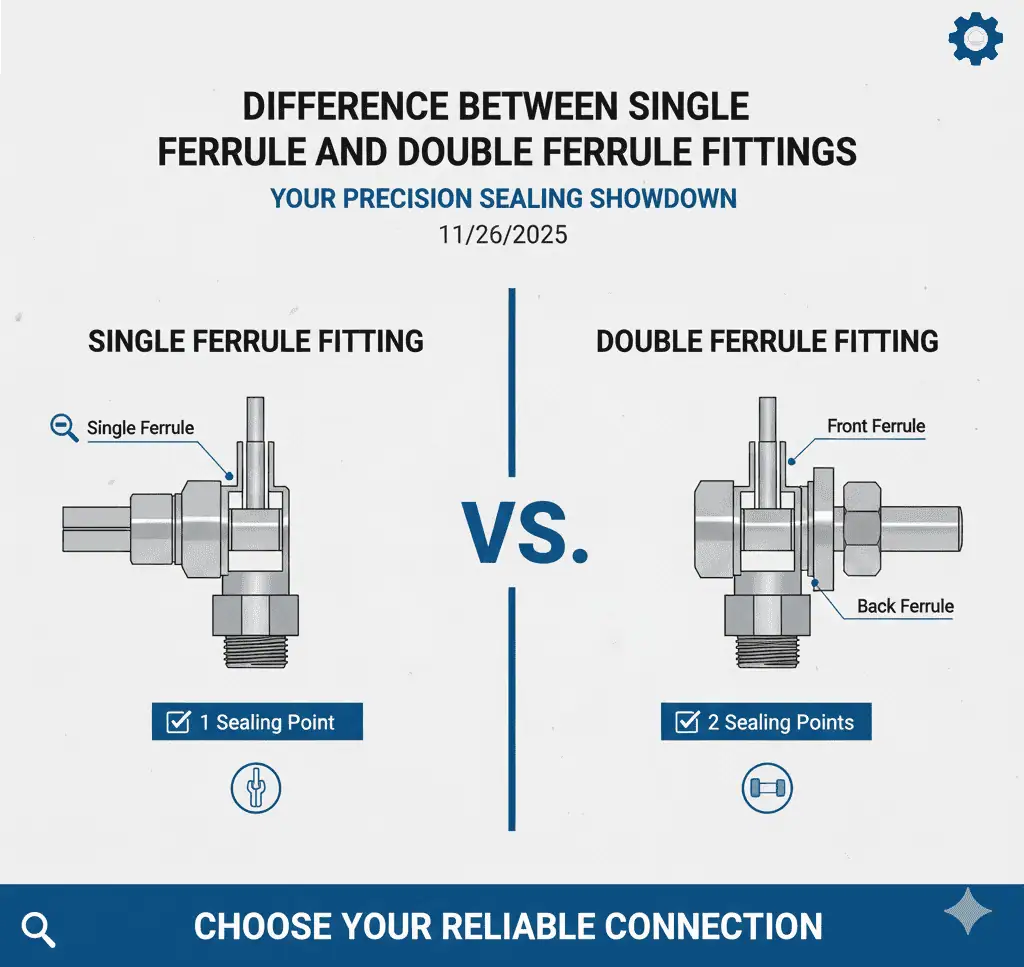

The main difference between single ferrule and double ferrule fittings is that single ferrule uses one ring to seal and grip the pipe, while double ferrule fittings use two rings for extra sealing and grip. You will find single ferrule fittings work well for basic compression fitting needs and easier installation. Double ferrule fittings offer enhanced safety and reliability in high-pressure environments. The table below shows how each type performs in industrial settings:

| Feature | Single Ferrule Fittings | Double Ferrule Fittings |

|---|---|---|

| Durability | Cost-effective, indoor use | Superior corrosion resistance |

| Application | Low-pressure systems | High-pressure systems |

| Installation | Simple | Complex, higher safety |

Choosing the right fitting protects your system from leaks and failures. Sunhy’s stainless steel fittings give you confidence in demanding conditions.

What Are Single Ferrule and Double Ferrule Fittings?

Single Ferrule Fittings Overview

Single ferrule fittings use one ferrule to create a secure seal and grip on the tubing.

You will find that single-ferrule designs rely on a single ring that deforms when tightened, locking the tube in place and preventing leaks. This type of compression fitting is popular for its simplicity and ease of installation. You can use single ferrule fittings in water supply systems, gas pipelines, and low-pressure hydraulic systems. These fittings offer reliable connections for basic industrial needs.

Tip: Single ferrule fittings work best when you need quick installation and straightforward maintenance.

Here is a quick look at the standard definition and core functions:

| Definition | Core Functions |

|---|---|

| Single ferrule fittings have one ferrule that deforms to create a seal. | They are used to form secure connections in applications such as water supply systems, gas pipelines, and low-pressure hydraulic systems. |

You will see single-ferrule fittings in many industries.

- Oil and gas: They provide leak-free connections under pressure and resist corrosion.

- Pharmaceuticals: You get clean seals that prevent contamination and allow easy disassembly.

- Food processing: Smooth surfaces help maintain hygiene and prevent contamination.

- Hydraulic systems: These fittings ensure reliable operation and prevent fluid loss.

Double Ferrule Fittings Overview

Double ferrule fittings use two ferrules for enhanced sealing and tube grip.

You will notice that double ferrule fittings, also called dual-ferrule or double ferrule compression fittings, have a front ferrule and a back ferrule. The front ferrule creates a tight seal, while the back ferrule grips the tube and prevents movement. This dual-ferrule design gives you extra protection against leaks and tube blowout, especially in high-pressure or vibration-prone environments.

Double ferrule fittings are common in industries where safety and reliability matter most.

- Chemical processing: You get strong seals that withstand aggressive chemicals.

- Marine applications: Dual-ferrule fittings resist corrosion from saltwater.

- Oil and gas: These fittings handle extreme pressures and harsh conditions.

- Instrumentation: You benefit from precise, stable connections for sensitive equipment.

You can choose between single ferrule and double ferrule fittings based on your system’s pressure, vibration, and safety requirements. Both types of compression fittings help you achieve leak-free, reliable connections in industrial settings.

Key Differences Between Single Ferrule and Double Ferrule Fittings

Design Comparison

Single ferrule and double ferrule fittings differ mainly in the number of ferrules and their internal structure.

You will see that single-ferrule fittings use one ferrule to seal and grip the tube. Double ferrule fittings, also called dual-ferrule fittings, use two ferrules: a front ferrule for sealing and a back ferrule for gripping. This design difference affects how each fitting performs under pressure and vibration.

Here is a table that summarizes the main design distinctions:

| Feature | Single Ferrule Fittings | Double Ferrule Fittings |

|---|---|---|

| Number of Ferrules | One | Two |

| Sealing Mechanism | Compression of a single ferrule | Front ferrule grips tubing; back ferrule supports |

| Installation Complexity | Simpler, fewer components | More complex, requires careful alignment |

| Performance Under Pressure | May not provide high sealing integrity | Excellent resistance to vibration and thermal cycling |

| Applications | Suitable for low-pressure systems | Preferred for high-pressure and high-temperature applications |

Sunhy’s advanced manufacturing ensures both single-ferrule and dual-ferrule fittings have precise dimensions and uniform wall thickness. This quality reduces the risk of leaks and improves reliability, especially in demanding environments.

Sealing and Grip Mechanism

Single ferrule fittings seal and grip with one ferrule, while double ferrule fittings use two ferrules for enhanced reliability.

You will notice that single ferrule fittings rely on a single ring to compress and create a seal. This simple design makes installation easy and works well for basic compression fitting needs. Double ferrule fittings, also known as dual-ferrule fittings, use a front ferrule to seal and a back ferrule to grip the tube. This separation of functions increases the fitting’s ability to resist vibration and thermal cycling.

- Single-ferrule fittings use one ferrule to grip the tubing and create a seal.

- Double ferrule fittings utilize two ferrules: one for gripping and one for sealing, which enhances reliability.

- Single-ferrule fittings are typically made from softer materials and are suitable for low-pressure applications.

- Dual-ferrule fittings are crafted from harder materials and provide a more robust and dependable connection.

Sunhy’s solution annealing process at 1040°C gives both types of fittings superior corrosion resistance. You get consistent sealing performance and long-lasting durability, even in harsh chemical or marine environments.

Installation Process

Single ferrule fittings install more easily, while double ferrule fittings require careful alignment for maximum safety.

You will find that single-ferrule fittings have fewer components, making them faster and simpler to install. Double ferrule fittings, or dual-ferrule fittings, need precise alignment of both ferrules. This extra step increases installation time but provides higher reliability in critical applications.

Here is a table comparing installation ease and application type:

| Type of Fitting | Installation Ease | Application Type |

|---|---|---|

| Single Ferrule | Easier to install | Low-pressure applications |

| Double Ferrule | More complex | High-pressure applications |

Sunhy’s stainless steel fittings feature uniform wall thickness and smooth surfaces. These qualities make installation easier and help you achieve a leak-proof connection, even when working with complex double ferrule fittings.

Tip: For high-pressure or safety-critical systems, choose double ferrule fittings from Sunhy for the best performance and reliability.

Performance and Reliability

Leak Prevention and Pressure Resistance

You get superior leak prevention and pressure resistance with double ferrule fittings, especially in demanding environments.

Double ferrule fittings use two rings to create a tight, metal-to-metal seal. This design helps you prevent leaks, even when your system faces high pressure. Single ferrule fittings also provide reliable sealing for basic needs, but double ferrule fittings excel in critical applications. Sunhy’s stainless steel fittings undergo solution annealing at 1040°C. This process restores the grain structure and boosts corrosion resistance, so your fittings maintain their integrity under pressure.

Tip: Choose double ferrule fittings for high-pressure systems where leak prevention is essential.

| Fitting Type | Leak Prevention | Pressure Resistance |

|---|---|---|

| Single-ferrule | Good | Moderate |

| Dual-ferrule | Excellent | High |

Vibration and Corrosion Resistance

Single ferrule and double ferrule fittings both resist vibration, but single-ferrule fittings may perform better in vibration-prone environments.

Compression fitting technology gives you strong vibration resistance. Research shows that single-ferrule fittings often handle vibration better than dual-ferrule fittings. Fretting fatigue of the front ferrule can cause sealing failure, especially in double ferrule fittings. When you work in environments with constant movement, single ferrule fittings may offer more reliability.

Corrosion resistance is vital for long-term performance. Studies note that dual-ferrule components are more likely to fail due to corrosion compared to single-ferrule fittings. Sunhy’s advanced manufacturing and solution annealing process ensure both single ferrule and double ferrule fittings have maximum corrosion resistance, even in chemical or marine settings.

Longevity and Maintenance

You experience longer service life and easier maintenance with Sunhy’s stainless steel fittings.

Single ferrule fittings require less maintenance because of their simple design. Double ferrule fittings need careful installation and regular checks, but they last longer in high-pressure systems. Sunhy uses cold mandrel forming and hydroforming to create fittings with uniform wall thickness. This reduces thinning and extends the lifespan of both single ferrule and double ferrule fittings.

- Single-ferrule fittings: Quick maintenance, fewer parts to inspect.

- Double ferrule fittings: Longer lifespan, ideal for tough conditions.

- Compression fitting: Both types offer easy disassembly and reassembly.

Note: Sunhy’s rigorous testing ensures every fitting meets strict safety and reliability standards.

Advantages and Disadvantages

Single Ferrule Fittings Pros and Cons

Single ferrule fittings offer quick installation and cost savings, but you may face limitations in high-pressure or high-vibration environments.

You can rely on single-ferrule fittings when you want a simple and efficient solution. These fittings work well for basic industrial needs. You will find them easy to install, and you do not need specialized tools. If you manage large projects, you can save money because single ferrule fittings are more economical than dual-ferrule options.

Here is a table that highlights the main advantages:

| Advantage | Description |

|---|---|

| Ease of Installation | You assemble fittings quickly without special tools. |

| Cost-Effectiveness | You reduce expenses, especially for large-scale installations. |

| Reliability | You achieve leak-free connections that stay stable under pressure and temperature changes. |

However, you should consider some drawbacks before choosing single-ferrule fittings. These fittings have lower grip strength compared to dual-ferrule fittings. You may notice that they do not perform as well in high-pressure, extreme temperature, or vibration-prone environments.

| Disadvantage | Description |

|---|---|

| Reduced Grip Strength | You get less grip, which can affect reliability in demanding situations. |

| Limited Application Suitability | You may experience loosening or failure in harsh conditions. |

Tip: Use single ferrule fittings for low-pressure systems where installation speed and cost matter most.

Double Ferrule Fittings Pros and Cons

Double ferrule fittings deliver superior sealing and grip, making them ideal for high-pressure and safety-critical applications.

You benefit from double ferrule fittings when you need extra protection against leaks and tube blowout. The dual-ferrule design separates sealing and gripping functions, so you get enhanced reliability. These fittings excel in environments with high pressure, vibration, or temperature changes.

Here are the main advantages you can expect:

- You achieve excellent leak prevention, even in demanding conditions.

- You get strong tube grip, which reduces the risk of loosening or failure.

- You can use double ferrule fittings in a wide range of industrial applications, including chemical processing and marine systems.

You should know that double ferrule fittings require more careful installation. You may spend more time aligning components, but you gain peace of mind in critical systems.

Note: Choose double ferrule fittings when your system faces high pressure, vibration, or safety requirements.

Single ferrule and double ferrule fittings each have strengths and weaknesses. You can select the best option by considering your system’s pressure, vibration, and reliability needs.

Applications of Single Ferrule and Double Ferrule Fittings

Industrial Use Cases

You will find single ferrule and double ferrule fittings in many industries, each serving specific needs.

Single ferrule fittings work best in low-pressure systems where cost and quick installation matter. Double ferrule fittings excel in high-pressure environments that demand extra safety and reliability. Sunhy’s stainless steel fittings offer durability and corrosion resistance, making them suitable for harsh conditions.

Common industry applications include:

- Oil and Gas: Double ferrule fittings handle extreme pressure and vibration. You use them for leak-free connections in pipelines and refineries.

- Chemical Processing: You rely on double ferrule fittings for strong seals against aggressive chemicals. Stainless steel, especially grade 316, resists corrosion from chloride salts.

- Water Treatment: Single ferrule fittings provide reliable connections in low-pressure water systems.

- Food and Beverage: Sunhy’s stainless steel fittings meet strict sterility standards. You use them in processing lines to prevent contamination.

- Pharmaceutical: You choose stainless steel fittings for sterile handling and compliance with regulations.

Tip: Sunhy’s solution-annealed stainless steel fittings offer long-lasting performance in environments that require strength, sterility, and heat resistance.

Choosing the Right Fitting for Your Needs

You should select the fitting type based on pressure, safety, and material compatibility.

Industry experts recommend that you assess your application before choosing a fitting. Double ferrule fittings suit high-pressure and safety-critical systems. Single ferrule fittings fit low-pressure applications where cost is important.

Key criteria for selection:

| Criteria | Recommendation |

|---|---|

| Pressure Level | Use double ferrule for high pressure |

| Assembly Reliability | Choose single ferrule for easier assembly |

| Safety Requirements | Select double ferrule for safety-critical systems |

| Material Compatibility | Ensure stainless steel matches transported fluids |

| Corrosive Environment | Use 316 stainless steel for maximum resistance |

- Stainless steel fittings are ideal when you need durability and sterility.

- You should use Sunhy’s fittings in food, beverage, and pharmaceutical industries to meet strict standards.

- For corrosive settings, grade 316 stainless steel provides a protective barrier and long service life.

Note: You improve system reliability and safety when you match the fitting type to your application’s demands.

How to Select the Best Fitting

Key Factors to Consider

You should focus on application needs, material compatibility, and installation requirements when selecting the best ferrule fitting.

You need to match the fitting type to your system’s pressure, environment, and reliability demands. The table below helps you compare the most important features between single ferrule and double ferrule fittings:

| Feature | Single Ferrule | Double Ferrule |

|---|---|---|

| Compression Mechanism | Asymmetrical compression | Symmetrical compression |

| Application Suitability | General applications | High-pressure applications |

| Design | Simpler design | More complex with two ferrules |

| Leakage Prevention | Moderate effectiveness | High effectiveness due to design |

| Material Compatibility | Suitable for various materials | Best for rigid materials like steel |

You should also consider the following factors before making your choice:

- Pressure Rating: Choose double ferrule fittings for high-pressure systems. Use single ferrule fittings for low-pressure or general use.

- Material Compatibility: Match the fitting material with the tubing and the fluid or gas. Stainless steel works well for most industrial applications.

- Environmental Conditions: Select fittings that resist corrosion if your system operates in humid or chemical-rich environments.

- Installation Complexity: Pick single ferrule fittings for quick and easy installation. Choose double ferrule fittings for extra safety and reliability.

- Industry Standards: Make sure the fittings meet relevant standards for your application, such as ASME or ASTM.

Tip: Always verify the outer diameter of your tubing to ensure a proper fit and prevent leaks.

Practical Tips for Selection

You can avoid common mistakes and improve system reliability by following best practices for ferrule fitting selection.

You should use these practical tips from industry professionals:

- Check Chemical Compatibility: Make sure the fitting material will not react with the fluid or gas. This prevents corrosion and contamination.

- Assess Environmental Conditions: Consider humidity, temperature, and exposure to corrosive substances. Stainless steel offers strong resistance.

- Match Materials: Use fittings and tubing made from compatible materials. This helps prevent galvanic corrosion and extends service life.

- Measure Accurately: Confirm the tubing’s outer diameter before selecting a fitting. Accurate sizing ensures a secure and leak-free connection.

- Review Pressure Ratings: Select fittings that meet or exceed your system’s pressure requirements.

- Follow Proper Installation Techniques: Insert the hose fully, align the ferrule correctly, and use the recommended crimping method.

You can see the most common mistakes and how to avoid them in the table below:

| Mistake Type | Description |

|---|---|

| Incorrect Ferrule Size | Using ferrules that are too large or too small can lead to leaks and system failures. |

| Improper Hose Insertion | Partial insertion or misalignment can create weak connections prone to failure. |

| Incorrect Crimping Technique | Over-crimping or under-crimping can damage the hose or lead to loose fits, causing leaks. |

| Neglecting to Deburr or Clean | Sharp edges or contaminants on the hose end can damage the ferrule and lead to weak connections. |

Note: You improve reliability and safety by following installation guidelines and double-checking measurements.

You should also stay updated on the latest trends in ferrule fitting selection. The table below highlights new developments in the industry:

| Trend | Description |

|---|---|

| Advancements in Material Science | New alloys and coatings improve corrosion resistance, reduce weight, and enhance performance. |

| Automation and Smart Assembly | IoT integration and smart tools enhance reliability and provide traceable installation records. |

| Sustainability and Compliance | Emphasis on recyclability, reduced carbon footprint, and eco-friendly materials in production. |

Tip: You can choose Sunhy’s stainless steel fittings for advanced corrosion resistance, easy installation, and compliance with industry standards.

By considering these factors and tips, you select the best fitting for your application and ensure long-term system performance.

Single ferrule fittings offer simple installation for low-pressure needs, while double ferrule fittings provide superior grip and sealing in high-pressure environments.

You improve safety and reliability when you match fitting type to your application. The table below highlights key differences:

| Feature | Single Ferrule | Double Ferrule |

|---|---|---|

| Installation | Simple | Complex |

| Grip/Seal | Moderate | Excellent |

Sunhy’s ISO-certified stainless steel fittings undergo strict verification and testing, ensuring dependable performance. You can consult Sunhy’s experts for tailored solutions in critical industries.

FAQ

What is the main difference between single ferrule and double ferrule fittings?

Single ferrule fittings use one ring for sealing and grip. Double ferrule fittings use two rings for extra sealing and grip.

You get easier installation with single ferrule. Double ferrule fittings offer better leak prevention in high-pressure systems.

When should you choose double ferrule fittings?

Choose double ferrule fittings for high-pressure, safety-critical, or vibration-prone environments.

You benefit from stronger seals and improved reliability. These fittings work best in oil, gas, chemical, and marine industries.

Are Sunhy’s stainless steel fittings suitable for corrosive environments?

Yes, Sunhy’s stainless steel fittings resist corrosion in harsh chemical and marine settings.

You get maximum durability due to advanced solution annealing and high-quality materials like ASTM A403 WP316L/304L.

How do you ensure a leak-proof connection?

You ensure a leak-proof connection by selecting the right fitting size and following proper installation steps.

You should measure tubing accurately, align ferrules correctly, and use recommended tightening techniques.

Can you reuse ferrule fittings after disassembly?

You can reuse ferrule fittings if the ferrules and tubing remain undamaged.

You should inspect all parts for wear or deformation before reassembly to maintain safety and reliability.