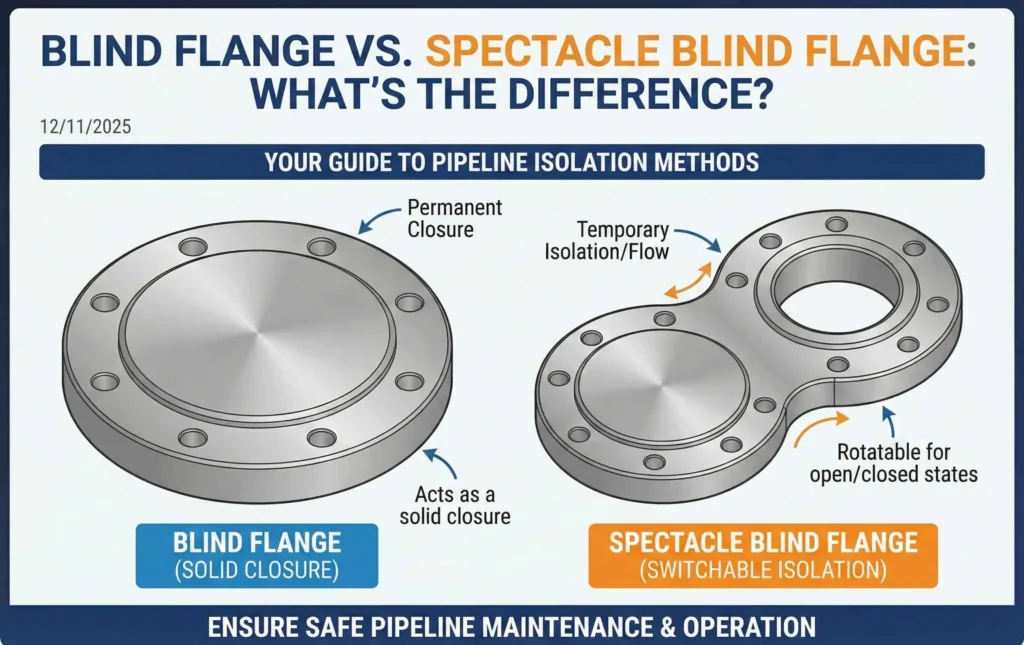

The main difference between a blind flange and a Spectacle Blind Flange lies in their structure and how they isolate pipelines. A blind flange acts as a solid closure, while a Spectacle Blind Flange allows operators to switch between open and closed positions without full disassembly. Choosing the right flange type is critical for safety, efficiency, and maintenance in industrial systems. Sunhy provides both solutions within its stainless steel flange range, supporting industries such as:

- Oil and gas: Secure connections in pipelines and processing facilities

- Chemical processing: Leak-proof joints for hazardous chemicals

- Power generation: High-pressure and high-temperature environments

- Water treatment: Robust piping for water management

| Feature | Spectacle Blind | Spade (Line Blank) |

|---|---|---|

| Structure | Two discs joined by a bridge | Single solid plate with handle |

| Isolation Function | Rotates between positions | Must be removed and replaced |

| Use Case | Frequent or semi-permanent isolation | Infrequent or heavy systems |

| Installation | Remains in-line, rotates | Needs disassembly and reassembly |

| Ideal for | Small to medium pipelines | Large or high-pressure pipelines |

Operators should always consider the system’s operational needs and safety requirements before making a selection.

Blind Flange Overview

What Is a Blind Flange?

A blind flange is a solid, single-piece plate used to seal the end of a pipe or nozzle.

This type of flange does not have a center opening. It blocks off the flow in a piping system, providing a reliable closure. Unlike other flanges that connect pipes or valves, a blind flange isolates sections for maintenance, pressure testing, or future expansion.

| Feature | Blind Flange | Other Flanges |

|---|---|---|

| Design | Solid plate, no bore | Opening for connections |

| Function | Seals pipe end | Joins pipes or valves |

| Applications | Isolation, maintenance, pressure testing | Connecting piping sections |

Sunhy manufactures stainless steel blind flanges from dual-certified 316/316L forgings. These flanges offer high strength and corrosion resistance, making them ideal for demanding environments.

Function and Use Cases

A blind flange provides a permanent or temporary closure for pipelines.

Operators use it to stop flow during repairs, isolate sections for safety, or pressure test a system. The solid design ensures leak-free performance, even under high pressure. Sunhy’s blind flanges meet strict ASTM A182 forging standards, ensuring durability and integrity.

Common use cases include:

- Isolating pipeline sections for maintenance

- Sealing off unused nozzles on pressure vessels

- Pressure testing new or repaired systems

The following table shows standard material grades and pressure ratings:

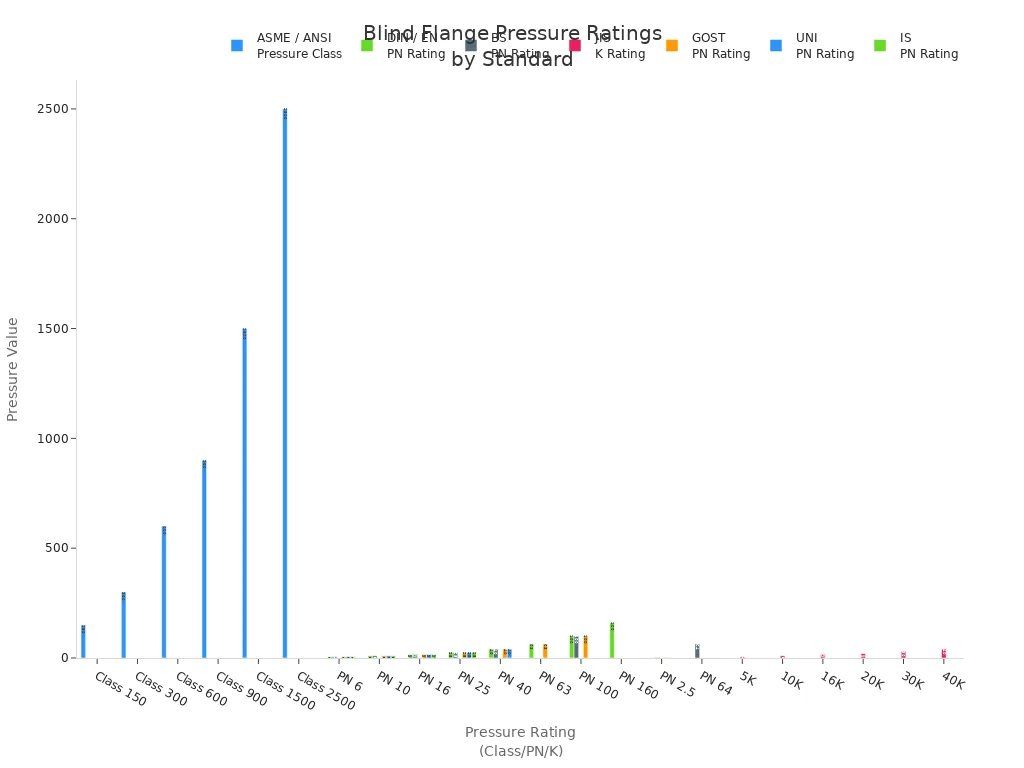

| Standard | Code / Designation | Size Range | Pressure Class / PN | Face Types |

|---|---|---|---|---|

| ASME / ANSI (USA) | BLRF / BLRTJ | ½″ – 24″, 26″ – 60″ | Class 150, 300, 600, 900, 1500, 2500 | RF, RTJ, FF, T&G, M&F |

| DIN / EN (Europe) | DIN 2527 | DN 10 – DN 2000 | PN 6, 10, 16, 25, 40, 63, 100, 160 | RF, FF, T&G, RTJ |

| JIS (Japan) | JIS B2220 | 10A – 1500A | 5K, 10K, 16K, 20K, 30K, 40K | FF, RF |

Typical Applications

Blind flanges are essential in many industries that require secure, leak-proof pipe closures.

Sunhy’s stainless steel blind flanges perform well in high-pressure and high-temperature systems. They are common in:

- Oil and gas pipelines

- Chemical processing plants

- Power generation facilities

- Water treatment systems

- Marine and shipbuilding

| Industry | Application Description |

|---|---|

| Oil and Gas | Secures pipelines under high pressure, prevents leaks, and allows safe maintenance. |

| Marine | Connects pipes in vessels and offshore platforms, resists corrosion. |

| Chemical Processing | Handles high-pressure, high-temperature pipelines in chemical plants. |

| Power Generation | Secures gas and water lines, prevents leakage of gas, water, or steam. |

| Agriculture | Connects hoses or pipes for fertilizers, pesticides, and irrigation. |

Blind flanges cover a wide range of sizes (1/2″ to 60″) and pressure classes (ANSI Class 150 to 2500). They withstand temperatures from -196°C to 650°C. For systems that need frequent switching between open and closed positions, a spectacle blind flange may be more suitable.

Tip: Sunhy’s precision machining and rigorous testing ensure every blind flange delivers reliable, leak-free service in critical environments.

Spectacle Blind Flange Overview

What Is a Spectacle Blind Flange?

A spectacle blind flange is a two-part device used for pipeline isolation and flow control.

This flange consists of two metal disks connected by a small bridge. One disk is solid and blocks the pipe, while the other has a hole that matches the pipe’s diameter. Operators rotate the spectacle blind so that either the solid disk or the open disk aligns with the pipeline. This design allows for quick switching between blocking and allowing flow.

- The solid disk provides complete isolation.

- The open disk allows material to pass through the pipeline.

- The connecting bridge keeps both disks together and ensures easy rotation.

Sunhy manufactures spectacle blind flanges with high-quality stainless steel. Each flange meets ASTM A182 and international standards, ensuring durability and safety in demanding environments.

Function and Use Cases

Spectacle blinds offer operational flexibility and visual confirmation of pipeline status.

Operators can see which disk is in use, making it easy to verify if the line is open or closed. The spectacle blind design allows for fast switching without removing the flange from the system. This feature reduces downtime during maintenance and improves safety.

| Benefit | Description |

|---|---|

| Safety | Prevents leaks, especially in hazardous pipelines. |

| Convenient Maintenance | Allows repairs without removing the entire flange. |

| Cost-Effective Solution | Reduces long-term repair costs with minimal maintenance. |

| Reduces Equipment Damage | Lowers the risk of leaks and equipment damage. |

| Versatility | Handles various fluids and gases, including corrosive materials. |

Sunhy’s spectacle blind flanges undergo strict testing and quality checks. Each product offers reliable performance and traceability for critical operations.

Typical Applications

Spectacle blinds are common in industries that require frequent pipeline isolation and visual verification.

These flanges work well in systems that need regular maintenance or testing.

| Industry | Typical Service Conditions |

|---|---|

| Oil and gas industry | Frequent isolation for maintenance, testing, and repairs to prevent leaks. |

| Chemical and petrochemical | Handles corrosive chemicals and prevents leaks. |

| Power generation | Isolates and seals to prevent hot steam or water leakage. |

| Pharmaceutical industries | Maintains sterile conditions during repairs and cleaning. |

| Marine and ship building | Seals vessels containing fuel, water, and other fluids. |

| Water treatment plants | Isolates piping for replacement, maintenance, and testing. |

Tip: Sunhy’s spectacle blind flanges combine operational flexibility with robust construction, making them ideal for critical and maintenance-heavy environments.

Blind Flange vs. Spectacle Blind Flange Comparison

Design and Structure

The key difference in design is that a blind flange is a solid disc, while a spectacle blind flange has two connected discs for switching between open and closed positions.

A blind flange features a circular plate without a central opening. It seals the end of a pipe or vessel. The spectacle blind flange consists of two discs joined by a bridge—one solid and one with a hole. Operators rotate the spectacle blind flange to select either isolation or flow.

| Feature | Spectacle Blind Flange | Blind Flange |

|---|---|---|

| Structure | One side closed, one side open, joined bridge | Solid disc, no hub or bore |

| Function | Isolates or opens line for inspection/maintenance | Blanks off end of pipe or vessel |

| Visual Confirmation | Shows open/closed status visually | No visual indication, acts as plug/cap |

Sunhy uses precision machining for both types, ensuring tight tolerances and reliable performance.

Operation and Switching

Blind flanges require removal for switching, while spectacle blind flanges rotate in place for quick changes.

Operators must unbolt and remove a blind flange to restore flow or access the pipe. This process takes time and may require special tools. The spectacle blind flange allows users to rotate the device, switching between the solid and open disc without removing the flange from the line. This design provides faster operation and clear visual confirmation of the pipeline’s status.

- Blind flange: Removal and reinstallation needed for switching.

- Spectacle blind flange: Simple rotation for open/closed positions.

Sunhy’s spectacle blind flanges offer easy switching, reducing downtime during maintenance.

Installation and Maintenance

Blind flanges need careful installation and regular checks for leaks, while spectacle blind flanges require alignment and less frequent maintenance.

Proper installation of a blind flange involves positioning, gasket selection, and bolt tightening. Safety steps, such as easing pressure before removal, are important in high-pressure systems. Maintenance includes regular inspections for leaks and integrity under pressure.

Spectacle blind flanges need clear marking of open and closed positions. Correct alignment during setup prevents strain on the piping system. Maintenance is less frequent due to the design, but checks for alignment and functionality remain necessary.

| Flange Type | Installation Procedures | Maintenance Requirements |

|---|---|---|

| Blind Flange | Positioning, gasket choice, bolt tightening, safety steps | Regular leak and integrity checks |

| Spectacle Blind Flange | Mark positions, align properly, secure bridge | Less frequent, check alignment and function |

Sunhy’s rigorous testing and quality assurance ensure both flange types meet industry standards for safety and reliability.

Space, Weight, and Handling

Blind flanges are compact and lighter, while spectacle blind flanges are larger and heavier due to their dual-disc design.

A blind flange’s simple structure makes it easier to handle and install, especially in tight spaces. The spectacle blind flange, with its two discs and bridge, takes up more space and weighs more. This difference affects handling and may require additional support or lifting equipment for larger sizes.

- Blind flange: Compact, easier to maneuver.

- Spectacle blind flange: Bulkier, may need extra handling equipment.

Sunhy offers both types in a range of sizes, with options for custom dimensions to fit specific space requirements.

Cost Factors

Blind flanges generally cost less than spectacle blind flanges due to simpler design and lower material use.

The blind flange’s single-piece construction reduces manufacturing costs and simplifies installation. The spectacle blind flange, with its dual-disc and bridge, requires more material and machining, resulting in higher costs. However, the operational flexibility and reduced downtime may offset the initial investment in maintenance-heavy systems.

| Flange Type | Cost Considerations |

|---|---|

| Blind Flange | Lower cost, simple design, less material |

| Spectacle Blind Flange | Higher cost, complex design, more material |

Sunhy’s advanced CNC machining and solution annealing process deliver high-quality flanges with excellent value for both types.

Note: Choosing between a blind flange and a spectacle blind flange depends on the system’s need for isolation, maintenance frequency, available space, and budget. Sunhy’s expertise ensures each flange meets strict quality standards for safety and performance.

Pros and Cons of Each Type

Blind Flange Advantages & Disadvantages

Blind flanges offer strong leak prevention and safety but may limit access and require careful installation.

Advantages

- Blind flanges create a secure seal that prevents leaks in pipelines.

- They ensure safety during pressure testing and maintenance by blocking hazardous substances.

- These flanges reduce the risk of accidents and environmental damage by providing a reliable closure.

- They withstand high pressures and temperatures, which ensures safety and efficiency in pipeline systems.

Disadvantages

| Disadvantage | Description |

|---|---|

| Limited Accessibility | After installation, they make it difficult to access that segment of the piping system. |

| Potential for Leakage | Leaking may occur if bolts are improperly fixed, undermining the isolation purpose. |

| Cost | Costs can arise from frequent installation and maintenance, requiring more spending over time. |

| Space Limitations | Often found in congested areas, requiring careful planning for integration into pipe designs. |

Tip: Regular inspection and proper installation help maintain the safety and performance of a blind flange.

Spectacle Blind Flange Advantages & Disadvantages

A spectacle blind flange provides flexible isolation and visual confirmation but requires more space and may add weight.

Advantages

- This flange provides an extra layer of security at equipment inlets and outlets.

- It prevents accidental passage of hot or pressurized fluids during servicing.

- The design allows for permanent shut-off of auxiliary pipelines until needed, which improves operational efficiency.

- Operators can isolate pipeline sections safely for maintenance, inspection, or repair.

- The flange rotates easily to open or close the pipeline, which increases versatility.

- It prevents foreign materials from entering the pipeline during maintenance.

- The flange ensures secure isolation, especially in high-risk scenarios with flammable or toxic fluids.

- It allows for temporary or permanent closure of pipelines without disrupting fluid flow.

- Quick changes in pipeline configuration save time during maintenance.

- The design reduces the need for expensive shutdowns and extensive disassembly.

Disadvantages

- The dual-disc structure makes the flange heavier and bulkier than a blind flange.

- More space is needed for installation and operation.

- Handling and alignment may require extra care, especially in large-diameter systems.

Note: A spectacle blind flange works best in systems that need frequent isolation and visual status checks.

Blind Flange vs. Spectacle Blind Selection Guide

Application Criteria

Choose a blind flange for permanent or infrequent isolation; select a spectacle blind flange for frequent switching and visual status checks.

Selecting the right pipeline isolation solution depends on several factors:

- Review the pipeline’s size, pressure, and temperature requirements.

- Match the flange material to the fluid type for compatibility and corrosion resistance.

- Use a blind flange for systems that need secure sealing and minimal access.

- Choose a spectacle blind flange when operators need to switch between open and closed positions often.

Sunhy offers both standard and custom flanges, ensuring a precise fit for any application.

Safety and Maintenance

Both flange types must meet safety standards and require regular maintenance for reliable operation.

Safety and maintenance considerations include:

| Safety Factor | Description |

|---|---|

| Material Compatibility | Select materials that resist corrosion and match the fluid in the system. |

| Size and Fit | Ensure the flange fits the pipe to prevent leaks. |

| Pressure and Temperature | Confirm the flange can handle system pressure and temperature. |

Routine maintenance tasks:

- Inspect flanges for wear, corrosion, or leaks.

- Clean surfaces to prevent buildup.

- Lubricate bolts to ease future maintenance.

- Monitor system pressure to avoid overloading the flange.

Sunhy’s flanges comply with ASME, ISO, and EN standards, providing full traceability and peace of mind.

Cost and Practicality

Blind flanges cost less and suit simple closures; spectacle blind flanges cost more but offer operational flexibility.

Key cost factors include:

| Cost Factor | Impact on Selection |

|---|---|

| Material | Stainless steel and alloys increase durability and price. |

| Size | Larger flanges require more material and higher costs. |

| Pressure Rating | Higher ratings demand thicker, more expensive flanges. |

| Manufacturing | Forged flanges offer better integrity than cast, affecting cost. |

Sunhy’s advanced manufacturing ensures high-quality flanges at competitive prices. Each product meets strict industry standards and comes with complete documentation for traceability.

Tip: Consult with Sunhy’s technical team to select the best flange for your project’s safety, maintenance, and budget needs.

The main difference:

A blind flange seals the end of a pipe, while a spectacle blind flange allows for easy switching and visual status checks.

| Feature | Blind Flange | Spectacle Blind Flange |

|---|---|---|

| Design | Solid, no opening | Two discs, one solid, one open, joined by a bridge |

| Functionality | Closes pipe ends | Rotates for flow control and visual confirmation |

| Application | Permanent or infrequent isolation | Frequent isolation and status checks |

Quick selection checklist:

- Choose material and size for your system.

- Confirm compliance with standards.

- Check pressure and temperature ratings.

- Inspect for quality and certifications.

Sunhy provides expert support, strict quality control, and full documentation for every project.

FAQ

What is the main difference between a blind flange and a spectacle blind flange?

A blind flange seals the pipe end; a spectacle blind flange allows switching between open and closed.

A blind flange blocks flow completely. A spectacle blind flange has two discs—one solid, one open—connected by a bridge. Operators rotate it to control flow.

When should operators choose a spectacle blind flange over a blind flange?

Choose a spectacle blind flange for frequent isolation and visual status checks.

Spectacle blind flanges work best in systems needing regular maintenance or inspection. They allow quick switching and clear visual confirmation of pipeline status.

Are Sunhy’s stainless steel flanges suitable for high-pressure applications?

Yes, Sunhy’s stainless steel flanges handle high-pressure environments.

Sunhy manufactures flanges from dual-certified 316/316L forgings. These flanges meet ASTM A182 standards and perform reliably in critical, high-pressure systems.

How do operators maintain blind and spectacle blind flanges?

Operators inspect, clean, and check alignment regularly.

Maintenance includes visual inspections for leaks or corrosion, cleaning surfaces, and ensuring bolts remain tight. For spectacle blinds, operators also verify correct alignment and rotation.

What standards do Sunhy’s flanges meet?

Sunhy’s flanges comply with ASME, ISO, and EN standards.

Each flange undergoes strict testing and comes with full traceability. Sunhy ensures products meet international requirements for safety and quality.