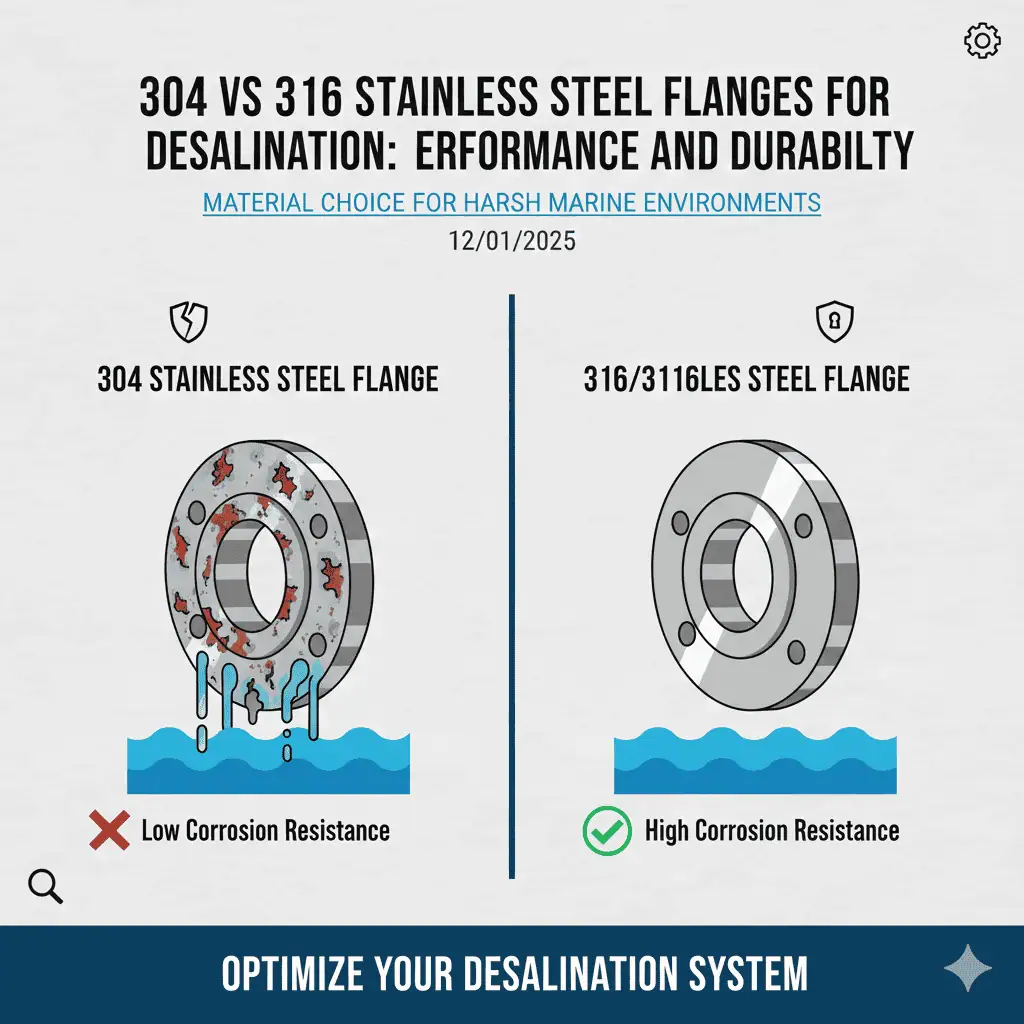

You should always choose 316 stainless steel flanges, especially dual-certified 316/316L, over 304 and 316 stainless steel flanges for seawater desalination because they offer much greater corrosion resistance. In harsh marine environments, selecting the right flange material protects your system from early failure and reduces long-term costs. The table below highlights the difference in performance between 304 vs 316/316L stainless steel flanges in marine settings:

| Stainless Steel Type | Corrosion Resistance | Lifespan in Marine Environments |

|---|---|---|

| 304 | Moderate | Shorter |

| 316/316L | High | Longer |

You benefit from the added molybdenum in 316, which helps prevent pitting and corrosion caused by saltwater exposure.

304 vs 316 Stainless Steel Flanges: Composition

Alloying Elements and Differences

304 vs 316 stainless steel flanges differ mainly in their alloying elements, which directly impact their performance in marine environments.

You will notice that both alloys contain chromium and nickel, but only 316 stainless steel includes molybdenum. This addition makes a significant difference in how each alloy performs under harsh conditions. Here is a comparison of their typical chemical compositions:

| Alloy Type | Chromium (%) | Nickel (%) | Molybdenum (%) |

|---|---|---|---|

| 304 | 18-20 | 8-10.5 | Trace |

| 316 | 16-18 | 10-14 | 2-3 |

- 304 stainless steel contains more chromium but lacks molybdenum.

- 316 stainless steel includes 2-3% molybdenum, which is essential for better performance in corrosive environments.

- The higher nickel content in 316 also improves its overall durability.

You will find that 304 stainless steel works well for general industrial use, but it does not offer the same level of protection in chloride-rich settings as 316 stainless steel.

Impact of Molybdenum on Corrosion Resistance

The presence of molybdenum in 316 stainless steel greatly improves its corrosion resistance, especially in environments with high chloride levels.

- Molybdenum helps prevent pitting and crevice corrosion, which are common problems in seawater and desalination systems.

- You can rely on 316 stainless steel flanges for long-term durability in marine and chemical processing applications.

- 304 stainless steel, while cost-effective, is more vulnerable to corrosion in these harsh conditions.

Tip: For any application exposed to seawater or brine, always select 316 stainless steel flanges to ensure the best protection and lifespan.

You will see that the addition of molybdenum is the key factor that makes 316 stainless steel the preferred choice for desalination and other demanding marine uses.

Corrosion Resistance in Desalination

Corrosion Mechanisms in Seawater

Corrosion in seawater desalination systems is driven by aggressive chloride ions, which attack stainless steel flanges through several mechanisms.

You encounter three main types of corrosion in marine environments:

- Crevice corrosion: Stagnant fluid trapped in flange joints accelerates localized attack.

- Chloride-induced pitting: Chloride ions penetrate the passive layer, causing small but deep pits.

- Stress corrosion cracking (SCC): High tensile stress combined with chlorides leads to cracking.

| Corrosion Mechanism | Description |

|---|---|

| Pitting Corrosion | Localized attack caused by breakdown of the passive oxide film, accelerated by chloride ions. |

| Crevice Corrosion | Occurs in stagnant micro-environments such as flange joints, leading to aggressive localized attack. |

| Stress Corrosion Cracking | Cracking due to simultaneous tensile stress and corrosive environment, especially in chloride-rich conditions. |

Note: Galvanic corrosion can also occur if you use dissimilar metals in your piping system.

304 Flanges: Performance in Saline Environments

304 stainless steel flanges offer moderate corrosion resistance but are not recommended for continuous exposure to seawater.

You will notice that 304 stainless steel is vulnerable to chloride attack. Pitting and crevice corrosion develop quickly in saline environments. The lack of molybdenum in 304 stainless steel reduces its pitting resistance, making it less suitable for desalination plants.

- 304 stainless steel flanges may perform well in less aggressive environments.

- In seawater, you face a higher risk of rapid corrosion and early flange failure.

- Maintenance costs increase due to frequent inspections and replacements.

316/316L Flanges: Superior Durability

316 stainless steel flanges, especially dual-certified 316/316L, deliver high corrosion resistance and long-term durability in desalination systems.

You benefit from the added molybdenum in 316 stainless steel, which boosts chloride corrosion resistance and pitting resistance. Dual-certified 316/316L flanges from Sunhy undergo rigorous solution annealing and precision machining, ensuring optimal performance in harsh marine conditions.

- 316 stainless steel flanges maintain integrity in constant saltwater exposure.

- Dual-certified 316/316L flanges provide versatility for welded structures and high-strength marine fittings.

- Even in high-chloride brine, 316/316L outperforms 304 stainless steel, though some corrosion may still occur over time.

| Material Type | Corrosion Resistance | Applications in Marine Environments |

|---|---|---|

| 304 | Moderate | General industrial use |

| 316 | High | Marine, chemical, and desalination |

| 316L | Superior | Welded pipe networks, pump impellers |

| Dual 316/316L | High | Versatile seawater applications |

Tip: Always select 316 stainless steel flanges for desalination to maximize system lifespan and minimize maintenance.

Real-World Data and Case Studies

Field studies confirm that 316/316L stainless steel flanges outperform 304 in seawater desalination plants.

You see that 316L stainless steel is widely used for pump impellers, acid transfer mechanisms, and subsea housing structures. In coastal piping and building materials, dual-certified 316/316L flanges provide reliable service and extended life. Academic research shows that while 316L can experience crevice corrosion and biofouling, its corrosion resistance remains superior to 304 stainless steel.

- 316 stainless steel flanges are reliable in marine and chemical environments.

- Chloride ions degrade the passive film on 316L, but the alloy’s molybdenum content slows pitting and stress cracking.

- In applications with constant saltwater exposure, 316 stainless steel maintains its integrity better than 304.

You protect your investment and reduce downtime by choosing flanges with proven pitting resistance and chloride corrosion resistance.

Cost and Value Comparison

Initial and Lifecycle Costs

316 stainless steel flanges cost more upfront, but you save money over the life of your desalination system.

- 316 stainless steel is usually 20–25% more expensive than 304 stainless steel because of its molybdenum content and higher corrosion resistance.

- This higher initial cost is important for desalination projects, where harsh conditions demand better materials.

- The extra investment in 316 stainless steel often leads to lower total costs over time.

| Factor | 304 Stainless Steel | 316 Stainless Steel |

|---|---|---|

| Initial Material Cost | Lower | Higher |

| Lifecycle Savings | Less | More |

Tip: You may pay more at first for 316 stainless steel, but you avoid frequent repairs and replacements.

Maintenance and Replacement Factors

You spend less on maintenance and replacement when you choose 316 stainless steel flanges.

- 304 and 316 stainless steel flanges both resist corrosion, but 316 stainless steel performs much better in marine environments.

- 304 stainless steel needs more frequent inspections and repairs due to faster corrosion.

- 316 stainless steel flanges last longer and require fewer replacements, which reduces downtime and labor costs.

| Factor | 304 Stainless Steel | 316 Stainless Steel |

|---|---|---|

| Maintenance Frequency | High | Low |

| Replacement Rate | High | Low |

| Downtime | More | Less |

Note: Lower maintenance means your system runs smoothly and you avoid unexpected shutdowns.

Long-Term Value in Desalination

316 stainless steel flanges deliver the best long-term value for desalination facilities.

| Benefit | Description |

|---|---|

| Corrosion Resistance | 316 stainless steel flanges resist corrosion in salty environments. |

| High Pressure Resistance | They handle the high pressures found in desalination systems. |

| Reduced Maintenance Costs | Their durability means you spend less on upkeep. |

| Extended Service Life | You get a longer operational lifespan, which protects your investment. |

You gain peace of mind by choosing 316 stainless steel for your desalination project. The material’s superior corrosion resistance and strength ensure reliable performance, lower costs, and longer service life compared to 304 vs 316 stainless steel flanges.

Practical Selection for Marine Applications

Installation and Compatibility

You must ensure proper installation and compatibility to achieve reliable performance in marine applications.

When you install 304 vs 316 stainless steel flanges in marine conditions, you face several challenges:

- Alignment Issues: You need to align the flange and pipe correctly. Poor alignment causes uneven pressure on the gasket and leads to leaks.

- Surface Cleanliness: You should clean the flange surface before installation. Dirt or debris can compromise the gasket seal and increase leak risk.

- Material Selection: You must choose the right grade. 316 stainless steel provides better pitting resistance and saltwater corrosion protection than 304 in marine applications.

Tip: Always inspect the flange and gasket surfaces before installation. This step helps you avoid leaks and extends the service life of your system.

Industry Standards and Certifications

You should select flanges that meet international standards for marine applications.

The following table shows key standards for stainless steel flanges in desalination and marine conditions:

| Standard | Application Area | Key Features |

|---|---|---|

| ASME B16.5 | Water Treatment and Desalination | Corrosion resistance and cost efficiency |

| ASME B16.47 | Marine and Offshore | Resistance to chloride-induced corrosion |

You ensure safety and reliability by choosing flanges that comply with these standards. Sunhy’s flanges meet ASTM A182, ASME B16.5, and ASME B16.47 requirements, giving you confidence in demanding marine applications.

Why Choose Sunhy Stainless Steel Flanges

You gain superior performance and peace of mind when you choose Sunhy stainless steel flanges for marine applications.

Sunhy manufactures flanges from SS316/L and SS304/L, following ASTM A182 specifications. You benefit from advanced CNC machining, which delivers precise measurements and tight tolerances. Sunhy performs rigorous quality assurance inspections to maintain dimensional accuracy and material integrity. You can select from a wide product range, including custom solutions for unique marine conditions. Sunhy’s commitment to quality and compliance ensures your flanges deliver excellent pitting resistance and long-term durability in saltwater corrosion environments.

Note: Sunhy’s support team helps you select the best flange for your marine applications, ensuring compatibility and reliability.

You should always choose 316/316L stainless steel flanges for seawater desalination because they deliver superior corrosion resistance and long-term value. Recent studies show that duplex grades outperform 304 and 316 stainless steel flanges in high-chloride zones, but 316/316L remains the industry standard for most marine applications.

| Support Service | Benefit |

|---|---|

| Timely Service | Reliable delivery and fair pricing |

| Engineering Specs | Meets top engineering standards |

| Customer Service | Expert guidance for your project needs |

Contact Sunhy’s support team for tailored flange solutions that meet your technical and operational requirements.

FAQ

What is the main difference between 304 vs 316 stainless steel flanges?

316 stainless steel flanges contain molybdenum, which gives you better resistance to corrosion from saltwater.

- 304 works for general use.

- 316 is best for marine and desalination systems.

Why should you choose dual-certified 316/316L flanges for desalination?

Dual-certified 316/316L flanges offer both high strength and excellent weldability.

- You get superior corrosion resistance.

- You meet strict industry standards for marine applications.

How do Sunhy flanges ensure long-term durability?

Sunhy flanges use 100% forged, dual-certified 316/316L stainless steel and strict quality control.

- Precision CNC machining

- Solution annealing at 1040°C

- Full traceability and compliance with ASTM and ASME standards

Can you use 304 stainless steel flanges in seawater applications?

You should avoid 304 stainless steel flanges in seawater because they corrode quickly.

- 316/316L flanges last longer.

- You reduce maintenance and replacement costs.