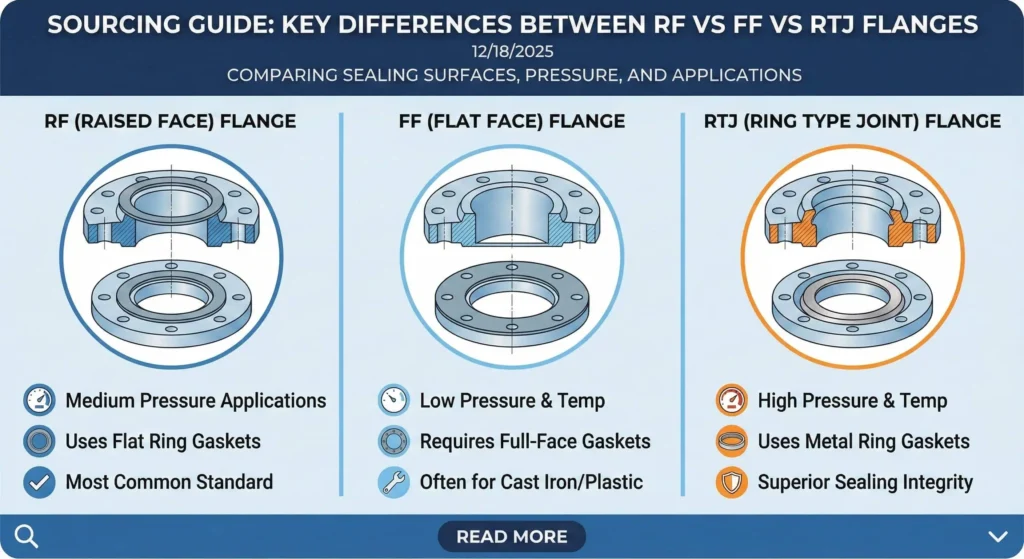

The key differences between RF, FF, and RTJ flanges lie in their sealing surface design, pressure handling, and application suitability.

Choosing the right flange face type impacts leakage rates and system reliability. The structural features, such as raised or flat faces and ring-type joints, directly affect sealing performance. Industry studies show that precise bolting and material selection reduce gasket failure and fluid leakage, especially in high-pressure systems.

SUNHY delivers precision fluid control solutions for critical applications, ensuring zero-leakage performance and compliance with global standards.

Selecting between RF vs FF vs RTJ flanges requires careful consideration of operating pressure, material compatibility, and sealing needs.

Flange Face Types Overview

What Are RF, FF, and RTJ Flanges?

RF, FF, and RTJ flanges represent the most common flange face types used in industrial piping systems. Each type features a unique sealing surface that determines its suitability for specific applications.

- Flat Face (FF) Flanges

- Raised Face (RF) Flanges

- Ring-Type Joint (RTJ) Flanges

Engineers also encounter other flange face types, such as Tongue and Groove (TG) and Male and Female Face (MFM), but RF, FF, and RTJ remain the industry standards for most fluid control systems.

The table below summarizes the defining characteristics and typical applications for these three flange face types:

| Flange Type | Characteristics | Applications |

|---|---|---|

| Flat Face (FF) | Uses non-metallic gaskets, serrated sealing surface, ideal for low-pressure systems, resists mechanical distortion | Pressure classes 125 and 250 |

| Raised Face (RF) | Circular sealing face, available in all pressure classes, uses serrated surfaces with non-metallic or semi-metallic gaskets | Chemical engineering, oil & gas |

| Ring Type Joint (RTJ) | Uses metal gaskets, designed for high pressure and temperature, provides metal-to-metal seal | Class 900 and above |

Why Face Type Matters for Sealing and Reliability

The choice of flange face types directly impacts sealing effectiveness and system reliability. Each face type interacts with gaskets and bolting forces in a specific way, influencing the risk of leakage and the ability to withstand pressure cycles.

- RF flanges offer versatility and suit a wide range of pressures.

- FF flanges provide stability in low-pressure environments and minimize the risk of flange bending.

- RTJ flanges deliver superior sealing in high-pressure, high-temperature services by creating a metal-to-metal seal.

Selecting the correct flange face types ensures optimal gasket compression, reduces maintenance needs, and supports long-term leak prevention. Engineers must match the flange face types to the system’s pressure class, media, and operational demands to achieve reliable performance.

RF Flange Features

RF Design and Sealing Principle

RF flanges use a raised face to concentrate gasket compression, delivering reliable sealing integrity in a wide range of piping systems. This type features a small raised surface around the bore, which increases pressure on the gasket during bolting. The design allows for effective sealing with both non-metallic and semi-metallic gaskets. Most rf flanges are manufactured from materials such as:

- Carbon steel (ASTM A105, ASTM A350 LF2, ASTM A694)

- Stainless steel (ASTM A182 grades 304, 304L, 316, 316L, duplex)

- Alloy steels (ASTM A182 F11, F22, F91)

- Specialty alloys (nickel, copper alloys)

Carbon steel provides high strength, while stainless steel offers corrosion resistance for aggressive media. Alloy steels enhance performance in demanding environments. This type supports a broad range of pressure classes, making it a versatile choice for many fluid control applications.

Typical RF Flange Applications

RF flanges serve as the industry standard for moderate to high pressure and temperature service. Their adaptability makes them suitable for many sectors. The table below highlights common industries and their use of this type:

| Industry | Application Description |

|---|---|

| Oil and Gas | Pressure containment in offshore drilling and onshore refineries |

| Petrochemical Processing | Secure seals and reliable fluid management in chemical processes |

| Water Treatment | Effective fluid control in treatment facilities, maintaining system integrity |

Engineers specify this type for pipelines, process equipment, and critical fluid transfer systems. The rf vs ff vs rtj selection often depends on the required sealing integrity and the operating environment.

RF Flange Pros and Cons

RF flanges offer a balance of cost, ease of installation, and reliable performance. The table below summarizes their main advantages and disadvantages compared to other types:

| Aspect | RF Flanges | RTJ Flanges |

|---|---|---|

| Price | Generally lower than RTJ flanges | Higher than RF flanges |

| Pressure and Temperature | Suitable for low to medium pressure and temperature | Designed for high pressure and temperature conditions |

| Installation | Easier installation | Requires precise alignment for reliable sealing |

| Application | Used in chemical, oil and gas, and water industries | More suitable for extreme conditions |

This type remains popular due to its straightforward installation and compatibility with a wide range of gaskets. It handles high pressure and high temperature service in most industrial applications, making it a preferred option for many engineers.

FF Flange Features

FF Design and Sealing Principle

FF flanges feature a flat, smooth sealing surface that provides stable gasket support and minimizes bending under bolt load. This type does not have a raised face. The gasket sits flush with the flange surface, which helps distribute compressive force evenly. Engineers often select this type when they need to prevent flange warping, especially with brittle materials like cast iron or non-metallic piping. FF flanges rely on non-metallic gaskets to achieve sealing integrity in low-pressure and moderate temperature systems.

Common materials used in FF flange manufacturing include:

- Low Alloy Carbon Steel: High tensile strength and weldability for general piping.

- Low-Carbon Nickel-Chromium-Molybdenum: Corrosion resistance for chemical and offshore service.

- Ferritic-Austenitic Stainless Steels: Strength and corrosion resistance for aggressive chemicals.

- Austenitic Stainless Steel: Durability for chemical and food-grade systems.

- Aluminum Alloys: Lightweight for aerospace and transport.

- Brass: Malleable and antimicrobial for plumbing.

- Bronze: Toughness for marine use.

- Nickel Alloys: Strength for high temperature and chemical plants.

- Titanium Alloys: Biocompatibility for medical and aerospace.

- Magnesium Alloys: Ultra-lightweight for aerospace components.

Typical FF Flange Applications

FF flanges are ideal for low-pressure, low-temperature, and non-metallic piping systems. This type appears in many industries where system pressure remains moderate and flange bending must be avoided. The table below shows common industries and their applications for FF flanges:

| Industry | Applications |

|---|---|

| Water Treatment | Lower temperature and pressure piping, potable and wastewater systems |

| HVAC & Plumbing | Chilled water, heating loops, plumbing with cast iron equipment |

| Fire Protection Systems | Sprinkler and hydrant connections for reliable low-pressure sealing |

| Marine & Corrosive Environments | Seawater lines and chemical handling to resist leaks in corrosive conditions |

| Non-Metallic Piping Systems | Fiberglass, PVC, or HDPE piping to prevent stress concentrations |

This type does not suit high pressure or high temperature service. Engineers often compare rf vs ff vs rtj to determine the best fit for their applications.

FF Flange Pros and Cons

FF flanges offer stability and cost-effectiveness for specific service conditions. The table below outlines the main advantages and disadvantages of this type:

| Aspect | FF Flanges |

|---|---|

| Cost | Lower than rf and rtj types |

| Installation | Simple, especially with cast iron or non-metallic piping |

| Sealing Integrity | Reliable for low-pressure, low-temperature service |

| Pressure Rating | Not suitable for high pressure |

| Application Range | Limited to specific systems and materials |

This type provides a practical solution for many low-pressure applications. RF flanges handle a wider range of pressures, while RTJ flanges excel in high pressure and high temperature environments.

RTJ Flange Features

RTJ Groove Design and Ring Gaskets

RTJ flanges use a precision-machined groove and a metal ring gasket to create a leak-proof seal in high-pressure and high-temperature environments. The ring type joint groove sits on the flange face and holds an oval or octagonal ring gasket. When bolted, the gasket deforms into the groove, forming a strong metal-to-metal seal. This design resists vibration and pressure cycling, making the ring type joint ideal for critical fluid control.

The most common materials and design standards for this type appear in the table below:

| Material Type | Design Standards |

|---|---|

| Stainless Steel | ANSI B16.5, ANSI B16.47, ANSI B16.36, ANSI B16.48, BS 4504, EN1092, UNI 2277/2278, DIN, JIS, SABS1123, GOST-12820 |

| Duplex & Super Duplex Steel | Flange Size: ½” (15 NB) to 48″ (1200NB) |

| Carbon Steel | Flange Class: 150 LBS, 300 LBS, 600 LBS, 900 LBS, 1500 LBS, 2500 LBS |

| Low-Temperature Carbon Steel | Forged, heat treated, and machined |

| Alloy Steel | EN 10204/3.1B, Raw Materials Certificate, 100% Radiography Test Report, Third Party Inspection Report |

| Copper Alloy | Spectrograph, Hydrostatic testing, X-ray, Ultrasonic, Magnetic particle detection |

| Nickel Alloy | Press, Bending, Pushing, electric bevelling, Sand-blasting machines |

RTJ flanges are available in pressure ratings from Class 150 to Class 2500. The ring type joint design ensures reliable sealing even in the most demanding conditions.

Typical RTJ Flange Applications

RTJ flanges serve as the preferred type for high-pressure and high-temperature service in critical industries. The ring type joint provides leak-proof connections that protect people and equipment. The table below shows where engineers specify this type most often:

| Industry | Application Type | Reason for RTJ Use |

|---|---|---|

| Oil | High-pressure systems | Leak-proof connections for extreme conditions |

| Gas | High-temperature applications | Ensures sealing integrity under high pressure |

| Petrochemical | Critical fluid control | Metal-to-metal sealing for operational safety |

Engineers choose the ring type joint for high-pressure applications where safety and reliability matter most. The metallic ring gasket enhances resilience, making this type unsuitable for low-pressure applications but essential for oil, gas, and petrochemical systems.

RTJ Flange Pros and Cons

RTJ flanges offer unmatched sealing integrity for extreme service but have specific limitations.

Advantages:

- Suitable for high-pressure, high-temperature, or critical hydrocarbon services (typically Class 900 and above).

- Provides metal-to-metal sealing, reducing the risk of leaks in demanding environments.

- Withstands vibration and pressure cycling better than rf or ff types.

Disadvantages:

- Not interchangeable with rf flanges, which limits use in lower pressure and temperature systems.

- Installation requires precise alignment and specialized gaskets, increasing complexity compared to ff types.

The rf vs ff vs rtj comparison shows that the ring type joint stands out for critical applications, while rf and ff types serve broader or less demanding needs.

RF vs FF vs RTJ Comparison

Key Differences Table (Pressure, Gaskets, Cost)

The main differences between rf, ff, and rtj flanges involve pressure handling, gasket used, and cost.

| Flange Type | Pressure Ratings | Gasket Types | Cost Differences | Installation Time | Maintenance Requirements |

|---|---|---|---|---|---|

| RF | 150#, 300#, 400# and above | Spiral wound, cam profile | More expensive due to machining | Easier, simple gaskets | Lower, easy gasket replacement |

| RTJ | High pressure and temperature | Metal ring gasket | Higher cost, specialized gaskets | Demanding, precise work | Complex, higher effort for maintenance |

| FF | Low pressure | Full-face gasket | Generally lower due to simple design | Simple, fast | Minimal, easy to maintain |

Tip: RTJ flanges provide the best sealing for high pressure and temperature, but require more time and cost for installation and maintenance. RF flanges offer a balance of performance and ease of use. FF flanges suit low-pressure systems and deliver cost savings.

Application Suitability by Industry and Service

Engineers must match flange type to system pressure, media, and environment for reliable performance.

- RTJ flanges excel in pipelines for chemical, petroleum, and natural gas industries. These applications demand high sealing performance and gasket compatibility under extreme conditions.

- RF flanges fit oil and gas, chemical processing, and water treatment. Their versatility supports a wide range of applications and gasket selection.

- FF flanges work best in water treatment, HVAC, and fire protection systems. These environments require even surface contact and simple maintenance.

How to choose the right flange face:

- Identify the system’s pressure handling needs.

- Assess the chemical and temperature environment for material and gasket compatibility.

- Select the flange face that matches the required sealing integrity and maintenance expectations.

For critical services, such as high pressure or corrosive media, engineers often select RTJ flanges with metal ring gaskets. For general industrial use, rf flanges provide a reliable and cost-effective solution. FF flanges remain the preferred choice for low-pressure, non-metallic, or cast iron piping.

Proper selection ensures long-term reliability and leak prevention in all applications.

Flange Selection Guide

How to Choose RF, FF, or RTJ for Your System

The most important factors for flange selection are pressure rating, fluid properties, cost, installation needs, and system standards.

Engineers must evaluate each factor to ensure reliable performance and leak prevention. The following ordered list outlines how to choose the right flange face for any fluid control system:

- Assess pressure and temperature ratings for the application.

- Examine fluid properties, including corrosiveness and viscosity.

- Consider cost and availability of rf, ff, and rtj flanges.

- Review installation and maintenance requirements for each type.

- Confirm system design and standards compliance.

Selecting the correct flange type supports long-term reliability and efficient gasket selection. Material choice also plays a critical role in safety and durability. Engineers should select alloys, carbon steel, or stainless steel based on project needs and environmental factors.

Compatibility with Standards and Existing Equipment

Compatibility with industry standards ensures safe and efficient integration of rf, ff, and rtj flanges into existing systems.

The table below summarizes flange types, sizes, pressure ratings, and sealing face options according to ASME and API standards:

| Flange Type | Sizes (NPS) | Pressure Ratings | Sealing Face Types |

|---|---|---|---|

| Weld Neck | 1/2 to 24 | Class 150 to 2500 | RF, RTJ, FF |

| Slip-On | 1/2 to 24 | Class 150 to 2500 | RF, RTJ, FF |

| Socket Weld | 1/2 to 24 | Class 150 to 2500 | RF, RTJ, FF |

| Threaded | 1/2 to 2 | Class 150 to 300 | RF, RTJ |

| Blind | 1/2 to 24 | Class 150 to 2500 | RF, RTJ |

| Lap Joint | 1/2 to 24 | Class 150 to 300 | RF, RTJ |

Engineers must verify flange compatibility with existing equipment and confirm adherence to standards such as ASME B16.5 and ASME B16.47. Proper sizing and certification guarantee safe operation and efficient leak prevention.

Installation and Maintenance Considerations

Proper installation and regular maintenance extend the service life of rf, ff, and rtj flanges.

Engineers should follow best practices to maintain sealing integrity and prevent leaks. Recommended maintenance practices include:

- Inspect gaskets regularly for rf flanges.

- Check ring grooves for wear or damage in rtj flanges.

- Use predictive and preventive maintenance to anticipate and schedule repairs.

- Replace gaskets and re-tighten bolts as part of routine maintenance.

- Address issues promptly with corrective maintenance.

Installation complexity varies by flange type. RTJ flanges require precise alignment and specialized gaskets, while ff and rf flanges offer simpler installation. Consistent maintenance supports system reliability and leak prevention.

RF, FF, and RTJ flanges differ in surface type, gasket compatibility, and application range.

| Feature | RF Flange | FF Flange | RTJ Flange |

|---|---|---|---|

| Surface Type | Raised | Flat | Grooved |

| Gasket Type | Soft or semi-metallic | Non-metallic | Metal ring |

| Application | Medium to high pressure | Low pressure | High pressure, critical |

- Proper flange selection supports system reliability and leak prevention.

- SUNHY provides trusted fluid control solutions with advanced manufacturing and technical support.

FAQ

What is the main difference between RF, FF, and RTJ flanges?

RF flanges have a raised face, FF flanges have a flat face, and RTJ flanges use a grooved face with a metal ring gasket.

This difference affects sealing performance, pressure rating, and gasket selection.

When should engineers use RTJ flanges?

Engineers should use RTJ flanges for critical applications with high pressure and temperature.

These flanges provide a metal-to-metal seal, making them ideal for oil, gas, and petrochemical systems.

What are the primary applications for FF flanges?

FF flanges work best in low-pressure, non-metallic, or cast iron piping systems.

They appear in water treatment, HVAC, and fire protection, where flange bending must be minimized.

Are RF flanges compatible with most gaskets?

Yes, RF flanges accept both non-metallic and semi-metallic gaskets.

This compatibility allows engineers to select gaskets based on system requirements and media.

How does flange face type affect maintenance?

Flange face type determines gasket replacement frequency and inspection needs.

RTJ flanges require precise alignment and more frequent checks, while FF and RF flanges offer easier maintenance.