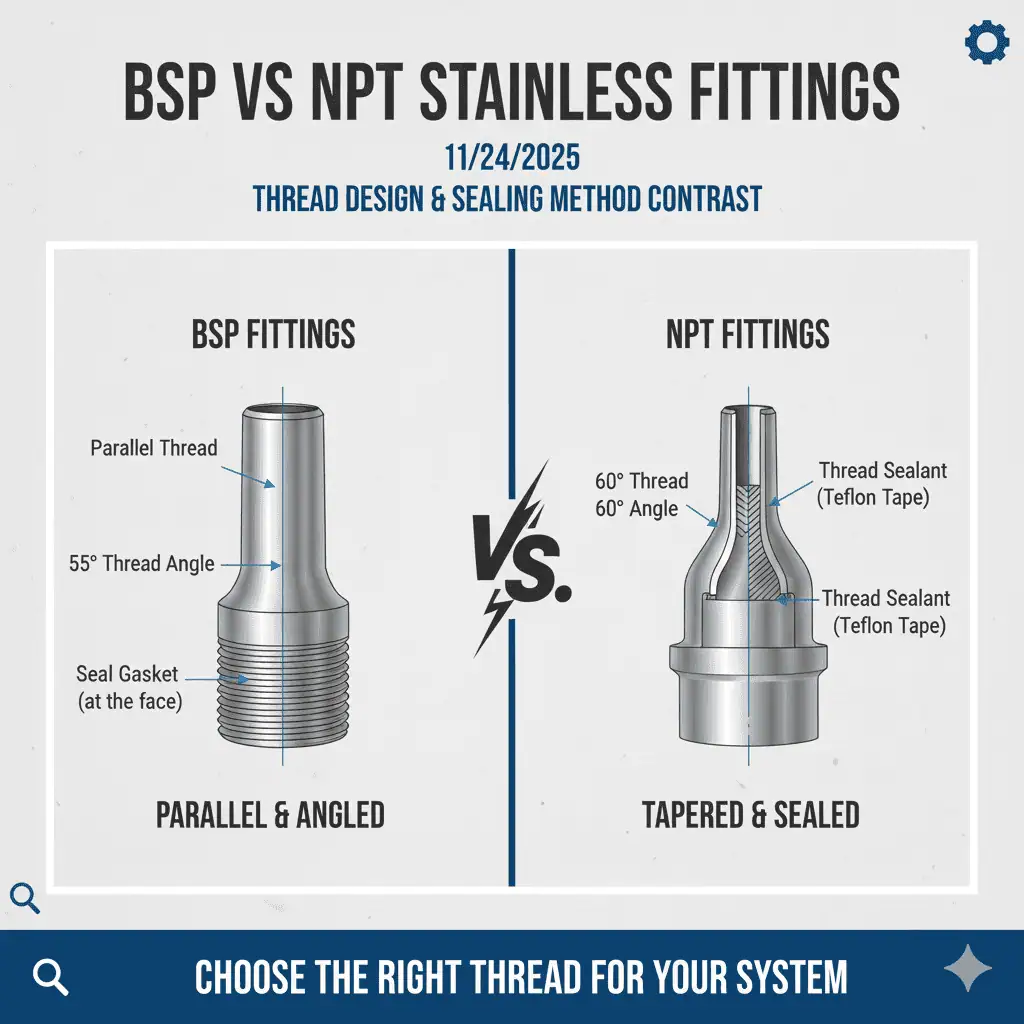

The main difference between BSP vs NPT stainless fittings lies in their thread design and sealing method.

You will notice BSP threads use a 55-degree angle, while NPT threads use a 60-degree angle.

- BSP fittings seal with a washer or O-ring.

- NPT fittings rely on thread taper to create a seal.

- BSP fittings appear mostly in Europe, Asia, and Australia.

- NPT fittings dominate in North America.

Correct identification ensures safety and reliable performance. Sunhy provides high-quality stainless steel fittings for both BSP and NPT standards. Keep reading to make the best choice for your application.

What Are BSP Stainless Fittings?

BSP Definition

BSP stainless fittings use the British Standard Pipe thread system to connect pipes and equipment in many industries. You will find that BSP threads follow the British Standard Pipe specification. These threads have become a global standard for fluid and gas transfer. When you choose BSP stainless fittings, you select a system trusted for its reliability and versatility.

BSP Thread Characteristics

BSP threads stand out because of their unique shape and sealing methods. You will see two main types: BSPP (Parallel) and BSPT (Tapered). The table below shows how these BSP threads differ:

| Feature | BSPP (Parallel) | BSPT (Tapered) |

|---|---|---|

| Thread Shape | Parallel | Tapered |

| Sealing | Needs O-rings | Seals itself |

| Pressure | Low (150 psi) | Medium (2500 psi) |

| Best For | Food/easy cleaning | General industry |

Bsp threads use a 55-degree angle, which sets them apart from other thread types. You will notice that BSP threads often require a washer or O-ring for sealing, especially in BSPP fittings. BSPT threads create a seal by tightening the tapered thread.

BSP Applications

You will find BSP stainless fittings in a wide range of applications. These fittings work well in industries that demand durability and resistance to corrosion. The table below highlights common applications for BSP threads:

| Industry | Application Description |

|---|---|

| Chemical Processing | Prevents backflow of hazardous substances and withstands tough chemicals without corroding. |

| Water & Wastewater Management | Stops contaminated water from flowing back into clean supply, preventing rust and wear. |

| Oil, Gas, and Petrochemicals | Withstands extreme pressure and heat, ensuring safety in pipelines and preventing backflow of flammable liquids. |

| Food, Beverage & Pharmaceuticals | Easy to clean, rust-resistant, and often polished to prevent bacterial growth, ensuring product purity. |

You will see BSP threads used in both high and low-pressure systems. These threads support safe and efficient operations in many critical applications.

Identifying BSP Threads

You can identify BSP threads by following a few simple steps.

Tip: Accurate identification helps you avoid leaks and ensures compatibility in your applications.

- Gather tools such as a tape measure, calipers, or thread gauges.

- Measure the thread size, pitch, diameter, and length.

- Check if the thread is parallel (BSPP) or tapered (BSPT).

- Count the threads per inch, as BSP threads have a specific thread count.

When you follow these steps, you can confidently select the right BSP stainless fittings for your applications. Recognizing the difference between BSP threads and other thread types helps you maintain safety and performance in your systems.

What Are NPT Stainless Fittings?

NPT Definition

NPT stainless fittings use the National Pipe Thread Tapered system, which is the official US standard for connecting pipes and equipment. You will see NPT threads specified by ANSI/ASME B1.20.1. The national pipe thread design creates a tight seal for liquids and gases. NPT threads are widely used in North American piping systems. You can rely on NPT stainless fittings for secure and leak-free connections.

NPT Thread Characteristics

NPT threads have a unique profile. You will notice that NPT threads use a 60-degree angle. The threads taper along the fitting, which means the diameter decreases from one end to the other. This taper helps NPT threads create a seal when tightened. You will find that NPT threads do not need a washer or O-ring for sealing. The national pipe tapered design relies on the thread shape and pressure to prevent leaks.

| Feature | NPT Threads |

|---|---|

| Thread Angle | 60 degrees |

| Thread Type | Tapered |

| Sealing Method | Thread-to-thread contact |

| Standard | ANSI/ASME B1.20.1 |

| Best For | High-pressure systems |

You will see NPT threads used in many industrial settings. The national pipe tapered design supports high-pressure and high-temperature applications.

NPT Applications

NPT stainless fittings serve many industries. You will find NPT threads in systems that require durability and corrosion resistance. Here are some common sectors:

- Plumbing and HVAC

- Construction Industry

- Marine Industry

- Agriculture Industry

- Food and Beverage Industry

- Oil and Gas Industry

- Manufacturing Industry

NPT threads help you maintain safe and efficient operations. You can trust NPT threads to perform in demanding environments.

Identifying NPT Threads

You can identify NPT threads by following these steps:

- Determine the gender of the coupler: Check if it is male or female.

- Identify the fitting and thread size: Use reference tables for NPT threads.

- Match the port connection to the hydraulic hose: Ensure compatibility.

- Identify the type of seal: Look for tapered or mated angle seals.

- Use a thread gauge to measure thread spacing.

- Use calipers to measure outer and inner diameters of NPT threads.

- Visually inspect to see if threads are tapered.

- If you see an O-ring, it is not an NPT thread.

- Measure the outer diameter to confirm the correct coupling size.

Tip: Accurate identification of NPT threads helps you avoid leaks and ensures system reliability.

You will find that NPT threads have a distinct tapered profile. When you follow these steps, you can select the right NPT stainless fittings for your application.

BSP vs NPT Stainless Fittings: Key Differences

Thread Angle and Profile

The main difference between BSP vs NPT stainless fittings lies in the thread angle and profile.

You will see that NPT threads have a 60-degree angle, while BSP threads use a 55-degree angle. This small difference changes how the threads fit together and how they seal. The NPT design uses a tapered profile, which means the diameter gets smaller along the length. The BSP system includes both parallel (BSPP) and tapered (BSPT) profiles. You can spot these differences by looking at the shape and measuring the angle.

- NPT: 60-degree thread angle, tapered profile

- BSP: 55-degree thread angle, available in both parallel and tapered profiles

Tip: Always check the thread angle before choosing fittings. This helps you avoid leaks and ensures proper sealing.

Sealing Methods

BSP vs NPT stainless fittings use different sealing methods to prevent leaks.

You will notice that NPT fittings create a seal by compressing the tapered threads together. This method often uses PTFE tape or a sealant for extra protection. The BSP system works differently. BSPT (tapered) threads seal by the thread shape, while BSPP (parallel) threads need a gasket or O-ring to make a tight seal.

- NPT: Seals by thread compression, usually with PTFE tape or sealant

- BSP (BSPT): Seals by thread shape alone

- BSP (BSPP): Needs a gasket or O-ring for sealing

This difference affects how you install and maintain your fittings. You must choose the right sealing method for your system to ensure safety and performance.

Compatibility Issues

BSP vs NPT stainless fittings are not compatible with each other, and mixing them causes serious problems.

You cannot interchange these threads because the angles and profiles do not match. If you try to connect BSP and NPT fittings, you will see poor thread engagement. This leads to leaks, equipment damage, and even thread failure.

- Mixing BSP and NPT threads results in:

- Leaks due to poor fit

- Damaged threads that cannot be reused

- Incomplete sealing, which puts your system at risk

- Loss of equipment reliability

Note: Always check compatibility before installation. Using the wrong fitting can cause costly repairs and downtime.

Geographic Use

You will find that BSP vs NPT stainless fittings are used in different regions due to historical standards.

The table below shows where each type is most common and why:

| Region | Fitting Type | Historical Influence |

|---|---|---|

| Europe | BSPT | Adoption of British standards (ISO 7-1) |

| Commonwealth Nations | BSPT | Historical ties to the UK |

| Southeast Asia | BSPT | Influence of British colonial history |

| North America | NPT | Standardization in the US and Canada |

| Philippines | NPT | Collaboration with US projects |

| Middle East | BSPT/NPT | Varies based on historical ties and project specifics |

You should always check the standard used in your region before selecting fittings. This ensures compatibility and helps you avoid costly mistakes.

Choosing the Right Stainless Fitting

Selection Factors

You should always choose stainless fittings based on your system’s standards, application needs, and compatibility.

When you select between BSP and NPT fittings, you must consider several important factors. These factors help you avoid leaks and ensure reliable performance.

- Geographic Standards: NPT fittings are standard in North America. BSP fittings are common in Europe, Asia, and Australia. Always match your fittings to the regional standard.

- System Compatibility: Mixing BSP and NPT fittings leads to leaks and equipment damage. You must use the correct type for your system.

- Pressure Ratings: Both BSP and NPT stainless fittings handle pressures from less than 10 bar to over 500 bar. You should check your system’s pressure requirements before choosing.

- Corrosion Resistance: Stainless steel fittings from Sunhy offer superior corrosion resistance, making them ideal for harsh environments.

- Custom Solutions: Sunhy supports both BSP and NPT standards. You can request custom fittings for unique applications.

Tip: Always verify the thread type and pressure rating before installation. This step prevents costly mistakes and downtime.

Application Considerations

You need to match your fittings to the demands of your specific application for safe and efficient operation.

Different applications require different features from your fittings. You must understand your system’s needs before making a selection.

- High-Pressure Environments: NPT fittings work well in oil and gas systems because their tapered threads create a strong seal. BSP fittings may need O-rings or gaskets for a perfect seal in high-pressure settings.

- Water Systems: BSP fittings are often preferred for water and wastewater management. Their design allows for easy installation and maintenance.

- Chemical Processing: Both BSP and NPT stainless fittings resist corrosion, but you should confirm compatibility with the chemicals in your system.

- Food and Beverage: Stainless fittings from Sunhy are easy to clean and maintain, supporting hygiene and product purity.

| Feature | NPT Fittings | BSP Fittings |

|---|---|---|

| Corrosion Resistance | Superior due to stainless steel | Superior due to stainless steel |

| Pressure Ratings | <10 bar to >500 bar | <10 bar to >500 bar |

Note: Sunhy’s precision engineering ensures that all fittings meet strict industry standards for safety and performance.

Maintenance and Longevity

You can extend the life of your fittings by choosing high-quality materials and following proper maintenance practices.

Stainless fittings from Sunhy offer long service life and easy maintenance. You should inspect your fittings regularly and replace any worn components.

- BSP fittings simplify maintenance because their design allows for quick inspection and replacement of sealing elements.

- NPT fittings require careful handling during installation to avoid thread damage. Their tapered design provides a secure seal without extra materials.

- Sunhy’s fittings use advanced CNC machining for tight tolerances and perfect sealing, reducing the risk of leaks and failures.

- You can request custom fittings from Sunhy to match your maintenance schedule and system requirements.

Tip: Regular inspection and proper installation help you maintain leak-free performance and maximize the longevity of your fittings.

Sunhy delivers stainless fittings engineered for high pressure, corrosion resistance, and precision. You can rely on Sunhy for both BSP and NPT standards, as well as custom solutions tailored to your needs.

Common Mistakes and Best Practices

Installation Errors

The most common installation errors with BSP and NPT stainless fittings include damaged threads, distorted fittings, and over-tightening.

You can prevent leaks and system failures by understanding these mistakes. The table below shows typical errors and their consequences:

| Installation Error | Consequence |

|---|---|

| Stripped or Galled Threads | Damaged threads can lead to leaks and ineffective seals, compromising system integrity. |

| Distorted Fittings | Distortion can prevent proper sealing, leading to potential system failures and leaks. |

| Over-tightening | Can cause thread damage and material failure, resulting in leaks and system inefficiency. |

Tip: Always use the correct tools and avoid excessive force during installation.

Inspection Tips

You ensure proper installation and safety by following best inspection practices for BSP and NPT fittings.

You should check each fitting before and after installation. Follow these steps for reliable results:

- Avoid over-tightening connections to prevent damage to threads and fittings.

- Use the correct sealant for the application to prevent leaks.

- Clean and inspect threads before installation to ensure proper sealing.

Note: Regular inspection helps you catch problems early and maintain system performance.

Training and Safety

You minimize safety risks by training technicians on proper fitting procedures and industry standards.

You should make sure your team understands the right techniques and uses the best tools. Key protocols include:

- Understanding torque specifications

- Using advanced tools

- Following industry best practices

🛠️ Well-trained technicians help you avoid costly mistakes and keep your system safe.

BSP and NPT stainless fittings differ in thread angle, sealing method, and compatibility.

You can see the main differences in the table below:

| Feature | NPT Threads | BSP Threads |

|---|---|---|

| Thread Angle | 60 degrees | 55 degrees |

| Sealing Method | Teflon tape or sealant | O-rings or washers |

| Compatibility | Not compatible with BSP | Not compatible with NPT |

Choosing the right fitting protects your system from leaks and failures. You should always verify thread type and follow best practices. Sunhy offers both BSP and NPT stainless steel fittings. For expert help, reach out to Sunhy’s team.

FAQ

What is the main difference between BSP and NPT stainless fittings?

BSP fittings use a 55-degree thread angle. NPT fittings use a 60-degree angle.

You will see BSP threads in Europe and Asia. NPT threads appear in North America.

Tip: Always check thread type before installation.

Can you connect BSP and NPT fittings together?

You cannot connect BSP and NPT fittings directly.

The thread angles and profiles do not match. Mixing them causes leaks and damage.

- BSP: 55-degree angle

- NPT: 60-degree angle

How do you identify BSP and NPT threads?

You identify BSP threads by their parallel or tapered profile and 55-degree angle. NPT threads have a tapered profile and 60-degree angle.

| Feature | BSP | NPT |

|---|---|---|

| Angle | 55 degrees | 60 degrees |

| Profile | Parallel/Taper | Tapered |

Which industries use stainless steel BSP and NPT fittings?

You find BSP fittings in chemical, water, and food industries. NPT fittings appear in oil, gas, and construction.

- BSP: Water, chemical, food

- NPT: Oil, gas, construction

Why should you choose Sunhy stainless steel fittings?

You get high pressure, corrosion resistance, and precision engineering with Sunhy fittings.

Sunhy supports both BSP and NPT standards. You can request custom solutions for your project needs.