To identify and fix hydraulic adapter problems, check for leaks, inspect threads and seals, and replace damaged parts immediately. Quick action ensures your hydraulic system stays reliable and safe. Sunhy hydraulic adapters use strong materials and smart engineering, so you get durability and easy maintenance. Most hydraulic adapter repair issues have simple solutions when you use the right tools and follow proper steps.

- Always look for signs of wear or damage.

- Use quality adapters for fewer problems.

- Follow safety steps before starting any repair.

Common Hydraulic Adapter Repair Issues

Leaking Hydraulic Fittings

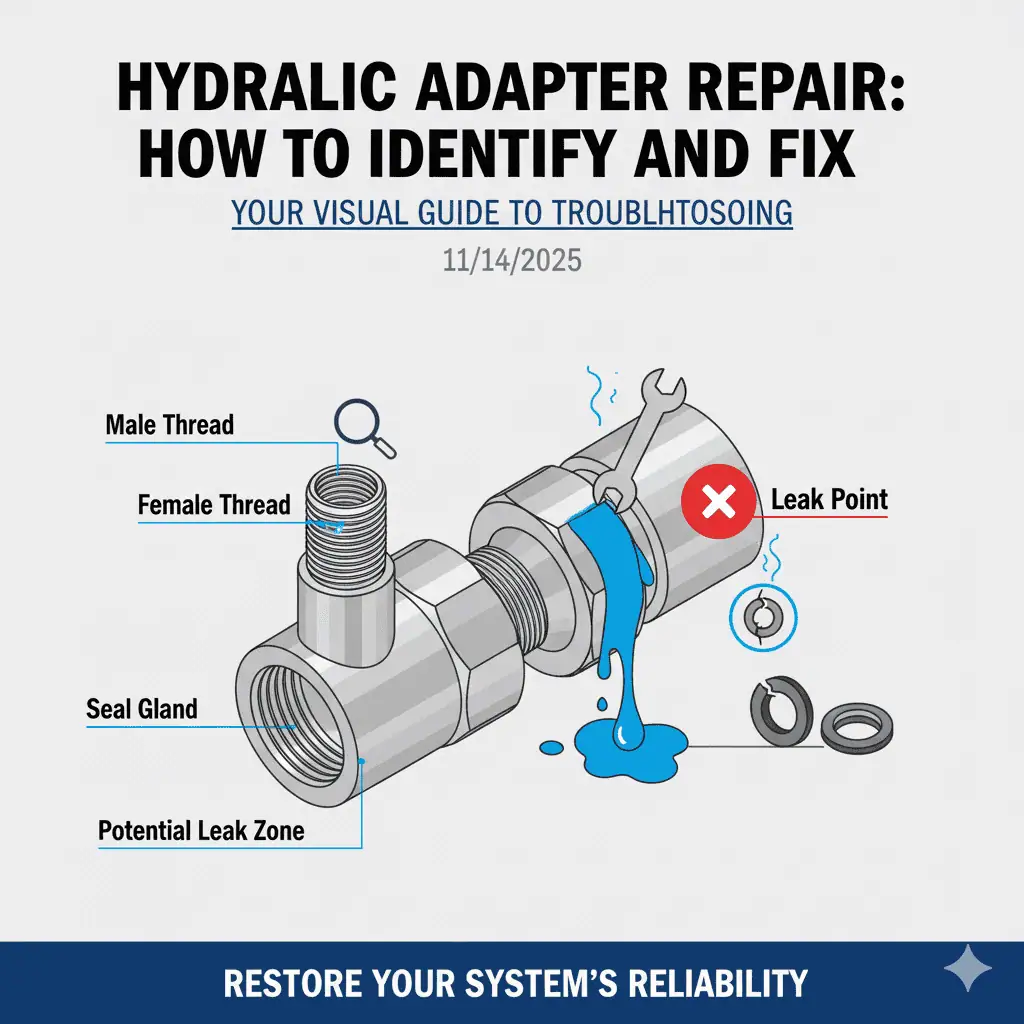

Leaking hydraulic fittings usually mean you have a problem with seals, threads, or installation.

You often notice a hydraulic line leak by seeing fluid around the connection or on the ground. Leaky hydraulic lines can cause pressure loss and system failure. Always check for leaks after any repair or maintenance. Sunhy adapters use precision engineering and quality seals to help prevent leaking hydraulic fittings. You can reduce leaks by choosing the right hydraulic fitting type and making sure you install it correctly.

Thread and Seal Damage

Thread and seal damage leads to leaks and weak connections.

You might see a hydraulic line leak if threads are stripped or if you have a damaged o-ring. Regular maintenance helps prevent this kind of damage. Here are some tips to keep threads and seals in good shape:

- Use proper torque tools to avoid overtightening.

- Lubricate threads when recommended.

- Clean threads before assembly.

- Start threads by hand to avoid cross-threading.

- Replace worn seals right away.

- Train technicians on correct installation.

Sunhy adapters use premium materials and tight tolerances, which help protect threads and seals from damage.

Corrosion and Wear

Corrosion and wear weaken adapters and cause leaks over time.

You can spot early corrosion by looking for rust, pitting, or leaks. Corrosion often happens when moisture, oxygen, salt, or acids reach the metal. Erosive wear comes from hard particles moving through the system. Both can lead to leaky hydraulic lines and pressure changes. Sunhy adapters offer surface treatments like zinc or chrome plating to resist corrosion and extend service life.

Tip: Regular inspection and using adapters with protective finishes help prevent corrosion and wear.

Installation Mistakes

Installation mistakes are a leading cause of hydraulic adapter repair needs.

Check the table below for common mistakes and how they affect your system:

| Mistake Type | Explanation |

|---|---|

| Choosing the Wrong Size | Wrong size can cause leaks or restrict flow. |

| Neglecting Material Compatibility | Using the wrong material can lead to corrosion or failure. |

| Ignoring Pressure Ratings | Low-rated adapters may burst under pressure. |

| Overlooking Environmental Factors | Not considering temperature or chemicals can reduce adapter life. |

| Failing To Consider Thread Compatibility | Mismatched threads can cause leaks and damage. |

You can avoid most problems by following the manufacturer’s guidelines and using Sunhy’s easy-to-install adapters. Regular checks and proper installation keep your system running smoothly and help prevent a hydraulic line leak.

Identifying Adapter Issues

Visual Inspection Steps

Direct Answer:

You can identify hydraulic adapter problems by looking for visible signs of damage, wear, or leaks.

Visual inspection is the first step in hydraulic adapter repair. You should check each fitting and adapter closely. Look for these signs:

- Loose fittings or adapters

- Corroded surfaces, including rust or pitting

- Fluid leaks around connections

- Cracked or deformed adapters

- Worn or missing seals

- Discoloration or residue near joints

If you see any of these issues, you should address them quickly. Loose or corroded adapters can lead to performance problems and safety risks, such as fluid leaks or blown hoses. Regular visual checks help you catch problems early and keep your hydraulic system running safely.

Pressure and Leak Testing

Direct Answer:

You can confirm leaks and pressure problems by performing a controlled pressure and leak test.

Pressure and leak testing helps you diagnose the leak and verify the integrity of your hydraulic adapters. Follow these steps:

- Fill the system or component with water and pressurize it above its normal operating pressure.

- Hold the pressure for the required time while watching for leaks or pressure drops.

- If you see no pressure loss, complete the pressure testing certificate. If you find leaks, fix them before retesting.

- Depressurize the system safely after the test.

- Remove any temporary testing equipment and restore the system to normal operation.

You should always use proper safety gear during testing. Pressure and leak testing ensures your adapters meet industry standards and helps prevent future failures.

Tip: Use ultrasonic detection, dye testing, or a simple soap solution test to find small leaks that are hard to see.

Using Diagnostic Tools

Direct Answer:

You can use specialized diagnostic tools to pinpoint hydraulic adapter problems with high accuracy.

Modern diagnostic tools make it easier to find issues that visual inspection might miss. Here is a table of effective tools and their benefits:

| Diagnostic Tool | Description | Benefits |

|---|---|---|

| Pressure Testing | Uses digital manometers and pressure transducers to check pressure readings. | Pinpoints issues within fittings or other hydraulic parts. |

| Thermal Imaging | Uses thermal cameras to detect overheating in fittings. | Finds friction or fluid restriction, showing possible fitting problems. |

| Ultrasonic Leak Detection | Uses ultrasonic detectors to hear high-frequency sounds from escaping fluid. | Detects tiny leaks in high-pressure systems. |

| Contamination Analysis | Checks hydraulic fluid for particles, water, or chemicals. | Prevents corrosion or damage by finding contamination early. |

| Vibration Analysis | Uses accelerometers and software to monitor vibration. | Finds areas that could loosen or wear out fittings. |

| 3D Scanning | Uses high-precision scanning to find cracks or deformations. | Detects potential failures after high pressure or impacts. |

| Hydraulic System Simulation Software | Models system behavior under different conditions. | Identifies possible fitting failures before they happen. |

Industry standards like ISO 8434, SAE J514, DIN 2353, and JIS B8363 set requirements for hydraulic adapter inspection and testing. You can use digital calipers, thread gauges, and go/no-go gauges to check dimensions and tolerances. Proof, burst, impulse, and salt spray tests help verify strength and corrosion resistance.

Note: Using the right diagnostic tools and following standards ensures your hydraulic adapter repair is thorough and reliable.

Fixing Leaky Hydraulic Lines and Fittings

Safety Precautions

Direct Answer:

Always follow strict safety steps before you start fixing leaky hydraulic lines.

You protect yourself and your equipment by preparing properly. Here are important safety measures you should take:

- Learn and follow all state and national safety rules for hydraulic hose and fitting repairs.

- Wear protective clothing, such as gloves and safety glasses, to prevent injuries from high-pressure fluid.

- Use only the correct tools and hoses that meet the system’s specifications.

- Check the hose length and routing to avoid pressure build-up or kinks.

- Depressurize the system fully before you disconnect any fittings.

- Test the system after repairs to confirm there are no leaks and everything works safely.

Tip: Never try to repair a hydraulic line while the system is under pressure. Always double-check that the pressure is released.

Step-by-Step Leak Repair

Direct Answer:

You can fix leaky hydraulic lines by identifying the leak source, using the right repair method, and following a clear process.

Start by finding the exact spot where the leak occurs. Most leaks in hydraulic lines and fittings happen because of:

- Damaged seals

- Loose fittings

- Damaged lines

- Worn O-rings

- Polluted fluid

- High operating pressure

- Temperature extremes

- Excessive vibration

- Physical damage

Once you know the cause, follow these steps for fixing leaky hydraulic lines:

- Shut down and depressurize the system.

Make sure the hydraulic hose is safe to handle. - Clean the area around the leak.

Remove dirt and oil so you can see the problem clearly. - Inspect the fitting and line.

Check for worn O-rings, damaged threads, or cracks. - Choose the right repair method:

- Thread Sealant: Clean the threads, apply a thin layer of sealant, and screw the adapter in place. Do not over-tighten.

- O-Ring Replacement: Remove the old O-ring, clean the groove, install a new O-ring, and reassemble the adapter.

- Thread Tape: Wrap tape around the male threads (clockwise), avoiding the first thread, and screw the adapter in carefully.

- Tighten all fittings to the recommended torque.

Use a torque wrench if possible. - Test the repair.

Pressurize the system and check for new leaks.

Sunhy hydraulic adapters make fixing leaky hydraulic lines easier. You do not need advanced tools, and you can disconnect and reconnect them quickly. Their leak-proof seals and durable materials help prevent future leaks. If you need a temporary hydraulic hose repair, you can use a patch or clamp, but always plan for a permanent fix as soon as possible.

Note: Always identify the source of the leak before you start repairs. This prevents wasted effort and ensures a lasting solution.

When to Repair or Replace

Direct Answer:

Repair minor issues, but replace the adapter if you see severe damage or repeated leaks.

Use this table to decide what action you should take:

| Condition | Action Required |

|---|---|

| Minor Issues | Repair by tightening connections, replacing O-rings, or applying thread sealant. |

| Severe Issues | Replace the adapter to ensure safety and performance. |

You should repair a hydraulic line if you find only a loose fitting or a worn O-ring. If you see cracks, heavy corrosion, or repeated leaks, replace the adapter. Sunhy adapters are easy to install and remove, so you can swap them out quickly. This reduces downtime and keeps your system running smoothly.

Tip: Regular inspections and using quality adapters help you avoid most problems with leaky hydraulic lines.

Common Challenges and Solutions

| Challenge | Solution |

|---|---|

| Wear and Tear | Inspect regularly to catch issues early. |

| Contamination | Keep the system clean and change fluid as needed. |

| Improper Installation | Follow manufacturer guidelines for every repair. |

| Environmental Factors | Store parts in a dry, controlled place. |

You can prevent many issues by following these best practices. Sunhy adapters work well in both new and old systems, and their design helps you avoid leaks and makes future repairs simple.

Maintenance Tips for Longevity

Regular Inspection Routines

Direct Answer:

You should follow a set inspection schedule to keep your hydraulic adapters in top condition.

Regular checks help you spot problems early and prevent costly breakdowns. Use this table to guide your inspection routine:

| Frequency | Inspection Tasks |

|---|---|

| Daily | Clean rod surfaces, check for scoring, look for leaks, and tighten end-cap bolts |

| Weekly | Check mount hardware torque and measure stroke speed |

| Quarterly | Take fluid samples for lab analysis and check rod straightness |

| Annually | Replace seal kits, hone barrels, and reset cycle counts |

You should also look for worn hoses, damaged seals, and signs of contamination. Train your team on these routines to make sure everyone knows what to check.

Preventing Future Leaks

Direct Answer:

You can prevent leaks by using proper inspection, assembly, and training.

Leaks often start with small mistakes or missed warning signs. Follow these strategies to avoid future problems:

- Inspect fittings and hoses for wear or damage.

- Assemble adapters using the correct torque.

- Use only high-quality components.

- Train staff on proper installation and maintenance.

- Replace filters and keep fluids clean.

Regular training and careful assembly reduce the risk of leaks and keep your system running smoothly.

Choosing Quality Adapters

Direct Answer:

You should always choose high-quality adapters for better reliability and longer system life.

Premium adapters, like those from Sunhy, use strong materials and precise engineering. This choice lowers the risk of leaks and failures. Here are some benefits:

- Fewer replacements and repairs

- Less downtime and lower costs

- Better system performance

New technologies, such as quick-connect fittings and smart sensors, make maintenance easier and faster. These features help you stay ahead of problems and improve your hydraulic adapter repair results.

You can keep your hydraulic system reliable by following these steps for hydraulic adapter repair:

- Inspect adapters and fittings regularly for leaks or damage.

- Replace damaged parts right away.

- Use proper tools and follow manufacturer guidelines.

High-quality adapters like Sunhy offer long-term reliability. Regular maintenance prevents costly downtime and extends equipment life. If you need expert help, professionals provide fast, safe repairs and on-site service.

| Benefit | Description |

|---|---|

| Experience | Skilled technicians ensure safety and proper installation. |

| Convenience | On-site service allows for quick repairs. |

| Saving Time | Fast response reduces downtime. |

FAQ

How do you know when to replace a hydraulic adapter?

You should replace an adapter if you see cracks, heavy corrosion, or repeated leaks.

Check for visible damage or leaks during inspections. If tightening or seal replacement does not fix the issue, install a new Sunhy adapter for safety.

What tools do you need for hydraulic adapter repair?

You need basic hand tools, a torque wrench, and inspection tools.

Use wrenches, thread sealant, O-ring picks, and cleaning cloths. For best results, keep a torque wrench and thread gauges in your toolbox.

Can you reuse hydraulic adapters after a leak?

You can reuse adapters only if they show no damage or wear.

Inspect threads and seals closely. If you find any cracks, corrosion, or deformation, replace the adapter. Always use new seals for reassembly.

How do you prevent leaks in hydraulic fittings?

You prevent leaks by using quality adapters and proper installation.

Follow these steps:

- Inspect parts before assembly

- Use correct torque

- Replace worn seals

- Clean threads

- Train staff on best practices

Regular checks and Sunhy adapters help you avoid leaks.