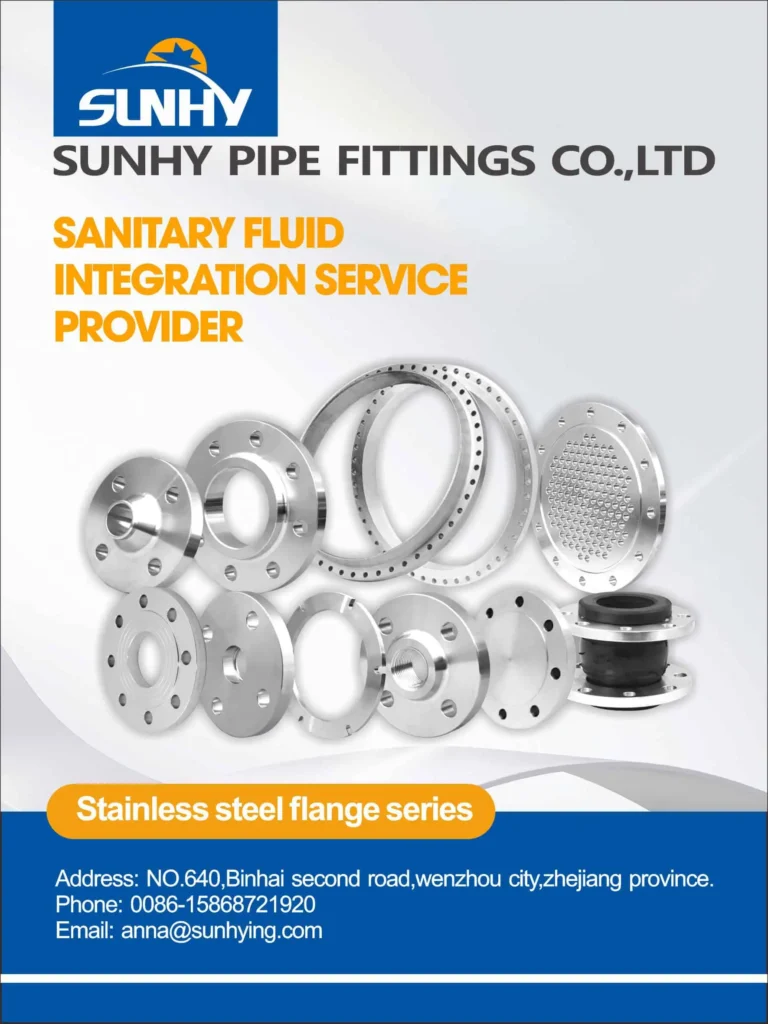

ASME B16.5 / B16.47 Forged Stainless Steel Flanges

Precision machined from dual-certified 316/316L forgings. Engineered for high-pressure integrity in Oil & Gas, Chemical, and Marine applications.

Looking for 100% forged integrity? We eliminate porosity risks associated with cast flanges. From standard Class 150 Slip-Ons to heavy-wall Class 2500 Weld Necks, Sunhy delivers flanges with optimized grain flow for superior fatigue resistance.

Metallurgical Excellence

The Science of Strength: 100% Forged & Solution Annealed

We strictly adhere to ASTM A182 forging specifications. Unlike casting, our forging process aligns the metal’s grain flow with the flange geometry, maximizing impact toughness. Post-forging, every flange undergoes Solution Annealing at 1040°C to dissolve carbides and restore optimal corrosion resistance against intergranular attack.

Precision Machining:

- 200+ CNC Lathes for tight tolerance

- Phonographic Finish (Ra 3.2-6.3μm)

➜ Ensuring perfect gasket seating

➜ ASME B16.5 dimensional accuracy

Advanced Metallurgy:

- Dual Certified 304/304L & 316/316L

- Controlled Carbon (0.03% max)

➜ Prevention of weld decay

➜ Ideal for sour gas (NACE) service

Large Scale Capacity:

- ASME B16.47 Series A & B capability

- Machining diameter up to 2000mm

➜ Custom Tube Sheet & Girth Flanges

The Flanges You're Looking For

Sunhy stocks a wide variety of flanges in all sizes and specifications.

01

ANSl Flanges

02

ASME Flanges

03

AWWA Flanges

01

ANSl Flanges

Our Products

Comprehensive Flange Portfolio (NPS 1/2" - 60")

Sunhy’s reputation for excellence comes from delivering stainless steel flanges of superior quality and value, backed by responsive customer service and reliable delivery. As a vital link in industrial piping systems, our comprehensive range of flanges is engineered to ensure strength, corrosion resistance, and leak-free performance across diverse industries and applications.

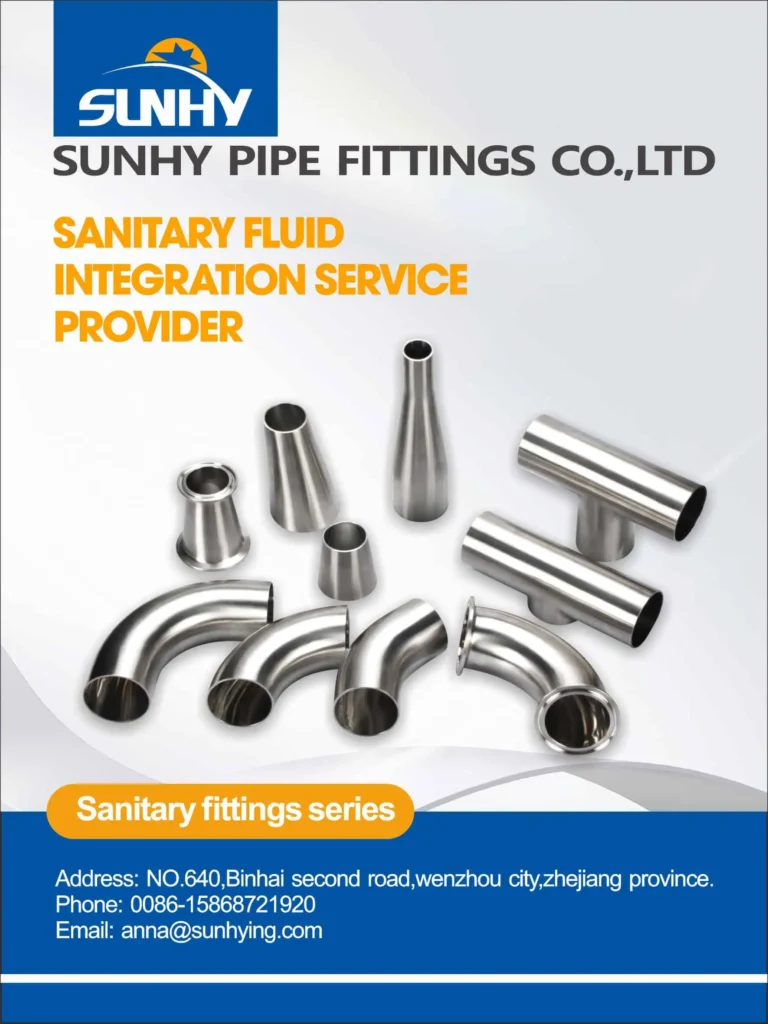

Cost-effective solution for low-pressure water lines. Must be used with full-face gaskets to prevent bending stress on cast iron mating parts.

Easy alignment for on-site fabrication. Double fillet welded (inside/outside) for secure joint strength in Class 150-300 systems.

Designed for small-bore high-pressure piping (≤ NPS 2). Counter-bore design ensures smooth flow and reduces turbulence.

No-weld installation for hazardous areas. Precision NPT threads per ASME B1.20.1 ensure tight sealing without hot work.

Used with Stub Ends. The flange rotates for easy bolt alignment. Ideal for systems requiring frequent dismantling or expensive alloy piping.

High-stress forged discs for line termination. Engineered to withstand maximum system pressure and water hammer effects.

Custom drilled precision discs for heat exchangers and boilers. CNC drilling ensures exact hole coordinates for tube bundles.

Heavy-duty long weld necks (LWN) and nozzle flanges designed for ASME Section VIII vessel fabrication.

Tailor-made solutions including Spectacle Blinds, Spacer Rings, and Orifice Flanges machined to your drawings.

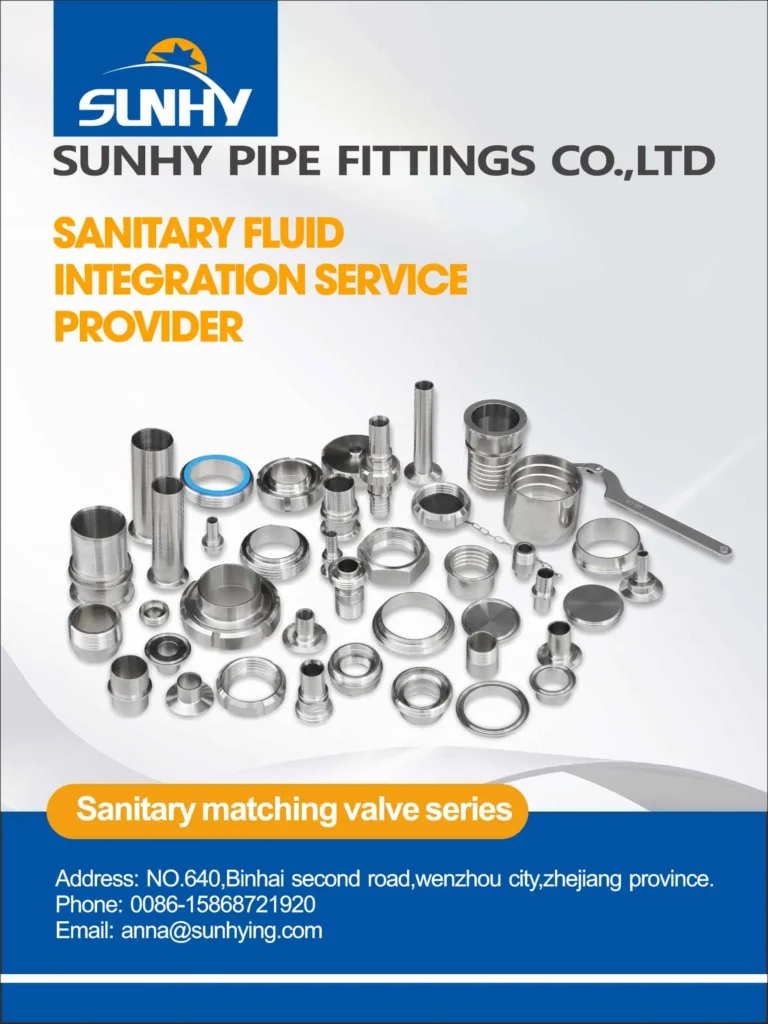

Application Engineering

Sealing Solutions for Critical Environments

Sunhy understands that a flange is not just a connector; it’s a pressure vessel component. We help engineers select the right Facing Finish (Stock, Spiral Serrated, or Smooth) to match your gasket type. Whether you are dealing with cryogenic LNG (-196°C) requiring 316L impact-tested flanges, or high-heat steam lines requiring A182 F321, our engineering team ensures your Bill of Materials (BOM) meets the exact pressure-temperature ratings of ASME B16.5.

One-Stop Source for Global Flange Standards

Beyond standard ASME B16.5, Sunhy delivers large-diameter solutions per ASME B16.47 Series A (MSS SP-44) for heavy-duty offshore platforms and Series B (API 605) for onshore pipelines. Our flexible manufacturing also covers DIN/EN 1092-1 (PN6 – PN100) and JIS B2220 standards, ensuring you have the right connection interface for any global project.

Pressure Classes:

- Class 150, 300, 600 (Stock)

- Class 900, 1500, 2500 (High Pressure)

- PN6, PN10, PN16, PN40, PN63

Industry Applications:

- Offshore Oil & Gas Platforms

- Chemical & Petrochemical Plants

- Water Treatment & Desalination

- Power Generation (Nuclear/Thermal)

Specialty Materials:

- Duplex 2205 / Super Duplex 2507

- Inconel 625, Monel 400, Hastelloy

- Low Temp Carbon Steel (A350 LF2)

Manufacturing & Material Integrity

Quality starts with the raw billet. We perform 100% Spectrometer Analysis (PMI) on incoming raw material to verify Nickel, Chromium, and Molybdenum content. Our forging process involves strictly controlled heating cycles to refine grain structure. Post-machining, we conduct Ultrasonic Testing (UT) to detect any internal voids or cracks, ensuring that every Sunhy flange is structurally sound for safety-critical duties.

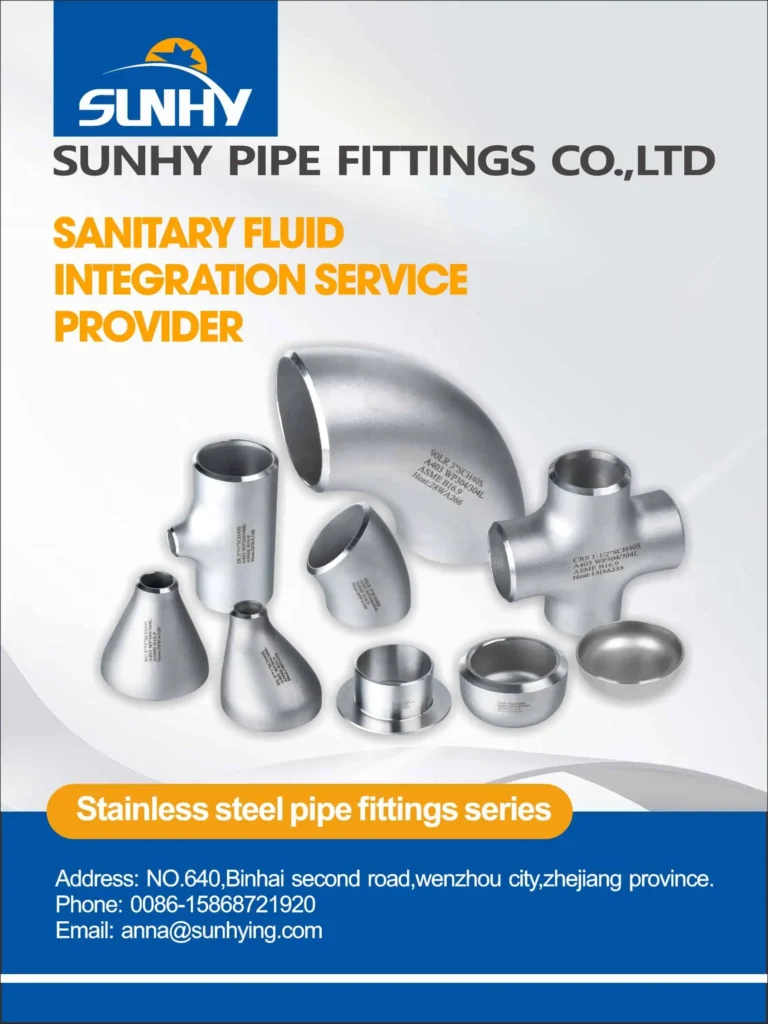

Raw Material & Forging

- Stainless Steel Plate

- Round Bar

- Blank Cutting

- Sawing

- Circular Saw Cutting

- Cold Heading

- Die Forging

- Ring Rolling

- Free Forging

Advanced Machining & CNC Precision

- Laser Cutting

- Pipe Cutting

- Large Flange Machining

- Flange Product Machining

- Fitting Product Machining

- Threaded Product Machining

- Gantry Machining

- Tube Sheet Machining

- 5-Axis Complex Part Machining

- 4-Axis Machining Center

- Square Flange Machining

Welding & Surface Treatment

- Automatic Welding

- Manual Welding

- Internal Polishing

- External Polishing

- Marking

- Laser Marking

- Penetrant Testing (PT)

Testing, Inspection & Packaging

- Roughness Inspection

- Spectrometry Analysis

- Ultrasonic Testing (UT)

- Carbon Element Analysis

- Wooden Case Packaging

Quality Assurance

Rigorous Testing Protocol

Every batch of flanges undergoes a comprehensive verification process. Dimensional Inspection is performed using CMM to verify bolt hole positions and facing flatness. Surface Roughness Testing ensures the sealing face meets the Ra 3.2-6.3μm standard for optimal gasket adhesion. We also offer Intergranular Corrosion Testing (per ASTM A262) for critical chemical applications.

Certified for Global Compliance

Sunhy acts as your compliant partner for international projects. Our quality system is audited to ISO 9001:2015, and our products comply with the European Pressure Equipment Directive (PED 2014/68/EU), allowing for use in European pressure systems. We provide full traceability with EN 10204 3.1 Material Test Reports (MTRs) included with every shipment, documenting chemical composition, mechanical properties, and heat treatment history.

Everyone will choose the right choice

Why Choose Sunhy

Sunhy Quality

VS

Low Quality

Materials: Top-tier steel mill source, Full Traceability (MTC).

Materials: Unknown origin, Vague MTC data.

Chemistry: Alloy content strictly controlled (e.g., Ni/Mo), Superior corrosion resistance.

Chemistry: Insufficient alloy (e.g., Low Ni), Poor corrosion resistance.

Accuracy: High-precision CNC finished, 100% Leak-Proof dimensional fit.

Accuracy: Relies on Manual Grinding for Dimensional Correction

Certifications: PED/DNV/TS approved, Strict UT/PT testing on every batch.

Certifications: Only basic ISO, Missing NDT reports.

Finish: Clear stamping, Thorough Passivation, Long-lasting clean surface.

Finish: Blurry mark, Rough finish, Oxide residue.

Global Logistics

Trusted Delivery, Anywhere

From a single emergency Blind Flange replacement to a full container of Slip-Ons for a new plant construction, Sunhy simplifies your supply chain. We export to 30+ countries, understanding specific packing requirements like plywood cases for phytosanitary compliance. Your flanges arrive protected, certified, and ready for installation.

Dedicated Customer Support Teams

Serving Impressive List Of Long Term Clients!

Our growth is a testament to how much we value our customers. Exceptional customer service has been the key to our success, ensuring satisfaction and fostering loyalty. Thank you for helping us grow together.

Seeing is believing

About Sunhy

See Quality in the Making, Build Trust in Person

Visit Sunhy Factory: See Quality, Build Trust

🏭 Full-Process Tour

See precision machining, assembly, and testing—witness how each stainless steel flange is born.

🤝 Technical Exchange

Our engineers provide on-site support for selection, customization, and solutions.

Submit your visit request—we’ll contact you within 24h to plan your custom tour.