What are NPT fittings? NPT fittings are threaded connectors that use tapered pipe threads to create a pressure-retaining joint in many fluid and gas services. In the field, “leak-tight” depends on more than the thread form: it depends on the thread standard, material pairing (for example 316 stainless into 316 stainless), sealant selection, and assembly control (cleanliness, engagement length, and avoiding over-torque). NPT threaded connections are common in:

- Plumbing and HVAC (water, glycol, air)

- Oil and gas (instrumentation and utility hookups)

- Chemical processing (ancillary services and sampling points)

- Construction (compressed air and temporary piping)

- Marine and agriculture (washdown, pumps, and skid piping)

- Food and beverage production (non-hygienic threaded auxiliaries, where code allows)

In North American supply chains, NPT remains widely specified because the thread form and gaging practice are standardized. For pressure-containing threaded fittings (forged elbows, tees, couplings), engineering procurement typically references ASME B16.11 for the fitting product standard and ASME B1.20.1 for the NPT thread form. Sunhy supplies stainless steel threaded fittings with controlled machining, material traceability, and inspection practices aligned to these requirements.

What Are NPT Fittings?

NPT Thread Basics

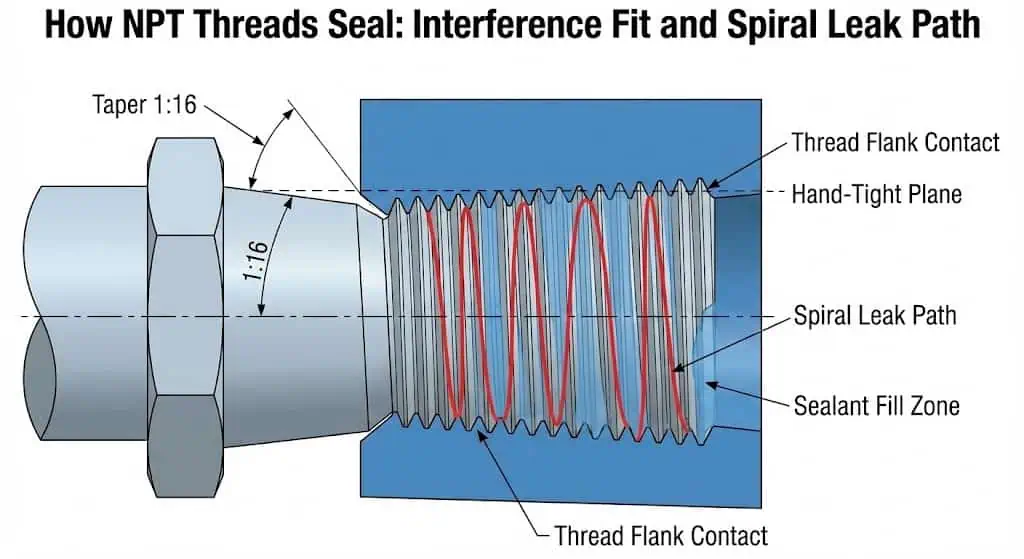

NPT fittings use tapered threads intended to form an interference fit as the male and female threads wedge together.

NPT stands for National Pipe Taper (commonly written as National Pipe Thread in purchasing language). The governing thread definition is specified by ASME B1.20.1 (Pipe Threads, General Purpose (Inch)), which defines the basic thread profile, taper, and acceptance criteria used across many industries.

From an engineering standpoint, three facts drive performance and troubleshooting:

- NPT is tapered: the taper is 1 in 16 on diameter (often described as 3/4 inch per foot). This taper creates increasing interference as the joint is tightened.

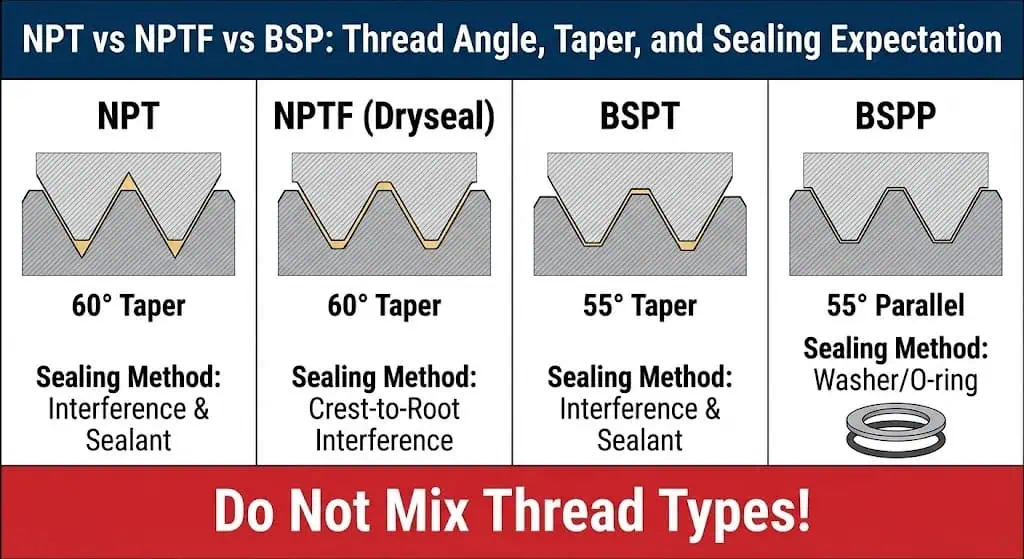

- NPT uses a 60° thread angle: this matters when someone attempts to mate NPT with BSP family threads (typically 55°) or straight threads that are designed to seal with an O-ring or gasket.

- Thread seal is system-dependent: NPT can pass a leak test in one service and seep in another because viscosity, temperature cycling, vibration, and pressure pulsation change the “micro-movement” at the thread interface.

Procurement note (verifiable): When a purchase order says “NPT,” the thread definition is controlled by ASME B1.20.1. For forged threaded fittings commonly used in pressure piping, the product standard reference is ASME B16.11 (Socket-Welding and Threaded Forged Fittings).

Engineering reality: NPT is not a “precision alignment” thread. If orientation is critical (for example gauge faces that must point forward), relying on “backing off” an NPT joint to align is a common leak cause. In those cases, engineers typically specify a different connection strategy (union, adjustable adapter, or a straight thread with a sealing element), depending on the system code and service.

How NPT Fittings Seal

NPT fittings seal through thread interference plus a sealant system that fills the microscopic leak paths and stabilizes the joint.

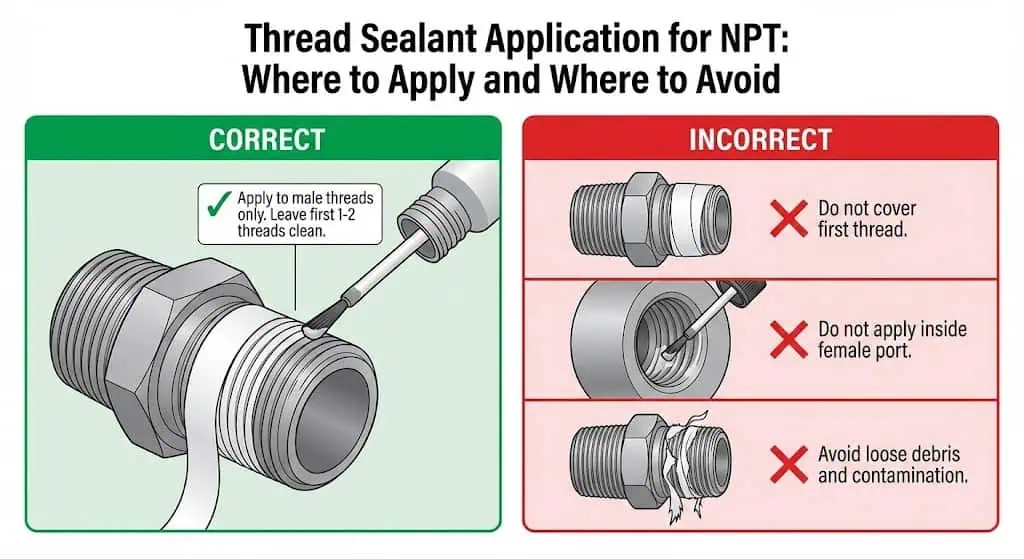

In practice, NPT sealing is a combination of: (1) metal-to-metal contact at the thread flanks as interference increases, and (2) a sealant that fills spiral leakage paths, reduces galling risk, and improves repeatability between installers. Because machining tolerances and surface condition vary (especially after rework or repeated assembly), most engineered systems specify a suitable sealant rather than relying on dry metal contact.

- Interference fit: taper creates wedging action; more turns increase contact stress.

- Sealant function: fills voids, lubricates threads, and reduces micro-leak paths under pulsation.

- Clean assembly: contamination (chips, PTFE shreds) can create a leak channel or damage the female thread.

Field case #1 (leak + galling): A 316 stainless male NPT nipple was installed into a 316 stainless instrument valve. The joint initially tightened “hard” and then seized; after disassembly, both threads showed scoring (galling). Cause: stainless-on-stainless with insufficient lubrication and high surface friction. Corrective action: replace damaged parts; reassemble using a compatible thread sealant that also provides lubricity; control wrench turns rather than “tighten until it stops.” Prevention: treat stainless NPT as a controlled assembly, not a brute-force tightening exercise—especially on small sizes.

Field case #2 (instrument plugging): A pressure transmitter line drifted because PTFE tape fragments migrated and partially blocked an instrument orifice. Cause: tape applied past the leading thread and shredded during make-up. Corrective action: clean the line and orifice; rebuild using controlled tape application (keep the first 1–2 male threads free) or use an appropriate liquid sealant approved for the service. Prevention: prioritize cleanliness on instrumentation—small debris becomes a metering restriction.

Assembly control checklist (typical engineering practice; depends on thread condition and sealant): clean threads; confirm no dents on the first female threads; apply sealant to male threads only; hand-tight to a stable stop; then apply wrench turns in a controlled manner. If the joint orientation matters, avoid loosening to “aim” the fitting—use a different joint design that supports orientation without compromising seal.

NPT vs Other Thread Types

NPT threads differ from other thread types by how they achieve sealing and what the design expects to do the sealing.

The most common mismatch problems happen when tapered threads are confused with straight threads, or when NPT is mixed with BSP family threads. Below is a practical engineering comparison:

| Thread Type | Sealing Mechanism | Common Use | Sealant Needed |

|---|---|---|---|

| NPT | Tapered, interference fit (thread flanks) + sealant | North American general piping, utilities, instrumentation hookups | Yes (typical engineered practice) |

| NPS | Straight thread; usually requires gasket/O-ring/seat elsewhere | Mechanical joints where the seal is not on threads | Depends on joint design |

| BSP (BSPT/BSPP) | Tapered or parallel; often seals via washer/O-ring or controlled seat depending on type | International equipment interfaces | Depends; do not assume NPT equivalence |

| NPTF (Dryseal) | Tapered “dryseal” thread designed to reduce spiral leak path by crest/root interference | Hydraulics/pneumatics and applications targeting minimal leakage without tape | Often still used (service-dependent) |

- Do not mix NPT and BSP by “it almost fits” logic: thread angle and pitch differences can create a joint that grabs but leaks or damages female threads.

- Know what seals: straight threads (many NPS-style uses) typically seal with an O-ring, gasket, or cone/seat—not by thread interference.

Field case #3 (thread mismatch): A maintenance team installed an NPT male into an imported BSPP female port. It tightened a few turns and then leaked during a hydro test. Cause: incompatible thread form—contact occurred at the wrong locations, leaving a helical leak path. Corrective action: replace with the correct adapter (BSPP-to-NPT) or re-specify the port connection type. Prevention: verify thread system at receiving inspection using pitch gauge + thread gage (and label ports on skids to prevent “assumed NPT” rework).

Standards references (for verification): NPT thread definition is governed by ASME B1.20.1. NPTF “dryseal” thread practice is addressed by ASME B1.20.5 (Dryseal Pipe Threads). BSP parallel thread reference for “threads where pressure-tight joints are not made on the threads” is covered by ISO 228-1.

Sunhy’s Stainless Steel NPT Fittings

Sunhy’s stainless steel NPT fittings are manufactured as controlled threaded components—not generic “hardware-store threads.”

For engineering users, the differentiators that matter are: consistent thread geometry, gaging discipline, material verification, and surface condition that supports stable assembly. Stainless threaded joints can be sensitive to galling and over-torque; controlled machining and inspection reduce variability across lots.

| Feature | Sunhy’s Stainless Steel NPT Fittings | Typical Market Range (verify with supplier) |

|---|---|---|

| Material | 304 / 316L stainless with heat/lot traceability on request | May vary by lot; traceability not always provided |

| Thread Design | NPT to ASME B1.20.1 with controlled machining and acceptance checks | Thread form may be “NPT-like” without disciplined gaging |

| Sealing Mechanism | Taper interference + sealant-based assembly (engineering practice) | Performance depends heavily on installer and sealant |

| Application Suitability | Designed for utility/instrument services where stainless corrosion resistance is required | Suitability varies; confirm fitting product standard and pressure class |

| Corrosion Resistance | Material-driven; 316L preferred for chloride/marine exposure (service-dependent) | Material substitutions can reduce pitting resistance |

Advantages of using NPT thread fittings (engineering framing):

- Standardized thread form: consistent sizing and interchangeability when suppliers follow ASME B1.20.1.

- Flexible maintenance: threaded joints can be disassembled for component replacement in many utility and instrument services (while recognizing wear limits).

- Broad component ecosystem: adapters, couplings, and valves are widely available in NPT ports and ends.

- Material options: stainless steel supports corrosive and outdoor environments when correctly selected for the media.

For engineered service, selection should be tied to: (1) fitting product standard/class, (2) thread standard, (3) material compatibility (media + chlorides + temperature), and (4) assembly control requirements.

NPT Thread Features

Tapered Design

The tapered design of npt thread is essential to how the joint generates interference and seating stress.

Per ASME B1.20.1, NPT is tapered at 1 in 16 (diameter), commonly described as 3/4 inch per foot. That taper means the male and female threads wedge tighter as the fitting is advanced. This wedging action is why over-tightening can crack brittle female components (cast or thin-wall) and why stainless pairs can gall if assembled dry.

- Taper creates interference that increases with engagement.

- Interference raises contact stress and helps resist pressure leakage.

- Excess interference (over-torque) can split female ports or permanently deform threads.

Sealing Mechanism

Npt thread sealing is a controlled interference joint, not a gasketed face seal.

When assembled correctly, thread flanks carry load and a sealant mitigates the spiral leakage path. The sealant is also a lubrication layer that improves repeatability and reduces galling. For services that demand reduced leakage without tape, engineers may evaluate NPTF dryseal threads (see ASME B1.20.5)—but acceptance still depends on the system leak test criteria and assembly practice.

Installation tip (controlled practice): Apply sealant to male threads only, keep the first 1–2 male threads clean (instrument cleanliness), hand-tighten to a stable stop, then add wrench turns in a controlled manner. Avoid backing off to align—rebuild with an orientation-capable joint if alignment is required.

Material Options

Material selection for npt fittings affects corrosion resistance, galling tendency, and service temperature limits.

In piping reliability work, many “NPT leaks” trace back to material mismatch or uncontrolled assembly rather than the thread standard itself. Stainless steel is frequently chosen for corrosion resistance; however, stainless-on-stainless pairs increase galling risk and benefit from a sealant/lubricant strategy. Sunhy offers 304 and 316L stainless steel npt fittings; selection should be tied to media chemistry (especially chlorides) and cleaning requirements.

| Material | Relative Corrosion Suitability (typical; service-dependent) | Common Applications |

|---|---|---|

| Plastic | Good for compatible chemicals at lower pressure/temperature; verify creep and code limits | Lightweight, specialized uses |

| 304 Stainless Steel | General corrosion resistance; verify for chlorides and aggressive acids | General use, mild chemicals, water systems |

| 316L Stainless Steel | Improved pitting resistance vs 304 in chloride exposure (typical); verify per media | Corrosive environments, marine engineering |

From a QA standpoint, repeatable performance requires: controlled machining of threads, inspection with appropriate gages, and material verification where the service demands it. For pressure piping supply, engineers often request MTRs/traceability and define the fitting standard/class in the purchase description (service-dependent).

NPT Sizing & Measurement

Measuring NPT Fittings

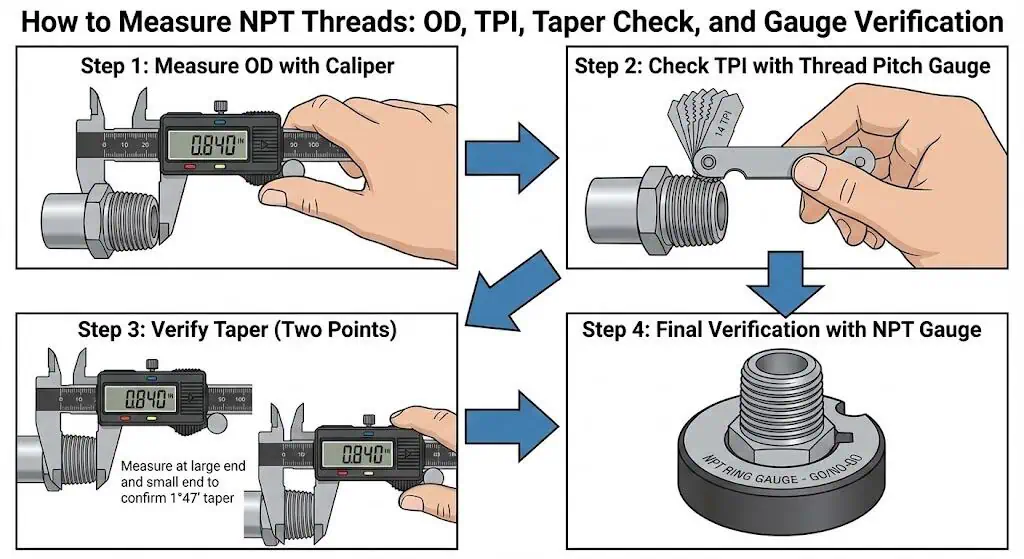

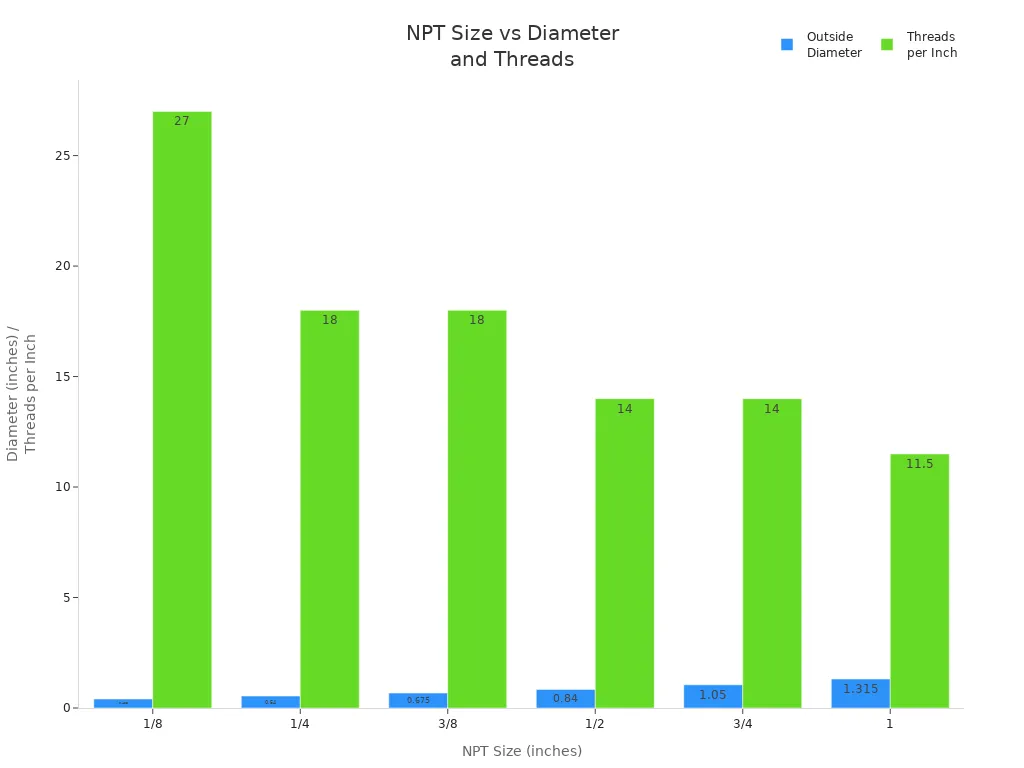

Measuring NPT correctly means separating “nominal pipe size” from the actual thread outside diameter.

In receiving inspection and field verification, a common mistake is assuming that “1/2 NPT” refers to a 1/2 inch measured diameter. It does not. The correct method uses a diameter measurement plus a threads-per-inch check, and—when the system is critical—confirmation with an NPT gage that reflects the acceptance practice.

Standard tools for measuring npt fittings include:

- Caliper (digital or vernier) for diameter measurements

- Thread pitch gauge for counting threads per inch

- NPT thread gauge for checking taper and fit

- Tape measure or ruler for quick checks

Steps for measuring npt fittings:

- Identify the fitting type (male or female).

- Measure the outer diameter at the base of the male threads (or the inner diameter at the opening for female as a screening check).

- Use a pitch gauge to determine threads per inch.

- Screen the taper by measuring at two points along the thread length (quick check).

- For critical services, confirm using an NPT gage consistent with ASME B1.20.1 acceptance practice.

Field case #4 (wrong size assumption): A mechanic measured a male thread OD and ordered “the closest inch size,” resulting in a thread that started but bound early. Cause: NPT nominal size confusion. Corrective action: re-identify using TPI + NPT gage; replace with correct nominal size. Prevention: train teams that NPT size is nominal; always confirm with pitch + gage for anything beyond low-risk utility service.

Sizing Charts

Sizing in npt threads is standardized, but engineering teams should verify critical dimensions against the governing standard and the supplier’s controlled drawings.

The ASME B1.20.1 standard defines thread geometry and acceptance. The table below is a quick reference for common small sizes used in instrumentation and utilities; always confirm exact values against the current standard and the manufacturer’s chart for procurement and inspection.

| Nominal Pipe Size | Outside Diameter (in) | Threads per Inch | Hand Tight Engagement (in) |

|---|---|---|---|

| 1/16 | 0.3125 | 27 | 0.160 |

| 1/8 | 0.405 | 27 | 0.1615 |

| 1/4 | 0.540 | 18 | 0.205 |

| 3/8 | 0.675 | 18 | 0.216 |

| 1/2 | 0.840 | 14 | 0.261 |

Note: For engineering-critical assemblies, use the governing standard and gaging practice as the acceptance basis (see ASME B1.20.1), and keep the supplier’s dimensional chart in the job file for traceable inspection.

Common Mistakes

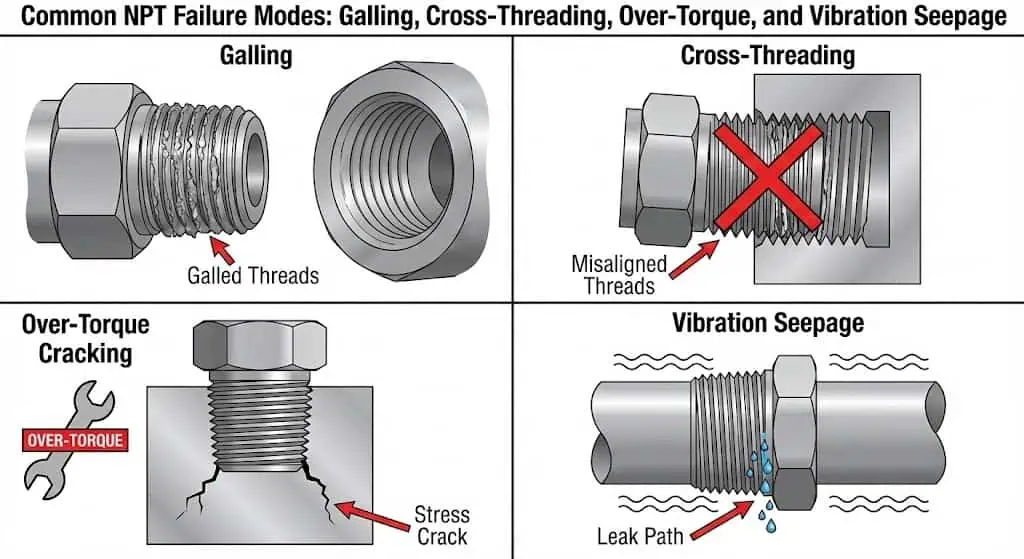

You avoid common NPT failures by treating the joint as an engineered interference connection with controlled assembly.

Many leaks show up only after pressure cycling or vibration exposure. Below are high-frequency failure drivers seen in maintenance and commissioning:

Most frequent errors include:

- Over-tightening the fitting: can crack female ports (especially thin-wall or brittle components) or permanently deform the thread interface.

- Applying sealant incorrectly: sealant on female threads can contaminate systems and reduce engagement predictability; excess tape can shred into lines.

- Ignoring material compatibility: stainless pairs may gall; brass or cast female ports may be damaged by excessive interference and torque.

Practical control point: Most sealant-related failures happen because sealant is applied inconsistently. Apply sealant to male threads only, control coverage, and keep the lead threads clean when contamination risk exists (instrumentation and small orifices).

Sunhy’s CNC machining and quality control reduce variation in thread geometry, but system integrity still depends on installation discipline: clean threads, controlled engagement, and selection of a sealant appropriate for the service and plant standards.

NPT Fittings Applications

Industrial Uses

NPT fittings are widely used in industrial utility and instrumentation services where threaded maintenance access is beneficial.

You commonly see NPT ports on pressure gauges, instrument valves, sample points, and small-bore utility connections. In these use cases, the engineering emphasis is on: repeatable sealing, resistance to vibration loosening, and avoiding contamination during assembly. Stainless steel NPT fittings are often selected where corrosion resistance is required, but they must be assembled with care to avoid galling and over-torque damage.

Reliability insight: In cyclic or vibrating services, the thread joint is only as reliable as its assembly control. If a system sees frequent vibration, engineers may add mechanical support, specify sealant compatible with vibration, or choose a different connection design for critical leak-tight requirements.

| Aspect | Contribution to Reliability |

|---|---|

| Secure Connections | NPT fittings can maintain pressure when assembled with controlled engagement and suitable sealant. |

| Tapered Thread Design | Taper creates interference; excessive interference can damage female ports if over-torqued. |

| Use of Thread Sealants | Sealants fill micro-voids and reduce galling risk; poor application can cause contamination. |

| Material Durability | Stainless resists corrosion; material pairing and assembly practice affect galling and leak risk. |

Where the consequence of leakage is high, engineers typically document the assembly method (sealant type, cleanliness controls, engagement expectations) and verify leak testing criteria during commissioning.

Plumbing & Gas Systems

NPT fittings are common in plumbing and gas distribution where the applicable code and authority allow threaded joints.

In these services, the failure modes are consistent: under-tightening causes weeping, over-tightening damages female ports, and mis-threading (cross-threading) destroys the first threads and makes the joint unpredictable. Temperature cycling can loosen marginal joints, especially if the assembly was “aligned by backing off.”

- NPT fittings are used in many plumbing systems for threaded connections where permitted.

- They appear in HVAC water/glycol loops and compressed air utilities.

- In gas service, leak detection requirements can be more stringent; assembly control and verification testing are essential.

- Do not mix thread systems; use the correct adapter when equipment ports are not NPT.

- Always treat thread sealant selection as service-specific (media, temperature, and cleanliness constraints).

Good practice in maintenance: if a joint is disassembled frequently, inspect threads for wear, scoring, and deformation; tapered threads can lose sealing reliability after repeated cycles, especially on softer materials.

Sunhy Product Solutions

Sunhy offers stainless steel npt fittings engineered for controlled assembly and predictable field performance.

You find Sunhy’s product line includes adapters and instrument-style fittings used in industrial utilities and skid packages. Each fitting is manufactured with attention to thread geometry and surface condition so installers can achieve repeatable results when following a controlled sealant and assembly procedure.

Quality perspective: For repeatable installation, control what you can control—thread geometry, material verification, cleanliness, and an assembly method aligned to the service and test criteria.

You can request stainless steel npt fittings tailored to your specifications. In engineered projects, the specification typically states: thread type (NPT or NPTF), fitting standard/class (where applicable), material grade (304/316L), and any documentation needs (traceability, inspection records).

- Choose stainless where corrosion resistance is required and verify media compatibility.

- Use a sealant strategy that supports both sealing and anti-galling performance.

- For imported equipment ports, confirm thread system early and plan adapters to prevent field rework.

Pros & Cons of NPT Fittings

Advantages

NPT fittings offer standardized geometry, broad availability, and serviceable threaded joints for many utility and instrument applications.

- Standardized thread form: defined by ASME B1.20.1, enabling consistent sizing when suppliers follow the standard.

- Progressive sealing behavior: taper increases interference with tightening, supporting pressure retention when correctly assembled.

- Broad ecosystem: common in valves, gauges, manifolds, and general pipefitting supply chains.

- Material flexibility: available in steel, stainless, brass, and plastics (service-dependent selection).

- Maintenance accessibility: threaded joints can be disassembled for component replacement in many non-welded assemblies.

- Simple field tooling: assembly and verification can be done with standard tools plus thread gages for critical services.

- Mpt and fpt options allow you to connect male pipe thread and female pipe thread ends for flexible installation.

Limitations

NPT fittings have limitations tied to thread wear, vibration sensitivity, and assembly variability.

- Leaks can occur if the joint is assembled without controlled engagement, correct sealant, or clean threads.

- High vibration and pressure pulsation can promote micro-movement and loosening on marginal joints.

- Repeated assembly/disassembly wears threads and can reduce sealing reliability over time (service-dependent).

- Stainless-on-stainless pairs can gall; improper assembly can seize and destroy threads.

- Tapered threads demand alignment discipline; cross-threading and “back-off alignment” are frequent field causes of weeping leaks.

| Failure Mode | Description |

|---|---|

| Micro-movement | Threads may shift under vibration or pulsation, creating leakage paths. |

| Thread wear and galling | Repeated use or stainless pairs can degrade the thread interface. |

| Systemic pressure loss | Small leaks can reduce pressure stability in instrument and utility systems. |

| Vibration-induced loosening | Marginally tightened joints may loosen over time. |

| Risk of hidden leaks | Seepage may only appear after thermal cycling or during higher-pressure tests. |

| Cost of rework | Leaks lead to shutdowns, retesting, and component replacement. |

| Safety risks | Pressurized leaks can create hazards depending on media and location. |

Choosing the Right Fitting

Selection should be driven by service criticality, media compatibility, and the required leak test criteria.

| Factor | Description |

|---|---|

| Material Choice | Match material to media chemistry, chlorides, temperature, and code constraints. |

| Application Needs | Define pressure/temperature cycling, vibration exposure, and allowable leakage criteria. |

| Use Cases | Consider whether frequent disassembly, orientation needs, or cleanliness constraints exist. |

- Review operating conditions, vibration, thermal cycling, maintenance frequency, and cleanliness requirements before selecting NPT.

- Where hygiene or frequent cleaning is required, alternative connection styles may be more appropriate than tapered threads.

- If imported equipment ports are BSP or another system, plan the correct adapters early to avoid field damage and leaks.

Tip: Always match the fitting type—mpt or fpt—to your pipe ends and check compatibility with the system’s pressure/temperature envelope and test requirements.

NPT fittings deliver reliable, serviceable threaded connections when specified to the correct standard and assembled with controlled practice. The taper and standardized thread pitch defined in ASME B1.20.1 support consistent field results. Where reduced leakage paths are targeted, engineers may evaluate NPTF dryseal practice in ASME B1.20.5—subject to service and test criteria.

- Choose the right nominal size using pitch + gage methods for reliable identification.

- Document the assembly method (sealant type and cleanliness controls) for repeatable commissioning results.

Select high-quality fittings and use controlled assembly practices to protect safety and long-term reliability.

FAQ

What does NPT stand for?

NPT stands for National Pipe Taper.

NPT threads are tapered pipe threads defined by ASME B1.20.1. The taper creates an interference fit as the joint is tightened, and most engineered installations use a suitable sealant to improve repeatability and reduce leak paths.

How do you identify NPT threads?

You identify NPT threads by verifying taper plus thread pitch (TPI), then confirming with the correct gage for critical services.

- Measure diameter at two points along the thread and confirm taper behavior (screening check).

- Count threads per inch using a pitch gauge.

- Use an NPT thread gage to confirm fit/acceptance practice when the application is critical.

Can you use NPT fittings with BSP threads?

You should not mix NPT and BSP threads.

They are different thread systems (angle/pitch and sealing expectations differ). A joint may “start” and then leak or damage threads. If equipment ports are BSP, use a purpose-made adapter or specify the correct thread system for the component.

What sealant should you use with NPT fittings?

Use a sealant approved for the service (media, temperature, cleanliness), typically applied to male threads only.

PTFE tape and liquid thread sealants are common; the better choice depends on contamination risk (instrumentation), vibration, and plant standards. Apply sealant consistently, keep lead threads clean when contamination matters, and do not rely on “backing off” to align orientation.

Why choose stainless steel NPT fittings?

Stainless steel NPT fittings offer corrosion resistance and durability in many industrial environments.

They are frequently chosen for outdoor exposure, chemical splash zones, and marine atmospheres (service-dependent). Stainless assemblies should be built with controlled practices to reduce galling risk (especially stainless-on-stainless thread pairs).