A flange is a bolted joint interface used to connect pipes, valves, pumps, and equipment by converting bolt preload into gasket seating stress to control leakage. In practical plant work, the “flange” is rarely the failure by itself; leakage almost always traces back to face condition + gasket selection + bolt load control + alignment. In 2025, flanges remain foundational because global dimensional standards and material specifications make the joint predictable when you assemble it correctly. The projected global market size for industrial flanges in 2025 stands at USD 6.1 billion, reflecting how widely flanged joints are still specified across infrastructure.

If you need a fast engineering answer before reading the full guide:

- Start from design conditions: pressure, temperature, and media (including corrosion/sour service constraints) define the standard, facing, gasket family, and bolting grade.

- Match the system standard end-to-end: ASME/ANSI Class systems are not dimensionally interchangeable with DIN/EN PN without adapters.

- Assume the joint lives or dies by bolt load control: torque is only a proxy; friction scatter and poor tightening sequence create uneven gasket stress and leakage paths.

- Never “pull” misaligned spools together with studs: misalignment loads the joint and relaxes bolt preload after thermal cycles.

We find flanges in a wide range of critical applications, from the high-pressure lines of chemical plants to oil and gas refineries, water treatment facilities, and power plants. Recent years have seen rapid growth in demand and innovation:

| Region | CAGR (2020-2024) | CAGR (2025-2035) | Key Drivers |

|---|---|---|---|

| United States | 3.8% | 4.9% | Oil and gas refurbishments, power modernization |

| India | 5.6% | 7.3% | Pipeline projects, refinery expansion |

You can also benefit from maintenance-driven upgrades such as improved gasket technologies, controlled tightening procedures, and inspection routines that catch flange issues before they become shutdown events. Use this guide to make informed choices and troubleshoot flange systems using checks you can actually execute in the field.

Field reality: If a flange “keeps leaking,” treat it as a joint system problem. Start with face damage and alignment, then gasket type and bolt condition, then tightening method. Replacing gaskets repeatedly without correcting the root cause just burns downtime.

Flanges Overview: The Fundamentals

What Are Flanges?

Simply put, flanges are disc-shaped interfaces that create a detachable pressure boundary between two components. Unlike welding, which is permanent, a flange joint is serviceable: you can open it for inspection, cleaning, or component replacement. The joint seals because bolt preload compresses a gasket against two flange faces. That means your sealing performance depends on:

- Face condition: nicks, radial scratches across the seating area, or corrosion pitting create leak paths.

- Gasket family and thickness: the gasket must match face type and service (steam vs chemicals vs water).

- Controlled bolt load: uneven bolt load distorts flange faces and creates local under-compression.

- Alignment and support: piping loads can relax bolt preload after temperature cycling.

If you want a fast functional overview tied to typical plant decisions, see: What Is the Function of a Flange and How Does It Work?

History and Evolution

Flanges became reliable when standardization made dimensions and materials predictable—and when gasket/bolting practices matured. As engineers, we can trace their evolution through stages that directly map to failure reduction:

- Early flanges were simple and lacked standardization, so bolt patterns and face details varied between suppliers and repairs became guesswork.

- During the Industrial Revolution, forged flanges and better gasket materials increased allowable pressure and temperature while improving fatigue performance.

- By the mid-20th century, global standards emerged. Organizations like ASME and API published specifications, making flanges interchangeable across projects.

- In recent years, we benefit from corrosion-engineered alloys (Duplex/Super Duplex, nickel alloys) and better assembly control (calibrated tools, documented tightening sequences, inspection routines).

Importance in Modern Industry

Flanges are critical to safe and efficient operation because they provide a controlled, inspectable seal at equipment interfaces. In real maintenance work, flanges are selected not only for pressure/temperature, but for how often you expect to open the joint and what happens if it leaks:

- Secure Connections: predictable bolt pattern + gasket seating area = repeatable assembly when done correctly.

- Reliable Sealing: correct face/gasket/bolting combination is essential for hazardous media and steam service.

- Maintenance Access: you can isolate and open joints without cutting pipe—this directly reduces outage scope.

- Non-Destructive Disassembly: inspection and replacement without hot work (critical in many plants).

- Adaptability: different flange types handle vibration, temperature gradients, and cyclic loads differently.

- Regulatory Compliance: using recognized standards and documented assembly procedures improves auditability.

We see flanges used extensively in these major sectors:

- Petrochemical sector (The largest consumer)

- Food & beverages processing (Fastest growing due to hygiene standards and frequent disassembly for cleaning)

- Oil & gas (Expanding global infrastructure)

- Power generation (Steam systems where gasket selection and bolt load control are non-negotiable)

Material selection matters more than marketing claims. For example, molybdenum-bearing stainless grades (e.g., 316/316L) are widely specified when chloride pitting risk is higher than what 304/304L can tolerate in the same temperature band—always verify against your media chemistry and operating temperature. A concise metallurgy-oriented reference is the Nickel Institute guidance on stainless selection and performance: High Performance Stainless Steels (Nickel Institute)

Case file (leak that “wouldn’t go away”): A cooling water line showed persistent weeping after every gasket change. Cause: flange faces had radial scoring from aggressive scraping; the gasket could not bridge the grooves. Fix: re-machine face to correct finish, replace gasket with correct thickness, and retighten per documented cross-pattern. The “problem gasket” was not the problem.

Flange Structure and Connection Methods

Basic Flange Design

A standard industrial flange includes the sealing face, bore, bolt holes (bolt circle), and—where applicable—a hub/neck that manages stress transfer. The reason these details matter is simple: if the flange geometry doesn’t match the standard, you can’t guarantee bolt-up alignment, gasket seating area, or pressure-temperature rating behavior. For dimensional scope and facing conventions in common Class-rated process flanges, refer to ASME B16.5 overviews and standard listings: ASME B16.5 (Pipe Flanges and Flanged Fittings)

The table below summarizes the main structural features and sealing faces of common flanges we encounter in the field:

| Flange Type | Structural Features | Sealing Faces |

|---|---|---|

| Weld Neck Flange | Tapered neck with V-groove for butt welding; neck transition disperses stress effectively. | Raised Face (RF), Ring Type Joint (RTJ) |

| Slip-On Flange | Larger inner diameter than pipe; fixed by fillet welding (internal and external). | Flat Face (FF), Raised Face (RF) |

| Socket Weld Flange | Pipe inserts into flange socket; requires a 1.6mm gap for thermal expansion. | Raised Face (RF) |

| Blind Flange | Solid flange without center hole; matches paired flange sealing face. | FF, RF, RTJ |

| Lap Joint Flange | Flange body plus a separate stub end; rotatable 360° for easy bolt alignment. | N/A (Uses Stub End face) |

| Threaded Flange | Internal threads; fits pipes with external threads (verify thread standard for your region). | FF, RF |

We select the flange type based on pressure, temperature, cyclic loading, corrosion allowance, and the need for repeatable maintenance access. A “cheaper” flange that forces frequent rework is not cheaper on an operating plant.

How Flanges Connect Pipes and Equipment

We connect flanges to pipes and equipment using methods that balance strength, inspectability, and assembly control. Each method has a typical failure mode you should plan for:

- Bolted Connection: serviceable and common; failures usually come from uneven bolt load, gasket mismatch, or misalignment loads.

- Welded Connection: strong and compact; failures often come from poor weld procedure control, lack of NDE where required, or thermal fatigue at transitions.

- Threaded Connection: fast; failures often come from thread damage, sealant mismatch, or vibration loosening in cyclic service.

- Socket Weld Connection: strong for small bore; failures often come from crevice corrosion at the socket and lack of gap control.

- Lap Joint Connection: maintenance-friendly; failures often come from wrong stub end material/finish or joint movement not considered in supports.

- Slip-On Connection: cost-effective; failures often come from lower fatigue strength and weld quality variability.

Where joint integrity is critical, documented assembly practice matters as much as the flange type. A commonly referenced assembly guideline for bolted flange joints is ASME PCC-1 (Guidelines for Pressure Boundary Bolted Flange Joint Assembly): ASME PCC-1 (ANSI Webstore)

Flange Assembly Process (Step-by-Step)

A disciplined assembly sequence is the difference between a stable joint and a leak that returns after the first thermal cycle. The steps below are written the way we actually execute them during shutdown work, not as a brochure checklist:

- Inspection (faces + studs + nuts): Inspect flange faces under good light; any scratch crossing the seating area is suspect. Check studs for necking, thread galling, and corrosion. Replace questionable fasteners—do not “hope” a stretched stud will hold load.

- Preparation (cleaning without damage): Remove old gasket material using methods that do not score the face. Solvent clean and dry. If you have pitting in the seating area, you need machining or an engineered gasket solution—new gaskets alone will not fix geometry damage.

- Alignment (no bolt-forcing): Align flanges so bolt holes match naturally. If you must lever flanges together, you have piping stress that will unload the gasket later.

- Gasket placement (center + correct type): Center the gasket; do not allow it to hang into the bore (erosion risk) or sit off-center (uneven compression).

- Lubrication control (consistency): Apply the specified lubricant to threads and nut bearing surfaces consistently. Changing lubrication changes friction and therefore changes achieved preload for the same torque.

- Hand-tightening (seat the joint): Bring the joint together evenly. If one side closes first, stop and correct alignment.

- Torquing (cross pattern + staged): Tighten in a star/cross pattern in multiple passes (commonly 30%, 60%, 100%). Follow with a final verification pass per your site procedure.

- Testing (controlled pressurization): Pressurize slowly and observe. If a joint weeps under low pressure, do not “just crank it”—stop and diagnose the cause (gasket type, face condition, alignment, bolt scatter).

Case file (steam line leak after startup): A Class-rated steam joint passed a cold hydrotest but leaked after heat-up. Cause: uneven bolt load from circular tightening sequence + no re-check after the first thermal cycle; gasket relaxed and the joint lost effective seating stress. Fix: reassemble with controlled cross-pattern staged tightening, verify stud condition/lubrication consistency, and perform a documented check pass after thermal stabilization.

We ensure the integrity of every flanged connection by treating assembly as a controlled process. If your site has ASME PCC-1-based work instructions, follow them; the details (pattern, passes, lubrication, tools) are exactly where joints succeed or fail.

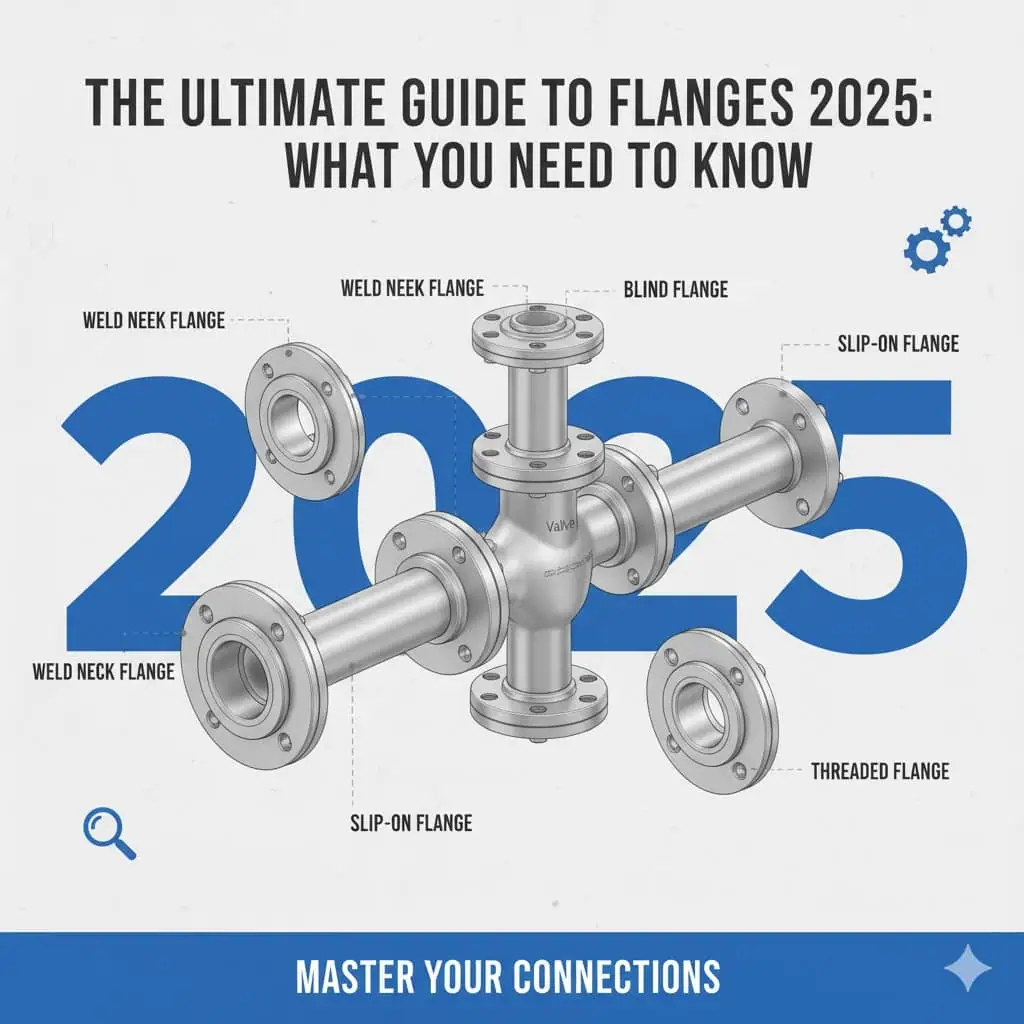

Detailed Guide to Types of Flanges

We encounter many different types of flange in industrial piping systems. Each type serves a specific purpose and offers unique advantages for your application. Below, you will find common flange types, how we actually select them, and what typically goes wrong when they are misapplied.

| Selection Question | What to check (engineering) | Why it matters |

|---|---|---|

| Is the service cyclic / vibrating? | Prefer Weld Neck; avoid Slip-On in severe cyclic duty unless engineered. | Fatigue and weld toe cracking show up first where stress concentrates. |

| Do you need frequent dismantling? | Lap Joint + Stub End can reduce outage time if materials and faces are correct. | Rotation solves bolt-hole alignment without forcing pipes. |

| Is welding restricted (hazard zone / on-site constraints)? | Threaded may be used only within its pressure/temperature limits; verify thread standard and sealing method. | Threaded leaks often come from vibration and improper sealant practice. |

| Is the media corrosive/chloride-bearing? | Verify material compatibility (316L vs duplex vs nickel alloy) and gasket chemistry resistance. | Corrosion products damage faces and reduce bolt load over time. |

Weld Neck Flanges

Weld neck flanges provide the highest joint reliability for critical piping systems because the tapered neck transfers stress smoothly into the pipe wall. We weld these directly to the pipe (butt weld), which reduces high-cycle fatigue risks compared with slip-on geometry in demanding service.

| Feature/Application | Description |

|---|---|

| Construction | Tapered neck with butt-weld connection for superior strength. |

| High-Pressure Use | Common choice for Class-rated process piping and rotating equipment nozzles where reliability is critical. |

| Industries | Oil and gas, power generation, chemical, marine, food and beverage, pulp and paper, mining. |

| Advantages | Even stress distribution, better fatigue performance under thermal cycling and vibration. |

| Types | Standard and Long Weld Neck (LWN) flanges for heavy-duty needs. |

- We specify weld neck flanges in:

- Oil and gas pipelines and processing plants

- Power generation (steam, condensate, high-temperature services)

- Chemical and pharmaceutical piping

- Marine fuel and LNG systems

Tip: If you see recurring gasket leaks on a vibrating line with slip-on joints, the “fix” is often upgrading joint stiffness and fatigue performance—not changing gasket brands.

Slip-On Flanges

Slip-on flanges offer easy installation and alignment for general-purpose piping. We slide the flange over the pipe and secure it with fillet welds on both sides (inside and outside). The trade-off is lower fatigue strength compared to weld necks, so service severity matters.

| Advantages of Slip-On Flanges | Disadvantages of Slip-On Flanges |

|---|---|

| Easy alignment during installation (rotatable) | Lower fatigue strength compared to weld neck flanges |

| Affordable and cost-effective | Not preferred for severe cyclic or high-vibration service |

| Versatile for various sizes | Weld quality variability can dominate joint performance |

- We often select slip-on flanges for water treatment, HVAC, and low-to-medium pressure services where cyclic loads are limited.

- If your plant sees repeated thermal cycling, plan inspection for weld toe cracking and bolt load relaxation during outages.

Socket Weld Flanges

Socket weld flanges are suited for small-diameter, higher-pressure piping where butt welding is difficult. You insert the pipe into the flange socket and weld it around the edge. The commonly specified insertion practice includes a small gap for thermal expansion control—verify your code/project requirements rather than “bottoming out” the pipe in the socket.

| Industry | Primary Use |

|---|---|

| Oil and Gas | Connecting hydraulic and instrument lines (within site engineering standards) |

| Chemical Processing | Joining small bore lines for chemicals and solvents |

| Power Generation | Small bore steam/condensate auxiliaries |

| Food and Beverage | Stainless steel small bore utilities where cleanliness matters |

| HVAC & Refrigeration | Joining small bore refrigerant and utility lines |

- Be aware of crevice corrosion risks in wet/chloride service; material choice and inspection access matter.

Lap Joint Flanges

Lap joint flanges give flexibility and faster bolt-up when alignment is difficult. You use them with a stub end, allowing the flange ring to rotate freely—this reduces the temptation to force misalignment with studs. For a deeper comparison tied to downtime and cost, see: Lap Joint Flange vs Slip-On Flange

- We assemble components separately for flexible installation.

- We position backing flanges before pipe installation, making adjustments simple.

- We reduce installation time in confined spaces, improving maintenance efficiency.

- Lap joint flanges allow for quick adjustments and frequent dismantling.

- Stub end material and face finish must match the service; a “cheap” stub end can become the leak driver.

Note: Lap joints are maintenance-friendly, but they are not a shortcut around correct gasket selection and bolt load control.

Threaded Flanges

Threaded flanges provide a weld-free connection for limited services where project standards allow it. We use them for low pressure/temperature lines and for repair scenarios where hot work is restricted. Where threaded flanges are used, verify the thread standard (region/project dependent) and adopt a sealing method that matches the media and temperature.

- Ease of installation—no welding required.

- Cost-effective for repairs and modifications.

- Adjustable—you can unscrew and reattach as needed.

- Best suited for low-pressure, low-temperature applications like water supply lines and air services.

For a practical overview with selection notes, see: Threaded Flanges

Case file (threaded leak on vibrating utility line): A threaded flange joint on a vibrating air header loosened repeatedly. Cause: vibration + insufficient thread engagement control + unsuitable sealant practice for the operating temperature. Fix: upgrade to a welded joint or add vibration mitigation; if threaded must remain, enforce thread standard, engagement, sealant specification, and periodic inspection.

Blind Flanges

Blind flanges seal off the ends of piping systems or unused openings. We use them to isolate sections for maintenance, testing, or future expansion. They see high net force from internal pressure acting across the bore area, so bolt condition, lubrication consistency, and tightening method are critical during isolation work.

- In chemical plants, we seal pipelines during cleaning or inspection.

- In water treatment and industrial facilities, we control flow and isolate sections for repairs.

- In power plants, we close steam, water, or gas lines during shutdowns.

When isolating systems, treat blind flanges as a safety boundary—document torqueing method and verify leak-tightness at low pressure before returning to service.

Long Weld Neck Flanges

Long weld neck flanges (LWN) feature an extended neck for added reinforcement and stress distribution. We weld them to pipes or vessels (tanks/columns) where local reinforcement and a smoother stress transition reduce failure risks near the shell/nozzle area.

- Extended neck design reduces mechanical failure risks near the vessel wall.

- Butt-welded connection enhances structural integrity and minimizes turbulence.

- Available in carbon steel, stainless steel, and other materials for diverse needs.

Safety tip: LWN selection is usually driven by nozzle loads and reinforcement needs. Treat it as a mechanical design decision, not only a “pressure class” decision.

Specialty Flanges

Specialty flanges address unique challenges in complex piping systems. We select these when standard flanges do not meet the specific engineering requirements.

| Flange Type | Unique Applications |

|---|---|

| Orifice Flange | Used with orifice plates to measure fluid flow rates in pipelines. |

| Spectacle Blind | A safety device to positively isolate pipeline sections for maintenance (Open/Closed positions). |

| Anchor Flange | Embedded in concrete to restrict pipe movement and absorb thrust forces. |

| Expander/Reducer Flange | Used to change pipe size at the flange connection, saving space. |

| Swivel Flange | Allows rotational adjustment for bolt alignment, similar to Lap Joints but higher pressure. |

| Nipoflange/Weldoflange | Combines a flange with a branch connection (Olet) for simplified branching. |

| Ring-Type Joint Flange | Specified for high-pressure oil, gas, and petrochemical pipelines (verify project class and groove standard). |

We rely on specialty flanges to solve specific engineering problems and ensure reliable performance in specialized applications.

Summary: Understanding flange type is only step one. The joint reliability is determined by the full system: face type, gasket family, bolting grade, alignment, and assembly control.

Flange Face Types: The Sealing Interface

We encounter several flange face types in industrial piping. The face type impacts sealing performance and determines gasket compatibility. For gasket-to-face interface guidance and face finish expectations used in industry, a widely referenced gasket manufacturer note is: Flange Facing and Surface Finish (Flexitallic)

| Flange Face Type | Characteristics | Common Applications |

|---|---|---|

| Flat Face (FF) | Flat surface, uses full face gasket, maximizes contact area and reduces local stress. | Water treatment, HVAC, cast iron pump/valve connections. |

| Raised Face (RF) | Raised surface concentrates pressure on gasket, improves sealing capability for many process services. | Oil and gas, power generation, standard Class-rated process lines. |

| Ring-Type Joint (RTJ) | Metal-to-metal seal using a ring in a machined groove; for high severity service when engineered. | Refineries, high-pressure/high-temperature services, severe duty projects. |

Flat Face Flanges (FF)

We use flat face flanges for low-pressure and low-temperature systems and for brittle mating materials. The flat surface increases gasket contact area and helps avoid overstressing cast iron or FRP components. In practice, flat face joints rely heavily on correct full-face gasket selection and controlled bolt load to avoid cracking or face distortion.

Case file (cast iron pump cracked at flange): A steel RF flange was bolted directly to a cast iron FF pump nozzle. Cause: the RF geometry created a gap and concentrated load; tightening bridged the gap by bending the cast iron face until it fractured. Prevention: match face types; if a mixed connection is unavoidable, machine the raised face flat or use an engineered spacer/adapter per project procedure.

Raised Face Flanges (RF)

We rely on raised face flanges for the majority of process plant applications because they provide higher gasket seating stress for a given bolt load. RF joints are tolerant of many gasket families (spiral wound, kammprofile, compressed fiber) when the face finish and gasket choice match the service.

- Advantages of Raised Face Flanges:

- Better sealing capability across broader service ranges than FF when assembled correctly.

- Accommodates multiple gasket designs, which helps maintenance planning.

- Common and widely standardized in Class-rated piping.

Male-Female & Tongue-and-Groove

We select Male-Female (M/F) and Tongue-and-Groove (T/G) faces to control gasket positioning and to protect the gasket from the media side.

- Male-Female: one face is raised (male) and the other recessed (female), keeping the gasket centered.

- Tongue-and-Groove: interlocking design that shields gasket edges and improves blowout resistance when engineered for the service.

Ring Type Joint Flanges (RTJ)

RTJ flanges are specified for high severity service where a metal ring in a machined groove provides a robust seal interface. Correct ring type, groove standard, and bolt load control are mandatory; the “RTJ” label alone does not guarantee integrity if ring material and groove finish are wrong for the duty.

Note: RTJ joints are not forgiving. Treat them as engineered joints: verify ring material, groove dimensions, bolt grade, lubrication, and tightening procedure.

Flange Materials Selection

Selecting the right flange material is essential for safety and lifecycle cost. We must consider mechanical strength, corrosion resistance, temperature tolerance, and the media chemistry (including chlorides, acids, sour service, and cleaning agents). “Stainless” is not one material; it is a family with very different behaviors in chloride and high-temperature service.

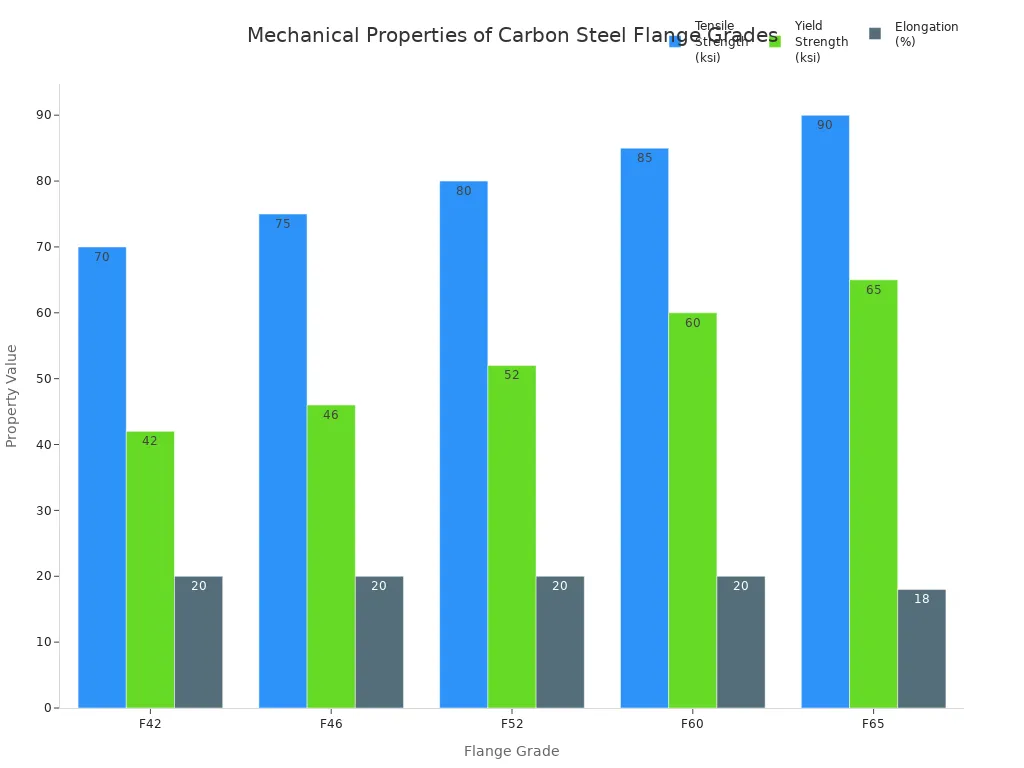

Carbon Steel Flanges

We choose carbon steel flanges for many high-pressure and elevated-temperature applications because they provide strength and weldability at a reasonable cost. Typical forged carbon steel flange grades include ASTM A105 (verify project spec). Where low-temperature toughness is required, your project may require additional impact testing and different material grades.

| Grade | Tensile Strength (ksi) | Yield Strength (ksi) | Elongation (%) | Impact Toughness |

|---|---|---|---|---|

| F42 | 70-90 | Minimum 42 | Minimum 20 | Meets Charpy V-notch requirements |

| F46 | 75-95 | Minimum 46 | Minimum 20 | Tested for impact toughness |

| F52 | 80-100 | Minimum 52 | Minimum 20 | Low-temperature impact resistance |

| F60 | 85-105 | Minimum 60 | Minimum 20 | Requires low-temperature testing |

| F65 | 90-110 | Minimum 65 | Minimum 18 | Charpy V-notch testing required |

Tip: Strength is not the full story. If the service sees low temperatures or high cycling, specify toughness requirements and verify MTRs/impact tests per project spec.

Stainless Steel Flanges

We rely on stainless steel flanges (304/304L, 316/316L and beyond) where corrosion resistance and cleanliness matter. The practical selection rule is to match stainless grade to chloride level, temperature, and crevice conditions. 316/316L is widely preferred over 304/304L in higher-chloride environments because molybdenum improves pitting resistance; verify against your media analysis and temperature band. A concise reference on stainless performance and selection is: Nickel Institute – High Performance Stainless Steels

| Material Type | Corrosion Resistance | Suitable Applications |

|---|---|---|

| Stainless Steel Flanges (304/316) | Good to excellent in many environments when grade matches the media chemistry | Chemical, food, and pharmaceutical industries |

| Alloy Steel Flanges | Good strength and temperature resistance; corrosion performance depends on environment | High-pressure boilers, high-temperature pipelines |

Case file (chloride pitting drives gasket weep): A 304L flange in warm chloride-bearing water developed localized pitting under the gasket seating area. Cause: crevice conditions + chloride + temperature. Fix: upgrade material (often 316L or duplex depending on chloride/temperature), improve drainage/crevice conditions, and replace gasket with one compatible with the media and cleaning regime.

Alloy Steel Flanges

We select alloy steel flanges (e.g., Cr-Mo families) where elevated temperature strength and creep resistance are required. These are typical in high-temperature steam and boiler-related services. Always verify heat treatment requirements and welding procedures; poor procedure control can become your failure origin at the HAZ.

Nickel Alloy Flanges

We use nickel alloy flanges for aggressive corrosion environments and high-temperature oxidation resistance. Selection is typically driven by specific chemistry (acids, chlorides, sour service), not by “better metal” assumptions.

| Nickel Alloy Type | Key Properties | Typical Applications |

|---|---|---|

| Inconel (625) | High temperature, oxidation resistance | Chemical, petrochemical, aerospace |

| Hastelloy (C276) | Supreme acid resistance, durability | Chemical processing, pollution control, scrubbers |

| Monel (400) | Seawater resistance, toughness | Marine, oil and gas, desalination plants |

Non-Metallic and Composite Flanges

We choose non-metallic and composite flanges for specialized, low-pressure applications where corrosion immunity or weight is the priority. Always verify temperature limits, bolt load behavior (creep), and flange stiffness; many composite flange problems show up after relaxation under sustained bolt load.

| Material | Advantages | Common Uses |

|---|---|---|

| PTFE | Extreme chemical resistance, non-stick | Chemical pipelines (lined pipe) |

| Fiberglass (FRP) | Lightweight, corrosion resistance | Water treatment, HVAC, seawater intake |

| Reinforced Polymer | Insulation, durability | Food processing, light industrial |

Tip: Composite and PTFE-lined joints are sensitive to bolt relaxation. Plan torque verification after initial service if your procedure requires it.

Flange Standards and Ratings Explained

ASME and ANSI Flanges

We rely on ASME standards for most Class-rated process piping flanges. As a practical rule: use ASME B16.5 for common sizes and classes, and ASME B16.47 for large diameter classes (project-dependent). For official scope/standard listings, use ASME and ANSI standard pages: ASME B16.5

- ASME B16.5: Pipe flanges and flanged fittings (commonly used in Class-rated piping)

- ASME B16.47: Large diameter flanges (project-dependent)

- “ANSI” is often used historically for dimensional conventions; verify the actual applicable ASME edition on your project.

DIN, EN, JIS, GB/T Flanges

We encounter DIN/EN, JIS, and GB/T standards in Europe and Asia, and they are not bolt-pattern interchangeable with ASME without adapters. The critical mismatch is usually bolt circle diameter and hole size/count conventions (metric vs imperial), not “quality.”

| Aspect | ASME/ANSI (USA/Global) | DIN/EN (Europe/Global) |

|---|---|---|

| Bolt Circle Diameter | Imperial (Inches) | Metric (mm) |

| Pressure Rating System | Class (150, 300, etc.) | PN (10, 16, 40, etc.) |

| Flange Thickness | Often heavier | Varies by PN and type; often lighter for comparable nominal ratings |

API and AWWA Flanges

We use API and AWWA standards for specialized industries where the design basis differs from general process piping.

- API 6A: specified for wellhead and Christmas tree equipment; the standard family includes high working pressures up to 20,000 psi in upstream equipment contexts. Use the official API listing when your project references API equipment: API Specification 6A (API)

- AWWA C207 / C228: specified for waterworks service; selection and drilling conventions follow water industry practice. Official listings: AWWA C207 (AWWA) and AWWA C228 (AWWA PDF)

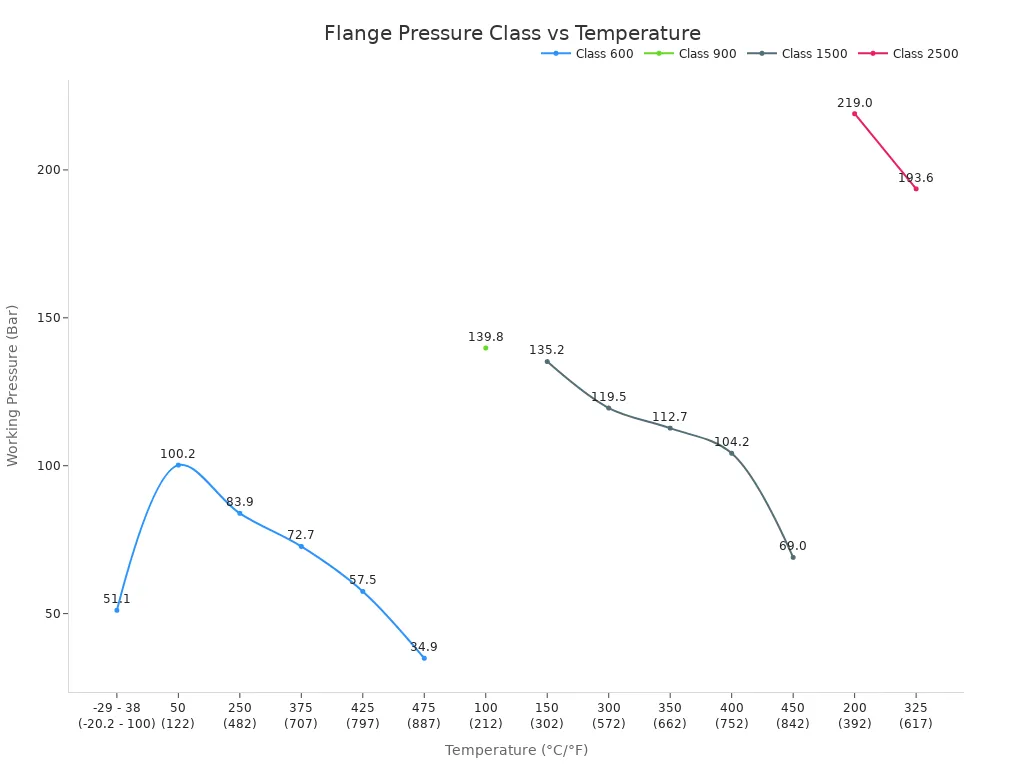

Pressure Classes and Markings

We determine a flange’s pressure capacity by its class or PN rating, always as a function of temperature and material group. The same Class number does not mean the same allowable pressure across materials at elevated temperatures—verify the rating table for the specific material group used on your project.

| Temperature °C (°F) | Class 300 Max Pressure | Class 900 Max Pressure | Class 2500 Max Pressure |

|---|---|---|---|

| -29 – 38 (-20.2 – 100) | 51.1 Bar (741 psi) | 153.2 Bar (2222 psi) | 425.5 Bar (6171 psi) |

| 100 (212) | 46.6 Bar (676 psi) | 139.8 Bar (2026 psi) | 388.4 Bar (5633 psi) |

| 200 (392) | 43.8 Bar (635 psi) | 131.4 Bar (1906 psi) | 365.0 Bar (5294 psi) |

We find markings stamped on the rim of the flange identifying type, size, material, pressure class, and heat number. Treat heat numbers as traceability keys—if you cannot trace MTRs on critical joints, you cannot verify compliance when something goes wrong.

Flange Dimensions and Measurement

Key Flange Dimensions

We must measure critical dimensions to ensure a proper fit and to avoid “almost matching” joints that fail during bolt-up. In shutdown work, verifying bolt circle diameter and hole size/count prevents rework and unsafe forcing.

- Outer diameter (OD)

- Inner diameter (ID / Bore size)

- Bolt circle diameter (BCD) – Crucial for alignment

- Bolt hole diameter and Number of holes

- Hub diameter at base and weld end (where applicable)

- Flange thickness (t)

Quick check: If two flanges “almost” align, stop. A few millimeters of mismatch is enough to load the joint and cause preload loss later.

Tools for Measuring Flanges

We rely on precise tools to measure flange dimensions in industrial settings. Tool selection depends on the tolerance you need and the joint risk profile.

| Feature | Description |

|---|---|

| Vernier Calipers | Precise measurements of OD, hub, and thickness. |

| Measuring Tape | Quick checks of large diameters. |

| Bolt Hole Gauge | Checks bolt circle dimensions and hole spacing. |

| Thread Gauge | Identifies thread pitch on threaded flanges. |

Weight and Pricing Factors

We determine flange weight and pricing by considering material volume, forging/casting route, machining complexity, and documentation requirements. In procurement, don’t ignore documentation: EN 10204 3.1 certification and PMI requirements can be mandatory in critical service.

| Factor | Description |

|---|---|

| Material Composition | Nickel alloys and duplex grades cost more than carbon steel due to alloying and processing. |

| Manufacturing Process | Forging typically offers better grain flow and toughness than casting, but costs more. |

| Surface Finish | Facing finish, groove machining (RTJ), and special coatings add cost. |

Flange Gaskets, Nuts, and Bolts

Types of Flange Gaskets

We need the right gasket to ensure a leak-free joint because the gasket must match face type, service, and assembly method. If your project references ASME gasket standards, the commonly cited standard listings are:

- Non-metallic gaskets: typically for lower pressure/temperature services. Standard listing reference: ASME B16.21 (ANSI Webstore)

- Semi-metallic gaskets: spiral wound and kammprofile are common in steam and process lines. Standard listing reference: ASME B16.20 (ANSI Webstore)

- Metallic gaskets: RTJ rings for severe duty when engineered; verify ring type/material and groove standard.

Selecting Nuts and Bolts

We must select the correct fasteners for a safe flange joint because fasteners define achievable preload and temperature capability. In many industrial projects, common bolting references include ASTM A193 (bolting for high temperature or high pressure service) and matching nut standards such as ASTM A194. Official standard pages can be used as procurement references:

| Fastener Type | Application Area | Material Options |

|---|---|---|

| Stud Bolts (Full Thread) | Common for industrial flanges (tightening from both sides) | Verify project spec (often ASTM bolting families for pressure boundary service) |

| Machine Bolts (Hex Head) | Low pressure, limited space applications | Carbon steel, stainless (verify spec) |

| Heavy Hex Nuts | High-load joints | Match nut material/grade to stud specification |

For bolt-up planning, bolt length matters (thread engagement and gasket stack). If you need a practical sizing approach, see: Flange Bolt Length Formula

Ensuring Proper Sealing

We achieve proper sealing by controlling the variables that actually change preload and gasket stress. Clean the faces, center the gasket, control lubrication, use calibrated tools, and tighten in a cross pattern with staged passes. If your procedure requires it, perform a verification pass after stabilization (thermal cycle) because gasket relaxation and embedment can reduce effective seating stress.

Flange Manufacturing and Quality Control

Forging, Casting, and Rolling

We manufacture flanges using forging, casting, or rolling—each affects grain structure and defect risk. In critical pressure boundary service, forged flanges are common because aligned grain flow improves toughness and fatigue resistance.

| Method | Process Description | Best For |

|---|---|---|

| Forging | Heating steel and pressing into shape; aligns grain flow. | Critical service flanges and higher integrity requirements. |

| Casting | Molten metal into molds; complex shapes but porosity risk. | Low-pressure fittings, complex geometries where allowed. |

| Rolling | Forming rings from bar/plate. | Large diameter, certain low-to-medium pressure applications. |

Heat Treatment and Machining

Heat treatment and machining are where “meets spec” becomes real performance. Heat treatment controls toughness and strength; CNC machining controls face finish, groove geometry (RTJ), and bolt hole pattern. If face finish is wrong for the gasket family, the joint can leak even with perfect torque numbers.

- Normalizing/Annealing: relieves internal stress from forging (spec-dependent).

- Machining: controls facing finish and bolt hole geometry for repeatable bolt-up.

Inspection and Testing

Quality control is not “nice to have” in flanges—it is what prevents field rework and leakage. On critical projects, you typically see dimensional checks plus material verification and NDE.

| Inspection Type | Purpose |

|---|---|

| Dimensional Check | Ensures bolt holes align and bore matches pipe. |

| Surface Finish Check | Verifies gasket seating area roughness and pattern. |

| Ultrasonic Testing (UT) | Detects internal cracks or voids. |

| Positive Material Identification (PMI) | Verifies chemical composition (alloy content). |

Marking and Packaging

Marking and packaging protect traceability and face integrity. Markings show size, material, class/PN, and heat number. Packaging must prevent face damage—face dings become leak paths in your next outage.

Flange Installation and Maintenance Guide

Preparation and Cleaning

We must prepare and clean all components before installing flanges. Inspect each flange for visible damage and contamination. Remove dirt, oil, and old gasket residue without scoring the face. Check gasket condition and verify bolt condition and correct grade. If you see pitting in the seating area, decide early whether re-machining is required—don’t wait until repeated leaks force a second shutdown.

Installation Steps

We can achieve a secure flange connection by controlling alignment and bolt load distribution:

- Align flanges so bolt holes match without external force.

- Place and center the gasket between faces.

- Lubricate threads and nut bearing surfaces consistently (per site spec).

- Insert bolts and hand-tighten evenly.

- Tighten in a Cross Pattern (Star) using a calibrated wrench.

- Apply torque in stages: 30%, 60%, and 100% of target torque.

- Perform a final verification pass as required by your procedure.

Case file (misalignment-induced leak): A spool was “pulled in” using studs to match bolt holes. Cause: residual piping stress relaxed bolt preload after temperature cycling and the gasket unloaded. Fix: correct supports/alignment, then reassemble. Bolt-up should never be used as an alignment tool.

Maintenance Procedures

We maintain flanges by inspecting for early indicators before they become shutdowns. Frequency depends on service severity and consequence of leakage.

| Maintenance Task | Frequency | Purpose |

|---|---|---|

| Visual Inspection | Monthly | Detect exterior corrosion or weeping. |

| Bolt Retightening | After first thermal cycle (if procedure requires) | Compensate for gasket relaxation/settlement. |

| Gasket Replacement | Every disassembly | Ensure sealing reliability (do not reuse gaskets). |

Troubleshooting Common Issues

Resolve flange issues by diagnosing the cause, not by repeating the same gasket change.

- Leakage: verify gasket type and centering, face damage, bolt condition, and bolt load distribution.

- Misalignment: check pipe supports and spool fit-up; do not use studs to force alignment.

- Bolt Loosening: check vibration, thermal cycling, and lubrication consistency; adopt documented tightening/verification steps.

- Corrosion: verify material compatibility and crevice conditions; consider protective measures where applicable.

Innovations and Trends in Flanges

Advanced Materials

We see flange materials evolving toward higher strength-to-weight and improved localized corrosion resistance. Duplex and nickel alloys are increasingly specified where corrosion risk or strength requirements make carbon steel or standard stainless insufficient.

| Material/Technique | Benefits |

|---|---|

| Duplex / Super Duplex SS | Higher strength than standard austenitic stainless, improved resistance in many chloride environments (verify for your temperature/chemistry). |

| Nickel Alloys | Useful for severe corrosion or high-temperature oxidation service. |

| Titanium | Specified for certain seawater and corrosive services where justified. |

| Electropolishing | Smoother surface can reduce fouling and improve cleanability in hygienic service. |

Automation and Smart Flanges

Monitoring and documentation are moving closer to the joint. In critical service, projects increasingly track tightening data, tool calibration, and inspection evidence. Where sensors are used, the value is in trending bolt load loss and detecting abnormal leakage early.

- AI and IoT in production and monitoring supports tighter tolerance control and better maintenance planning.

- Embedded monitoring concepts are being applied in critical joints to detect loosening/leakage indicators before visible failure.

- Predictive maintenance reduces “surprise leaks” by linking joint history to inspection schedules.

Sustainability and Future Developments

Sustainability in flanges is mostly about reducing rework and over-engineering. Better selection tools, documented assembly practices, and right-first-time material decisions reduce scrap, leaks, and outage emissions.

You now understand the essentials about flanges: types, faces, materials, standards, installation, and maintenance. To keep piping systems safe and reliable, we must select the correct joint system and execute assembly under control. Use the checklists above to troubleshoot problems and make decisions that hold up after the first thermal cycle.

FAQ

What factors should you consider when selecting a flange?

Focus on design pressure/temperature, media chemistry, standard compatibility, face type, gasket family, and bolt-up control. In practice, selection is only “correct” if the flange, gasket, and bolting work as a system under your assembly method.

- Confirm standard: ASME Class vs DIN/EN PN compatibility.

- Confirm face type: FF/RF/RTJ must match the gasket family.

- Confirm material: corrosion risk (chlorides, acids, sour service) and temperature band.

- Confirm maintenance needs: frequency of opening joints and inspection access.

How do you ensure a leak-proof flange connection?

Use the correct gasket for the face and service, ensure true alignment, and apply controlled bolt load in a cross pattern with staged passes. Leak-proof outcomes are built before torqueing starts.

- Inspect faces (no deep radial scratches across seating area).

- Center the gasket and use the correct type/thickness.

- Control lubrication consistently.

- Tighten in star pattern with staged torque and verification pass per procedure.

Tip: If the joint weeps at low pressure, stop and diagnose—do not keep increasing torque without confirming face condition and alignment.

Which flange material works best for corrosive environments?

There is no single “best” material; it depends on the media chemistry and temperature. 316L is commonly selected over 304 in higher-chloride environments, duplex grades are often used when higher strength and better localized corrosion resistance are required, and nickel alloys are used for severe chemical service. Always verify against your media analysis and project corrosion allowance.

How often should you inspect flange connections?

Inspection frequency depends on consequence and service severity. A typical approach is monthly visual checks for weeping/corrosion, plus detailed inspection during shutdowns on critical joints. Where required, use NDE and documented bolt-up records for high consequence service.

Can you reuse flange gaskets after disassembly?

No—do not reuse gaskets after disassembly. Once compressed, most gasket types lose resilience and seating behavior. Reuse is a common root cause of maintenance-related leaks.

Note: If a joint must be reopened, plan gasket replacement and face inspection as a standard work step.