Custom Flanges

At Sunhy, we are not just suppliers; we are expert manufacturers of high-specification custom flanges. We specialize in transforming your technical drawings into precision-engineered components that perform flawlessly under pressure. Leveraging our high-precision CNC machinery and a strict, ISO 9001-certified quality management system, we deliver custom flanges in stainless steel, duplex, and high-nickel alloys that meet the world’s most stringent standards.

Home / Stainless Steel Flange / Custom Flanges

Product Categories

By Design Type

By Standard & Class

Advanced Materials

Custom Machined Stainless Steel Core Flange for High Pressure Applications

Precision CNC Machined Star-Shaped Plate Custom Designed Per Drawing

Non-Standard Flange with Milled Grooves, Custom Stainless Steel Gasket Ring

Bespoke Fabricated Metal Blind Plate with Large Central Opening and Bolt Holes

High-Precision Laser-Cut Non-Standard Toothed Rotor Disc for Industrial Machinery

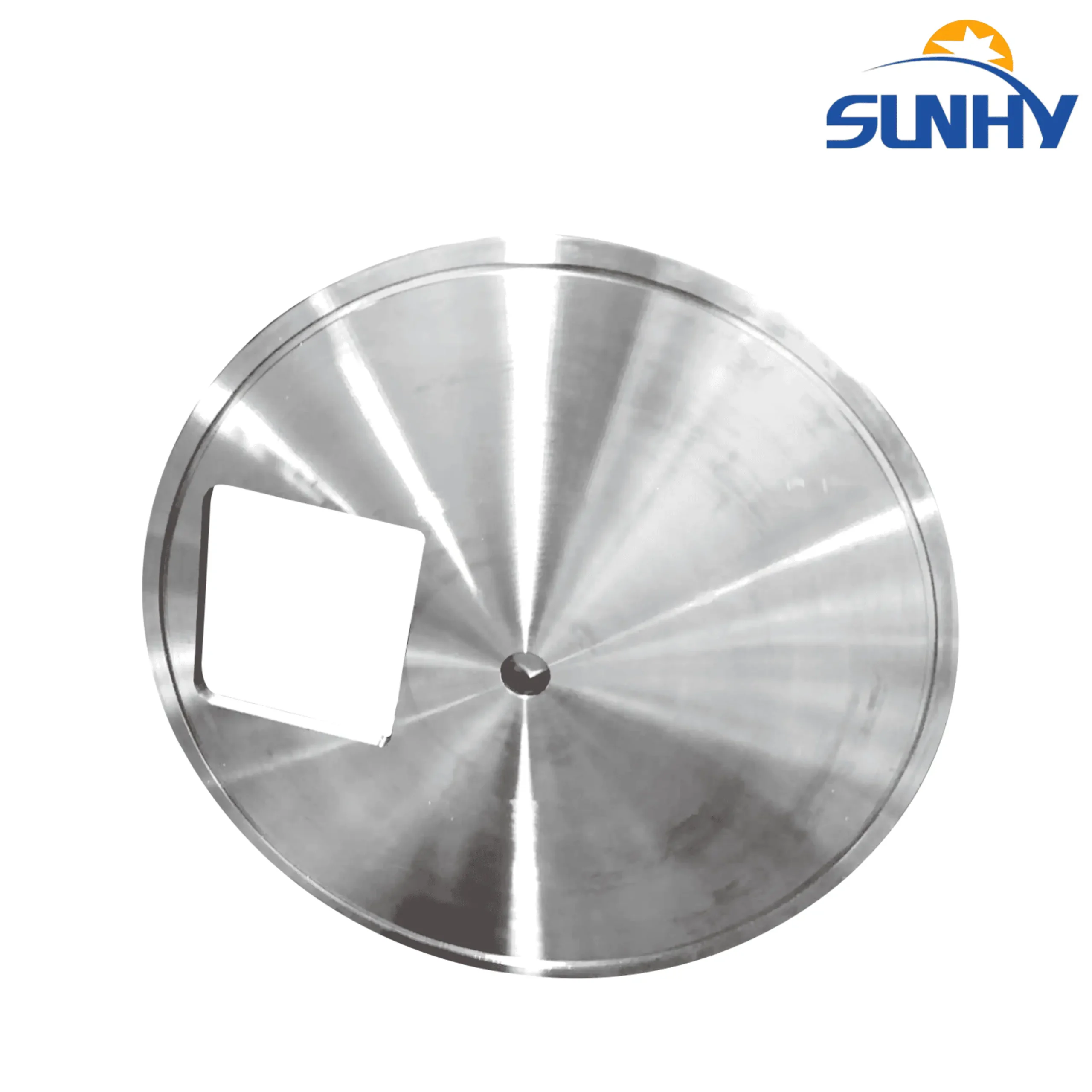

Custom Metal Fabrication Blind Plate with Square Cutout and Polished Finish

Heavy-Duty Non-Standard Adapter Flange with Asymmetric Bolt Pattern

Thin Profile Custom Flange Gasket Ring with Alignment Notches

Precision Machined Non-Standard Hub Flange with Keyway Slots

Custom Metal Blind Flange with Through-Bore and Opposing Relief Cuts

High-Pressure Stainless Steel Standard Pattern Custom Slip-On Flange

Lightweight Non-Standard Perforated Round Disc for High-Speed Rotation

High-Precision CNC Machined Non-Standard Valve Seat Insert

The Sunhyings Difference: Manufacturer, Not Just Supplier

In a market saturated with traders, we stand apart. From raw billet forging to final inspection, every process happens under our roof. This ensures full traceability, competitive pricing, and accountability.

Certified Quality Control

- ISO 9001:2015: Our system is data-driven, not just a certificate.

- PMI Testing: 100% material check via Handheld XRF Spectrometers.

- Certified NDT: Inspections by in-house ASNT Level II technicians.

Verified Precision

- Tight Tolerances: Critical dimensions held to ±0.05mm.

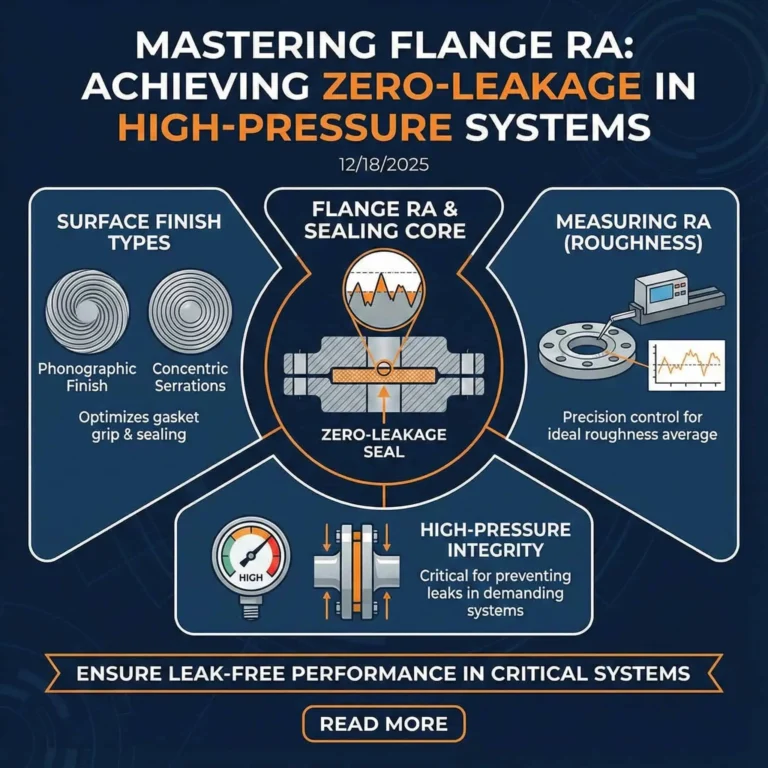

- Surface Finish: Automated facing for Ra 3.2-6.3μm or mirror finish.

- Large Capacity: Machining range up to 3,000mm diameter.

In-House Control

- No Sub-Contracting: We forge, heat-treat, and machine internally.

- Speed: Expedited production as fast as 7-10 days.

- Traceability: Digital records kept for 10 years linked to Heat Numbers.

Engineering Intelligence

- DFM Review: Free manufacturability analysis within 24 hours.

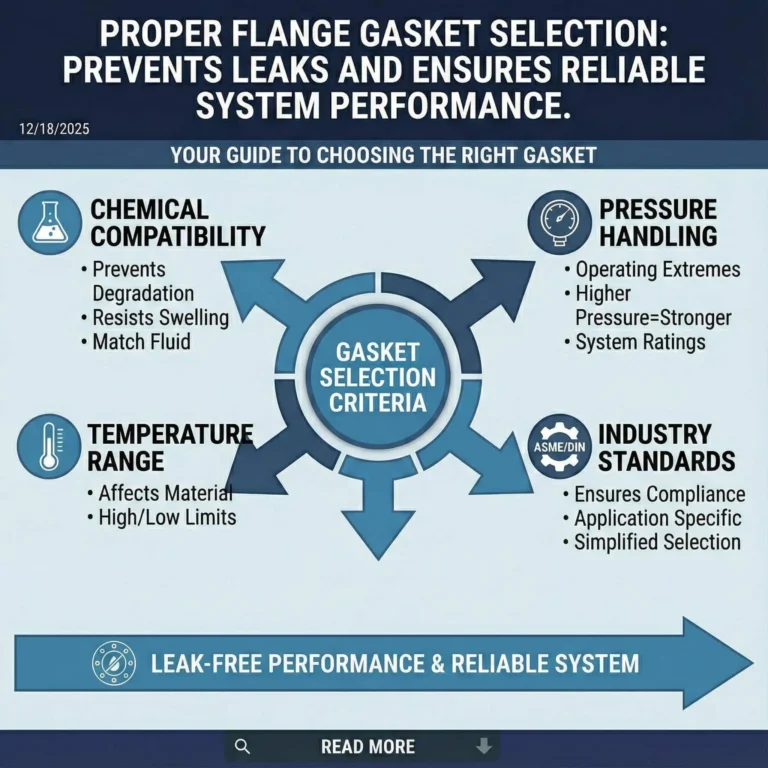

- Compliance: Expertise in NACE MR0175 & Low-Temp service.

- Global Standards: Meeting specific pressure-temp ratings for your piping class.

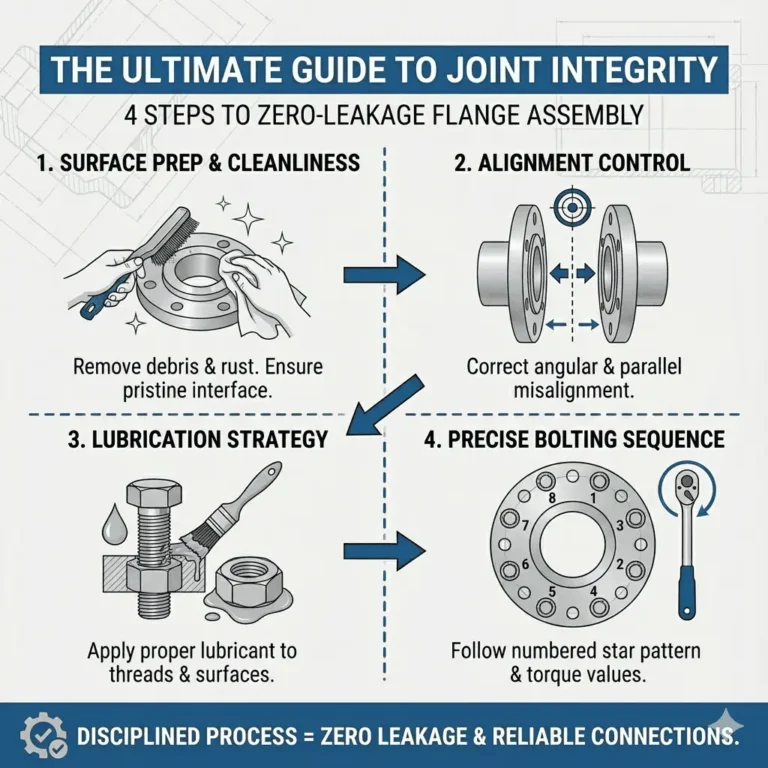

From Drawing to Delivery: The Sunhyings 6-Step Process

We replace guesswork with engineering precision. Our ISO 9001:2015 certified workflow ensures every flange meets your specifications, timeline, and documentation requirements.

We procure raw billets only from mills holding ISO/PED certifications.

Data Point: Before production begins, 100% of raw material undergoes Spectrographic Analysis (PMI) to confirm chemical composition matches ASTM standards.

Materials are forged to optimize grain flow, then heat-treated in our calibrated furnaces.

Precision: Furnace temperatures are monitored with digital recorders to ensure strictly controlled cycles (Normalizing/Quenching) within ±10°C of the required setpoint.

Forging blanks move to our CNC centers for turning, drilling, and facing.

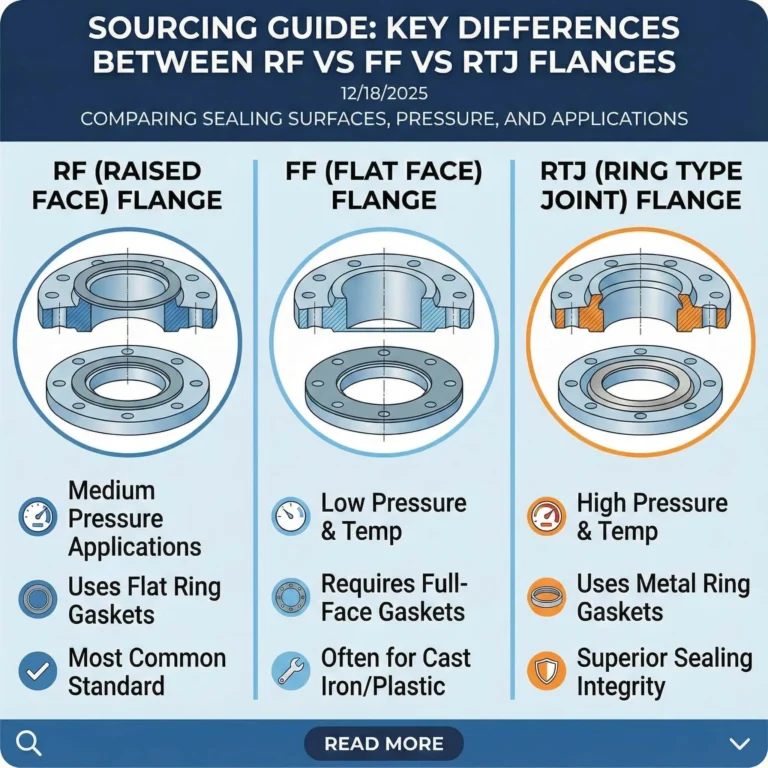

Standards: We machine seal faces (RF, RTJ) to specific Roughness Averages (Ra), typically Ra 3.2–6.3μm for standard finishes, or smoother upon request.

We don't skip steps. Finished flanges undergo NDT and mechanical testing.

Authority: All NDT inspections are conducted by technicians certified to ASNT SNT-TC-1A Level II.

We provide permanent hard-stamping for traceability.

Protection: Goods are packed in ISPM 15 compliant wooden cases with VCI anti-corrosion film, ready for sea freight.

Documentation: Every shipment includes a full EN 10204-3.1 MTC dossier.

Our Core Manufacturing Capabilities

We control 100% of critical processes in-house. This vertical integration allows us to maintain a rejection rate of less than 0.1%.

1. End-to-End Forging & Heat Treatment

Our metallurgical control ensures structural integrity superior to cast alternatives.

Forging Range:

Open-Die Forging: For large/custom flanges up to 4,000 kg.

Ring Rolling: Seamless rolled rings up to 3,500 mm OD (建议填 3-4米).

Closed-Die Forging: For high-volume precision parts (DN15 – DN100).

In-House Heat Treatment:

Capability: Normalizing, Quenching & Tempering (Q&T), Solution Annealing.

Performance: We guarantee impact test values (Charpy V-Notch) down to -46°C for LF2 materials or -196°C for Cryogenic Stainless Steel.

2. Precision Machining Capabilities

Our workshop is equipped with [Number] sets of CNC vertical lathes and drilling centers.

Capacity: Turning and drilling capacity for flanges from 1/2″ up to 140″ (3,500 mm).

Tolerances:

Dimensional Tolerance: Controlled within ±0.05 mm for critical mating surfaces.

Bolt Hole Position (PCD): Accuracy within ±0.2 mm, ensuring hassle-free alignment on site.

Complex Geometries: Expert machining of RTJ grooves, Lens Ring joints, and custom anchor flange profiles.

3. Rigorous Quality Assurance (Lab & NDT)

Our in-house CNAS-accredited laboratory validates quality using data, not assumptions.

Material Verification: 100% PMI (Positive Material Identification) using Handheld XRF Spectrometers.

Non-Destructive Testing (NDT):

UT (Ultrasonic): per ASME V / ASTM A388 (to detect internal cracks).

PT/MT: For surface integrity checks.

Destructive Testing:

Tensile strength, Yield strength, and Elongation testing.

Hardness Testing (Brinell/Rockwell) to ensure max 237 HB (NACE MR0175 compliance).

Final Inspection: 100% CMM (Coordinate Measuring Machine) or Caliper check for critical dimensions.

Adherence to International Standards

Our manufacturing system guarantees compliance with major global standards, suitable for Oil & Gas, Petrochemical, and Marine applications.

Dimensional & Pressure Standards

ASME/ANSI: B16.5 (½” – 24″), B16.47 Series A & B (26″ – 60″), B16.36, B16.48.

API: API 6A (Wellhead), API 17D (Subsea).

EN/DIN: EN 1092-1, DIN 2633/2634/2635.

JIS: JIS B2220 (5K, 10K, 16K, 20K, 30K).

AWWA: C207 (Class B, D, E, F) for Waterworks.

Material Specifications

Carbon Steel: ASTM A105, A350 LF2 (Low Temp), A694 (F42 – F70 High Yield).

Stainless Steel: ASTM A182 F304/L, F316/L, F321, F347.

Duplex/Super Duplex: ASTM A182 F51 (UNS S31803), F53, F55.

Special Alloys: Inconel 625, Monel 400, Hastelloy C276.

Stainless Steel Flanges

Stainless Steel Flanges