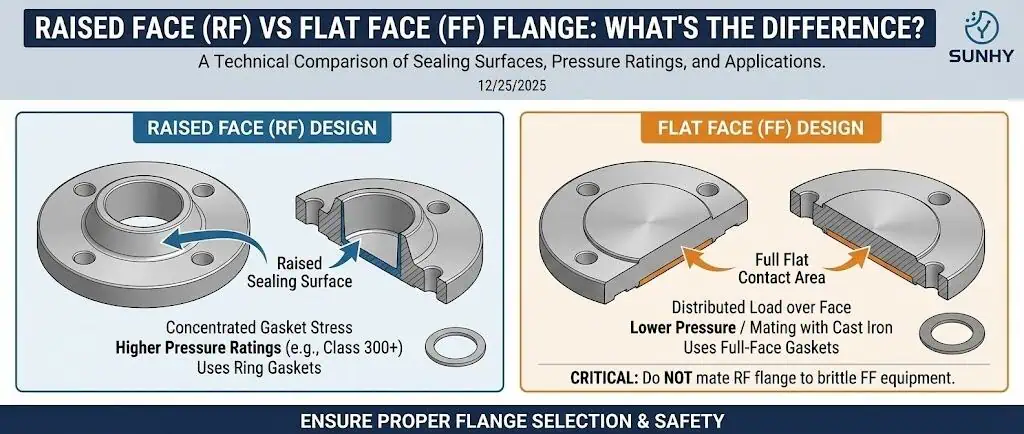

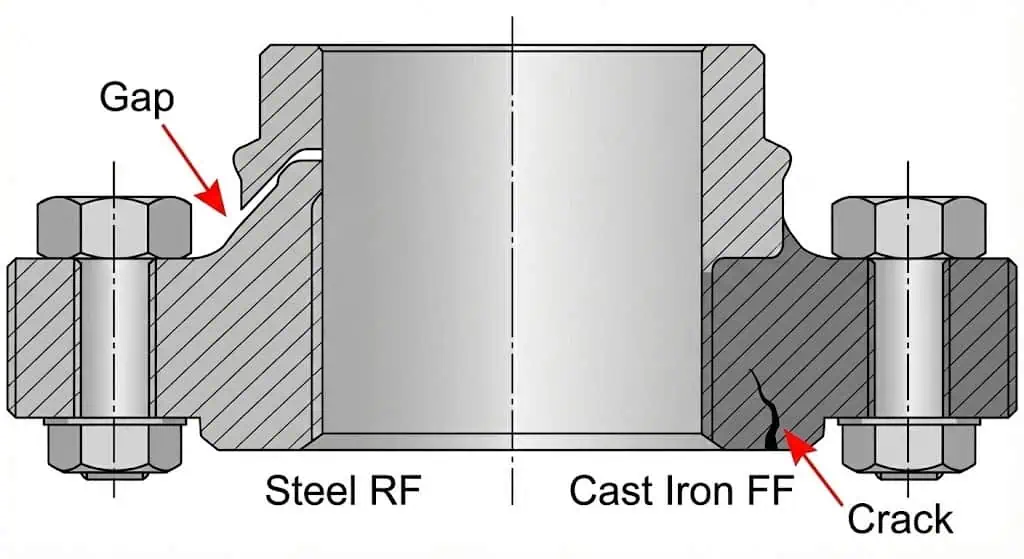

La différence technique critique entre les brides à face surélevée et les brides à face plate réside dans la géométrie de la face (zone de contact), qui dicte strictement la sélection des joints, les calculs de charge de boulons et la compatibilité d'accouplement. Une défaillance fréquente et coûteuse sur le terrain est l'accouplement d'une bride en acier à face surélevée (RF) avec une bride en fonte à face plate (FF) sans atténuation ; l'espace résultant au bord extérieur introduit un “ moment de flexion ” qui peut casser la bride en fonte fragile lors du serrage.

- Face surélevée (RF) : La norme pour la tuyauterie de procédé en acier. Sa zone de contact réduite concentre la charge des boulons pour atteindre une haute la contrainte d'appui du joint, essentielle pour l'étanchéité des fluides haute pression.

- Face plate (FF): Obligatoire lors de l'accouplement avec des équipements fragiles ou à faible ductilité (vannes en fonte, réservoirs en PRFV, pompes en bronze) pour répartir la charge uniformément et empêcher la rotation de la bride.

L'expertise de Sunhy dans la fabrication brides en acier inoxydable garantit que chaque face RF et FF répond aux exigences strictes de dimensions et de rugosité (Ra) de ASME B16.5 et EN 1092-1. Lors de la spécification, traitez “ RF vs FF ” non pas comme un choix, mais comme une exigence d'interface dictée par votre équipement.

Définitions et caractéristiques

Aperçu de la bride à face surélevée

Une bride à face surélevée (RF) présente une surface d'étanchéité usinée à une hauteur spécifique au-dessus du cercle de boulonnage, conçue pour concentrer la force de serrage.

Dans les industries pétrolière et gazière et chimique, RF est la valeur par défaut car cette charge concentrée permet à la bride de “ mordre ” dans les joints durs et semi-métalliques (comme les joints spiralés). Cela crée un joint de haute intégrité capable de résister aux fluctuations de pression et aux cycles thermiques.

Par ASME B16.5, la hauteur de la face surélevée dépend de la classe de pression :

| Classe de pression | Hauteur de la face surélevée | État de surface (Standard) |

|---|---|---|

| Classe 150 & 300 | 1,6 mm (1/16 pouce) | 125 à 250 µin Ra (Dentelé) |

| Classe 400 – 2500 | 6,4 mm (1/4 de pouce) | 125 à 250 µin Ra (Dentelé) |

| Fonction technique | Concentre la pression d'étanchéité | Augmente le frottement pour empêcher l'expulsion de la jointure |

Les brides RF sont typiquement forgées en Acier Carbone (ASTM A105) ou Acier Inoxydable (ASTM A182 F304/F316). La finition standard “phonographique” (rainure concentrique) est critique—elle crée un frottement qui maintient la jointure en place. Utiliser une finition lisse avec une jointure standard peut entraîner une expulsion hydraulique.

Cas terrain #1 (La conduite de vapeur “suintante”) : Un client a signalé une fuite sur une conduite de vapeur Classe 300 RF. L'enquête a révélé qu'ils utilisaient une bride à finition lisse destinée à une jointure métallique RTJ mais avaient installé une jointure en graphite. L'absence de dentelure signifiait une adhérence nulle par frottement. Solution : Nous avons fourni des brides avec la finition dentelée correcte de 125-250 µin Ra pour adhérer à la jointure.

Aperçu de la bride à face plate

Une bride à face plate (FF) a une surface d'étanchéité qui est au niveau du cercle de boulonnage, offrant un contact à pleine face de l'alésage au diamètre extérieur.

Les ingénieurs spécifient les faces FF principalement pour protéger l'équipement d'accouplement fabriqué à partir de matériaux fragiles comme Fonte (ASTM A126), Bronze ou Plastique. En supportant toute la face de la bride, la conception élimine le “porte-à-faux” qui provoque des contraintes de flexion.

Voici les caractéristiques techniques définissantes :

| Caractéristique | Raison technique |

|---|---|

| Conception de surface | Plan à fleur (sans espace) réduit la rotation de la bride et empêche la fissuration des oreilles fragiles. |

| Joint obligatoire | Joint pleine face (avec trous de boulons) est requis pour supporter le cercle de boulons extérieur. |

Cas sur site #2 (La bride de pompe fissurée) : Une équipe de maintenance a boulonné une bride RF en acier à une pompe en fonte FF. En serrant les boulons, la face surélevée a agi comme un point d'appui. Le bord extérieur de la bride en fonte n'avait aucun support et s'est cassé. Prévention : Utilisez toujours des brides FF ou usinez la RF lors de la connexion à de la fonte.

Caractéristiques clés de conception

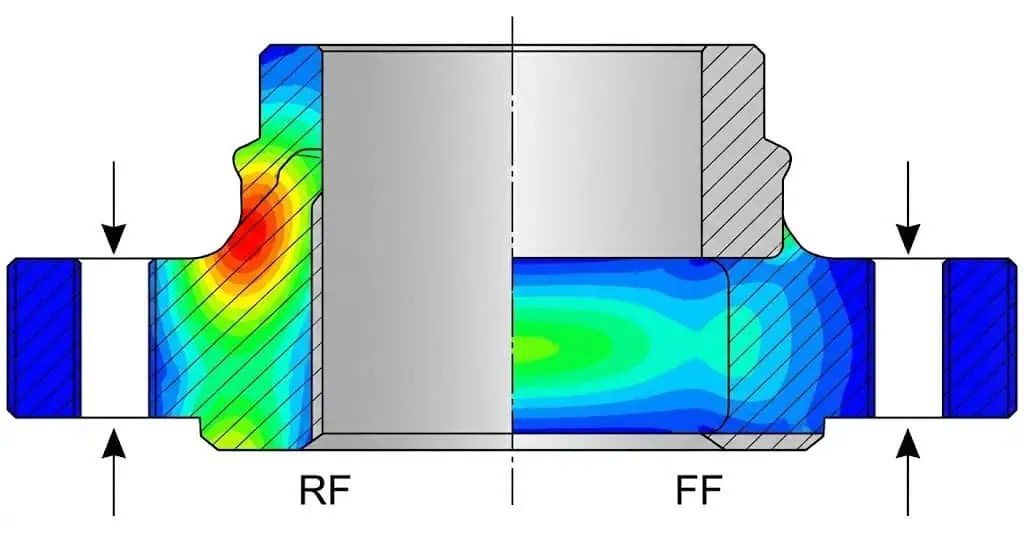

La différence structurelle dicte la mécanique de l'assemblage : Concentration vs. Distribution.

Une bride RF concentre l'énergie pour sceller contre les hautes pressions. Une bride FF distribue l'énergie pour protéger le matériel. Le bon choix est dicté par les propriétés du matériau du composant d'accouplement.

| Caractéristique | Face surélevée (RF) | Face plate (FF) |

|---|---|---|

| Géométrie | Changement d'étape à la surface du joint | Plan unique continu |

| Efficacité de la charge du boulon | Élevée (Force ÷ Petite Surface = Contrainte Élevée) | Inférieur (Force ÷ Grande Surface = Contrainte Répartie) |

| Matériau d'accouplement typique | Acier forgé, Acier inoxydable | Fonte, Bronze, PVC, PRFV |

| Joint Compatibles | Enroulé en Spirale, Joint Annulaire, Camprofile | Pleine Face uniquement en Caoutchouc/Fibre/PTFE |

Règle de terrain : Si vous pouvez glisser un calibre entre les bords extérieurs de deux brides serrées, il s'agit probablement d'un joint à Face Surélevée. Si les bords extérieurs sont en contact étroit, c'est un joint à Face Plate. (Toujours vérifier avec les fiches techniques, car les contrôles visuels peuvent être trompeurs sur les lignes isolées.)

Assurance qualité : Sunhy garantit que toutes les brides respectent les normes ISO 9001. Pour les projets critiques en alliage, nous fournissons une Identification Positive des Matériaux (IPM) pour vérifier que votre bride 316L est bien du 316L, évitant ainsi les défaillances par corrosion.

Bride à face plate vs bride à face surélevée : Principales différences

Perspective d'Ingénierie : Les brides RF sont conçues pour la contrainte d'étanchéité ; les brides FF sont conçues pour la protection structurelle.

Surface d'étanchéité et construction

La principale différence réside dans la Contrainte d'Assise du Joint vs. le Risque de Rotation de la Bride.

Dans un joint RF, la plus petite surface de contact signifie que vous avez besoin de moins de couple de boulon pour obtenir une étanchéité serrée. Dans un joint FF, la grande surface de contact signifie que la contrainte d'assise est plus faible, c'est pourquoi le FF est généralement utilisé pour les services utilitaires à basse pression (Eau, Air).

| Type de bride | Description du mécanisme d'étanchéité |

|---|---|

| Bride à face surélevée | Concentre la charge des boulons sur la zone annulaire (IBC – Cercle intérieur des boulons). Idéal pour les joints semi-métalliques. |

| Bride à face plate | Répartit la charge des boulons sur toute la surface. Requis pour les joints souples sur les équipements fragiles. |

Le choix du joint est non négociable ici. Vous devez utilisez des joints pleine face sur les assemblages à face plate. L'utilisation d'un joint annulaire (IBC) sur une bride à face plate laisse le bord extérieur non supporté. Lorsque les boulons sont serrés, la bride pivote dans cet espace, provoquant des fuites ou des ruptures.

| Type de bride | Type de joint | Note d'installation |

|---|---|---|

| face surélevée | Type annulaire (IBC) | Compatible avec les joints spiralés, à profil Camprofile et en graphite. |

| face surélevée | Pleine face | Rarement utilisé. Peut être utilisé mais nécessite un couple plus élevé pour assurer l'étanchéité. |

| Face plate | Pleine face | Obligatoire pour les assemblages en fonte/FRP pour éviter les moments de flexion. |

Avertissement : N'utilisez jamais un joint spiralé sur une bride en fonte à face plate. L'enroulement métallique est plus dur que la fonte et s'enfoncera dans la face, endommageant la bride.

Adéquation à la pression et à la température

Les brides à face surélevée sont les plus courantes pour les applications haute pression/température (ASME B16.5). Les brides à face plate sont limitées par le matériau fragile avec lequel elles sont généralement assemblées (ASME B16.1).

Vérifiez toujours la pression-température nominale du plus faible composant du système.

| Type de bride | Cote de pression maximale | Limite de température (typique) | Service typique |

|---|---|---|---|

| Face plate (fonte) | Classe 125 / 250 (selon ASME B16.1) | Faible (limitée par la ductilité de la fonte et du joint) | Eau, conduites incendie, CVC |

| Face surélevée (acier) | Classe 150 – 2500 (selon ASME B16.5) | Élevée (jusqu'à 1000°F+ selon l'alliage) | Vapeur, Hydrocarbures, Chimique |

Alerte de confusion : La Classe 125 (Fonte) et la Classe 150 (Acier) ont le même motif de boulons. Elles peuvent être boulonnées physiquement, mais mélanger leurs faces (RF à FF) est dangereux. Vérifiez toujours l'étiquette de matériau.

Procédé de fabrication

Sunhy utilise un usinage CNC de précision pour garantir que la finition de surface (Ra) correspond aux exigences du joint.

Pour les brides RF, nous usinons une dentelure précise de 125 à 250 µin Ra. Pour les brides à face plate, la planéité est le paramètre critique pour assurer un support complet sur les trous de boulons.

| Certification | Pourquoi c'est important pour les brides |

|---|---|

| ISO 9001 | Assure la traçabilité des numéros de coulée depuis la billette jusqu'à la bride finie. |

| PED 2014/68/UE | Essentiel pour la conformité des équipements sous pression sur le marché européen. |

| Test PMI | L'identification positive des matériaux garantit la composition chimique (par exemple, Mo > 2.0% pour l'acier 316L). |

Même de petites déviations dans la hauteur de la face surélevée ou la planéité peuvent entraîner des fuites. Sunhy effectue une inspection dimensionnelle à 100% avant l'expédition pour garantir un montage sans faille sur site.

Comparaison des avantages et inconvénients des brides à face surélevée vs face plate

I. Brides à face surélevée (RF) : Avantages et inconvénients

La face surélevée (RF) est le cheval de bataille de l'industrie pour une raison, mais elle n'est pas sans limites.

Avantages

- Intégrité d'étanchéité élevée : La charge concentrée crée un joint plus serré, essentiel pour les fluides volatils ou toxiques.

- Polyvalence des joints : Peut utiliser presque tous les types de joints (enroulés spiralés, RTJ, graphite, caoutchouc).

- Facilité d'installation : Les joints annulaires (IBC) sont auto-centrants à l'intérieur des boulons, ce qui accélère l'installation.

Inconvénients

- Risque de matériau fragile : Ne peut pas être boulonné directement à la fonte sans risque de fissurer la bride d'accouplement.

- Sensibilité à l'alignement : Parce que la surface de contact est petite, un désalignement angulaire peut provoquer un écrasement localisé du joint.

II. Brides à face plate (FF) : Avantages et inconvénients

La face plate (FF) est une conception protectrice, priorisant la sécurité de l'équipement plutôt que l'étanchéité haute pression.

Avantages

- Protection de l'équipement : La seule option sûre pour l'accouplement avec des équipements en fonte, émaillés ou en plastique.

- Rigidité : Le contact sur toute la face réduit les vibrations et la rotation de la bride.

- Vérification visuelle : Facile à vérifier la serrage—s'il n'y a pas d'espace au diamètre extérieur, la bride est probablement assise (bien qu'une vérification du couple soit toujours nécessaire).

Inconvénients

- Pression limitée : En raison de la charge répartie, il est difficile d'atteindre la contrainte d'assise élevée nécessaire pour les pressions de Classe 600 et plus.

- Règles strictes pour les joints : Doit utiliser des joints pleine face. Ne peut pas utiliser des joints spiralés haute performance.

- Pénalité de surface : Nécessite une charge totale de boulons plus élevée pour atteindre la même étanchéité qu'une bride RF.

| Caractéristique | Face surélevée (RF) | Face plate (FF) |

| Capacité d'étanchéité | Élevé (Contrainte concentrée) | Modéré (Contrainte répartie) |

| Utilisation principale | Tuyauterie en acier (Lignes de process) | Fonte / PRFV / Utilitaire |

| Facteur de risque | Peut fissurer les pièces mates fragiles | Peut fuir si le joint est inapproprié |

| Types de joints | Polyvalent (SWG, RTJ, IBC) | Limité aux joints souples pleine face |

Applications et cas d'utilisation

Bride à face surélevée dans l'industrie

Les brides RF sont la norme partout où l'étanchéité est critique.

Les ingénieurs spécifient RF pour les systèmes soumis à la dilatation thermique, aux surpressions ou contenant des fluides dangereux.

- Pétrole & Gaz : Lignes de transport haute pression où les joints spiralés sont obligatoires pour la sécurité incendie.

- Traitement chimique : Lignes d'acides/alcalis corrosifs utilisant des alliages exotiques (Hastelloy/Duplex) avec faces RF.

- Systèmes à vapeur : Les lignes de vapeur des centrales électriques utilisent des brides RF car les cycles thermiques desserreraient un joint à face plate.

Bride à face plate dans l'industrie

Les brides FF sont la norme pour les services utilitaires et basse pression impliquant des composants en fonte/fonte ductile.

Elles sont omniprésentes dans les systèmes de support municipaux et industriels généraux.

- Traitement de l'eau : Connexions aux grandes vannes à guillotine en fonte et vannes anti-retour (AWWA C207 ou ASME B16.1).

- Protection incendie : Les bouches d'incendie et les conduites principales d'arrosage utilisent généralement des interfaces Classe 125 FF.

- Marine/CVC : Les boucles de refroidissement à l'eau de mer utilisant des pompes en bronze ou cuivre-nickel nécessitent souvent FF pour éviter la fissuration du corps de la pompe.

Compatibilité et installation

La règle d'or du tuyautage : Ne jamais boulonner une bride en acier RF directement à une bride en fonte FF sans atténuation.

C'est un scénario de “défaillance critique”. L'espace créé par la face surélevée agit comme un levier, et la bride en fonte se cassera.

| Scénario | Solution correcte |

|---|---|

| Raccordement d'un tuyau en acier à une vanne en fonte | Option 1 : Acheter une bride en acier à face plate. Option 2 : Usiner la face surélevée de votre bride en acier pour la rendre plate. |

| Sélection du joint | Utilisez un Joint pleine face (Caoutchouc/Fibre) pour combler tout l'espace et répartir la charge. |

| Contrôle du couple | Utilisez les valeurs de couple pour Fonte, pas l'acier. Un couple excessif peut endommager les filets de la fonte ou fissurer le corps. |

Astuce : Si vous ne pouvez pas usiner la bride, certains sites utilisent un “Anneau d'espacement” pour combler l'écart, mais l'usinage ou l'achat de la bride FF correcte est toujours la solution d'ingénierie plus sûre et étanche.

Choisir la bonne bride

Facteurs clés de sélection

La sélection de la bride est généralement déterminée par le “Maillon le plus faible” de votre système—typiquement la connexion de la vanne ou de la pompe.

Utilisez cette liste de contrôle de décision d'ingénierie :

| Facteur | Règle de décision |

|---|---|

| Équipement d'accouplement | La pompe/vanne est-elle en fonte, en plastique ou en bronze ? Utilisez Face plate. Est-elle en acier ? Utilisez face surélevée. |

| Pression du système | La classe 150/300/600+ utilise généralement RF par défaut. La classe 125 (fonte) utilise strictement FF par défaut. |

| Type de joint | Avez-vous besoin d'un joint spiralé résistant au feu ? Vous avez besoin face surélevée Les brides doivent être correctement positionnées pour assurer l'étanchéité. |

| Service du fluide | Les services dangereux/toxiques nécessitent généralement la meilleure étanchéité d'un joint RF avec un joint semi-métallique. |

L'équipe technique de Sunhy peut comparer les fiches techniques de vos pompes et vannes pour aider à confirmer le choix des faces et des joints avant la fabrication, évitant ainsi des retards lors de l'assemblage sur site.

Normes et codes industriels

Vos brides doivent respecter les codes applicables pour garantir la sécurité et l'interchangeabilité.

Sunhy soutient les projets conformes à ces principales normes mondiales :

| Norme/Code | Description |

|---|---|

| ANSI/ASME B16.5 | La “ Bible ” des brides en acier pour tuyauterie. Définit les hauteurs RF et les classes de pression. |

| ASME B16.1 | La norme pour les brides en fonte grise pour tuyauterie (généralement FF en Classes 125/250). |

| AWWA C207 | Brides pour réseaux d'eau (Brides à collerette en acier). Souvent à face plate pour basse pression. |

| DIN EN 1092-1 | Norme métrique européenne (Type 11 = Bride à col soudé RF ; Type 01 = Bride à collerette à face plate). |

Assurez-vous que votre bon de commande spécifie explicitement la norme (par exemple, “ ASME B16.5, Classe 150, RF, A182 F316L, NPS 4, Finition 125-250 AARH ”).

Erreurs courantes à éviter

Évitez ces coûteuses défaillances sur site en respectant une discipline appropriée de spécification et d'assemblage :

- L'erreur de “Jeu” : Laisser un jeu visible entre les bords extérieurs d'une connexion RF-FF. Cela indique une contrainte de flexion sur la bride.

- L'erreur du “Mauvais Joint” : Utiliser un joint spiralé rigide sur une bride à face plate souple. L'enroulement métallique écrasera la face ou fissurera la bride.

- Sur-serrage : Appliquer des valeurs de couple “Acier” à des brides “Fonte”. La fonte est fragile ; respectez les limites de couple inférieures des équipements ASME B16.1.

- Réutilisation des joints : Une fois comprimés, les joints perdent leurs propriétés de récupération. Installez toujours de nouveaux joints lors du réassemblage d'un raccord.

Note : Contactez les experts Sunhy si vous n'êtes pas sûr d'une connexion. Nous pouvons usiner des brides sur mesure pour résoudre les problèmes d'incompatibilité RF/FF.

FAQ

Quelle est la principale différence entre les brides à face surélevée et les brides à face plate ?

La géométrie de la surface d'étanchéité et la distribution de charge. Les brides à face surélevée (RF) ont un rebord surélevé (1/16″ ou 1/4″) pour concentrer la pression pour une étanchéité haute performance. Les brides à face plate (FF) sont à fleur du diamètre extérieur pour distribuer la charge uniformément, évitant d'endommager les matériaux fragiles comme la fonte.

Pouvez-vous raccorder une bride à face surélevée à une bride à face plate ?

Pas directement sur un équipement fragile. Si vous connectez une bride à joint saillant en acier à une bride à joint plat en fonte, vous devez usinez la face surélevée à plat et utilisez un joint pleine face. Ne pas le faire crée un moment de flexion qui cassera la bride en fonte. Si vous connectez de l'acier à de l'acier, c'est généralement sûr mais pas idéal.

Dans quelles industries les brides à face surélevée sont-elles le plus souvent utilisées ?

Industries de procédés (Pétrole & Gaz, Chimique). La face surélevée est la norme pour la tuyauterie en acier car elle supporte les joints spiralés haute pression et assure l'étanchéité la plus étroite pour les fluides dangereux.

Quel joint utiliser avec chaque type de bride ?

RF : Joints spiralés, joints annulaires (RTJ) ou joints à profil de came (à l'intérieur du cercle de boulons).

FF : Joints pleine face (avec trous de boulons) en caoutchouc, fibre ou PTFE. N'utilisez jamais un joint métallique dur sur une face plate.

Comment choisir la bride adaptée à votre système ?

Vérifiez d'abord l'équipement d'accouplement. Si votre vanne est en fonte (Classe 125), vous avez besoin d'une bride à face plate. Si votre vanne est en acier (Classe 150/300), vous avez besoin d'une bride à face surélevée. Toujours adapter la face aux limites de matériau de l'équipement.

| Facteur | Bride à face surélevée | Bride à face plate |

|---|---|---|

| Pression | Courant dans les classes ASME B16.5 (selon le matériau) | Souvent lié aux normes de fonte/utilité (selon le service) |

| Matériau | Acier / Inox | Fonte / PRFV / Plastique / Équipement revêtu |

Conseil : Consultez l'équipe d'ingénierie de Sunhy pour la stratégie de couple, la compatibilité des joints et la vérification des faces—en particulier pour les assemblages dissemblables et les interfaces d'équipement fragiles.

Pour un aperçu complet des types de brides et normes, consultez notre guide complet